How to Achieve the Perfect Matte Carbon Fiber Look? JCSPORTLINE Explains

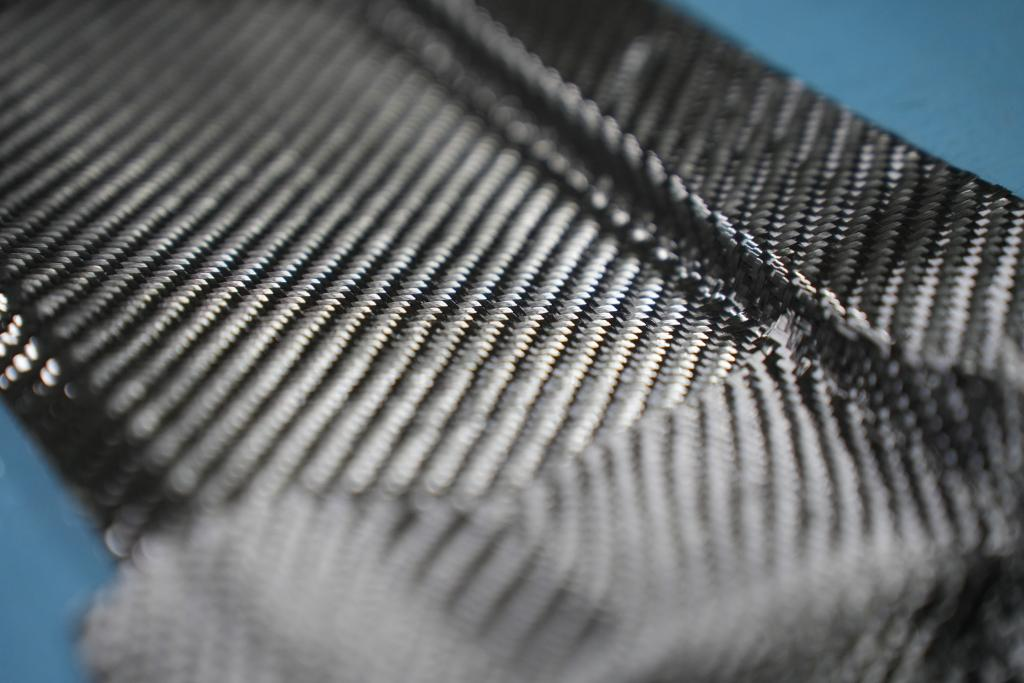

Matte carbon fiber isn’t just a style—it’s a sign of quality and skill in the car modification world. A matte carbon finish is highly sought after for its unique, non-reflective appearance and premium feel. But taking the right action to achieve carbon fiber parts with an even, smooth matte finish—without white spots, watermarks, or peeling—requires careful surface preparation, the correct choice of coatings, and precise application techniques. Enthusiasts often find the best methods by experimenting with matte lacquers, clear coats, or sanding techniques to achieve a flawless matte carbon finish. While a glossy finish can provide a shiny, clear layer that enhances durability and appearance, a matte finish offers a unique, non-reflective look. The quality of the surface is crucial in achieving the perfect matte carbon fiber look.

Matte carbon fiber isn’t just a style—it’s a sign of quality and skill in the car modification world. A matte carbon finish is highly sought after for its unique, non-reflective appearance and premium feel. But taking the right action to achieve carbon fiber parts with an even, smooth matte finish—without white spots, watermarks, or peeling—requires careful surface preparation, the correct choice of coatings, and precise application techniques. Enthusiasts often find the best methods by experimenting with matte lacquers, clear coats, or sanding techniques to achieve a flawless matte carbon finish. While a glossy finish can provide a shiny, clear layer that enhances durability and appearance, a matte finish offers a unique, non-reflective look. The quality of the surface is crucial in achieving the perfect matte carbon fiber look.Who Cares About Matte Carbon Fiber Quality?

