Table of Contents

Carbon fiber engineering does not end at CAD.

In fact, for OEM programs, CAD is only the hypothesis.

Validation is where carbon fiber designs are proven, corrected, and made production-ready.

Unlike metals or injection-molded plastics, carbon fiber performance is highly sensitive to layup strategy, insert design, and process control.

Without a structured testing and iteration loop, even a visually perfect carbon fiber part can fail in real-world use.

This article explains how professional carbon fiber engineering teams validate designs, and why iteration is not a delay—but a critical risk-reduction mechanism for OEM programs.

Why Carbon Fiber Designs Require Validation Beyond CAD

CAD models describe geometry.

They do not fully capture:

- Fiber waviness

- Resin distribution

- Ply interaction

- Cure-induced distortion

- Real-world assembly stress

Carbon fiber is anisotropic and process-dependent.

Two parts built from the same CAD file can perform very differently if their layup or curing conditions vary.

For this reason, engineering validation is mandatory, not optional.

The Carbon Fiber Design Validation Loop

A professional validation loop follows a repeatable structure.

Skipping steps or compressing the loop usually leads to expensive problems later in production.

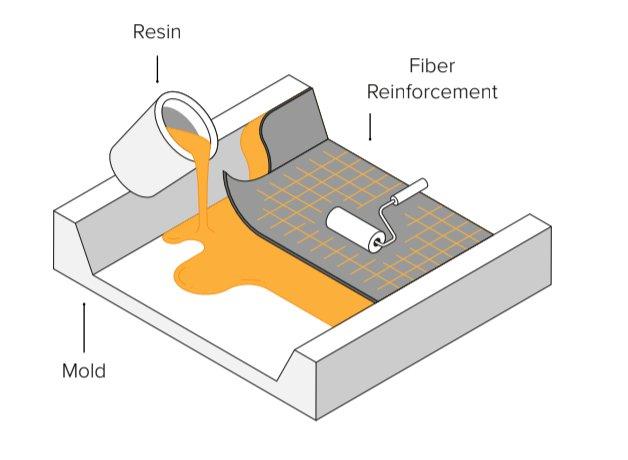

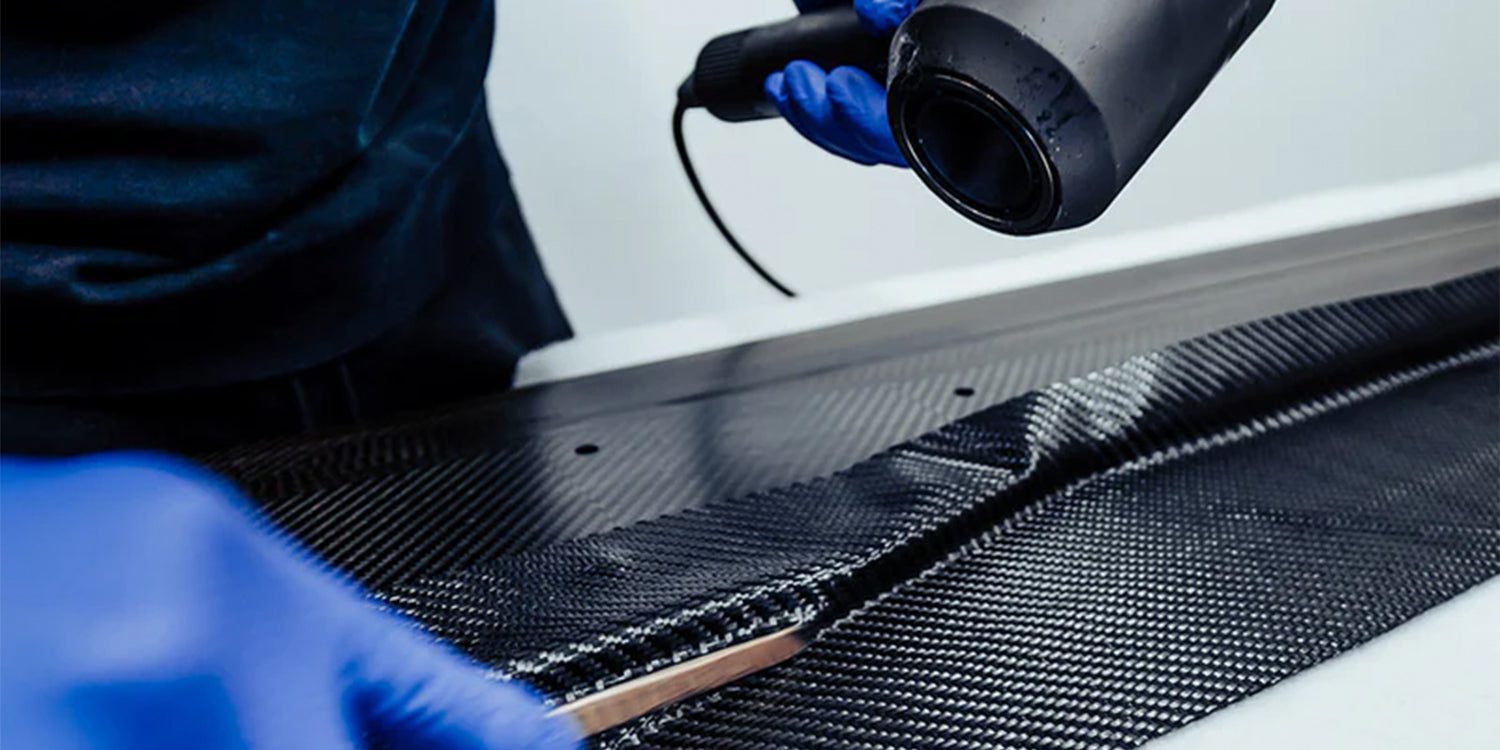

1. Prototype Build: Turning Design Intent into Reality

The first prototype is not about aesthetics—it is about translating design intent into a physical structure.

During prototype builds, engineers evaluate:

- Layup sequence accuracy

- Ply drop-offs and transitions

- Insert placement stability

- Resin flow and consolidation

- Initial dimensional behavior

This step often reveals gaps between theoretical design and manufacturable reality.

OEM takeaway:

A prototype is not a “sample.” It is a diagnostic tool.

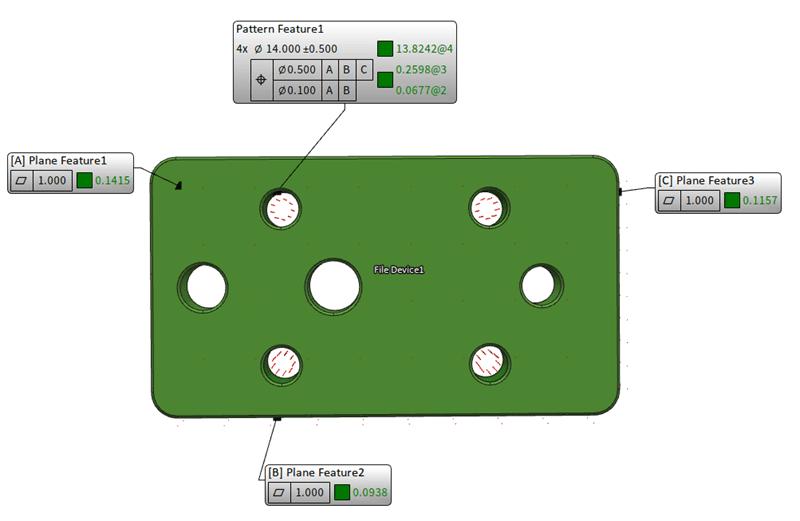

2. Fitment Verification: Interfaces Matter More Than Shape

Fitment issues are among the most common causes of carbon fiber project delays.

During fitment verification, teams assess:

- Mounting interface alignment

- Hole position stability

- Insert flushness

- Assembly preload effects

- Stack-up tolerance behavior

Carbon fiber does not behave like metal under assembly stress.

Fasteners, bonding, and preload can introduce deformation that CAD cannot predict.

OEM takeaway:

If a carbon fiber part fits once but not repeatedly, it is not production-ready.

