Table of Contents

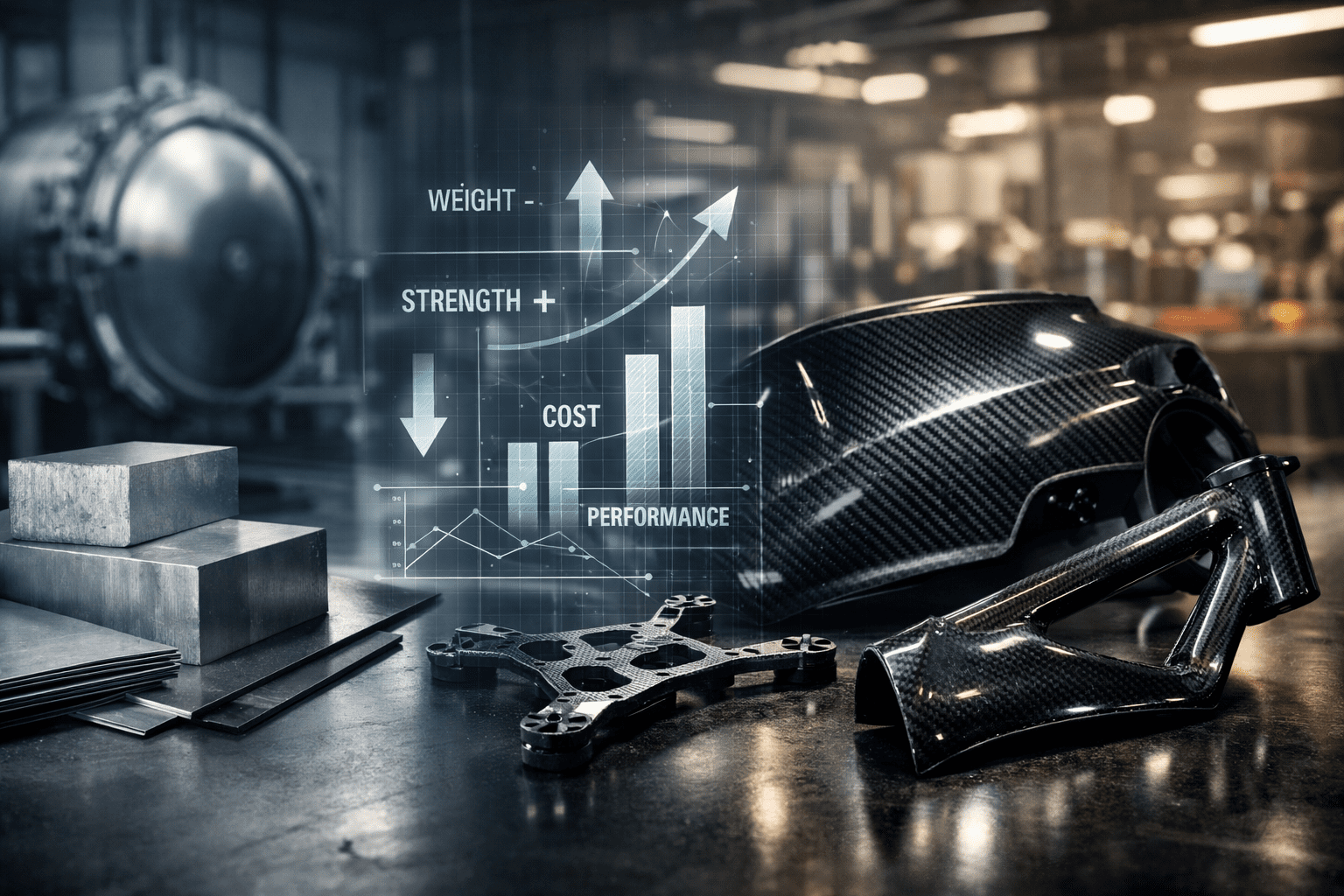

For OEM brands, carbon fiber is no longer just a premium material choice — it has become a core engineering decision that directly impacts product weight, strength, surface quality, development speed, and long-term scalability.

However, many OEM projects fail or stall not because of carbon fiber itself, but because the collaboration process with the carbon fiber engineering partner is poorly structured.