At JCSPORTLINE, we serve a wide range of customers, including:- European brands needing TÜV certification and consistent finishes, where choosing a reputable brand is important for quality assurance

- Customers from hot Middle Eastern climates worried about fading or whitening

- US shops chasing the “Black Warrior” 90% matte blackout look

- Export OEMs demanding batch-to-batch color and texture consistency

Customer Story: Why Did Mike’s Forged Wing Clear Coat Always Turn White?

Mike runs a carbon fiber shop in California. He loves forged wings, which are a type of carbon fiber composites, with a 90% matte finish but faced problems with three suppliers:

Mike runs a carbon fiber shop in California. He loves forged wings, which are a type of carbon fiber composites, with a 90% matte finish but faced problems with three suppliers:- White spots, especially on forged textures

- Clear coat peeling within a few months

- Color inconsistencies between batches

- Wet carbon fiber and water sanding trapped moisture, causing bubbles and white patches

- No temperature or humidity control during spraying led to uneven finishes

How JCSPORTLINE Ensures High-Quality Matte Carbon Finish

We focus on six key steps:

We focus on six key steps:- Material Control: Precise resin and fiber mix plus special weaves for smooth surfaces

- Dry Sanding: Recommended for 80%+ matte to avoid moisture and white spots

- Automated Spray in Clean Rooms: Consistent clear coat, no dust, controlled climate

- Multiple Matte Levels: From 50% soft matte to 90% blackout finish, with options for gloss and satin finishes as well. Each kind of finish—matte, gloss, or satin—requires different application techniques to achieve the desired appearance and durability.

- White Spot Testing: Lab simulations of heat and humidity to prevent whitening, along with testing for resistance to scratches to ensure the finish remains durable in real-world conditions. There is a strong connection between UV stabilization and UV resistance, so both are tested to guarantee long-lasting protection and appearance. This information is provided to help customers understand the importance of these tests in ensuring product durability.

- Pre-Production Samples: Show customers samples based on weave type to set clear expectations

Why Choose JCSPORTLINE?

With over 20 years of experience in automotive carbon fiber manufacturing, JCSPORTLINE delivers custom matte carbon fiber parts with outstanding consistency and long-term durability. Powered by advanced equipment and strict quality control, we help brands worldwide bring their ideas to life with premium carbon fiber finishes that meet both visual and performance standards. Looking for matte carbon fiber components that are built to impress—and built to last? [Contact us today] to start your project.Ready for High-Quality Matte Carbon Fiber Parts?

Contact JCSPORTLINE today for samples and expert advice. Visit our website to see real projects and product collections.Recent Posts

jcsportline.com0 Comments

Why High-End Car Enthusiasts Choose Custom Carbon Fiber Kit

jcsportline.com0 Comments

Ultimate Arbon Fiber Care Guide: Keep the Shine and Extend Lifespan

jcsportline.com0 Comments

Carbon Fiber Parts vs. Regular Car Mods: Which Material Is Worth Your Investment?

Tags

adhesive layer control Automotive Aftermarket automotive composites Brand Reputation carbon fiber case study Carbon Fiber Durability carbon fiber engineering carbon fiber failure prevention carbon fiber for racing carbon fiber interior carbon fiber parts Carbon Fiber Precision carbon fiber production tips carbon fiber prototype Carbon Fiber QC carbon fiber quality carbon fiber simulation carbon fiber vs aesthetics carbon fibre composite part development custom carbon parts DIY Installation fake carbon fiber Fitment Accuracy fitment issues functional carbon fiber parts layup angle Manufacturing Tolerances motorsport carbon fiber Mounting Point Failure OEM Standards original structure Precision Manufacturing Private Label Manufacturing Quality Control Process real carbon real carbon fiber resin flow control Screw Hole Alignment stress test carbon fiber Supplier Reliability Thread Quality tuning shop carbon parts User Experience ±0.3mm Tolerance