Table of Contents

Are you paying for looks—or for structure that actually fits and performs?

Who This Blog Is For

- Automotive OEM project leaders

- Performance tuning brands or distributors

- High-end modification shops with structural requirements

- Exporters who need strength + aesthetics in one piece

❗ The Real Question Isn’t “How Much?”

Let’s be honest—when most people ask about a carbon fiber hood, their first two questions are:

-

- “What’s the price?”

- “Do you have stock?”

But when it comes time to actually install and use the hood, the real issues show up:

-

- It doesn’t fit.

- It flexes or pops when driving.

- It cracks after a few weeks.

This isn’t just bad luck. It’s usually the result of cutting corners in structure, mold design, and testing.

One of our VIP clients in Europe told us straight:

“I’ve never seen a single carbon fiber hood that perfectly fits the BMW F80, F87, or G-series.”

That’s not an isolated case—it’s a pattern in the industry caused by one thing:

Low-cost shortcuts.

Common Issues with Cheap Carbon Hoods

Here’s what typically goes wrong when the focus is only on price:

- Weak Layup → Not enough carbon layers = poor stiffness

- Hood flexes when you pop the latch

- Center bulges over time

- Inaccurate Molds → Misaligned mounting points

- Mounting holes don’t line up

- Edge gaps, rubbing, or panel lift

- No Stress Testing → Unsafe at high speed

- Vibrates at 100+ km/h

- May crack or fly up under stress

A Story From the Front Lines

We’ve built and tested hundreds of carbon fiber hoods, from street builds to full OE projects. One of our most demanding clients was working on a BMW F87 performance hood. Their goal?

A hood that looks sleek but can handle real use—track days, mountain roads, and everyday slams from gas struts.

Here’s what we learned:

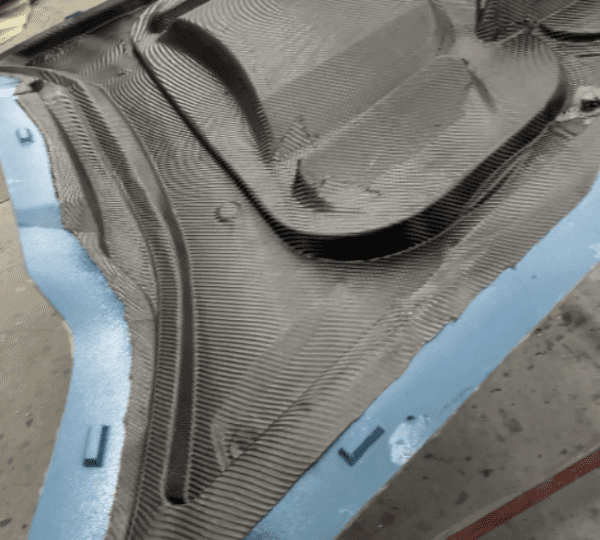

The Layup Must Be Engineered, Not Just Stacked

We designed a 7-layer composite structure:

- Inner layers: unidirectional carbon for tensile and compression

- Mid layers: cross-ply orientation for balance

- Outer layer: woven carbon for appearance and surface protection

Every layer has a job. Leave one out?

Your hood might flex, warp, or even break.

By comparison, many cheap hoods use only 3-5 random layers, which simply can’t handle real-world force.

Our reference point?

Why Does a Quality Carbon Fiber Hood Cost So Much? The “Xiaomi Hood” Example

In the carbon fiber hood market, there’s a popular model often called the “Xiaomi hood” — widely sought after for its blend of quality and price. But here’s the truth most don’t talk about:

Its retail price is around ¥42,000 RMB (about $6,000 USD), and the production cost alone—including raw materials and labor—is over ¥12,000 RMB per unit.

Why so high? Because to achieve the level of fitment precision and structural strength required for real use (not just showroom display), you must invest in:

- Multiple engineered layers of carbon fiber, carefully arranged to balance strength and weight.

- Precision molds created from full 3D scans, machined to less than ±0.3mm tolerance.

- Comprehensive quality control, including stress tests and fit checks before mass production.

Cutting any of these corners brings down the price but guarantees a hood that won’t fit right, flexes under stress, or cracks after a short time.

This “Xiaomi hood” isn’t cheap because it’s flashy—it’s expensive because it works. And that’s the cost of doing carbon fiber right.

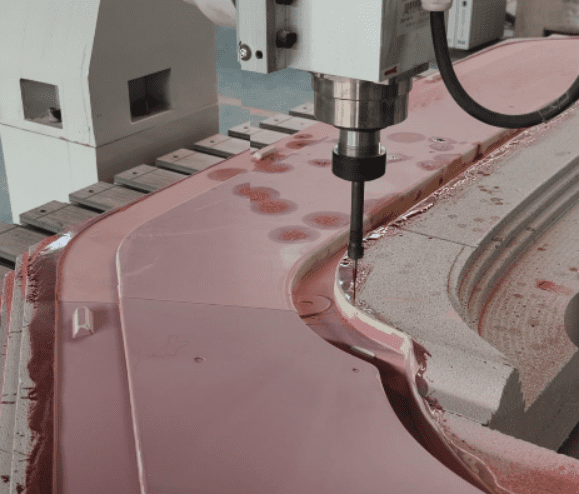

The Mold Must Be Dead-On Accurate

We started from real car 3D scans, not guesswork or old data.

Each mold was:

Reverse-engineered from the car’s body

CNC-machined from stable, reinforced tooling

Accuracy verified within ±0.3mm tolerance

Every hood was trial-fitted on a real car before production started. No surprises. No last-minute grinding.

What You Actually Pay For in a Quality Carbon Fiber Hood

|

Investment |

Result |

| High-strength prepreg carbon |

Real stiffness, long-term durability |

| Precision molds & CNC work | Fast install, reduced returns |

| Structural & thermal testing | No cracks, no vibration at speed |

| Manual polishing & topcoat | Premium look, higher resale & brand value |

And on the flip side, a “cheap” hood may cost you much more:

- Refunds and returns

- Delays from fitment issues

- Brand reputation damage

- Safety risks at highway speeds

Bottom Line: What Are You Really Buying?

You’re not buying just a look.

You’re buying fitment, safety, and long-term value.

A real carbon fiber hood:

- Doesn’t rattle or flex

- Fits like OEM

- Keeps its shape—even after 10,000km of hard driving

Ready to Start a Project?

👉 Send us your vehicle model and drawing—our engineers will help you evaluate whether your current design has structural risks.

👉 Don’t gamble on price. Let’s build it right the first time.

👉 Follow us to learn more about carbon fiber structural design that actually performs.