What’s the Most Cost-Effective Way to Start a Carbon Fiber Project?

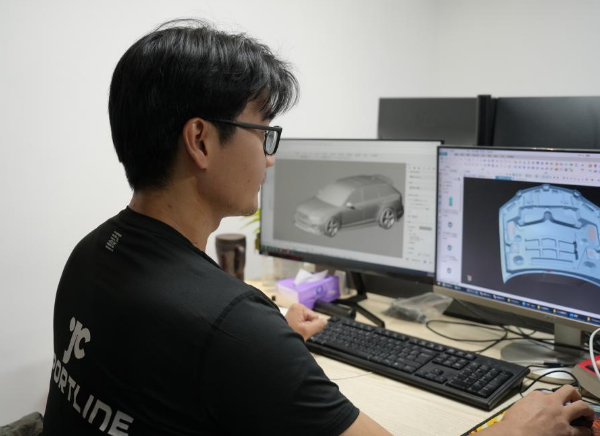

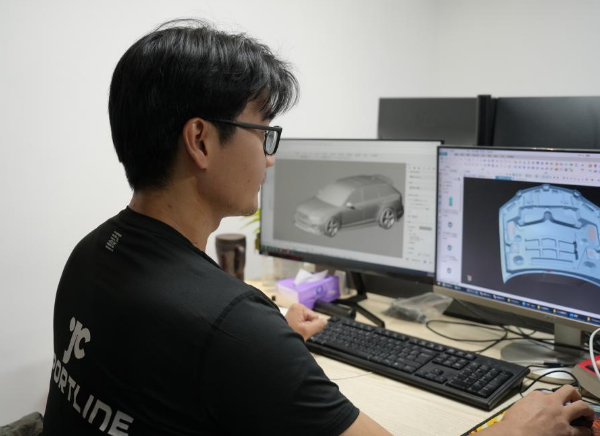

JCSPORTLINE’s Smart Multi-Mold Solution Explained

Custom carbon fiber parts are getting more popular every year. But if you’re starting a new project, here’s the big question:

How do you create a mold for carbon fiber parts without breaking the bank—or wasting time?

At JCSPORTLINE, we’ve developed a flexible and cost-effective system called the Multiple Mold Solution. It’s designed for different types of customers, budgets, and timelines. Whether you're a pro shop or a car mod enthusiast, our system helps you reduce risk, save money, and get your product to market faster.

Custom carbon fiber parts are getting more popular every year. But if you’re starting a new project, here’s the big question:

How do you create a mold for carbon fiber parts without breaking the bank—or wasting time?

At JCSPORTLINE, we’ve developed a flexible and cost-effective system called the Multiple Mold Solution. It’s designed for different types of customers, budgets, and timelines. Whether you're a pro shop or a car mod enthusiast, our system helps you reduce risk, save money, and get your product to market faster.

No problem. Here’s what we do:

No problem. Here’s what we do:

Want to test your idea fast?

Ask us about our “quick mold” silicone option — great for market testing before full production.

Want to test your idea fast?

Ask us about our “quick mold” silicone option — great for market testing before full production.

Great — this is the fastest and cheapest route.

Great — this is the fastest and cheapest route.

We’ve got your back.

We’ve got your back.

Example: Front lips often scrape or don’t fit if molded from just a sample.

We test the car’s body line accuracy to avoid problems like poor angles or misalignment.

Whether you’re:

Whether you’re:

Custom carbon fiber parts are getting more popular every year. But if you’re starting a new project, here’s the big question:

How do you create a mold for carbon fiber parts without breaking the bank—or wasting time?

At JCSPORTLINE, we’ve developed a flexible and cost-effective system called the Multiple Mold Solution. It’s designed for different types of customers, budgets, and timelines. Whether you're a pro shop or a car mod enthusiast, our system helps you reduce risk, save money, and get your product to market faster.

Custom carbon fiber parts are getting more popular every year. But if you’re starting a new project, here’s the big question:

How do you create a mold for carbon fiber parts without breaking the bank—or wasting time?

