- Home

- Services

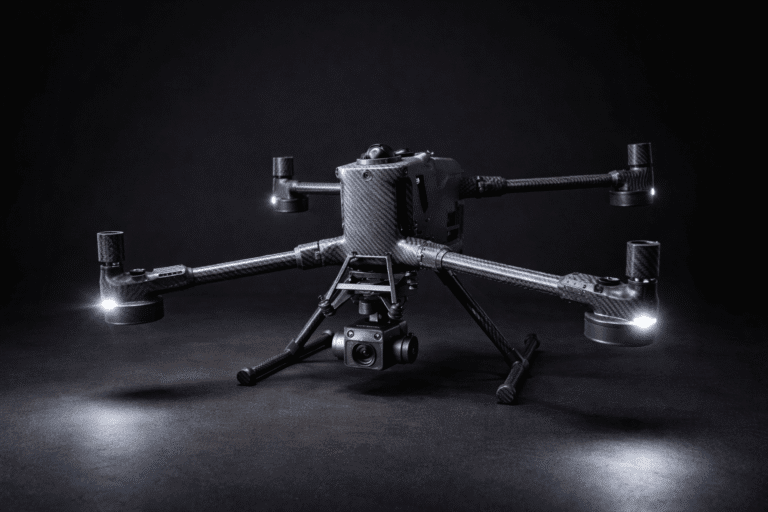

- Industries

- Capabilities

- Resources

- Company

Where professionals turn concepts into carbon reality

Turning New Technologies into Production-Ready Products

We integrate new materials, processes, and technologies into existing designs.

Not experimental concepts — but scalable, manufacturable improvements.

Innovation that performs in real products, not just prototypes.

