Why Accurate 3D Scanning Matters for Carbon Fiber Fitment

Avoid Costly Mistakes with JCSPORTLINE’s Expert Support

Let’s look at who’s affected:

Let’s look at who’s affected:

Tom, a respected tuning shop owner in the UK, reached out to us after struggling with a new carbon fiber project. He had scanned a vehicle using his own 3D equipment to develop a front lip and rear spoiler.

Here’s what went wrong:

Tom, a respected tuning shop owner in the UK, reached out to us after struggling with a new carbon fiber project. He had scanned a vehicle using his own 3D equipment to develop a front lip and rear spoiler.

Here’s what went wrong:

4.Don’t have access to high-end scanning tools? No problem.

JCSPORTLINE offers scanning services from our labs in Canada, UK, Thailand, and China, with support for:

4.Don’t have access to high-end scanning tools? No problem.

JCSPORTLINE offers scanning services from our labs in Canada, UK, Thailand, and China, with support for:

From accurate scan data to mold design, carbon fiber production, and installation advice — we handle the full process.

This ensures:

From accurate scan data to mold design, carbon fiber production, and installation advice — we handle the full process.

This ensures:

In carbon fiber, 1mm off can ruin the entire product — both in looks and function.

Whether you're a:

Whether you're a:

Don’t let bad scan data ruin a great product idea.

Contact JCSPORTLINE today and get expert help, global scanning resources, and decades of experience — all working to make your carbon fiber project faster, cleaner, and more accurate.

Don’t let bad scan data ruin a great product idea.

Contact JCSPORTLINE today and get expert help, global scanning resources, and decades of experience — all working to make your carbon fiber project faster, cleaner, and more accurate.

The Challenge: “Perfect Data” That Doesn’t Fit

Across the globe, more customers are using 3D scanners to speed up the development of custom carbon fiber parts. Sounds great in theory — but in practice, poor scanning accuracy often leads to huge fitment problems. Let’s look at who’s affected:

Let’s look at who’s affected:

- Tuning shops with in-house scanning tools looking to develop new products fast

- Auto design firms outsourcing scan work with mixed data quality

- Overseas distributors needing precise specs to ensure compatibility across markets

- High-end car owners who expect millimeter-perfect custom parts

Real Story: When “High-Tech” Becomes a Headache

Tom, a respected tuning shop owner in the UK, reached out to us after struggling with a new carbon fiber project. He had scanned a vehicle using his own 3D equipment to develop a front lip and rear spoiler.

Here’s what went wrong:

Tom, a respected tuning shop owner in the UK, reached out to us after struggling with a new carbon fiber project. He had scanned a vehicle using his own 3D equipment to develop a front lip and rear spoiler.

Here’s what went wrong:

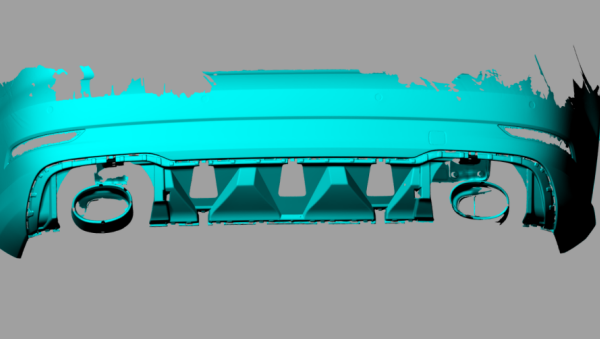

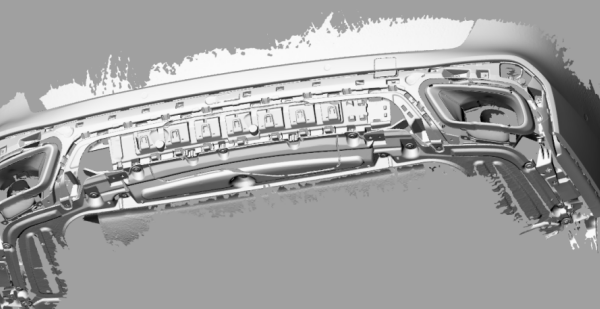

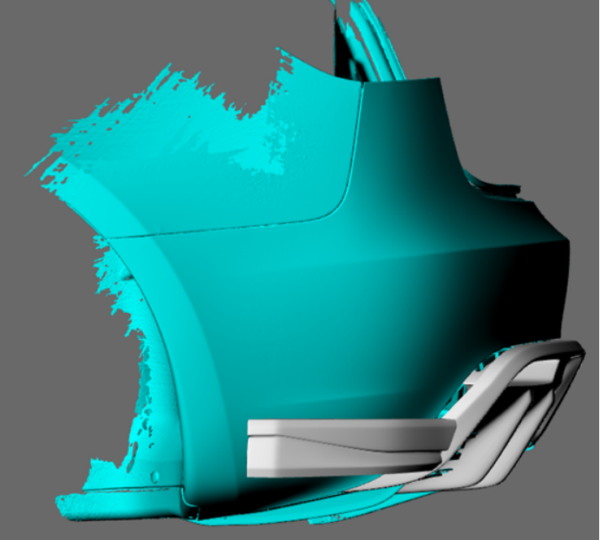

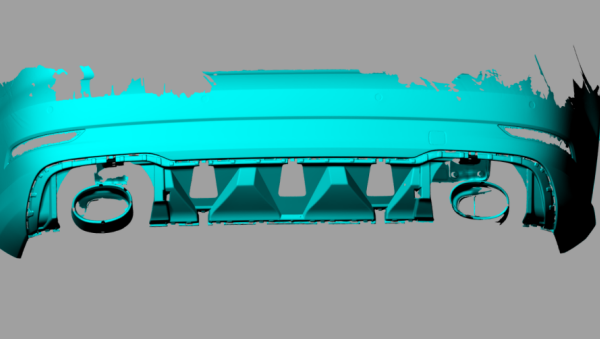

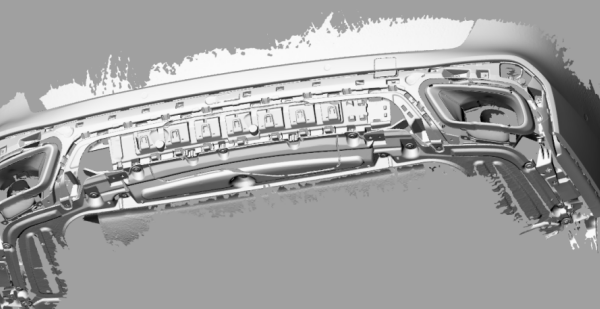

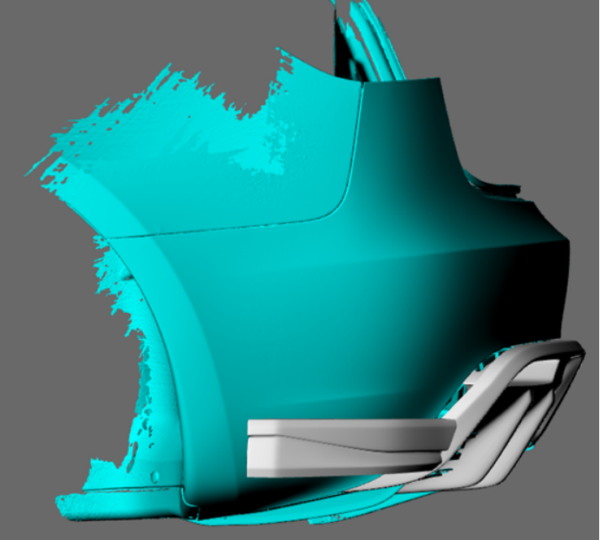

- The 3D data had rough edges and missing areas

- The parts based on that data had visible gaps when installed

- Even 3D-printed samples didn’t match — fitment failed repeatedly

- The project faced cost overruns and delays due to constant rework

JCSPORTLINE’s Solution: Precision from Start to Finish

1. 20 Years of Carbon Fiber Expertise

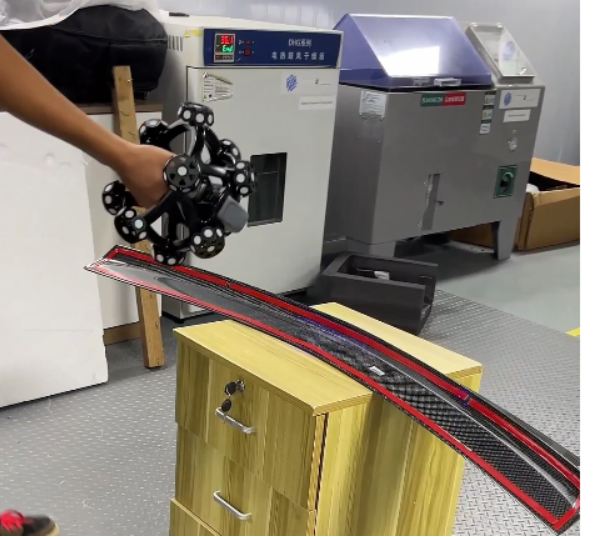

We helped Tom improve his scan process by:- Identifying critical measurement zones

