- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Concept Consulting Engineering Manufacturing Marketing

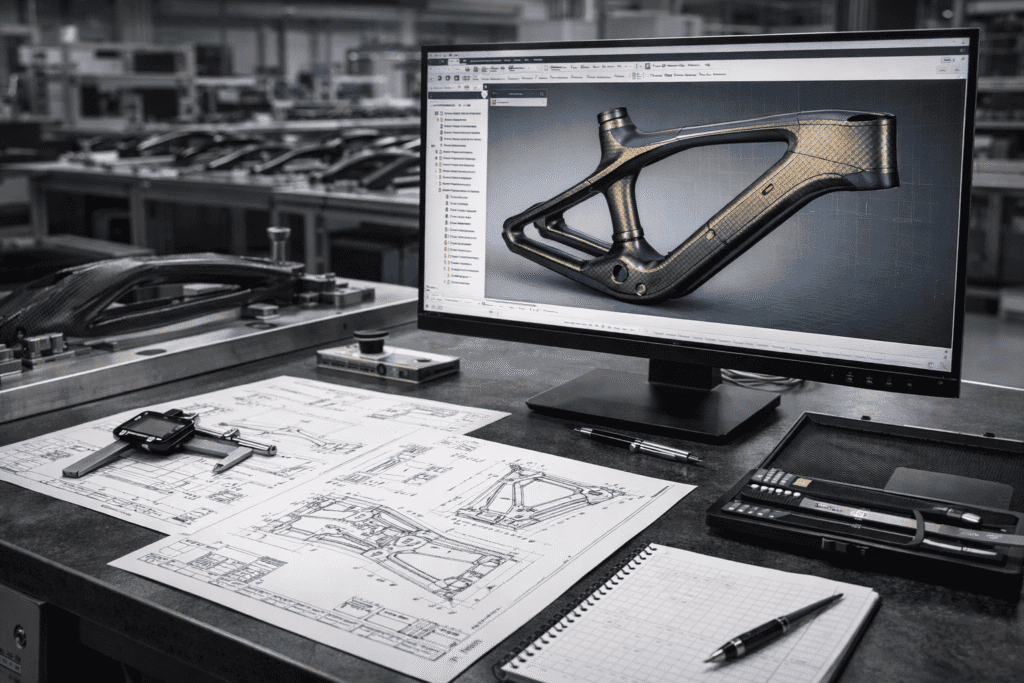

Carbon Fiber Design Services for Manufacturable Composite Products

What We Design

We design and engineer a wide range of carbon fiber components, including:

- Automotive exterior and interior carbon fiber parts

- Structural and semi-structural composite components

- Lightweight enclosures and functional housings

- Aesthetic carbon fiber surfaces and Class-A components

- Custom one-off concepts and scalable production designs

Every design is developed with material behavior, process limitations, and cost efficiency in mind—never as a purely visual exercise.

Our Carbon Fiber Design Capabilities

Our design services combine creative surface development with engineering-driven decision making, ensuring designs can move seamlessly into prototyping and production.