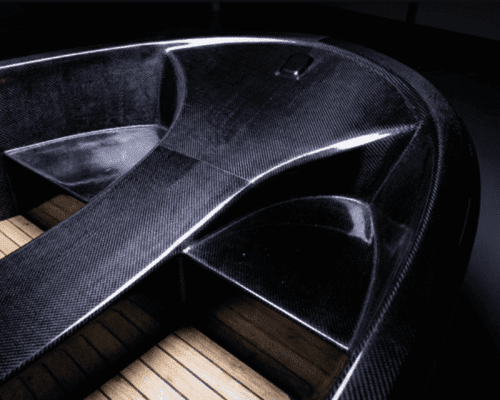

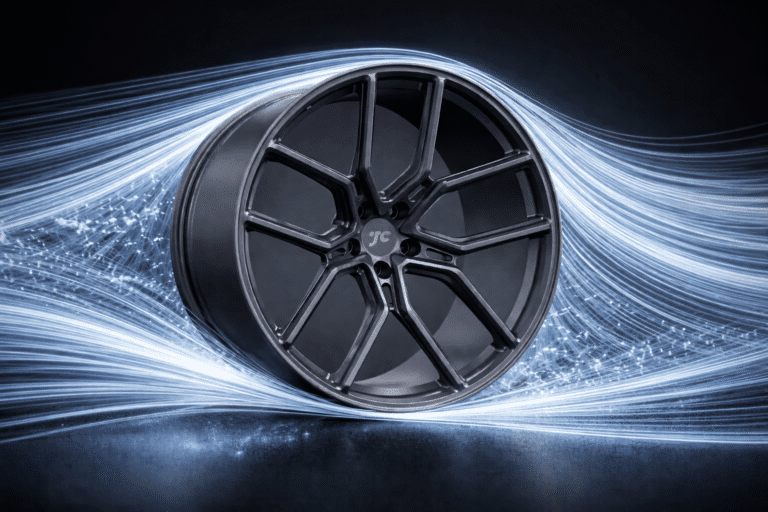

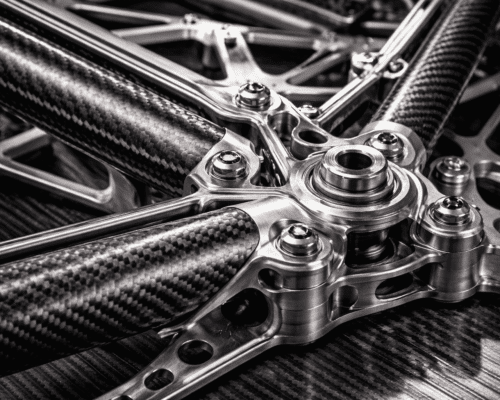

Engineering Rebuilt Around Carbon Fiber

Carbon fiber is not a replacement — it’s a new engineering foundation.

Structures, load paths, and processes are redesigned from the ground up.

Built for strength, consistency, and reliable mass production.

Designed for Long-Term Brand Value

True differentiation goes beyond features or short-term trends.

We create defensible product identities through engineering and materials.

Positioning your brand for sustainable, premium growth.

Where professionals turn concepts into carbon reality

Turning New Technologies into Production-Ready Products

We integrate new materials, processes, and technologies into existing designs.

Not experimental concepts — but scalable, manufacturable improvements.

Innovation that performs in real products, not just prototypes.

Engineering Rebuilt Around Carbon Fiber

Carbon fiber is not a replacement — it’s a new engineering foundation.

Structures, load paths, and processes are redesigned from the ground up.

Built for strength, consistency, and reliable mass production.

Designed for Long-Term Brand Value

True differentiation goes beyond features or short-term trends.

We create defensible product identities through engineering and materials.

Positioning your brand for sustainable, premium growth.

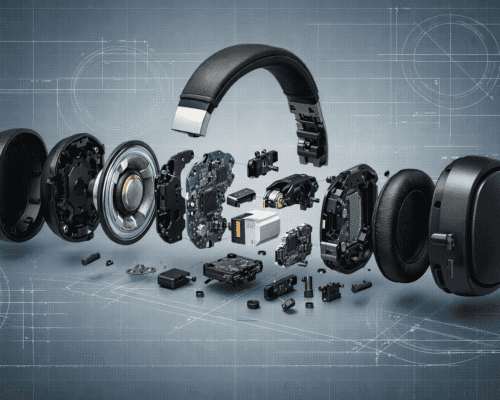

Our engineering capabilities

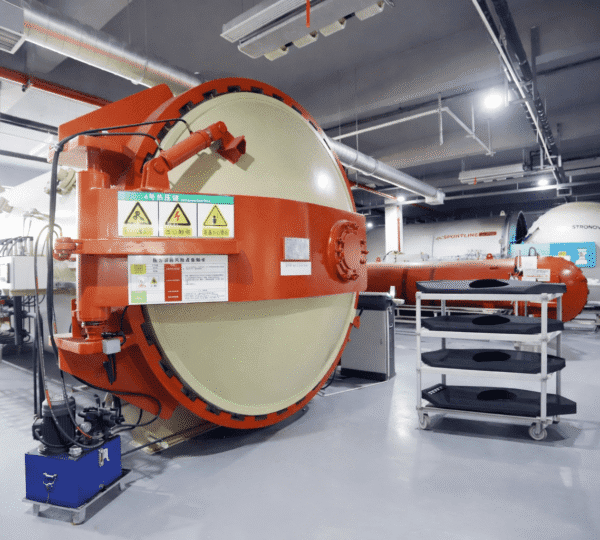

At JCSPORTLINE, we provide complete carbon fiber solutions—from prototypes to mass production.Our capabilities include prepreg carbon fiber (autoclave- or oven-cured), vacuum-infusion and RTM-molded composites, and compression-molded or forged-carbon components—customized to your exact needs.Using advanced processes such as autoclave curing, RTM, and vacuum infusion, we deliver strong, precise, and high-quality parts. Whether for custom projects or large-scale production, we turn your ideas into premium carbon fiber components.

