Table of Contents

Strengthening Execution for Long-Term Partnerships

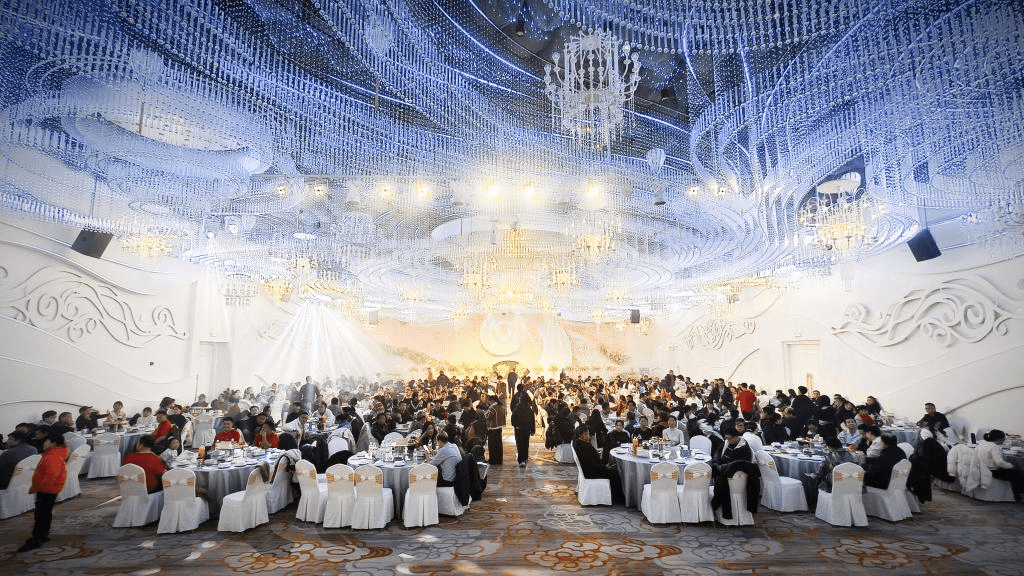

For JCSPORTLINE, the 2025 Factory Annual Meeting was not simply a year-end gathering.

It was a structured review of what truly mattered over the past year:

execution quality, system stability, and the ability to deliver complex carbon fiber projects with consistency.

Reviewing 2025 from the Factory Floor

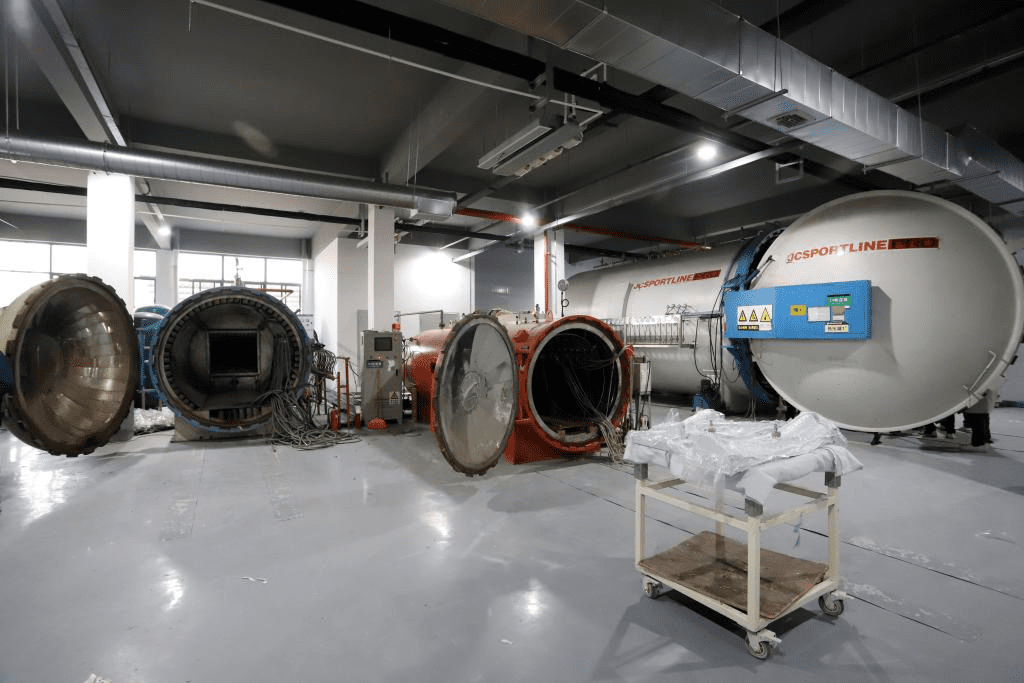

From an operational perspective, 2025 was a year of refinement rather than expansion.

