- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Advanced Carbon Fiber UAV Engineering

Custom Carbon Fiber Drone Frames for OEMs

Built with TORAY 3K carbon fiber and aerospace-grade composites, our drones offer high strength-to-weight performance, extended endurance, and reliability in demanding industrial environments.

Carbon Fiber Materials & Manufacturing That Define Performance

From material selection to structural forming, every carbon fiber drone is engineered to achieve optimal weight reduction, structural rigidity, and long-term durability.

High-Grade Carbon Fiber Materials

Integrated Composite Forming

Multi-Process Capability

Not All Carbon Fiber Is Created Equal

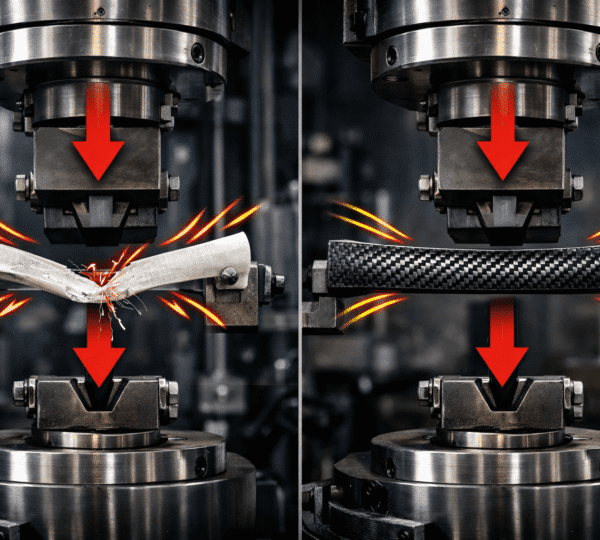

Wet Carbon vs. JCSPORTLINE Dry Carbon

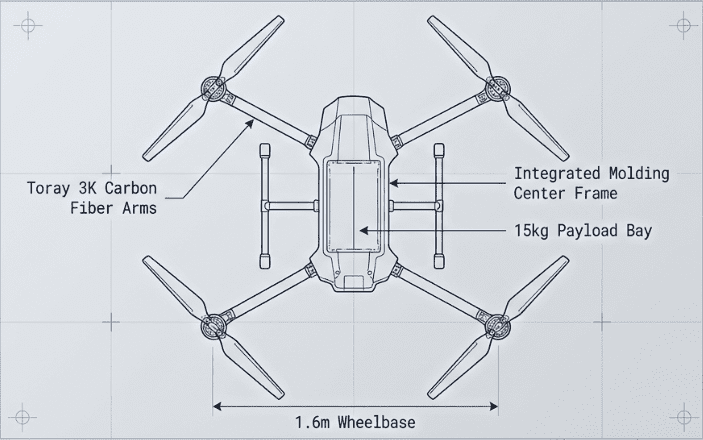

A Carbon Fiber Airframe Designed as the Drone’s Backbone

The carbon fiber structure forms the primary load-bearing skeleton of the drone, integrating the central frame, arms, battery compartment, payload bay, and gimbal mounts. This unified structure supports flight control systems, propulsion units, sensors, and mission equipment with maximum rigidity and minimal weight.

Raw Material

Toray T700/T800 carbon fiber filaments, woven in-house

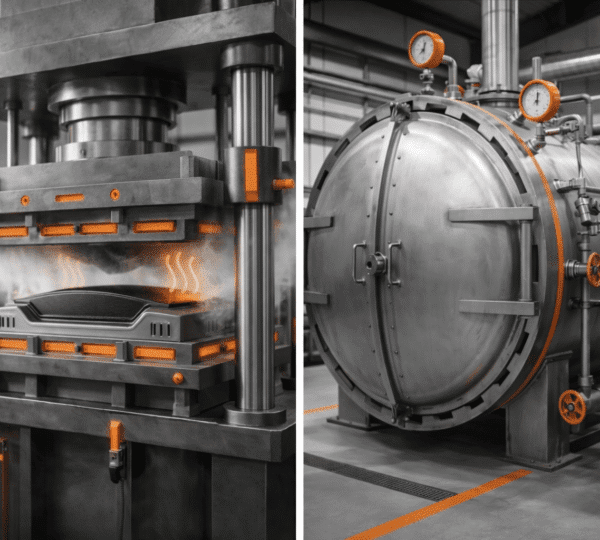

One-Piece Molding

Complex geometry formed in a single structure

Autoclave Curing

High-pressure consolidation for optimal strength

Built to Perform Where Standard Drones Cannot

Master the elements with a drone built for the extreme. From the icy depths of -20°C to level 8 gale-force winds, our carbon-fiber reinforced platforms deliver unwavering stability and all-weather readiness when the mission can't wait,designed for real-world industrial missions, not ideal conditions.

Lightweight Structure, Heavy-Duty Capability

Carbon fiber enables a rare balance between low mass and high load capacity—unlocking longer missions and higher operational efficiency.

Ultra-Light Airframe

High Payload Capacity

Extended Endurance

Frequently Asked Questions

Common Technical Questions About Carbon Fiber Drones Development and Manufacturing

Carbon fiber provides significantly higher strength at much lower weight, enabling heavier payloads, longer flight time, and longer service life compared to metal or plastic airframes.

Light payloads (≤5kg) suit compact multi-rotor platforms, heavy payloads (5–15kg) require reinforced multi-rotor designs, while long-range missions benefit from VTOL fixed-wing drones.

Yes. The platform supports -20°C to 45°C operation, light rain, and high wind conditions depending on configuration.

Low temperatures may reduce endurance by 10–20%. Preheating batteries before flight minimizes this impact.

VTOL drones use vertical lift only for takeoff and landing, switching to fixed-wing cruise for long endurance, higher speed, and extended control range.

Carbon fiber structures resist corrosion and fatigue. Routine maintenance typically involves inspection and surface cleaning, with lower long-term costs than metal airframes.

Make Carbon Fiber Your Signature

Lightweight. Durable. Distinctive.Elevate your product line with JCSPORTLINE.