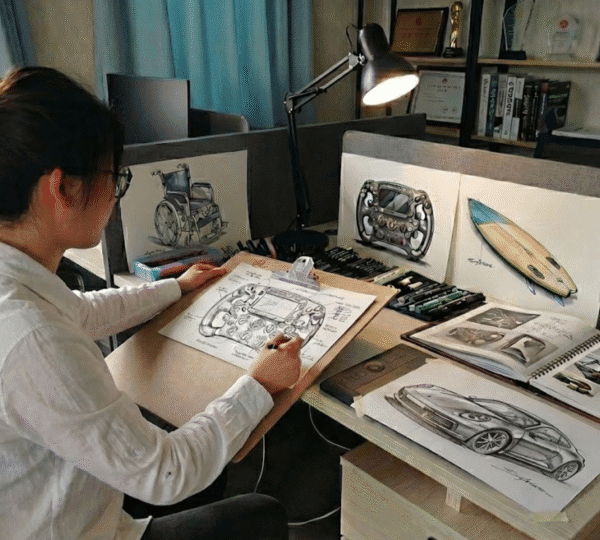

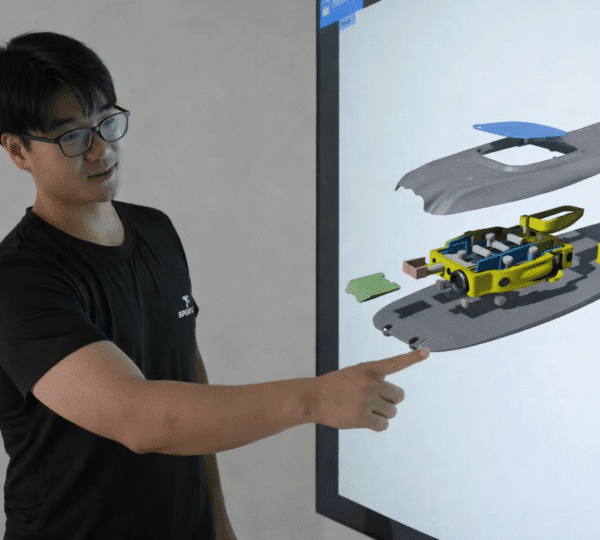

Concept feasibility development

From ideas to engineering-ready solutions

Concept sketches from designers

Feasibility & Structural reports

Composite material & Process selection

Structural planning: Single/split molds

Lead time: 3–7 days

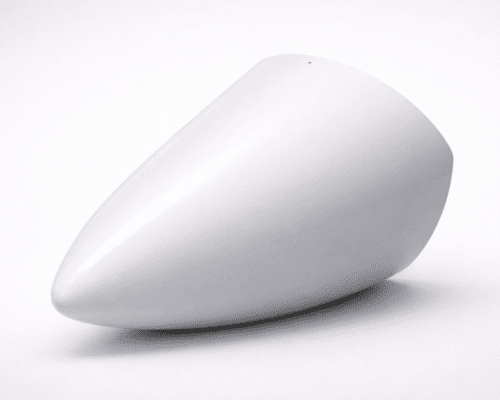

Rapid carbon fiber prototyping

Fast, accurate low-volume prototyping

CNC tooling and 3D printed molds

Autoclave prepreg prototype fabrication

±0.3 mm tolerance for functional parts

Automotive, sports, and marine use

Lead time: 7–15 days

Small - Batch production

Flexible production for niche projects

Production volume from 1–500 pcs

Prepreg autoclave, infusion, wet lay-up

Cosmetic and structural carbon parts

Matte, gloss, or clear coat finish

Lead time: 5–20 days

See our small-batch production

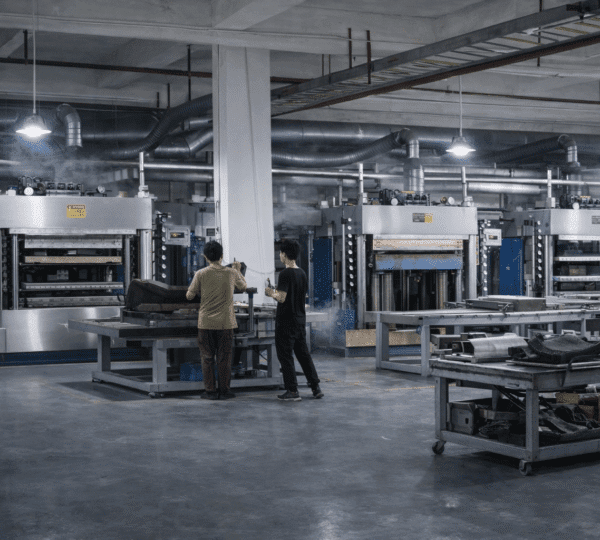

Mass production programs

Scalable manufacturing for volume orders

Automated compression molding

P20 steel molds with stable tooling

ISO / IATF 16949 quality control

Scalable lines in Hubei and Huizhou

Lead time: volume dependent

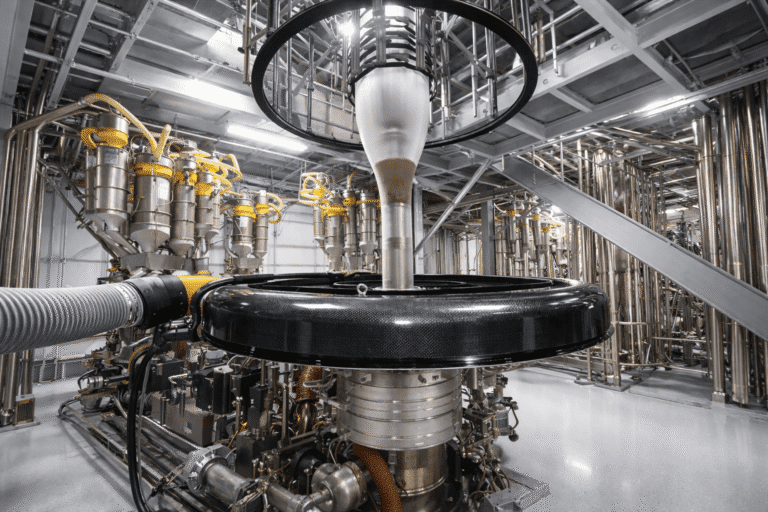

Composite Manufacturing, Coordinated for Your Success

At JCSPORTLINE, our multiple factories specialize in different composite manufacturing processes, ensuring the right solution for your project’s volume and technical requirements.

