Table of Contents

A year of engineering collaboration behind global carbon fiber projects

Shenzhen is the core base for JCSPORTLINE’s design, engineering, and project management teams.

This annual gathering in Shenzhen was not simply a social event.

It served as a moment to pause, reflect, and look back on a full year of engineering-driven project delivery—while also aligning the team for the challenges ahead.

Over the past year, the Shenzhen team has continuously supported carbon fiber programs for customers across different industries and regions, covering the full development cycle from concept design and structural development to manufacturing validation and production preparation.

One team supporting multiple industries in parallel

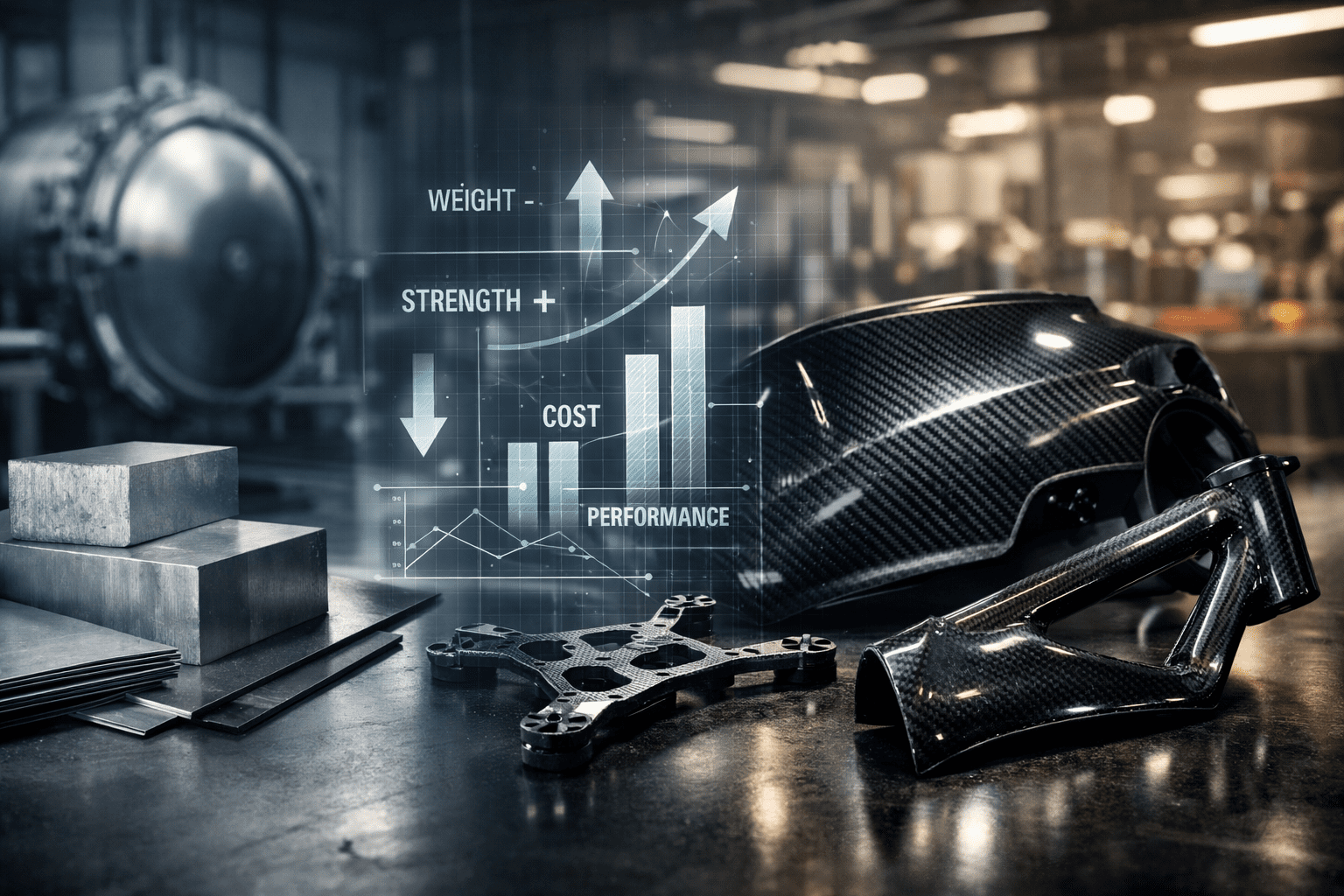

Throughout the year, the Shenzhen engineering team worked on carbon fiber projects across a wide range of application fields, including:

- automotive and mobility structural components

- carbon fiber furniture and spatial application products

- industrial equipment housings and structural parts

- consumer and professional composite products

These projects are not limited to appearance-driven components.

They typically involve:

- structural feasibility and load-path design

- laminate design and joint / interface engineering

- tooling strategy and manufacturing route selection

- surface quality control and batch consistency verification

Each application scenario brings its own engineering challenges.

Supporting multiple industries at the same time requires not only technical capability, but also strong cross-project coordination and process discipline.

This has been one of the core focuses of the Shenzhen team throughout the year.

