Table of Contents

In 2026, carbon fiber design is no longer limited to supercars or aerospace projects.

Today, carbon fiber is being used across many industries—not because it looks premium, but because lightweighting has become a real performance requirement.

From electric vehicles and drones to marine products and consumer electronics, designers and engineers are using carbon fiber in smarter, more practical ways.

This article explains the key carbon fiber design trends in 2026, using clear language and real-world logic.

Carbon Fiber Is No Longer “Just for Supercars”

4

In the past, carbon fiber was mostly associated with:

- Supercars

- Race cars

- Aircraft

It was expensive, complex, and often used to show off.

In 2026, that mindset has changed.

Carbon fiber is now used because:

- Products need to be lighter

- Systems need to be more efficient

- Designers want strong parts without extra weight

This shift has created several clear design trends.

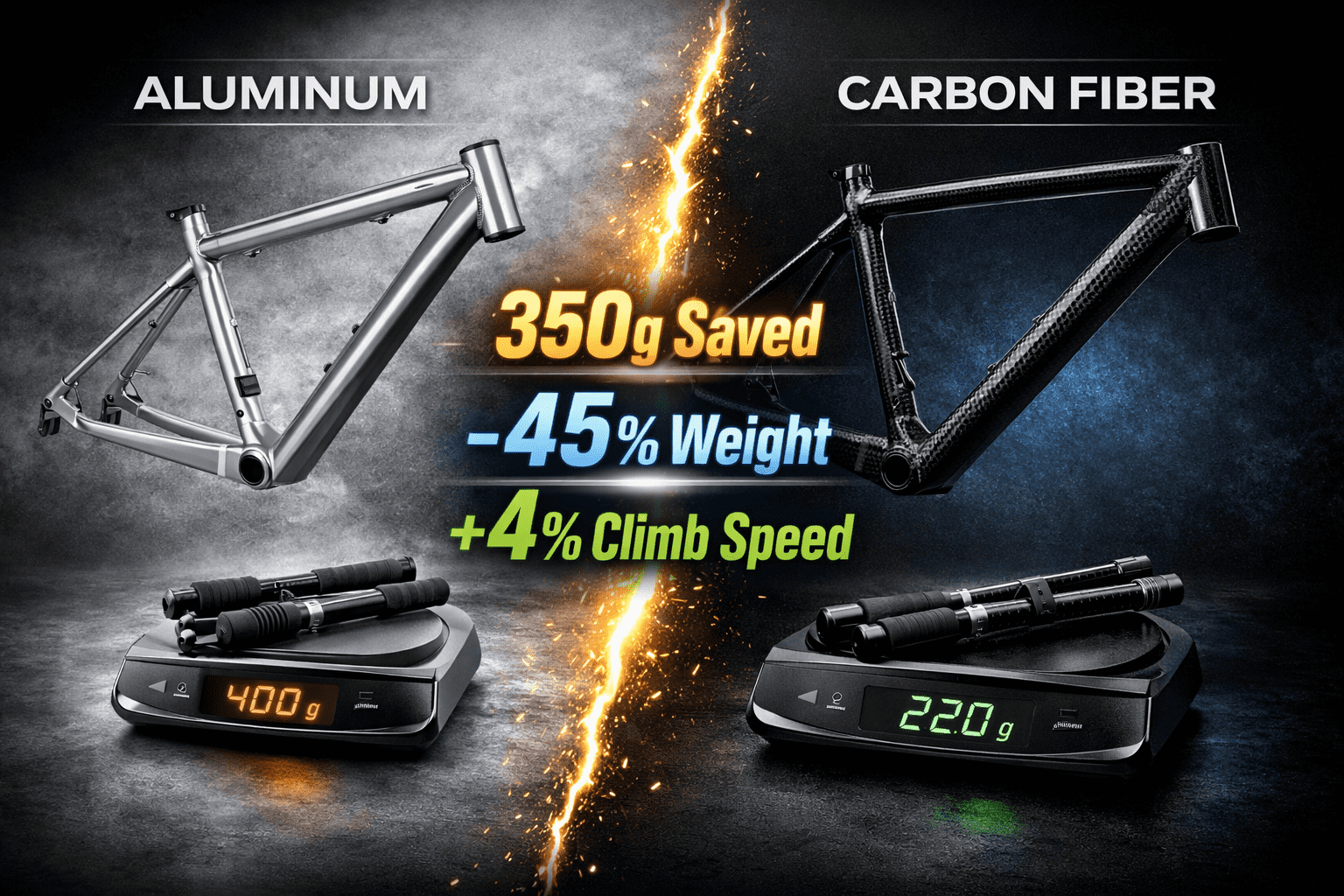

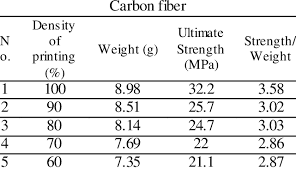

Key Trend 1: Functional Lightweighting (Not Just Looks)

In 2026, carbon fiber design is focused on function first.

