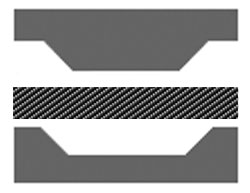

The compression molding process plays a crucial role in the production of carbon fiber products. Carbon fiber products are highly favored for their lightweight, high strength, and excellent corrosion resistance, with compression molding providing an ideal manufacturing method to achieve these properties. In the compression molding process, carbon fiber pre-preg material is typically placed into a mold and then molded by applying high pressure and temperature. The mold applies pressure of approximately 7 to 20 MPa to ensure the pre-preg material flows evenly throughout the mold and fills all the intricate details and contours. Meanwhile, the heated mold helps cure the resin and ensures the final product meets the required performance and appearance standards.

- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Compression molding process

3. Closing the Mold

4. Applying Pressure and Temperature

5. Cooling and Curing

6. Opening the Mold and Retrieving the Product

Advantages of compressin molding

Manufacture of highly complex parts

Compression molding can produce carbon fiber parts with complex geometries, including curves, protrusions, and recesses, enabling designers to realize creative ideas.

Excellent surface quality

Due to the high pressure and temperature of the mold, compression molding can produce smooth, uniform surfaces, reducing the need for subsequent machining operations and ensuring the quality of the final product’s appearance.

High strength and lightweight

Through compression molding, carbon fiber can be fully compacted under high pressure, resulting in higher strength and stiffness while maintaining lightweight properties.

Mass production

Compression molding is suitable for large-scale production and can achieve high efficiency through automation or mechanical operation, reducing production costs and increasing production capacity.

Our expertise and advanced technology will help you succeed

Cost Savings

Providing a cost-effective solution for composite components project

OTD 98% through AI

Our AI system tracks the entire product development and production process with transparent on time delivery

Quality Consistant

Enhancing your brand reputation and customer satisfaction

Design Solutions

We create precise design solutions that fulfill your aspirations and requirements

Feasibility Studies

To ensure successful projects, our cross-functional teams meticulously review and validate designs for both practicality and production feasibility, closely aligning with our customers

Sustainability

Our oxpertise and advanced technology will help you succeed

Our projects

Tank 300 roof spoiler