Moving from sample capability to real production engineering

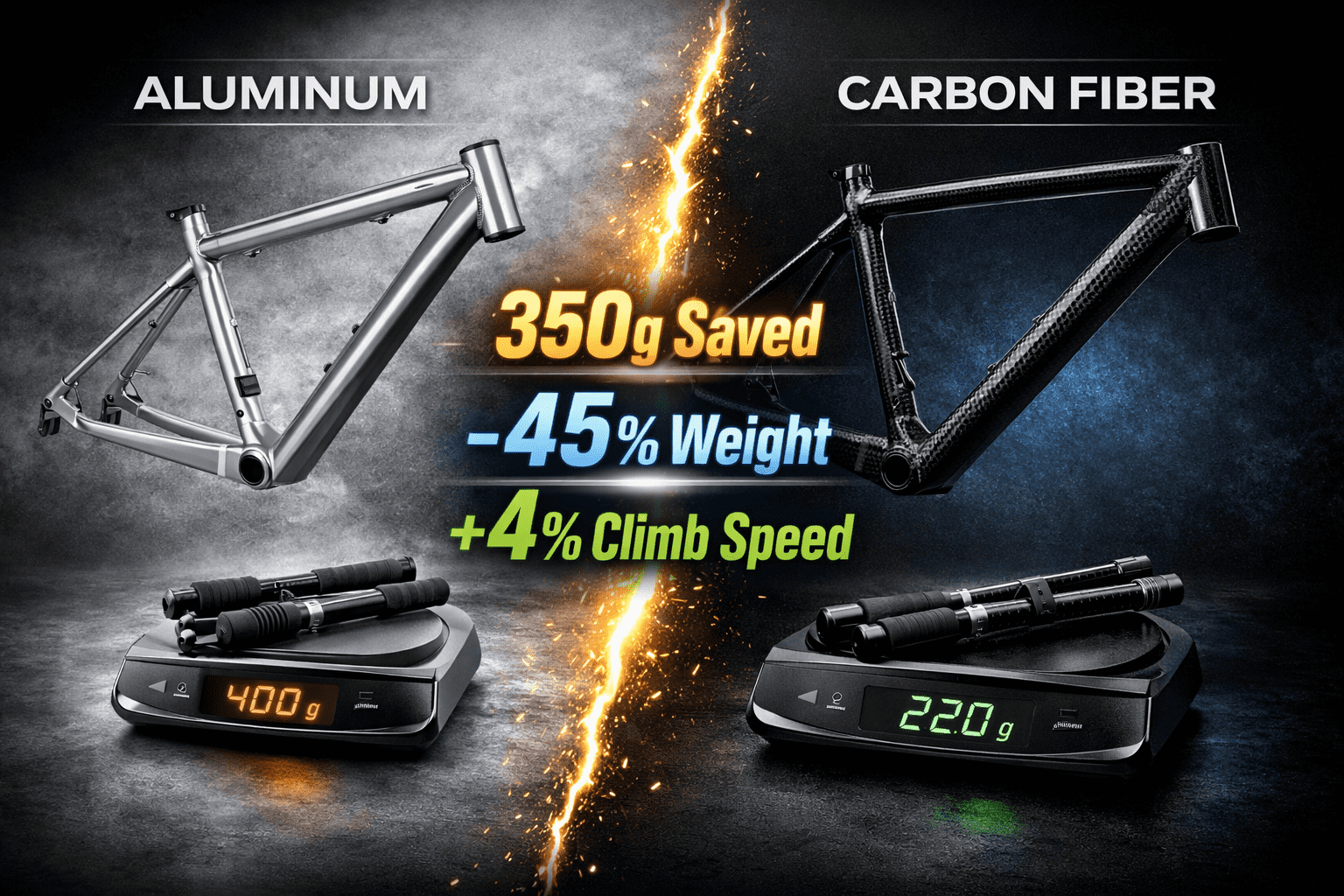

One of the most important shifts in this year’s project execution has been the transition from sample-oriented development toward full production engineering readiness.

Instead of focusing only on whether a prototype meets visual expectations, the team increasingly concentrates on:

- structural suitability for long-term usage

- reinforcement strategies in critical load areas

- manufacturable process routes for stable batch production

- surface consistency and cosmetic stability across multiple production runs

This change reflects a deeper engineering mindset.

For carbon fiber products—especially furniture and structural components—successful prototyping alone is not enough.

Scalable and repeatable manufacturing performance is what ultimately determines project success.

The gathering as a practical project review and exchange

From the on-site atmosphere, it was clear that the event was less about formal ceremonies and more about genuine communication.

Team members gathered around tables, discussing ongoing projects, sharing engineering challenges, and exchanging experience related to design coordination, process optimization, and project execution efficiency.

These informal yet focused discussions are an important part of how the Shenzhen team maintains alignment and collaboration under demanding project schedules.

Engineering teams as the most valuable long-term asset

The composite manufacturing industry differs fundamentally from traditional manufacturing.

Project success is not driven only by equipment capacity, but by:

- stable and experienced engineering teams

- close collaboration between design, process, and production

- continuous iteration and engineering learning within real projects

Over time, the Shenzhen team has built a cooperative workflow that connects design, tooling, manufacturing, and quality control into a unified development system.

This foundation enables the company to support increasingly complex and demanding carbon fiber programs.

Moving forward with stability and engineering focus

After the gathering, the team returned to daily project execution and development work.

Looking ahead, JCSPORTLINE will continue to operate with an engineering-driven mindset, focusing on:

- manufacturable design strategies

- stable and scalable process routes

- consistent and reliable production quality

Our long-term objective is not limited to the success of individual projects.

It is the continuous accumulation of engineering capability and the development of a collaborative team structure that can support complex carbon fiber programs for customers around the world.

This remains the direction of the Shenzhen team as we move into the next stage of growth.