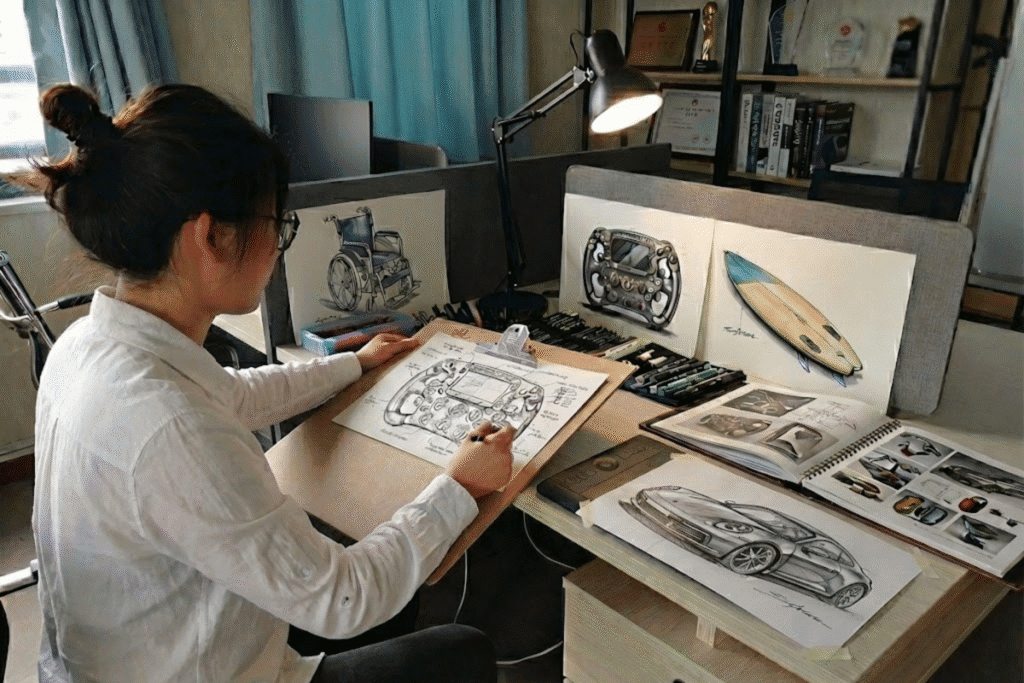

Concept & Surface Design

- Early concept sketches and design direction

- Surface modeling and visual proportion control

- Design translation based on functional requirements

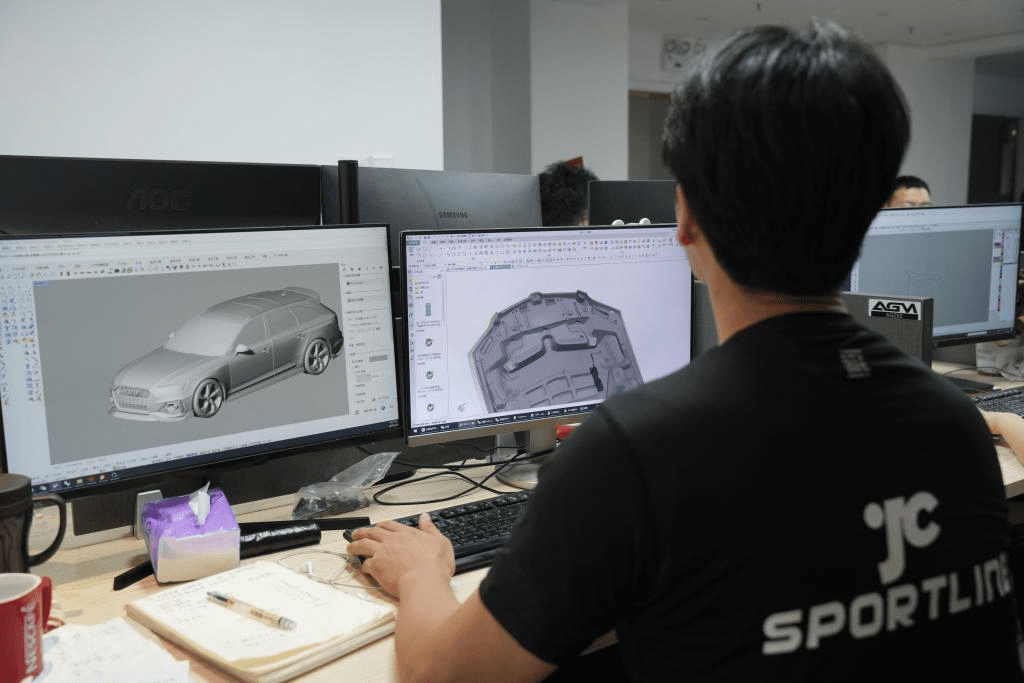

3D CAD Modeling & Technical Design

- High-accuracy 3D CAD modeling (STEP / IGES)