- Recommending best angles for key areas

- Making sure all essential points for carbon fiber mounting were captured correctly

2. Easy-to-Follow 3D Scan Guide

Our clients receive a full guide including:- Scanner setup and calibration tips

- Multi-angle scanning strategies

- Where and how to measure mounting holes and edges

- Visual examples to ensure data quality before modeling

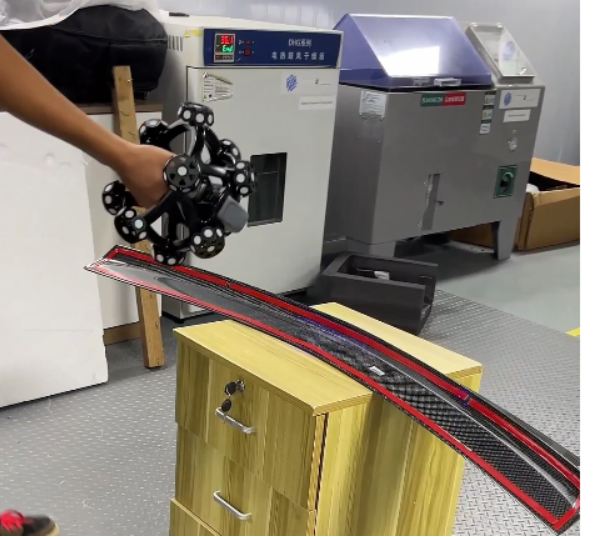

3. Access to Global 3D Scanning Equipment

4.Don’t have access to high-end scanning tools? No problem.

JCSPORTLINE offers scanning services from our labs in Canada, UK, Thailand, and China, with support for:

4.Don’t have access to high-end scanning tools? No problem.

JCSPORTLINE offers scanning services from our labs in Canada, UK, Thailand, and China, with support for:

- Full vehicle scans

- Localized part scans

- Real-time technical support

5. One-Stop Design & Manufacturing

From accurate scan data to mold design, carbon fiber production, and installation advice — we handle the full process.

This ensures:

From accurate scan data to mold design, carbon fiber production, and installation advice — we handle the full process.

This ensures:

- Better fitment

- No guesswork

- No costly rework

Why Scan Accuracy Is Everything in Carbon Fiber

Imprecise scan data can cause:| Problem | Impact |

| Jagged or warped edges | Gaps in fit, poor aesthetics |

| Missing geometry | Incorrect hole locations, failed installations |

| Distorted models | Mold misalignment, costly delays |

Are You Facing These Issues Too?

Whether you're a:

Whether you're a:

- Tuning shop with scanners but limited carbon fiber experience

- Distributor needing help with accurate 3D data

- Car owner looking for custom parts that fit perfectly

- Remote technical guidance

- High-accuracy scan services

- Professional design and manufacturing follow-up

Let’s Make 3D Data Work for You — Not Against You

Don’t let bad scan data ruin a great product idea.

Contact JCSPORTLINE today and get expert help, global scanning resources, and decades of experience — all working to make your carbon fiber project faster, cleaner, and more accurate.

Don’t let bad scan data ruin a great product idea.

Contact JCSPORTLINE today and get expert help, global scanning resources, and decades of experience — all working to make your carbon fiber project faster, cleaner, and more accurate.

Recent Posts

jcsportline.com0 Comments

Custom Carbon Fiber Parts for Car Clubs & Teams: From Idea to Installation

jcsportline.com0 Comments

How Carbon Fiber Wrapped Parts Are Made: A Simple Guide for Car Enthusiasts

jcsportline.com0 Comments

How to Keep Carbon Fiber Car Parts Shipping and Installation Safe

Tags

adhesive layer control

Automotive Aftermarket

automotive composites

Brand Reputation

carbon fiber case study

Carbon Fiber Durability

carbon fiber engineering

carbon fiber failure prevention

carbon fiber for racing

carbon fiber interior

carbon fiber parts

Carbon Fiber Precision

carbon fiber production tips

carbon fiber prototype

Carbon Fiber QC

carbon fiber quality

carbon fiber simulation

carbon fiber vs aesthetics

carbon fibre

composite part development

custom carbon parts

DIY Installation

fake carbon fiber

Fitment Accuracy

fitment issues

functional carbon fiber parts

layup angle

Manufacturing Tolerances

motorsport carbon fiber

Mounting Point Failure

OEM Standards

original structure

Precision Manufacturing

Private Label Manufacturing

Quality Control Process

real carbon

real carbon fiber

resin flow control

Screw Hole Alignment

stress test carbon fiber

Supplier Reliability

Thread Quality

tuning shop carbon parts

User Experience

±0.3mm Tolerance