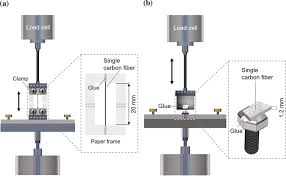

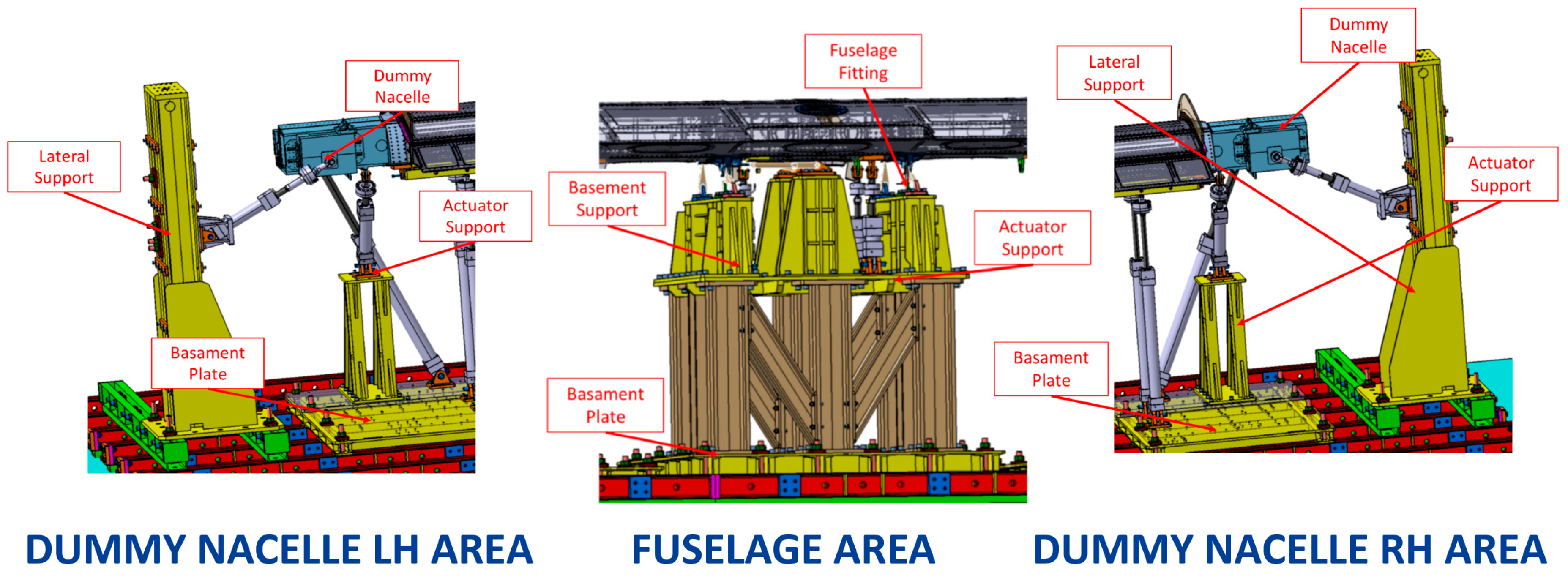

3. Load & Fatigue Testing: Proving Structural Assumptions

Structural validation confirms whether the part performs as intended under real conditions.

Typical tests include:

- Static load testing

- Bending or torsion evaluation

- Fatigue cycling

- Local stress testing around inserts

This phase often uncovers:

- Unexpected flex zones

- Overbuilt regions with excess weight

- Stress concentration near inserts or edges

OEM takeaway:

Passing CAD simulation does not guarantee passing physical load tests.