At JCSPORTLINE, we’ve developed a flexible and cost-effective system called the Multiple Mold Solution. It’s designed for different types of customers, budgets, and timelines. Whether you're a pro shop or a car mod enthusiast, our system helps you reduce risk, save money, and get your product to market faster.

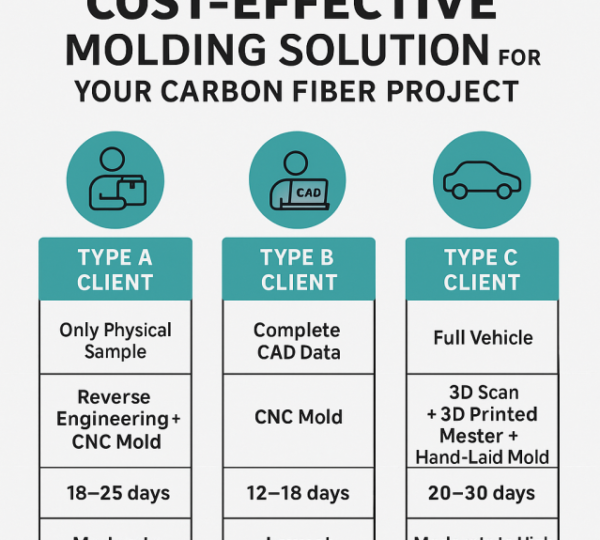

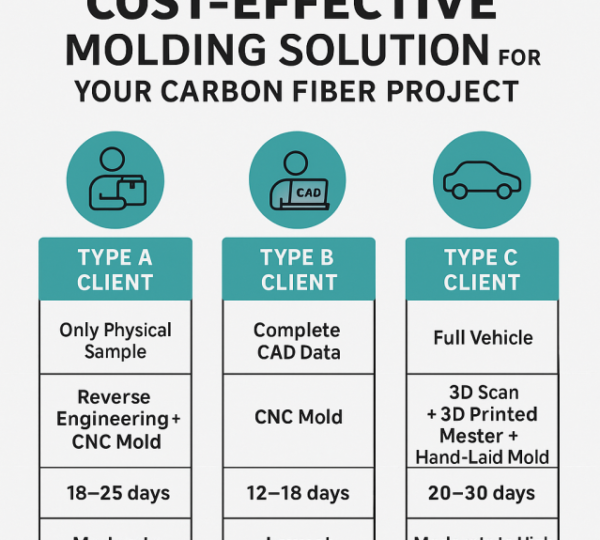

3 Types of Customers, 3 Smart Mold Solutions

| Customer Type | What You Provide | Recommended Mold Process | Time Estimate | Cost | Best For |

| Type A | Only a physical sample, no 3D files | Reverse scan + model fix + CNC mold | 18–25 days | Medium-High | Older cars, beginners |

| Type B | Full CAD files (STEP/IGS) | Direct CAD cleanup + CNC mold | 12–18 days | Lowest | Experienced teams, mass production |

| Type C | No data or samples, but full car | 3D scan full car + 3D print + fiberglass mold | 20–30 days | Medium | New model dev, low-volume runs |

Detailed Mold Process Breakdown

(And what we do that others can’t)You have a physical part, but no 3D files?

No problem. Here’s what we do:

No problem. Here’s what we do:

- We scan your part using high-precision 3D tools

- Our engineers rebuild and fix the model for proper fitment

- CNC machines cut your mold

- We test-fit the sample, adjust if needed, then start production

Want to test your idea fast?

Ask us about our “quick mold” silicone option — great for market testing before full production.

Want to test your idea fast?

Ask us about our “quick mold” silicone option — great for market testing before full production.

You have clean 3D CAD data?

Great — this is the fastest and cheapest route.

Great — this is the fastest and cheapest route.

- Send us your STEP/IGS files

- We check critical areas: bolt holes, thickness, edge wrap

- Go straight to CNC mold making and production

No part, no files, just your car?

We’ve got your back.

We’ve got your back.

