Price Too High? The Real Story Behind Carbon Fiber Aftermarket Parts and OEM Quality Assurance

When a customer recently asked us,

“Your carbon fiber parts are so expensive. I saw the same parts selling for $7,000 elsewhere. Why do you charge $10,000?”

This question reflects a common concern among buyers in the aftermarket car parts industry. We fully understand the confusion — after all, price is the first factor most consider.

But buying carbon fiber aftermarket parts is like buying a car itself: you must understand what you’re really paying for. Just as a BMW OEM vehicle demands a higher price than an economy model due to quality and engineering, OEM quality carbon fiber parts carry a justified premium over cheaper alternatives.

When a customer recently asked us,

“Your carbon fiber parts are so expensive. I saw the same parts selling for $7,000 elsewhere. Why do you charge $10,000?”

This question reflects a common concern among buyers in the aftermarket car parts industry. We fully understand the confusion — after all, price is the first factor most consider.

But buying carbon fiber aftermarket parts is like buying a car itself: you must understand what you’re really paying for. Just as a BMW OEM vehicle demands a higher price than an economy model due to quality and engineering, OEM quality carbon fiber parts carry a justified premium over cheaper alternatives.

Goal: Clarify Why Carbon Fiber Aftermarket Parts Price Varies, and Why OEM-Level Quality Matters

Our goal is simple: We want to help customers truly understand what drives the cost of carbon fiber parts, why JCSPORTLINE strictly follows OEM standards (such as BMW’s), and how choosing low-cost, low-quality products risks serious brand damage and costly aftersales problems.Reason: Why JCSPORTLINE’s Carbon Fiber Parts Cost More

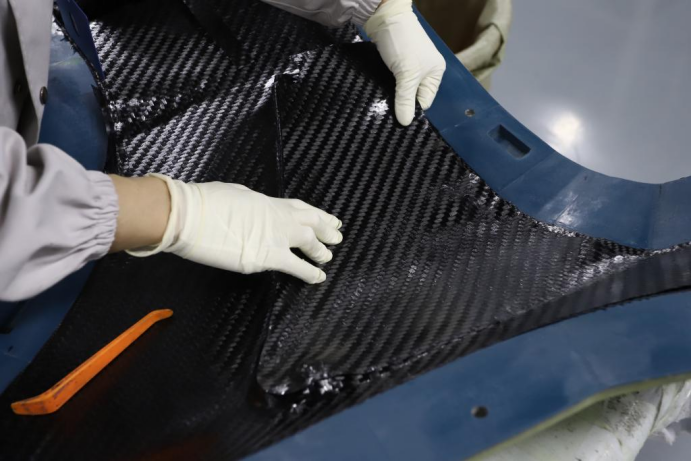

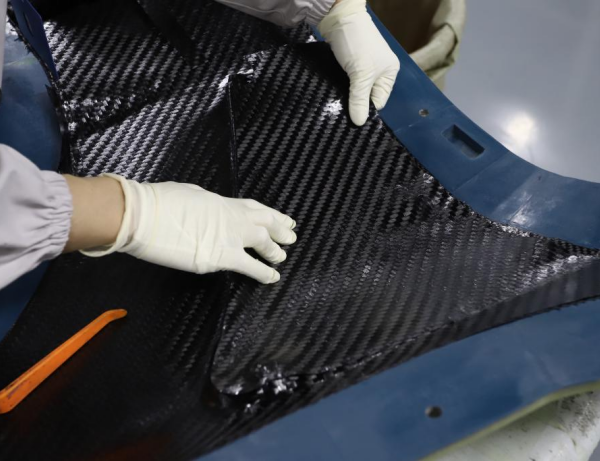

JCSPORTLINE produces carbon fiber aftermarket parts adhering to strict BMW OEM standards, as well as requirements from leading electric vehicle manufacturers. This means we use premium raw materials, precision manufacturing, and rigorous quality controls throughout the production process.

By contrast, many low-priced carbon fiber parts flooding the market come from small workshops lacking uniform quality control. These products are prone to:

Poor paint durability and UV resistance — leading to yellowing and peeling.

Low-grade carbon fiber fabric or substitutes with inadequate strength and flexibility.

Short-lived molds causing dimensional inaccuracies and poor fitment.

Inconsistent production batches resulting in higher defect and return rates.

Minimal or no aftersales service, leaving customers unsupported after purchase.

These hidden defects not only frustrate end users but also expose distributors and brands to complaints, returns, fines, and lasting reputation harm.

JCSPORTLINE produces carbon fiber aftermarket parts adhering to strict BMW OEM standards, as well as requirements from leading electric vehicle manufacturers. This means we use premium raw materials, precision manufacturing, and rigorous quality controls throughout the production process.

By contrast, many low-priced carbon fiber parts flooding the market come from small workshops lacking uniform quality control. These products are prone to:

Poor paint durability and UV resistance — leading to yellowing and peeling.

Low-grade carbon fiber fabric or substitutes with inadequate strength and flexibility.

Short-lived molds causing dimensional inaccuracies and poor fitment.