With a global engineering and sales team, we facilitate seamless communication between our overseas R&D teams and China’s production teams, reducing communication costs and enhancing efficiency. This close collaboration ensures your projects are delivered on time, no matter the scale.

Explore the Factory

Your Products. Built with Specialized Carbon Fiber Facilities and Local Engineering Support

Hubei – Autoclave & Vacuum Infusion Facility

Core Technologies:

• Autoclave prepreg molding

• Vacuum infusion

Best For:

• Automotive exterior components

• Water-sports products

• Applications requiring clear, high-definition carbon weave

Shenzhen HQ– Marketing & Design Center

Core Resources:

Marketing support and client management

Design collaboration and product customization

Car data scanning & reverse engineering

R&D product selection support

Best For:

Carbon fiber solutions for automotive, sports, and lifestyle

Supporting distributors with marketing and customer outreach

Assisting R&D with product design and selection

Dongguan – Compression Molding (SMC/CMC) Factory

• High-pressure compression molding

• Forged carbon fabrication

Best For:

• Sports equipment

• 3C electronics & digital accessories

• Aerospace components

• Medical housings & lightweight structures

Shenzhen – Carbon Fiber R&D & Pilot Production Center

• Early-stage testing and validation

• RTM, hot-press, compression molding pilot runs

• Small-batch prototypes (1–50 pcs)

• Cross-category carbon fiber innovation

Role in Your Project:

• Complex composite structures are tested and validated here before mass production

• Creates feasibility reports, structural testing, and process evaluations

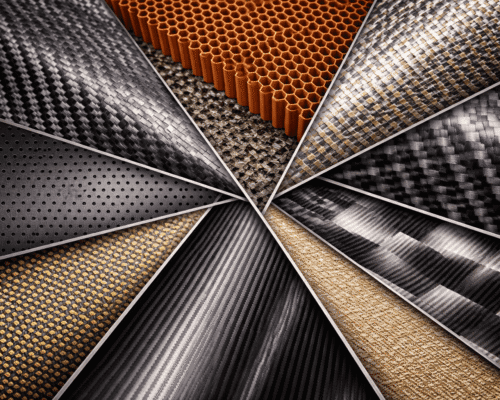

In-House Carbon Fiber Weaving Factory

Core Capabilities

Custom woven patterns

Toray carbon fiber

In-house weaving control

Logo / texture customization

Best For

Auto / aero / sports

High-precision patterns

Unique branded designs

Global Design & Engineering Network

• Worldwide teams support JCSPORTLINE China projects

NL Netherlands – EU Hub:

• Design support, 3D scanning, warehousing

US Los Angeles – Engineering Center:

• Aero engineering, 3D scanning, local support

CA Canada – Structural Center:

• Structural analysis & prototype validation

AI-powered on-time delivery for carbon fiber projects

JCSPORTLINE provides full AI-powered transparency for carbon fiber projects and orders—so customers can track every stage in real time.

1. On-Time Project Delivery

AI shows clear, step-by-step project progress—from design to sampling—ensuring predictable timelines.

2. On-Time Order Delivery

Every order milestone is visible in real time, covering production, quality checks, packing, and shipment.

58-Day Concept-to-Sample: Fast, Precise, Reliable

We transform your ideas into reality in just 58 days. From initial concept to sample, our process ensures fast, efficient delivery with exceptional quality. Starting with a detailed feasibility report, we move through requirements analysis, engineering design, prototype manufacturing, and testing. Every stage is carefully managed to meet your deadlines and deliver the best results.

Our tracking process for projects

Receive ID

Your unique code unlocks your entire project & ecosystem.

Design & Drawing

Initial project concept and design.

CNC Machining & Mold Making

Precision machining and mold production.

Sample Production

Creation of sample parts.

Sample Shipping

Dispatching samples to the customer.

Customer Feedback

Receiving and reviewing client approval or feedbac.

Our tracking process for orders

Customer ID

Retrieve customer ID for the specific order.

Order Date

Check the date when the order was placed.

Production Status

Track the current stage of production.

Order Quantity

Check how many units are completed and remaining.

Estimated Completion

Check the expected order completion date.

Estimated Shipment Date

Confirm the projected shipping date to the customer.

Centralized standards for consistent quality

At JCSPORTLINE, we believe that quality is built through design and manufacturing, not just inspection. Every carbon fiber part we create for you begins with a detailed feasibility analysis, structural simulation, and controlled design inputs to eliminate risks before production even starts. We ensure that your project is set up for success from the very beginning.

ISO Certification

Our carbon fiber production follows ISO 9001 and IATF 16949 certified quality systems, ensuring traceable, documented processes from raw materials to final inspection.

Quality by design

Every project begins with feasibility analysis and engineering validation—ensuring quality is built into the design, not discovered during production.

Consistent production

Standardized processes and controlled production parameters guarantee consistent quality across prototypes, small batches, and full mass production.

Who We Are

Your Engineering Partner for Advanced Composites

We bridge the gap between innovative design and manufacturable reality.

Our mission is to empower creators, engineers, and entrepreneurs to bring their boldest ideas to life—faster, lighter, and stronger.

Years Experience

Projects Delivered

Countries Served

Who We Work With

We partner with professionals from diverse industries to solve carbon-fiber engineering challenges—transforming ideas into manufacturable, production-ready solutions.

