China’s Carbon Fiber Game Is Changing — Here’s Why American Tuners Should Care

The Global Tuning Landscape Is Shifting

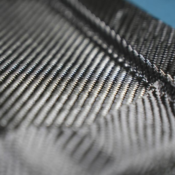

For decades, the carbon fiber industry has been synonymous with elite performance, sky-high prices, and limited accessibility. Carbon fiber components were once confined to aerospace and Formula 1 garages. However, in recent years, particularly post-2020, this high-performance material has entered a new chapter — one led, innovated, and scaled by China. China's rise as a dominant force in carbon fiber manufacturing is not just a trend; it's a supply chain transformation that should be on every American tuner’s radar. Whether you're an independent builder, a mid-size tuner brand, or a global parts distributor, understanding how the carbon fiber ecosystem is evolving in China is essential to staying competitive.From Low-End Manufacturing to Global Precision

Let’s rewind a bit. Historically, Chinese carbon fiber manufacturing was seen as budget-tier, suitable for basic styling but not structural performance. Products were often made with wet layup methods, inconsistent quality, and poor UV protection. But this perception is no longer accurate — and continuing to assume it is could be a costly mistake. In the past five years, China has dramatically advanced in three major areas:- Raw Material Independence: Domestic PAN (polyacrylonitrile) production has grown, reducing reliance on imported Japanese or American fiber spools.

- Pre-preg & Autoclave Mastery: More manufacturers are investing in pre-preg carbon fiber with vacuum bagging and curing via industrial autoclaves — resulting in lightweight, high-strength, OEM-level components.

- Precision Trimming & CAD Matching: CNC edge-trimming, laser-guided mold making, and 3D scanning have brought Chinese factories within millimeters of fitment perfection — a key concern for American tuners.

Tuners’ New Playground: Custom Carbon Aero, Made in China

Tuning culture has evolved — and so have the demands of enthusiasts. Aesthetic upgrades alone no longer suffice. Today’s tuners want performance with a purpose: aggressive styling that’s backed by wind-tunnel validation, CFD simulation, and true downforce. Whether it’s a widebody kit for a BMW G80 M3, a functional rear diffuser for the Audi RS5, or a dry carbon hood for the Tesla Model S Plaid, buyers want form and function in one. Chinese suppliers have taken notice. Some now offer:- Custom mold development for individual shops and YouTube tuners

- In-house design using CFD software like Ansys Fluent or Siemens NX

- High-temp pre-preg carbon for endurance racing teams

- Serialized QR code tracking and ISO/TS 16949 process documentation

| Benefit | What It Means for You |

|---|---|

| Lower Unit Costs | Up to 40% less than U.S./Europe equivalents |

| Lower MOQs | Small-batch production (even 20 sets possible) |

| Faster Tooling | Mold turnaround in 15–20 days |

| Full Services | Design + CFD + Prototyping = All-in-one support |

| Freight Integration | Most suppliers integrate with FedEx, DHL, or Amazon FBA logistics |

Case Study: The G80 M3 Front Lip

Let’s consider a real-world scenario. A mid-size tuning brand in Florida wanted to launch a carbon front lip for the G80 M3. They received quotes from U.S. suppliers at \$450–\$600 per unit, not including mold cost or packaging. Estimated lead time: 75–90 days. The same product was quoted by a Chinese factory at \$210/unit, including autoclave-cured pre-preg carbon, logo engraving, packaging with foam inserts, and 30-day air shipping included. Lead time: 25 days. They went with the Chinese supplier. Now they sell 100+ units/month with a 2x margin — and their customers praise the consistent weave alignment and perfect fit.But What About Quality?

Yes, quality matters — especially when your customer is bolting a splitter to a \$70,000 M car or importing a widebody kit for their show car. Here’s how to ensure you're sourcing from the right Chinese factory:- Ask for their ISO/TS certification

- Request high-resolution weave close-ups

- Demand a fitment test video using factory OEM bumpers

- Look for in-house autoclave photos, not just marketing slides

- Vet their past export brands (many factories are white-label providers for top eBay/Amazon stores)

The “Quiet Giants” in Dongguan, Zhejiang, and Guangzhou

While Shenzhen is known for tech hardware, cities like Dongguan and Taizhou have become the epicenter of carbon fiber automotive parts. Hundreds of factories — big and small — now specialize in carbon fiber spoilers, diffusers, side skirts, door mirrors, and even roll cage trims. Some operate 24/7 autoclave curing lines. Others run full in-house CFD simulation labs. And some are run by former engineers from Taiwanese or European firms who have brought a global mindset to a local operation. For tuners, this means more choice, more leverage, and more innovation.Not Just B2C — It’s OEM+ Level Production

We’re seeing more American tuners start private label production with Chinese partners — offering "brand X" carbon fiber aero kits that compete with Varis, Vorsteiner, or APR, but at half the production cost. These aren’t just visual mods anymore. Some front splitters have built-in active brake duct channels. Some hoods are made from sandwich composite with carbon on the outer layer and fiberglass underneath for cost control. Some suppliers even offer raw data integration for 3D renderings in Blender or Unreal Engine. This is no longer “copycat” territory — it’s creative, collaborative, and competitive.Final Thoughts: Don’t Sleep on This

The carbon fiber revolution is here, and it’s global. American tuners who embrace China’s carbon fiber renaissance early will enjoy:- Quicker product launches

- Higher margin per unit

- Faster design cycles

- More customization opportunities

- Stronger control over QC & branding

Recent Posts

jcsportline.com0 Comments

Custom Carbon Fiber Parts for Car Clubs & Teams: From Idea to Installation

jcsportline.com0 Comments

How Carbon Fiber Wrapped Parts Are Made: A Simple Guide for Car Enthusiasts

jcsportline.com0 Comments

How to Keep Carbon Fiber Car Parts Shipping and Installation Safe

Tags

adhesive layer control

Automotive Aftermarket

automotive composites

Brand Reputation

carbon fiber case study

Carbon Fiber Durability

carbon fiber engineering

carbon fiber failure prevention

carbon fiber for racing

carbon fiber interior

carbon fiber parts

Carbon Fiber Precision

carbon fiber production tips

carbon fiber prototype

Carbon Fiber QC

carbon fiber quality

carbon fiber simulation

carbon fiber vs aesthetics

carbon fibre

composite part development

custom carbon parts

DIY Installation

fake carbon fiber

Fitment Accuracy

fitment issues

functional carbon fiber parts

layup angle

Manufacturing Tolerances

motorsport carbon fiber

Mounting Point Failure

OEM Standards

original structure

Precision Manufacturing

Private Label Manufacturing

Quality Control Process

real carbon

real carbon fiber

resin flow control

Screw Hole Alignment

stress test carbon fiber

Supplier Reliability

Thread Quality

tuning shop carbon parts

User Experience

±0.3mm Tolerance