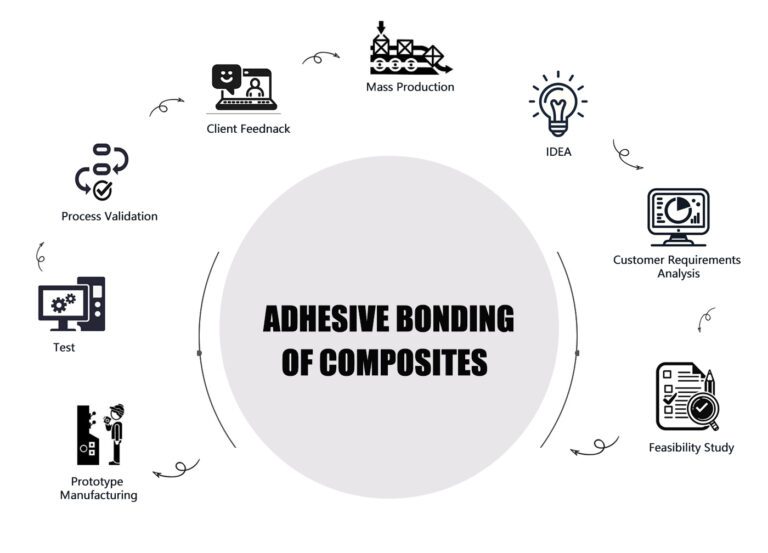

Project Background

To meet the demands of high-performance vehicles, we developed a new carbon fiber intake pipe system utilizing autoclave technology and advanced molding techniques. The goal was to optimize airflow and simplify manufacturing processes.