This article explains, step by step, how successful OEM brands work with a professional carbon fiber engineering partner, from concept to mass production — and what you should expect at each stage to reduce risk, control cost, and accelerate launch.

1. Defining the Engineering Objective (Not Just “Make It Carbon Fiber”)

The biggest mistake OEM brands make is starting with a material request instead of an engineering goal.

A professional carbon fiber partner will first help you clarify the real objective, such as:

- Weight reduction target vs. OEM baseline

- Structural load paths and stress zones

- Surface quality expectations (Class-A vs functional finish)

- Integration with metal inserts, electronics, or moving parts

- Regulatory, durability, or environmental constraints

At this stage, your partner should challenge assumptions, not simply accept drawings. Carbon fiber is anisotropic — strength depends on fiber orientation, layup logic, and tooling constraints.

Outcome of this phase:

- Clear performance targets

- Initial feasibility confirmation

- Material and process direction (prepreg, infusion, hybrid, etc.)

2. Data Acquisition & Geometry Validation

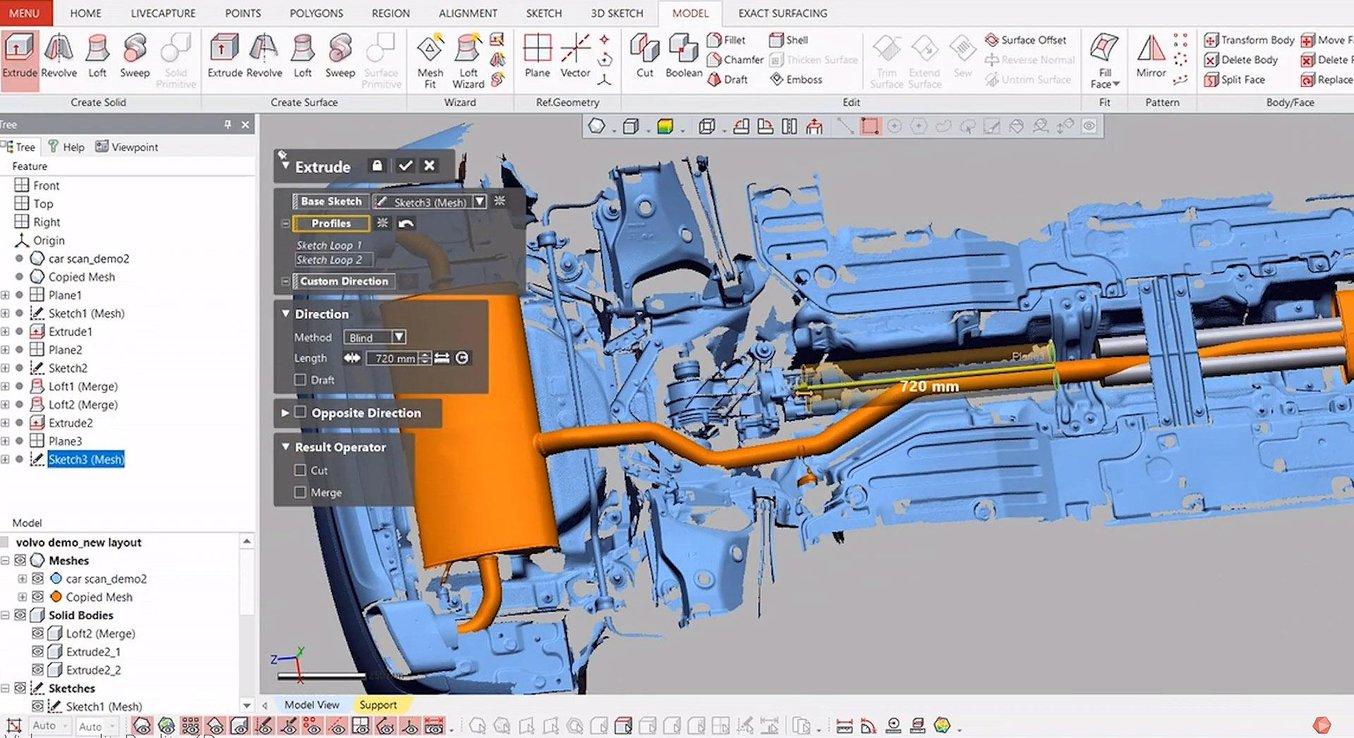

When OEM brands do not have finalized CAD data — or when accuracy is critical — physical data acquisition becomes essential.

