- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Carbon Fiber Aircraft Applications & Lightweight Aerospace Parts Manufacturing

Overview

The aviation industry increasingly relies on carbon fiber composites for aircraft components that require lightweight performance, durability, and aerodynamic efficiency. From small civilian aircraft to specialized aerospace applications, carbon fiber materials play a critical role in reducing structural weight, improving fuel efficiency, and enhancing overall aircraft performance.

As an experienced composite manufacturer, JC Sportline focuses on application-driven carbon fiber solutions for aircraft parts. By combining advanced composite engineering, precision tooling, and controlled manufacturing processes, we support custom aerospace projects that demand consistent quality, dimensional accuracy, and reliable performance in challenging operating environments.

Typical Carbon Fiber Aircraft Parts We Manufacture

Carbon fiber composites are widely used in aviation for both structural and non-structural components where lightweight performance, strength, and durability are critical. Typical aircraft parts we manufacture include:

Nose cones and radomes

Aerodynamic fairings and exterior covers

Interior panels and cabin components

Lightweight composite shells and housings

Custom non-load-bearing aircraft components

These components are designed to meet aerospace application requirements while supporting OEM customization and low- to mid-volume production.

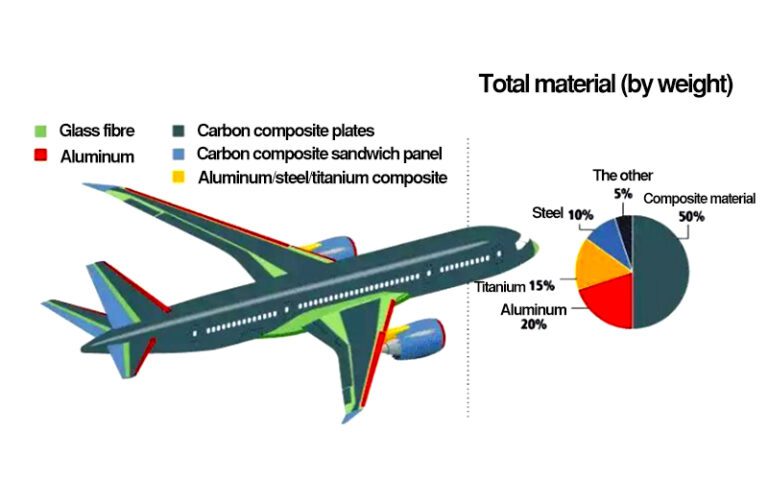

Why Carbon Fiber Is Used in Aircraft Manufacturing

Carbon fiber composites offer a unique combination of lightweight strength and design flexibility, making them ideal for aircraft component manufacturing. Compared with traditional materials, carbon fiber significantly reduces component weight while maintaining excellent mechanical properties, which directly contributes to improved fuel efficiency and extended flight range.

In aerospace manufacturing, even small weight reductions can generate meaningful operational cost savings over an aircraft’s service life. Carbon fiber composites also provide strong corrosion resistance, fatigue performance, and a low coefficient of thermal expansion, helping aircraft components maintain dimensional stability under varying environmental conditions. These advantages make carbon fiber an essential material in modern aircraft component design and composite engineering.