- Design structured for carbon fiber layup logic

- Integration with assemblies and surrounding systems

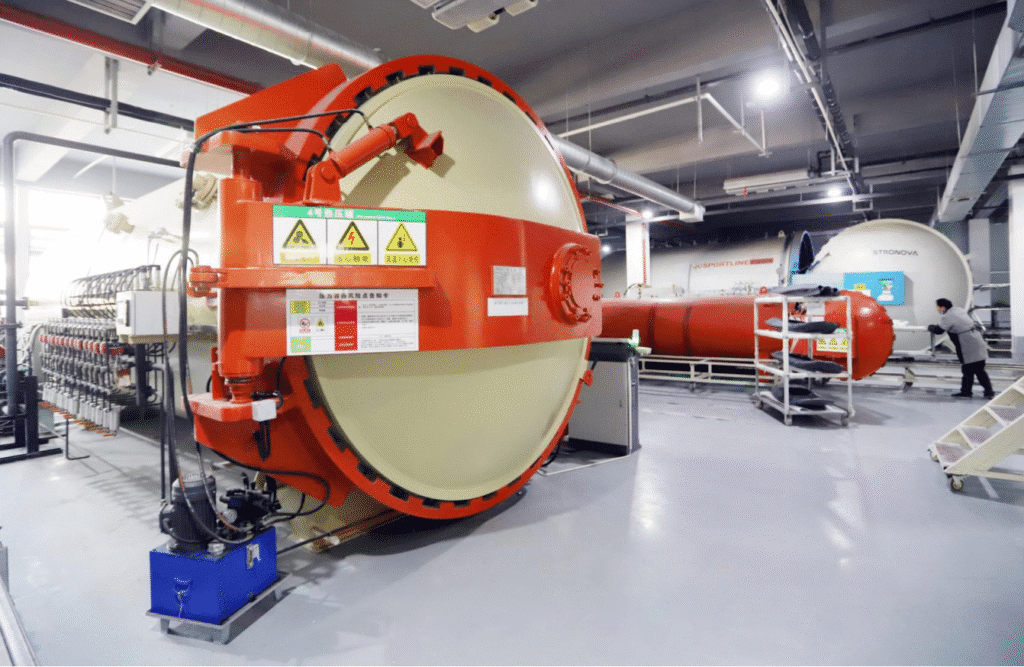

Material & Layup Strategy

- Prepreg, forged carbon, and compression molding considerations

- Ply orientation logic for strength and stiffness balance

- Material recommendations aligned with performance goals

From Concept to Engineering & Prototype

Design at JCSPORTLINE is never isolated from engineering or manufacturing.

Our carbon fiber design services are closely integrated with:

-

Engineering & DFM evaluation to identify risks early

-

Prototype development for fitment, surface, and functional validation

-

Manufacturing support to ensure smooth production handoff

This integrated approach reduces redesign cycles, shortens development timelines, and improves production success rates.

👉 Related services:

Carbon fiber products & Industry solutions

Carbon Fiber Automotive Components

High-performance body kits, aerodynamic parts, and exterior upgrades.

Carbon Fiber Performance & Track Parts

Racing seats, sport steering wheels, aero kits for track-focused vehicles.

Carbon Fiber Sports & Outdoor Gear

Lightweight boards, paddles, trekking poles, and adventure equipment.

Carbon Fiber Lifestyle & Home Series

Premium furniture, luxury accessories, and stylish carbon fiber goods.

Carbon Fiber Aerospace Parts

Lightweight carbon composite parts for aircraft, UAVs, and high-performance drones.

Carbon Fiber Medical Mobility Solutions

Lightweight wheelchairs, frames, and medical assistance devices.

Carbon Fiber Motorcycle Components

Fairings, exhaust covers, and exterior upgrades for motorcycles.