A qualified carbon fiber engineering partner typically supports:

- High-precision 3D scanning of OEM parts

- Reverse engineering of complex surfaces

- Tolerance and interface validation

- Assembly clearance analysis

This step is especially important for:

- Body panels

- Interior structural components

- Parts requiring direct bolt-on installation

Why this matters:

Carbon fiber parts do not “flex into place” like plastics. Poor geometry data leads to fitment issues that cannot be corrected late in production.

Outcome of this phase:

- Verified digital geometry

- Fitment-ready CAD baseline

- Reduced downstream tooling risk

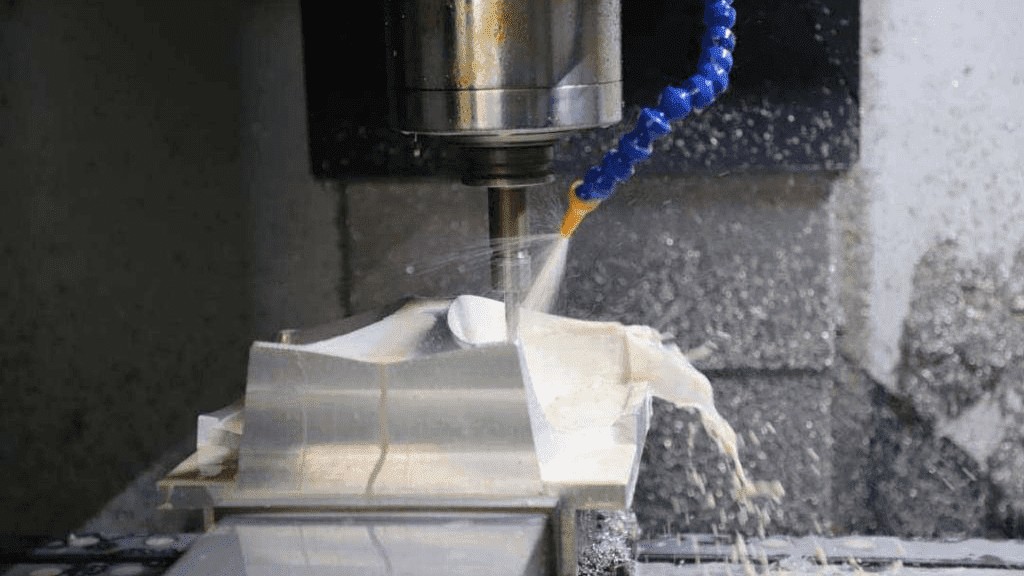

3. Engineering Design & DFM Optimization

This is where a carbon fiber engineering partner creates real value.

