- Home

- Services

- Industries

- Capabilities

- Resources

- Company

We achieve mass production of carbon fiber composites through advanced equipment, high-tech processes, and standardized R&D procedures. The main steps are as follows: Firstly, we utilize automated production lines and high-precision molds designed using computer-aided technologies to ensure consistency and accuracy. Our efficient prepreg preparation and optimized curing processes guarantee the superior performance and durability of the materials. Secondly, we conduct rigorous quality inspections using state-of-the-art non-destructive testing equipment to monitor product quality in real-time. Finally, our comprehensive R&D process involves meticulous material selection, prototype development, and iterative optimization to refine and validate our production techniques, ensuring that the final products meet the highest industry standards.

Equipped with comprehensive production and inspection equipment

Autoclave

Use large autoclaves for curing composite materials, ensuring uniform temperature and pressure distribution to enhance product consistency and performance.

Compression molding equipment

Introduce highly automated production lines, including automated lay-up machines,

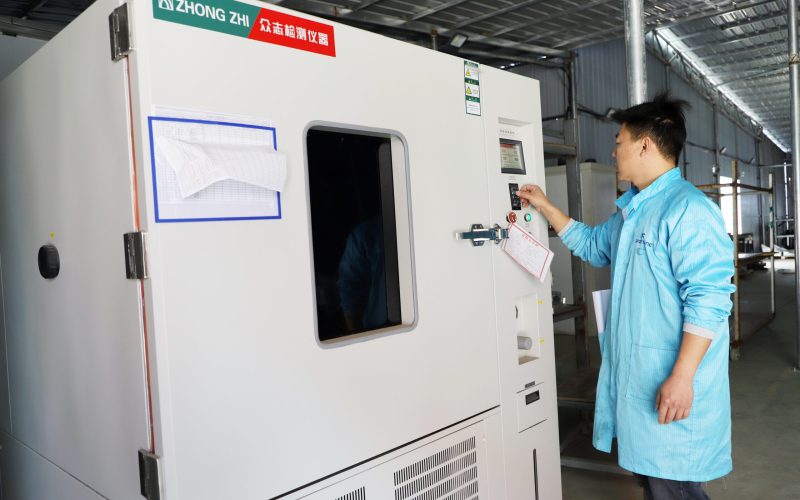

Quality Inspection Equipment

Equip with advanced non-destructive testing equipment (such as ultrasonic testing and X-ray imaging) to monitor product quality in real-time and reduce defect rates.

Standards and R&D Process

Material Selection:

Choose appropriate carbon fibers and resin systems based on application requirements.

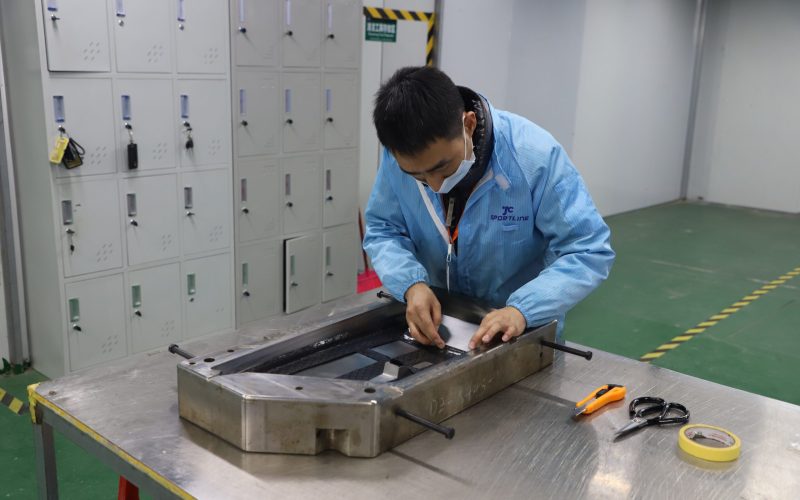

Prototype Development

Conduct small-scale trial production and performance testing to validate the feasibility of processes and equipment.

Optimization and Iteration:

Optimize process parameters and equipment configurations based on test results to gradually improve production efficiency and product quality.

Mass Production Preparation:

Perform process validation and equipment commissioning before mass production to ensure process stability and consistency.

Quality Standards:

Implement the ISO 9001 quality management system to standardize production processes and quality control.

Mass production sustainability

1. Layered Design Optimization

2. Continuous Process Improvement

3. Production Process and Product Testing

By focusing on layered design optimization, continuous process improvement, and rigorous production process and product testing, we aim to achieve sustainable mass production while reducing costs and enhancing efficiency.

Better quality, efficiency, and applications.

Discover how to apply these advantages to your project