- Ship us your vehicle (or visit our modeling center)

- We 3D scan the body surface

- 3D print a master mold, then build fiberglass molds by hand

- Adjust structure for production

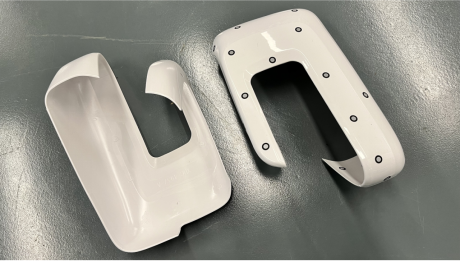

Mold Type by Installation Area

| Part Area | Precision Needed | Best Mold Process |

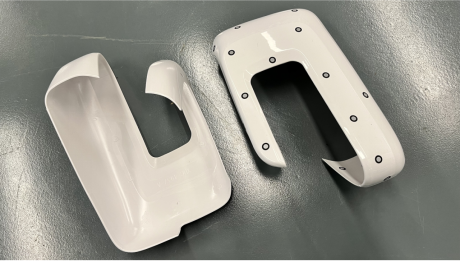

| Hood / Spoiler / Mirror Covers | Medium | Physical part or CAD |

| Door Panels / Grilles / Side Skirts | Medium-High | CAD files preferred |

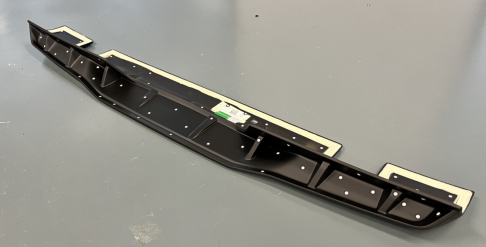

| Front Lip / Rear Lip / Bumper Trim | Very High (surface must match car curves) | 3D scan full car |

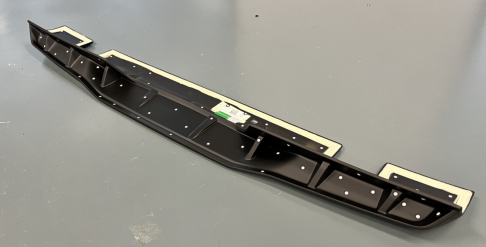

Why Choose JCSPORTLINE for Carbon Fiber Molding?

- In-house 3D scanning, modeling, CNC, and 3D printing

- We offer tailored solutions — not one-price-fits-all

- We know real-world fitment — we design with installation in mind

- Support for hand-laid molds, low volume prototyping, and mass production

Let’s Build Your Carbon Fiber Idea — Together

Whether you’re:

Whether you’re:

- A first-time customer with just a sample

- A project manager with files but no production experience

- A tuner brand launching a new carbon fiber body kit

Recent Posts

jcsportline.com0 Comments

Custom Carbon Fiber Parts for Car Clubs & Teams: From Idea to Installation

jcsportline.com0 Comments

How Carbon Fiber Wrapped Parts Are Made: A Simple Guide for Car Enthusiasts

jcsportline.com0 Comments

How to Keep Carbon Fiber Car Parts Shipping and Installation Safe

Tags

adhesive layer control

Automotive Aftermarket

automotive composites

Brand Reputation

carbon fiber case study

Carbon Fiber Durability

carbon fiber engineering

carbon fiber failure prevention

carbon fiber for racing

carbon fiber interior

carbon fiber parts

Carbon Fiber Precision

carbon fiber production tips

carbon fiber prototype

Carbon Fiber QC

carbon fiber quality

carbon fiber simulation

carbon fiber vs aesthetics

carbon fibre

composite part development

custom carbon parts

DIY Installation

fake carbon fiber

Fitment Accuracy

fitment issues

functional carbon fiber parts

layup angle

Manufacturing Tolerances

motorsport carbon fiber

Mounting Point Failure

OEM Standards

original structure

Precision Manufacturing

Private Label Manufacturing

Quality Control Process

real carbon

real carbon fiber

resin flow control

Screw Hole Alignment

stress test carbon fiber

Supplier Reliability

Thread Quality

tuning shop carbon parts

User Experience

±0.3mm Tolerance