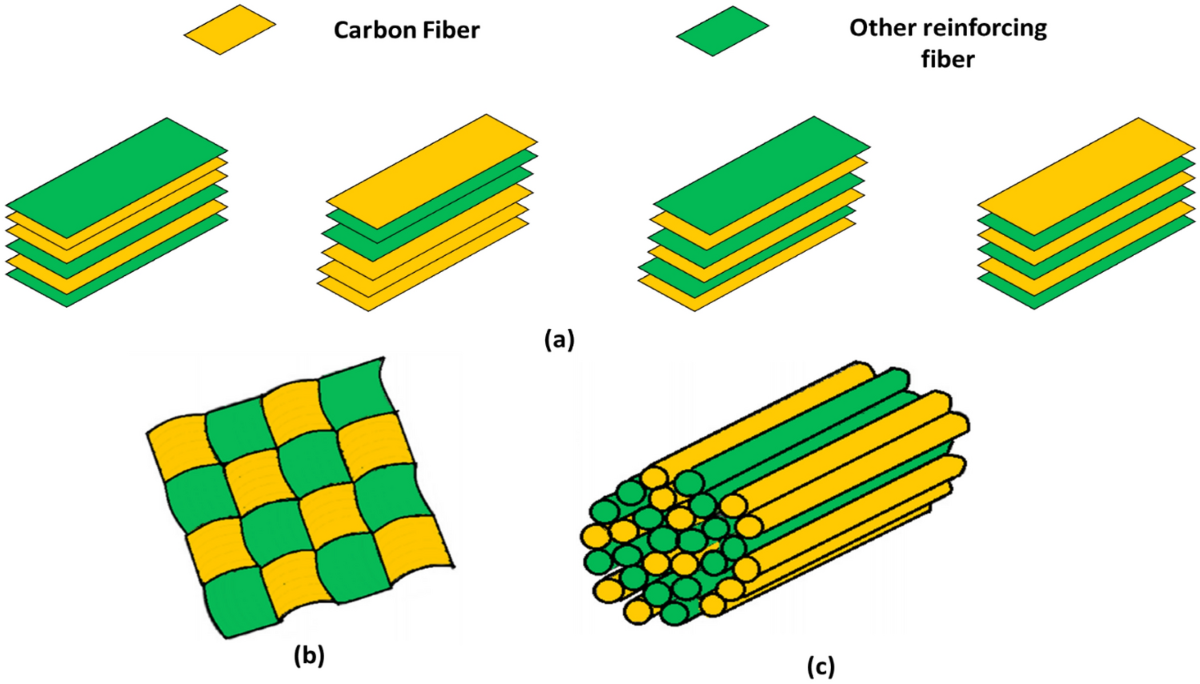

Instead of simply copying the OEM shape, engineers will:

- Redesign internal structures for stiffness and weight balance

- Optimize fiber orientation (0° / ±45° / 90°)

- Define insert locations and bonding strategies

- Adjust geometry for mold release and repeatability

- Balance aesthetics with manufacturability

A strong partner will apply DFM (Design for Manufacturing) principles early, ensuring that:

- The part can be produced consistently

- Scrap rate is controlled

- Tooling cost remains reasonable

- Surface quality is repeatable at volume

Outcome of this phase:

- Production-ready CAD

- Confirmed process route

- Predictable cost structure

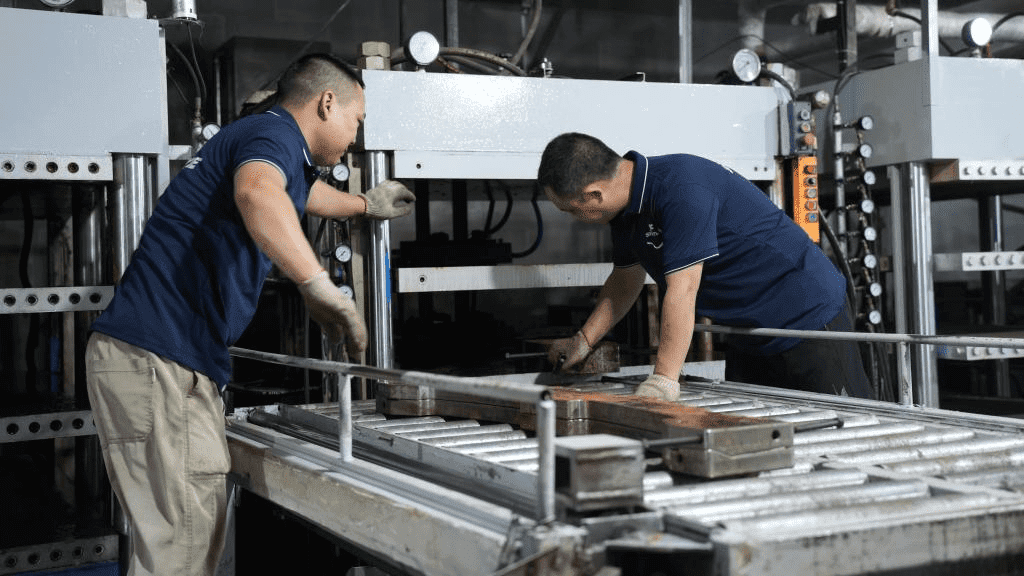

4. Tooling & Mold Development

Tooling quality determines 70% of final part quality.