Inconsistent production batches resulting in higher defect and return rates.

Minimal or no aftersales service, leaving customers unsupported after purchase.

These hidden defects not only frustrate end users but also expose distributors and brands to complaints, returns, fines, and lasting reputation harm.

The Hidden Costs of Cheap Carbon Fiber Parts

- Inferior Materials and Durability Cheap carbon fiber cloth or substitute materials don’t meet strength requirements. They degrade faster and risk structural failure.

- Paint and Finish Problems Low-cost coatings lack proper UV protection, causing discoloration, cracking, and peeling that damage the car’s aesthetics.

- Poor Mold Quality and Fitment

Substandard molds wear out quickly, producing parts with incorrect dimensions and fit, leading to difficult installations and poor vehicle appearance.

Substandard molds wear out quickly, producing parts with incorrect dimensions and fit, leading to difficult installations and poor vehicle appearance.

- Weak Quality Control and Batch Variability Without strict oversight, quality fluctuates, causing inconsistent product performance and more frequent repairs or returns.

- Lack of Aftersales Support Cheap manufacturers rarely offer effective warranty or repair services, forcing buyers to bear all risks.

JCSPORTLINE’s Solution: OEM-Grade Carbon Fiber with Full Quality Assurance

At JCSPORTLINE, we invest in:

Imported high-performance carbon fiber fabrics that meet or exceed OEM standards.

Advanced UV-resistant clear coat technology to ensure long-lasting color stability and durability.

Self-developed precision molds guaranteeing exact dimensions and effortless fitment.

A comprehensive quality management system with multi-stage inspection to ensure consistent product excellence.

Multiple production lines and flexible materials options to suit various budgets and technical requirements.

Tailored customization services that match your specific vehicle models and project goals.

Years of industry experience helping clients avoid common pitfalls and deliver successful product launches.

At JCSPORTLINE, we invest in:

Imported high-performance carbon fiber fabrics that meet or exceed OEM standards.

Advanced UV-resistant clear coat technology to ensure long-lasting color stability and durability.

Self-developed precision molds guaranteeing exact dimensions and effortless fitment.

A comprehensive quality management system with multi-stage inspection to ensure consistent product excellence.

Multiple production lines and flexible materials options to suit various budgets and technical requirements.

Tailored customization services that match your specific vehicle models and project goals.

Years of industry experience helping clients avoid common pitfalls and deliver successful product launches.

Value to Customers

Choosing JCSPORTLINE means you get:

High-quality carbon fiber parts that significantly reduce maintenance and customer complaints.

Strengthened brand image and enhanced trust among end-users and distributors.

Optimized cost-performance balance thanks to flexible material and process choices.

Expert technical support and shared know-how for reliable, long-term product performance.

Choosing JCSPORTLINE means you get:

High-quality carbon fiber parts that significantly reduce maintenance and customer complaints.

Strengthened brand image and enhanced trust among end-users and distributors.

Optimized cost-performance balance thanks to flexible material and process choices.

Expert technical support and shared know-how for reliable, long-term product performance.

Actionable Advice

Don’t just compare prices — compare quality guarantees and aftersales service. Contact us with your quality standards and budget, and we will customize the optimal carbon fiber solution for you. We also welcome you to visit our factory and witness firsthand our OEM-grade manufacturing processes. Partner with JCSPORTLINE to secure your project’s success and protect your brand reputation.Who Should Read This?

Wholesalers and distributors balancing carbon fiber aftermarket parts quality and price. Brands demanding OEM-level carbon fiber quality assurance. E-commerce sellers aiming for high-quality aftermarket carbon fiber products without quality risks. Tuning shops and installers recovering from complaints due to low-quality products. [embed]https://youtube.com/shorts/9-ihNH-MmZM?si=N3p_m1acacsa5Wqg[/embed]Recent Posts

jcsportline.com0 Comments

Tailored Solutions in Carbon Fiber Customization for Every Application

jcsportline.com0 Comments

Carbon Fiber Yellowing Solutions: How JCSPORTLINE Ensures Product Quality and Customer Satisfaction

Tags

adhesive layer control

Automotive Aftermarket

automotive composites

Brand Reputation

carbon fiber case study

Carbon Fiber Durability

carbon fiber engineering

carbon fiber failure prevention

carbon fiber for racing

carbon fiber interior

carbon fiber parts

Carbon Fiber Precision

carbon fiber production tips

carbon fiber prototype

Carbon Fiber QC

carbon fiber quality

carbon fiber simulation

carbon fiber vs aesthetics

carbon fibre

composite part development

custom carbon parts

DIY Installation

fake carbon fiber

Fitment Accuracy

fitment issues

functional carbon fiber parts

high speed carbon fiber

layup angle

Manufacturing Tolerances

motorsport carbon fiber

Mounting Point Failure

OEM Standards

Precision Manufacturing

Private Label Manufacturing

Quality Control Process

real carbon

real carbon fiber

resin flow control

Returns Reduction

Screw Hole Alignment

stress test carbon fiber

Supplier Reliability

Thread Quality

tuning shop carbon parts

User Experience