Advantages of overlay process

Complex Geometry Capability

- The Overlay Process can handle intricate shapes, including curves, protrusions, and recesses.

- This capability allows for innovative design solutions, enabling customers to realize their creative visions without compromising on structural integrity or performance.

Superior Surface Quality

- By using precise pressure and temperature control, the Overlay Process produces smooth, uniform surfaces.

- This reduces the need for post-processing and ensures a high-quality finish, which is particularly important for products where aesthetics are a key selling point.

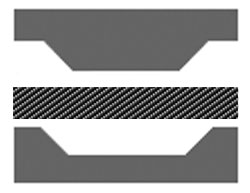

Strength with Lightweight

- The process ensures optimal fiber alignment and resin density, resulting in products that are both strong and lightweight.

- This balance is crucial for industries such as aerospace and automotive, where reducing weight without sacrificing strength can lead to improved performance and fuel efficiency.

Efficiency and Scalability

- The Overlay Process is designed for large-scale production. Automation and mechanical precision streamline manufacturing, reducing production costs and increasing capacity.

- This efficiency allows for quicker turnaround times and the ability to meet large orders, benefiting customers who need reliable and timely supply chains.