OEM brands should expect transparency on:

- Mold material selection (aluminum, steel, composite tools)

- Surface treatment and thermal stability

- Mold life expectancy

- Dimensional tolerance control

🔘 Get Your Personalized Quote Now

🔘 Get Your Aerodynamic Upgrade Plan

For carbon fiber projects, tooling is not a one-size-fits-all decision. The right partner will align tooling strategy with:

- Expected production volume

- Surface finish requirement

- Part complexity

- Cost and lead-time constraints

Outcome of this phase:

- Stable production molds

- Controlled tolerances

- Clear scalability path

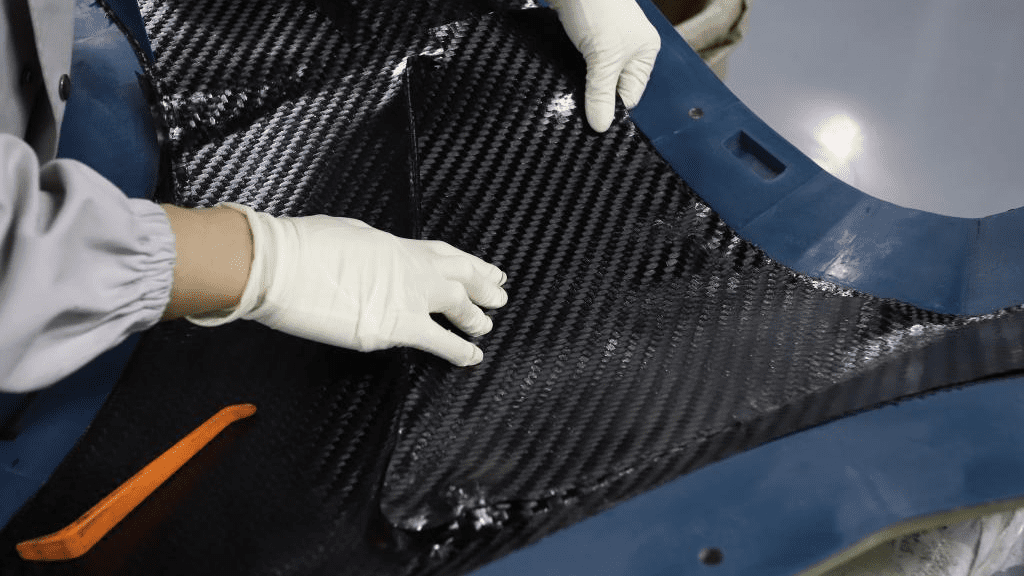

5. Prototype Validation & Iteration

Prototyping is not just about “seeing the part” — it is about engineering validation.

OEM brands should work with partners who validate:

- Dimensional accuracy

- Assembly fitment

- Structural behavior under load

- Surface finish consistency

- Weight reduction versus target

Feedback from this phase often drives small but critical adjustments that dramatically improve long-term production stability.

Outcome of this phase:

- Engineering-validated prototype

- Locked design baseline

- Reduced production risk

6. Process Definition & Quality Control Planning

Before mass production, the carbon fiber engineering partner must define:

- Layup standards

- Cure cycles and process parameters

- Inspection points and acceptance criteria

- Cosmetic grading standards

- Traceability and documentation

For OEM brands, this is where consistency is protected, especially when scaling beyond small batches.

Outcome of this phase:

- Stable, repeatable process

- Defined quality benchmarks

- Audit-ready production system

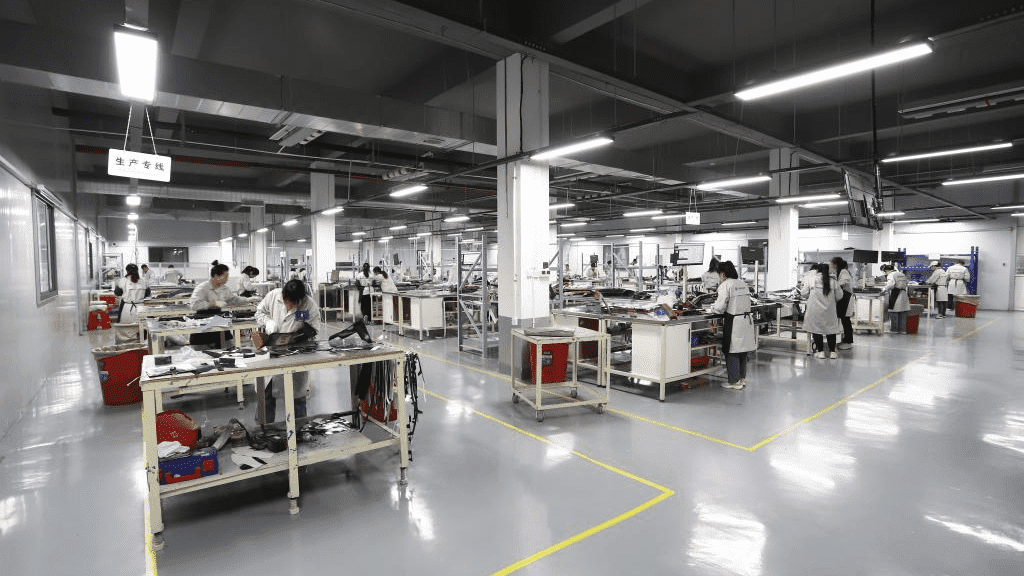

7. Mass Production & Scalable Delivery

A true carbon fiber engineering partner does not disappear after prototyping.

OEM brands should expect support in:

- Capacity planning

- Batch scaling

- Lead-time management

- Continuous improvement

- Engineering change control

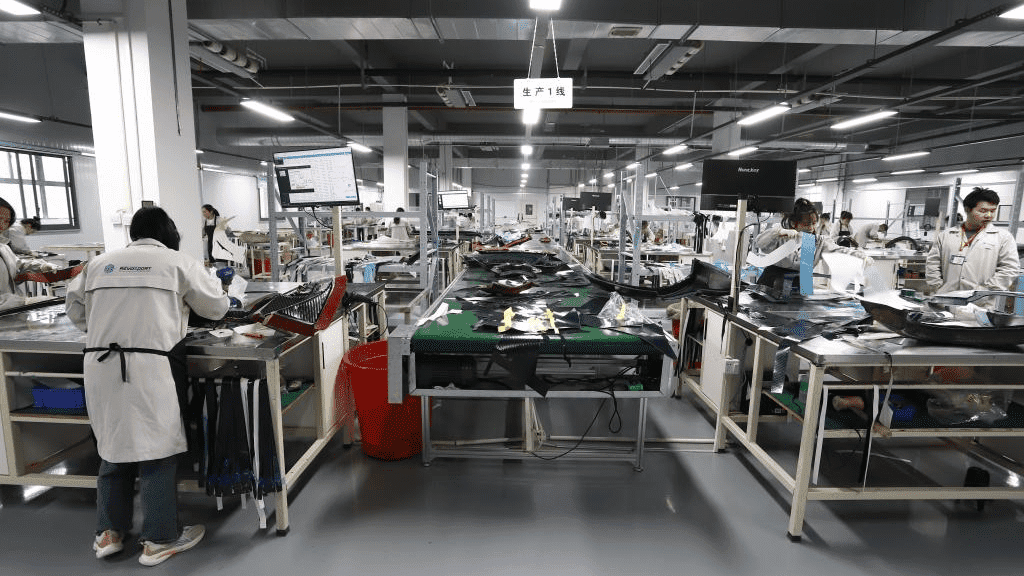

This is where factory scale, process discipline, and delivery reliability become decisive.

Outcome of this phase:

- On-time delivery

- Stable quality at volume

- Long-term partnership foundation

Why OEM Brands Choose an Engineering-Driven Partner Like JCSPORTLINE

OEM brands working with JCSPORTLINE benefit from:

- Engineering-first collaboration, not catalog selling

- Integrated design, tooling, and production under one roof

- Clear development milestones and cost transparency

- Flexible MOQs aligned with OEM project realities

- Proven ability to scale from prototype to mass production

Our role is not just to manufacture carbon fiber parts — it is to make your product manufacturable, scalable, and reliable.

FAQ: Working with a Carbon Fiber Engineering Partner

Q1: When should an OEM involve a carbon fiber partner?

As early as possible. Early involvement reduces redesign, tooling waste, and delays.

Q2: Do OEM brands need final CAD before starting?

Not necessarily. Samples, sketches, or partial data can be sufficient to begin feasibility and engineering planning.

Q3: What is the typical MOQ for carbon fiber OEM projects?

MOQ depends on tooling and process, but engineering-driven partners typically support small-to-mid batch programs.

Q4: How long does a full development cycle take?

With a structured process, concept-to-prototype cycles can be completed within weeks, not months.

