aircraft

- Home

- aircraft

aircraft

Aircraft

Nose

Cone

Overview

The aviation industry, particularly the niche of small civilian seaplanes, demands materials that are lightweight, durable, and capable of withstanding harsh environments. JC Sportline initiated a project to develop a fiberglass nose that not only meets these stringent requirements but also enhances the overall performance and safety of seaplanes.

As experts in composite application materials, JC Sportline combines advanced technology with cutting-edge design to produce high-quality, durable, and aesthetically appealing products for the aviation industry.

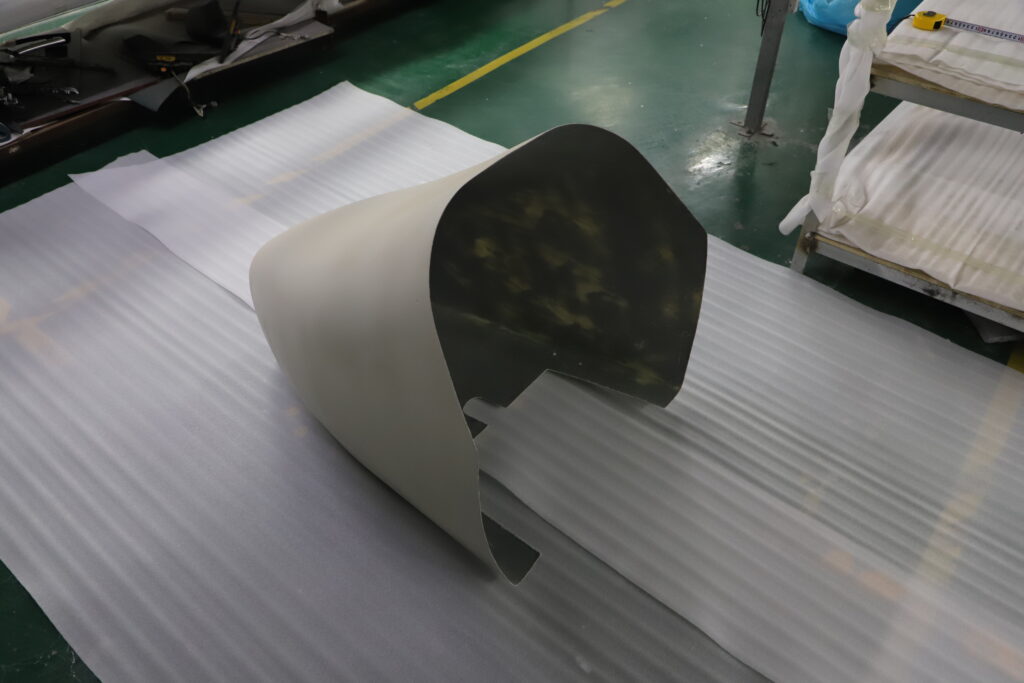

Manufacturing Process

We employ the advanced Vacuum Evacuation Process to manufacture our premium fiberglass small seaplane nose cones. This cutting-edge technique ensures that our nose cones are both lightweight and exceptionally durable, capable of withstanding the demanding conditions of aviation. The precision and strength provided by the Vacuum Evacuation Process result in components that offer superior aerodynamic performance and reliability.

Project Achievements

Weight Reduction

The use of fiberglass resulted in a lighter airplane nose, contributing to overall weight savings and enhanced fuel efficiency.

Enhanced Durability

The high-strength properties of fiberglass ensured that the airplane nose could withstand the harsh conditions encountered during water takeoffs and landings, as well as in-flight stresses.

Improved Performance

The refined design and excellent aerodynamic and hydrodynamic properties of the fiberglass nose improved the aircraft's performance, reducing drag, and enhancing fuel economy and stability on water.

Key Features

Materials Selection

Fiberglass Advantages

was chosen for its optimal balance of strength, weight, and flexibility, making it ideal for the aviation industry. It provides the necessary durability to withstand the demanding conditions faced by seaplanes.

Performance and Durability

The fiberglass used provides the necessary durability to withstand the demanding conditions faced by seaplanes, including impacts, vibrations, and varying temperatures.

Advanced Manufacturing

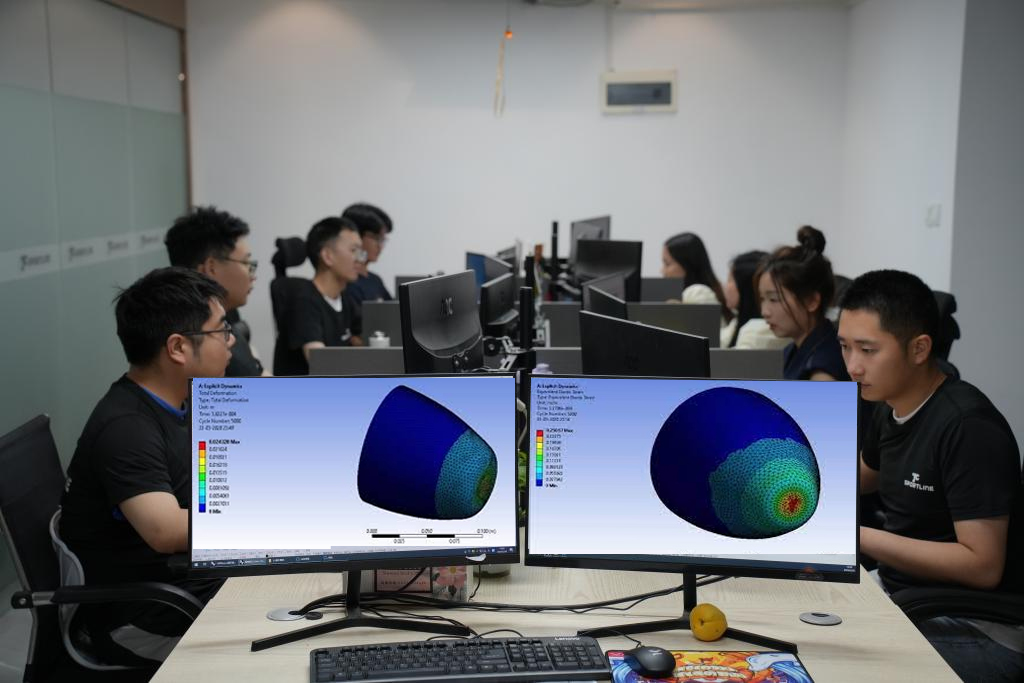

Computer-Aided Design (CAD)

Utilizes advanced software for precise modeling and simulation, allowing for aerodynamic optimization and performance enhancement.

Advanced Curing Processes

Advanced curing processes were used to achieve the desired strength and durability of the fiberglass material.

Precision Machining

Utilizes CNC machining processes to achieve intricate shapes and tight tolerances, ensuring a perfect fit and seamless integration with the aircraft.

Customer Feedback

Aircraft manufacturers and pilots have praised the performance, quality, and aesthetics of JCSPORTLINE fiberglass nose cones. They have noted significant improvements in aircraft handling, fuel efficiency, and overall flight experience

Performance and Efficiency

Enhanced Aerodynamics

The refined design of the fiberglass nose significantly improves aerodynamic efficiency, reducing drag and enhancing flight performance.

Weight Reduction

The use of lightweight fiberglass contributes to a significant reduction in the overall weight of the seaplane, directly impacting fuel efficiency and operational costs.

High-Strength Properties

The high-strength characteristics of fiberglass ensure that the airplane nose can withstand the stresses of both flight and water operations, including extreme weather conditions and high-impact scenarios.