Instead of focusing on volume alone, the factory concentrated on improving the fundamentals that directly impact OEM and B2B projects:

- Carbon fiber layup consistency and structural standards

- CNC machining accuracy and mold repeatability

- Clearer project milestones and internal traceability

- Improved first-pass quality rates

- Stronger coordination between engineering, production, and delivery teams

These improvements are not visible on the surface, but they determine whether a carbon fiber component can be installed reliably, reproduced at scale, and delivered on schedule.

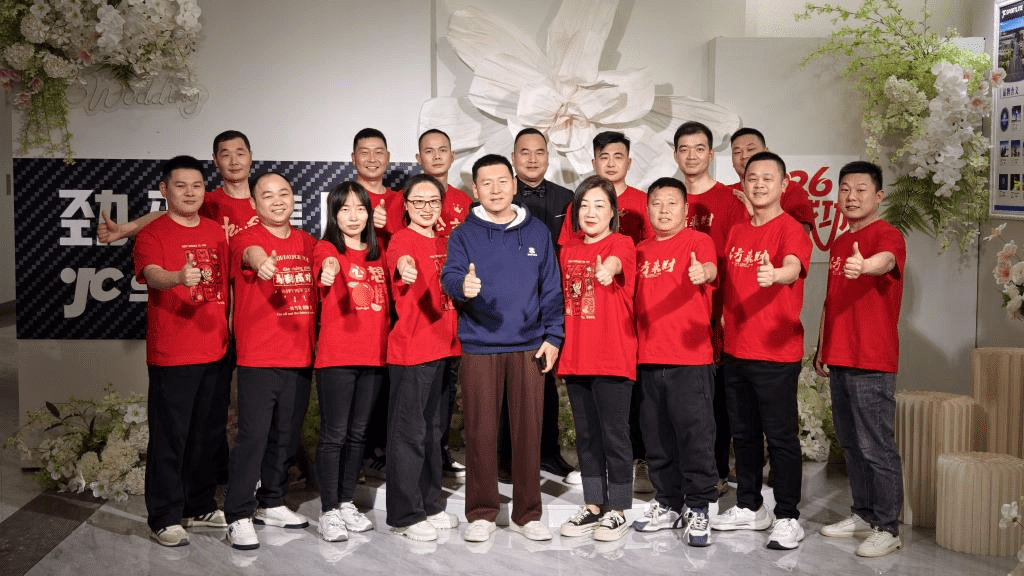

A Manufacturing Team Built as a System

One of the key purposes of the annual meeting was internal alignment.

Production, CNC, mold-making, composite layup, quality control, packaging, logistics, engineering, and management teams reviewed the year together — not as separate departments, but as one connected system.

For manufacturing partners, this matters.

A carbon fiber project does not succeed because of a single department.

It succeeds when decisions made in engineering remain valid on the production floor, and when quality standards are upheld even under delivery pressure.

What This Means for OEM and B2B Clients

For partners evaluating carbon fiber suppliers, the outcomes of 2025 send a clear signal:

- Projects are not dependent on individual expertise alone

- Quality is managed through repeatable processes, not ad-hoc inspection

- Engineering decisions are aligned with real manufacturing constraints

- Delivery schedules are based on proven workflows, not assumptions

When project complexity increases, system stability becomes more important than speed alone.

This is the foundation required for long-term OEM and B2B collaboration.

Recognition of Execution, Not Just Results

During the annual meeting, recognition focused on roles that sustain long-term manufacturing reliability:

- Production teams maintaining consistency under high load

- Technical staff supporting complex or high-risk projects

- Quality teams protecting standards at critical checkpoints

- Operations teams preventing delays through process discipline

In manufacturing, sustainable performance is built by teams who consistently do the right work — often without visibility.

Looking Ahead to 2026

The direction moving into 2026 is clear and unchanged:

- Higher structural and quality consistency across product lines

- More mature cross-industry carbon fiber solutions

- Clearer project timelines and feasibility alignment

- Processes designed for long-term international cooperation

Rather than redefining goals each year, the focus remains on strengthening execution step by step.

A Long-Term Manufacturing Mindset

The 2025 Factory Annual Meeting reinforced a simple principle:

Reliable manufacturing is built through systems, people, and discipline — repeated every day.

This mindset is what allows JCSPORTLINE to support OEM and B2B partners who value stability, predictability, and long-term collaboration.