Creating production-ready carbon fiber designs.

Developing innovative consumer and industrial products.

Engineering strong, lightweight mechanical structures.

Optimizing composite materials and manufacturing processes.

Advancing material science applications

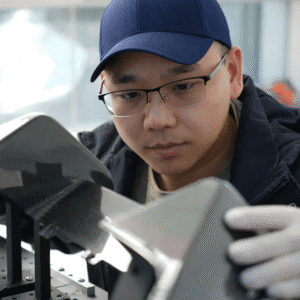

Our Team

Engineering-driven experts empowering every role in your carbon-fiber project

Sandy

Founder

Brandon

Motorsports Engineer

Mehmet

Head of Europe Operations

Mamoru Ozawa

Head of Japan Operations

Brendon

Head of North America Operations

Liu Jian

Composite Structural Engineer

Wu Jiangming

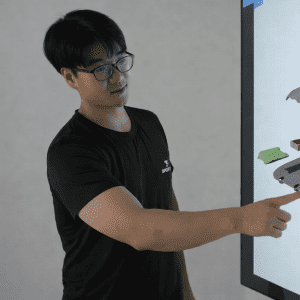

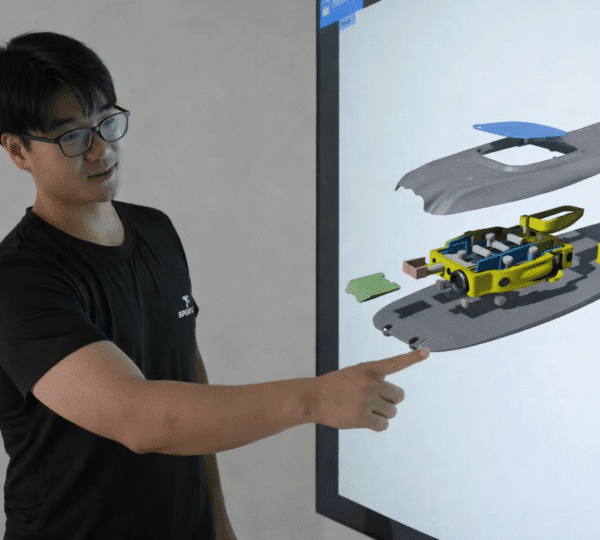

3D Reverse Engineering Lead

Ye Cheng

CNC Engineering Manager

He Dong

Automotive & Motorcycle Engineering Specialist

Master Nie

Prototype & Model Making Specialist

Sandy

Founder

Sandy

Founder

Brandon

Motorsports Engineer

Brandon

Motorsports Engineer

Mehmet

Head of Europe Operations

Mehmet

Head of Europe Operations

Mamoru Ozawa

Head of Japan Operations

Mamoru Ozawa

Head of Japan Operations

Brendon

Head of North America Operations

Brendon

Head of North America Operations

Liu Jian

Composite Structural Engineer

Liu Jian

Composite Structural Engineer

Wu Jiangming

3D Reverse Engineering Lead

Wu Jiangming

3D Reverse Engineering Lead

Ye Cheng

CNC Engineering Manager

Ye Cheng

CNC Engineering Manager

He Dong

Automotive & Motorcycle Engineering Specialist

He Dong

Automotive & Motorcycle Engineering Specialist

Master Nie

Prototype & Model Making Specialist

Master Nie

Prototype & Model Making Specialist

Brand & IP Protection

Protecting your product designs, engineering data and intellectual property throughout the entire development and manufacturing lifecycle.

Free Technical Evaluation

Ask for a Free Carbon Fiber Project Review

Our engineers will review your concept and provide suggestions on materials, structure, and manufacturability – tailored to your carbon fiber application.

Response within 24 hours by our engineering team

OEM/ODM Support for Mobility Products

NDA and confidential review available on request

Start Your Carbon Fiber Project

Get expert guidance on materials, structure, and feasibility.