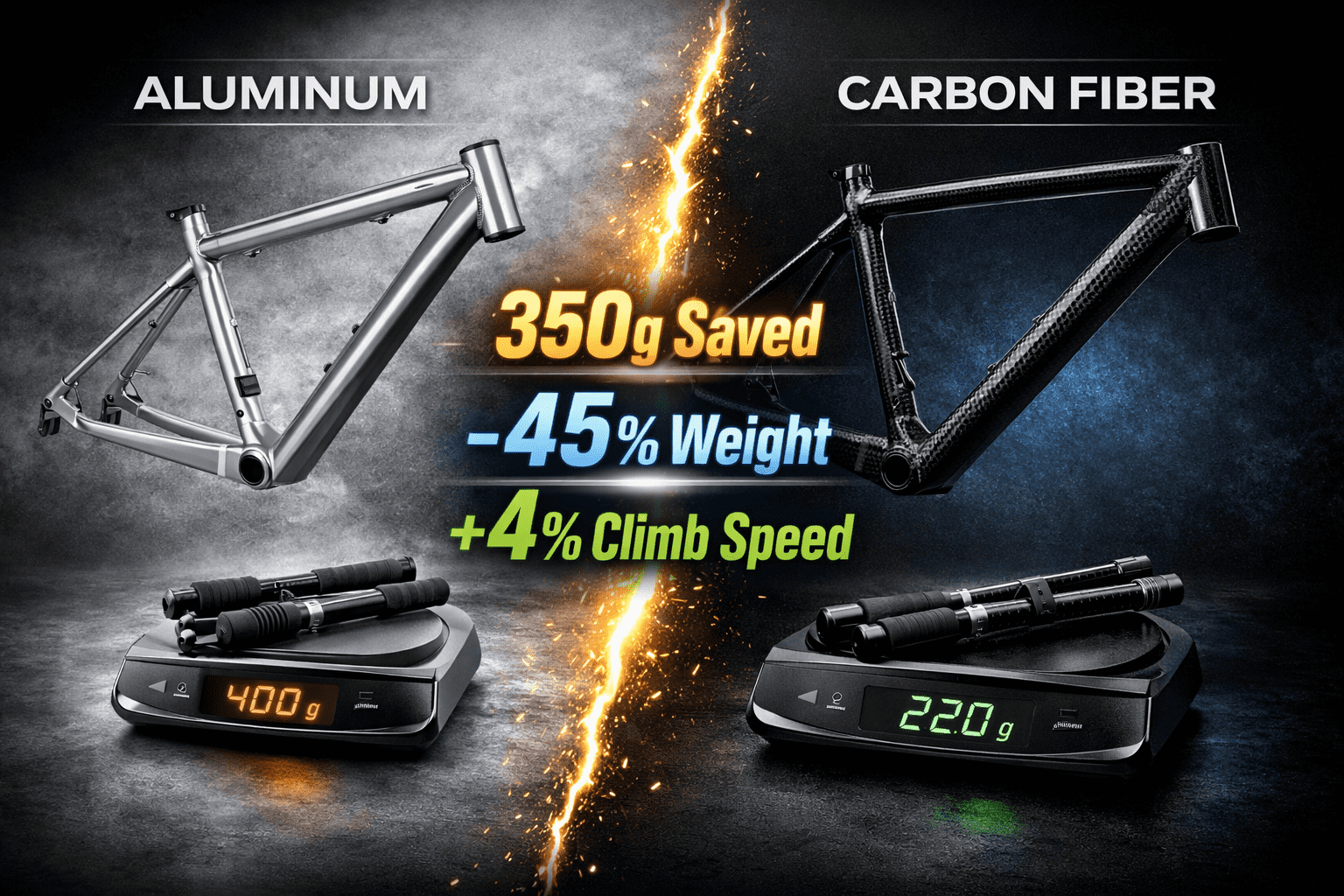

Q5: Can carbon fiber parts be lighter than OEM metal or plastic parts?

Yes — when structure and layup are engineered correctly, not simply copied.

Looking for an Engineering-Driven Carbon Fiber Partner?

If your OEM project requires precision, lightweight performance, and scalable production, working with the right carbon fiber engineering partner makes all the difference.

Talk to JCSPORTLINE’s engineering team and start your project with clarity, not trial and error.