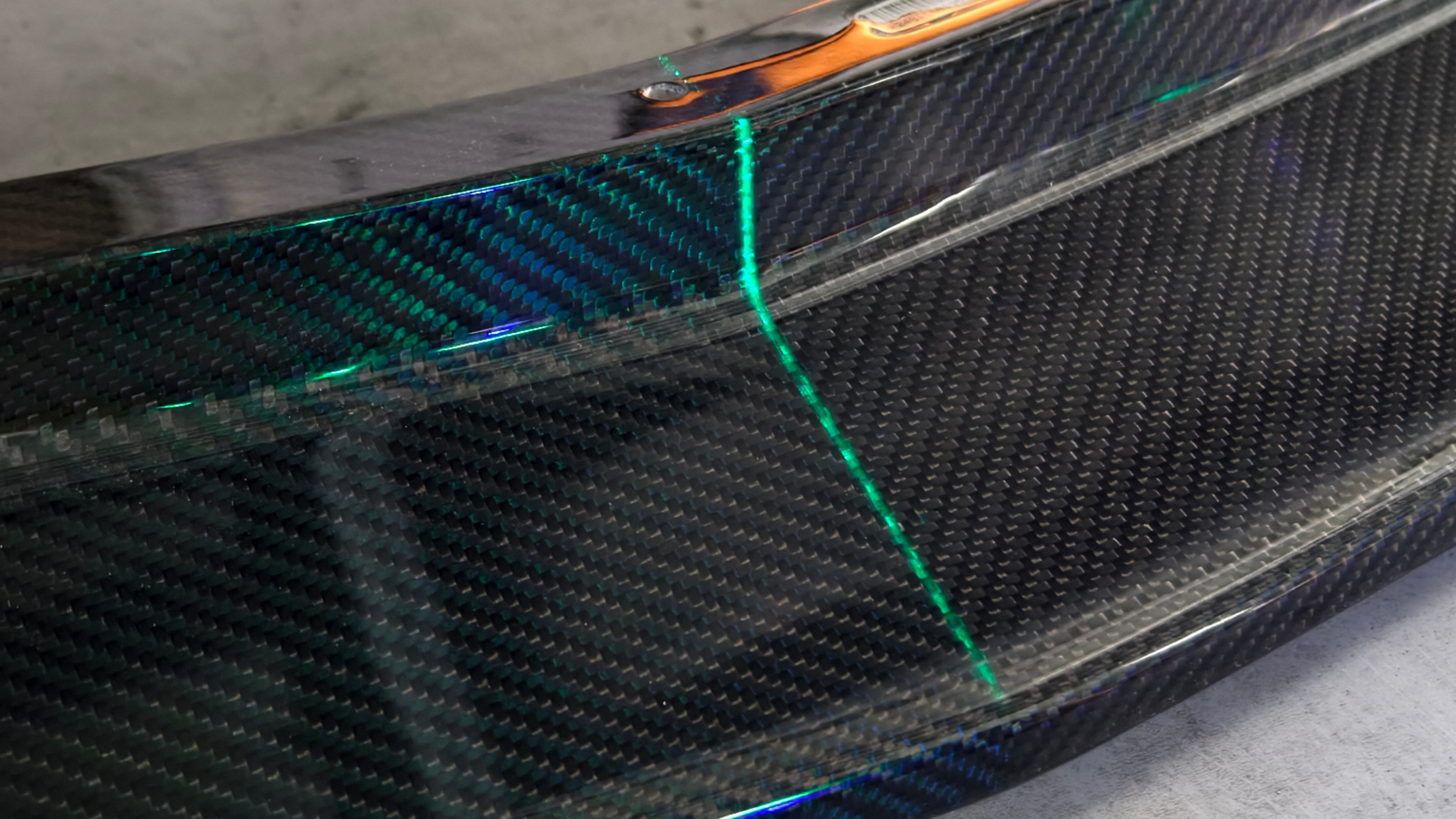

4. Surface & Cosmetic Evaluation: Consistency Over Perfection

For many OEM products, appearance is part of functional acceptance.

Surface evaluation checks:

- Fiber print-through

- Resin richness or dryness

- Pinholes or voids

- Gloss and weave consistency

- Repeatability across builds

A single perfect-looking part is meaningless if the surface cannot be repeated at scale.

OEM takeaway:

Cosmetic validation is about process stability, not one-off beauty.

🔘 Get Your Aerodynamic Upgrade Plan

5. Design Refinement: Small Changes, Big Impact

This is where iteration delivers its true value.

Small adjustments in:

- Ply orientation

- Ply count or stacking sequence

- Insert geometry or bonding method

- Cure temperature or pressure profile

can lead to significant improvements in:

- Stiffness

- Fatigue life

- Weight efficiency

- Dimensional stability

In carbon fiber engineering, millimeters and degrees matter.

OEM takeaway:

Iteration is not rework—it is optimization.

Why Iteration Matters in Carbon Fiber Engineering

Unlike metals, carbon fiber does not have a single “correct” design state.

Performance emerges from:

- Material behavior

- Manufacturing process

- Assembly conditions

Iteration allows engineers to:

- Reduce uncertainty

- Eliminate overdesign

- Improve consistency

- Lock down production parameters

Skipping iteration often results in:

- Late-stage failures

- Excessive weight margins

- Cosmetic instability

- Costly tooling revisions

OEM Insight: Testing Is Not Delay — It Is Risk Reduction

OEM teams often feel pressure to compress development timelines.

Testing is sometimes seen as a bottleneck.

In reality:

- Testing reduces warranty risk

- Testing stabilizes production

- Testing protects brand reputation

- Testing prevents large-scale recalls

A program that skips validation may appear faster—until it reaches mass production.

The fastest OEM programs are not the ones that skip testing, but the ones that test correctly, early, and systematically.

Final Thought: Validation Turns Carbon Fiber Into an Engineering Asset

Carbon fiber becomes a competitive advantage only when:

- Design assumptions are verified

- Manufacturing variables are controlled

- Iteration is embraced

For OEM brands, a structured validation and iteration loop is the difference between:

- A fragile prototype

and - A scalable, reliable carbon fiber product

Carbon fiber engineering does not end at CAD.

It begins there.

Q1: Why isn’t CAD analysis enough for carbon fiber design validation?

Because CAD and simulation cannot fully predict real-world factors such as fiber waviness, resin distribution, curing distortion, and assembly-induced stress. Physical validation is required to confirm actual performance.

Q2: What tests are typically used to validate carbon fiber designs?

Validation usually includes prototype builds, fitment verification, static load testing, fatigue testing, and surface quality evaluation to ensure structural and cosmetic consistency.

Q3: How many prototype iterations are usually required?

There is no fixed number. Most OEM programs require multiple iterations to fine-tune ply orientation, insert design, and process parameters before locking the production design.

Q4: Does testing slow down carbon fiber product development?

No. Proper testing reduces downstream risks such as production failures, warranty issues, and tooling rework. In most cases, testing shortens the overall project timeline.

Q5: What design changes most commonly result from validation testing?

Common refinements include adjusting fiber orientation, modifying insert geometry, optimizing bonding methods, and fine-tuning curing temperature or pressure profiles.

Q6: When is a carbon fiber design considered production-ready?

A design is production-ready only after it demonstrates consistent fitment, structural performance, cosmetic repeatability, and process stability across multiple builds.