That means:

- Reducing weight only when it improves performance

- Measuring real benefits, not just visual appeal

Examples of functional benefits:

- Longer driving range in electric vehicles

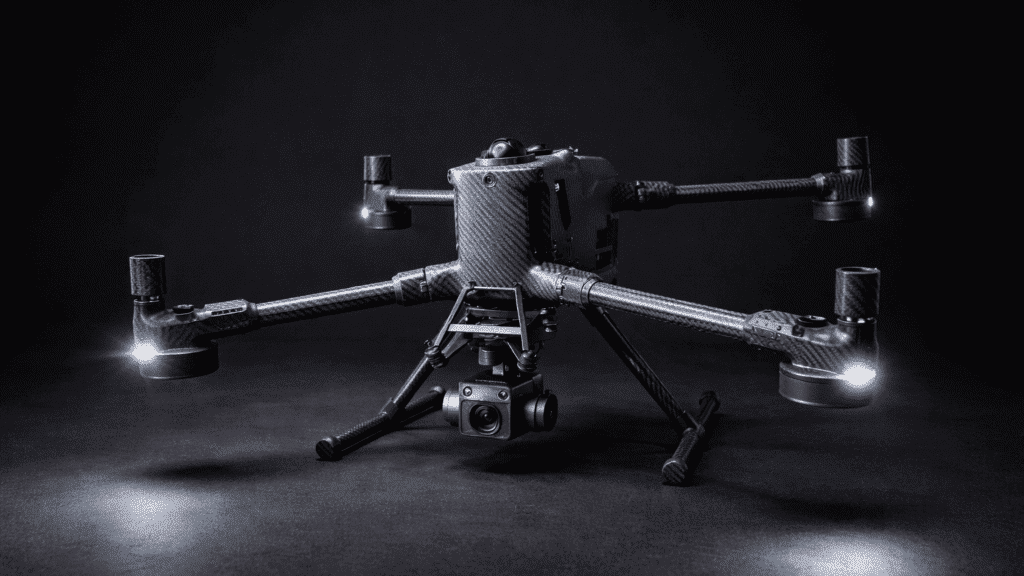

- Better flight time and stability in drones

- Easier handling for mobility products

- Lower vibration in marine structures

Designers are no longer asking:

“Does this look like carbon fiber?”

They are asking:

“What does weight reduction actually improve in this system?”

If weight reduction does not change performance, carbon fiber is often not used.

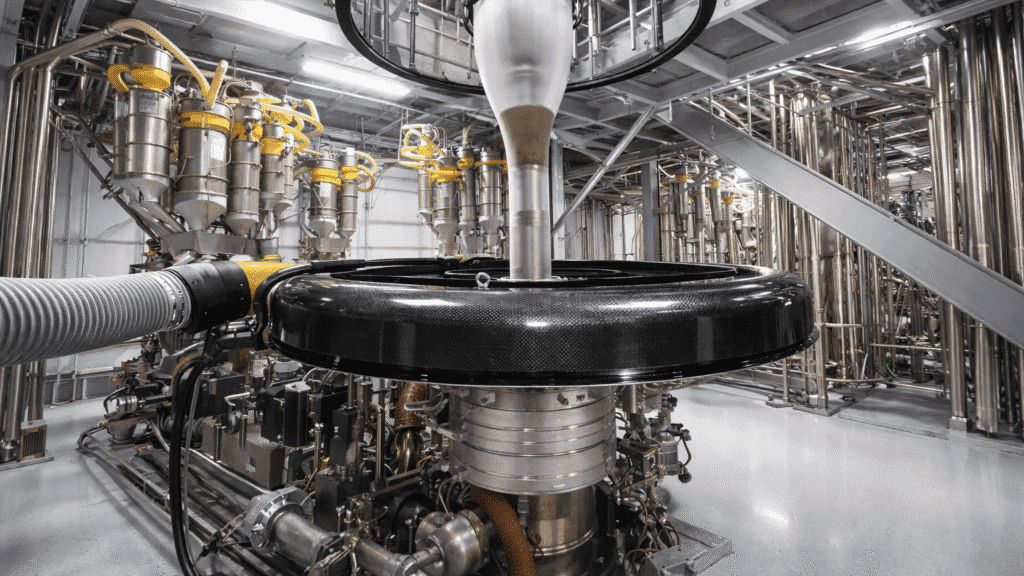

Key Trend 2: Multi-Industry Cross-Pollination

One of the biggest trends in 2026 is that industries are learning from each other.

🔘 Get Your Aerodynamic Upgrade Plan

Automotive, UAV, marine, and consumer electronics now share:

Structural Concepts

- Load paths

- Reinforcement zones

- Stiffness-focused layouts

Layup Strategies

- Fiber direction tuning

- Local reinforcement instead of thick parts

- Strength placed only where needed

Tooling Approaches

- Modular molds

- Scalable tooling strategies

- Surface + structure combined in one mold

A design solution proven in a drone frame may later appear in:

- An electric vehicle enclosure

- A marine component

- A lightweight consumer product

Carbon fiber design knowledge is no longer locked inside one industry.