Custom Carbon Fiber Aircraft Parts Manufacturing

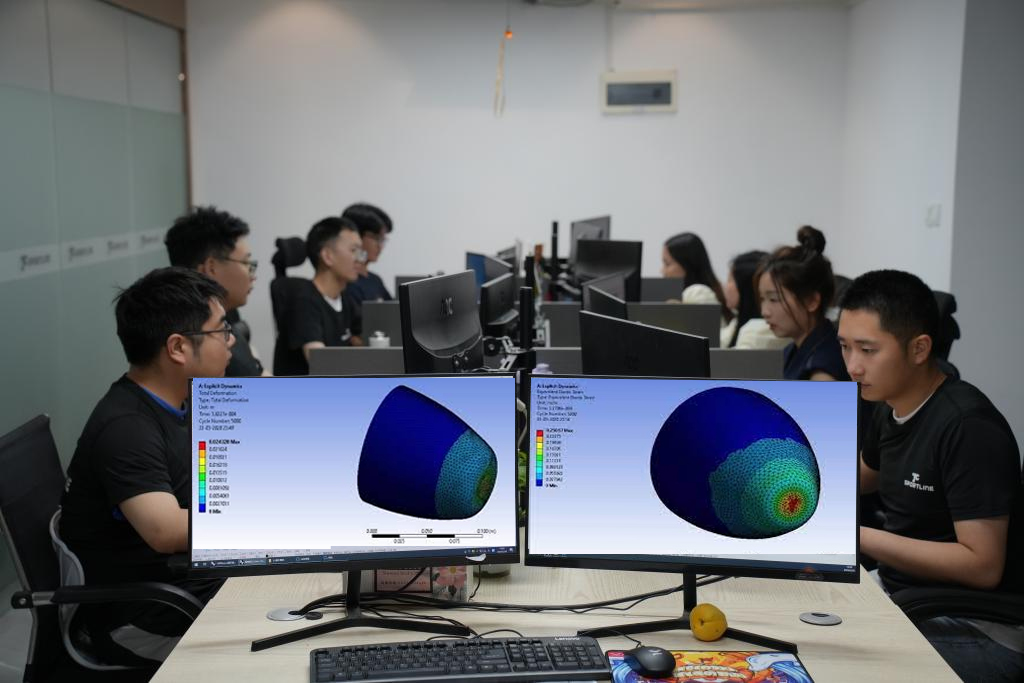

JC Sportline provides custom carbon fiber aircraft parts manufacturing services for aerospace and aviation applications. Our capabilities support OEM projects that require precision molds, consistent composite layup, and application-specific design optimization.

We assist clients with prototype development, custom tooling, and low- to mid-volume production of carbon fiber aircraft components, helping engineering teams transform design concepts into reliable, production-ready composite parts.

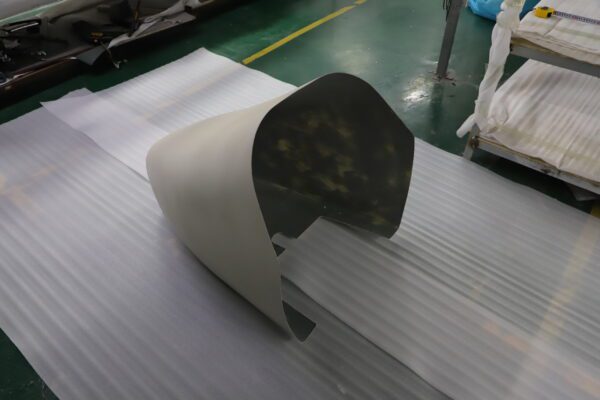

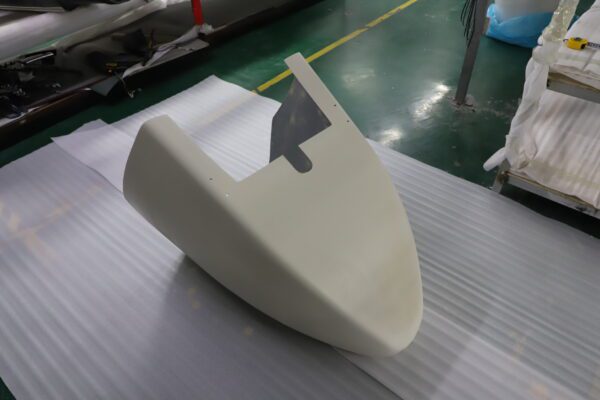

Case Example: Carbon Fiber Aircraft Nose Component

Enhanced Aerodynamics

The refined carbon fiber nose design improves aerodynamic efficiency by reducing drag and optimizing airflow, contributing to better flight performance and handling characteristics.

Weight Reduction

The lightweight properties of carbon fiber composites help reduce overall aircraft component weight, supporting improved fuel efficiency and lower operational costs.

High-Strength Properties

Carbon fiber structures provide high strength and impact resistance, enabling aircraft nose components to withstand stresses encountered during flight operations and challenging environmental conditions.

Customer Feedback

Aircraft manufacturers and aviation professionals have recognized the performance, build quality, and surface finish of JC Sportline’s carbon fiber aircraft components. Feedback highlights improvements in aerodynamic efficiency, fuel performance, and overall aircraft handling when lightweight composite parts are integrated into aircraft designs.

Frequently Asked Questions About Carbon Fiber Aircraft Applications

Q1. What aircraft parts are commonly made from carbon fiber?

Q2. Are carbon fiber parts suitable for certified or experimental aircraft?

Q3. How does carbon fiber improve aircraft performance and fuel efficiency?

Q4. Can carbon fiber aircraft parts be custom manufactured for OEM projects?

Other areas of application

Beyond aviation, carbon fiber composites are widely applied in automotive lightweighting, marine engineering, renewable energy, rail transportation, and sports equipment, where strength-to-weight optimization and durability are essential.

Carbon fiber composites are widely used across emerging industries including renewable energy, automotive lightweighting, rail transportation, and aerospace. Their high strength-to-weight performance continues to drive innovation and efficiency across advanced engineering sectors.