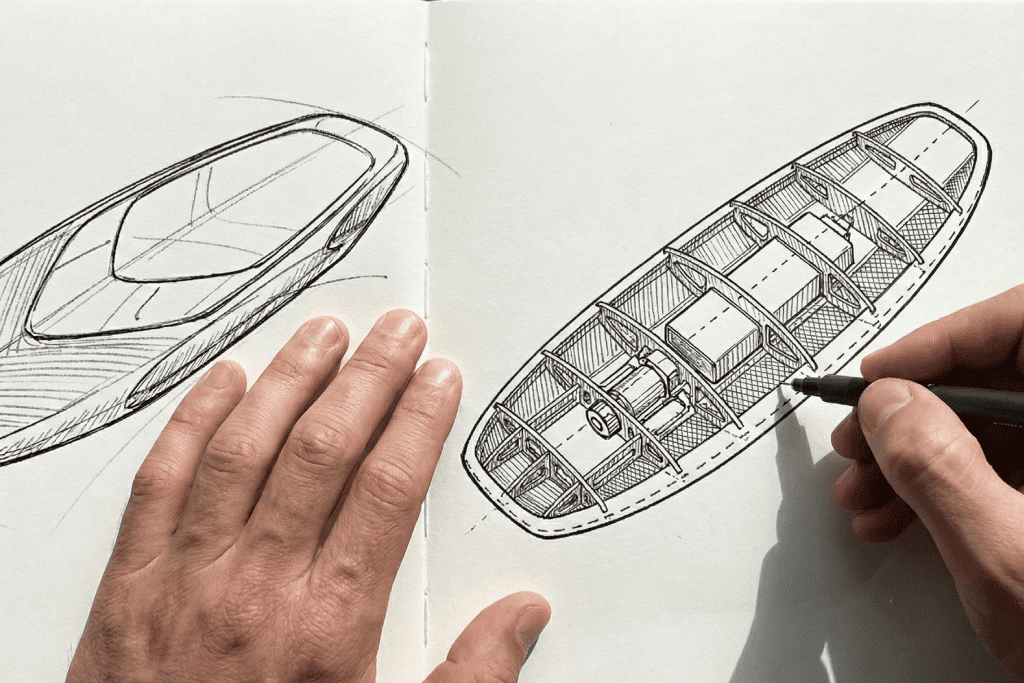

Carbon Fiber Marine Series

Designed for a wide range of water sports, including surfboards, fins, and more, our Carbon Fiber Marine Series delivers lightweight, high-strength solutions for optimal performance and durability on the water.

Carbon Fiber 3C Electronics Series

Engineered for cutting-edge electronics, our Carbon Fiber 3C Series combines lightweight strength and sleek design, enhancing the performance, durability, and aesthetics of your devices.

Any Carbon Fiber Element Products

OEM/ODM tailored carbon fiber solutions for all industries.

Design Deliverables

Depending on project scope, our carbon fiber design services can include:

3D CAD files (STEP / IGES formats) 3 d

2D technical drawings

Material and process recommendations

Layup and structural design guidance

Production-oriented design notes

All deliverables are prepared to support real manufacturing conditions, not just conceptual visualization.

Carbon fiber components & Advanced composite parts

Beyond our core carbon fiber manufacturing capabilities, JCSPORTLINE can support nearly any carbon-fiber requirement—from complex geometries to highly cosmetic surfaces—using custom lay-ups, specialty resins, and a full suite of finishing and bonding processes.

Hood for 2024 Ford Mustang S650 GT

Process

Autoclave curing (Prepreg carbon)

Material

3K carbon fiber + high-temperature epoxy resin

Surface finish

Gloss or matte clear coat (UV-resistant)

Industry

Automotive / Performance aftermarket

Customizable Carbon Fiber Dive Fins

Process

Compression molding / Hand lay-up composite forming

Material

Toray 3K carbon fiber fabric + flexible resin system

Surface finish

Gloss or matte clear coat (UV-resistant, anti-scratch)

Industry

Freediving / Spearfishing / Water sports equipment

Custom Carbon Fiber Electric Surfboard

Process

Autoclave curing + CNC-trimmed composite assembly

Material

Prepreg 3K carbon fiber + PMI/PU structural core

Surface finish

High-gloss or matte nano-coated finish

Industry

Water sports / Electric surfboard manufacturing

Custom Carbon Fiber Mouse Shell

Process

Compression molding / Hand lay-up precision forming

Material

3K carbon fiber composite (lightweight + high-rigidity)

Surface finish

Matte or gloss clear coat (fingerprint-resistant, durable)

Industry

Consumer electronics / Gaming peripherals

Carbon Fiber F1 Steering Wheel

Process

Autoclave-cured carbon fiber shell + CNC-machined aluminum mounting structure

Material

Prepreg 3K carbon fiber + high-strength alloy inserts

Surface finish

Matte or gloss clear coat

Industry

Motorsport / Racing simulation / Performance automotive

Carbon Fiber Luggage Case

This global network strengthens every stage of your development:

• Faster communication and immediate technical responses

• Localized after-sales support in Europe, North America, and Canada

• Engineering collaboration between overseas experts and Chinese R&D

• More accurate data through 3D scanning, CFD, and structural analysis

• A seamless link between your market needs and factory-level execution

Why design with JCSPORTLINE

Carbon fiber–first mindset

Design decisions are always based on composite behavior, not metal logic.

Engineering-aware design approach

Every design considers tooling, process, and scalability.

Proven cross-industry experience

From performance automotive to medical and marine applications.

Seamless transition to prototype & production

Fewer surprises, fewer redesigns, faster progress.

Free Technical Evaluation

Ask for a Free Carbon Fiber Project Review

Our engineers will review your concept and provide suggestions on materials, structure, and manufacturability – tailored to your carbon fiber application.

Response within 24 hours by our engineering team

OEM/ODM Support for Mobility Products

NDA and confidential review available on request

Start Your Carbon Fiber Project

Get expert guidance on materials, structure, and feasibility.