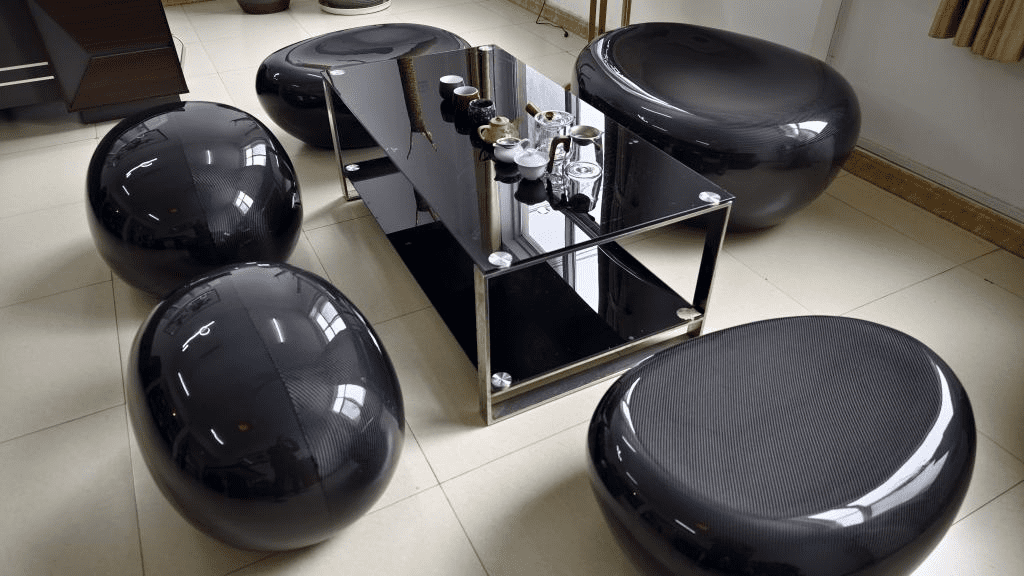

Key Trend 3: Integrated Engineering (One Part, Multiple Jobs)

In 2026, carbon fiber parts are designed to do more than one job.

Instead of separate parts, designers now combine functions.

A single carbon fiber part may be:

- Load-bearing (structural)

- Cosmetic (visible surface)

- Interface-ready (mounting points, inserts)

This means:

- Fewer parts

- Less assembly

- Lower total system weight

Carbon fiber makes this possible because structure and surface can be created at the same time, inside the same mold.

The goal is not to make parts lighter alone—but to make the entire product simpler and lighter.

Key Trend 4: Engineering-Driven Partnerships

In the past, many OEMs selected carbon fiber suppliers based on:

- Catalog products

- Appearance samples

- Unit price

In 2026, this approach no longer works.

OEMs now prioritize partners who can:

- Help decide if carbon fiber should be used at all

- Provide design feedback early

- Adjust structures for manufacturing

- Support testing and iteration

- Scale from prototype to production

This is why engineering-driven partnerships are becoming the standard.

OEMs are not just buying carbon fiber parts.

They are buying engineering decisions and risk control.

What These Trends Mean for OEMs

For OEM teams, these trends lead to three important changes:

- Carbon fiber is a design strategy, not a styling choice

- Lightweighting must deliver real system benefits

- The right partner matters as much as the material

In 2026, successful carbon fiber projects are:

- Engineered early

- Validated through testing

- Designed for production, not just prototypes

Final Thought: Lightweighting with Purpose

Carbon fiber design in 2026 is no longer about pushing extremes.

It is about:

- Using less material

- Achieving more performance

- Making products simpler, not more complex

When used with clear engineering intent, carbon fiber becomes one of the most powerful tools available.

When used without that intent, it quickly becomes an expensive mistake.

The difference is not the material.

The difference is the design thinking behind it.

Q1: Why is carbon fiber being used in more industries in 2026?

Because many products now need to be lighter to improve efficiency, range, handling, or user experience. Carbon fiber helps reduce weight without sacrificing strength.

Q2: What does “functional lightweighting” mean?

It means reducing weight only when it creates real performance benefits, such as longer battery life, better stability, or easier handling—not just for looks.

Q3: Is carbon fiber still mainly used in supercars and aerospace?

No. In 2026, carbon fiber is widely used in electric vehicles, drones, marine products, mobility equipment, and consumer electronics.

Q4: What does “integrated engineering” mean in carbon fiber design?

It means designing one carbon fiber part to handle structure, appearance, and mounting interfaces at the same time, reducing part count and assembly complexity.

Q5: Why are OEMs choosing engineering-driven partners instead of catalog suppliers?

Because modern carbon fiber projects require early design input, manufacturing knowledge, and testing support—not just finished parts from a catalog.

Q6: Will carbon fiber continue to grow after 2026?

Yes, especially in industries focused on lightweighting, electrification, and efficiency. Growth will be driven by smarter design, not just material popularity.