- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Carbon Fiber Furniture OEM

Luxury Lifestyle & Home Series

Elevate your living space with furniture engineered for the future,We bridge the gap between innovative design and manufacturable reality, creating high-performance composite pieces that are lighter, stronger, and visually striking.

A New Engineering Foundation for Modern Interiors

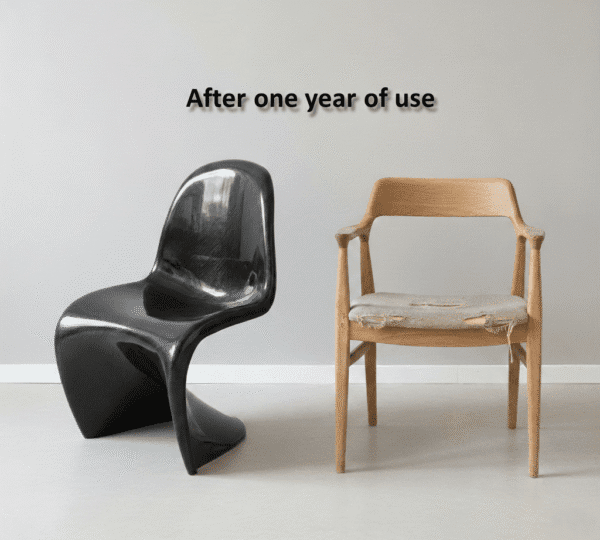

Carbon fiber is no longer just for racing—it is a revolutionary material that redefines durability and luxury in home design

Ultra-Lightweight Portability

Exceptional Strength-to-Weight Ratio

Corrosion & Fatigue Resistance

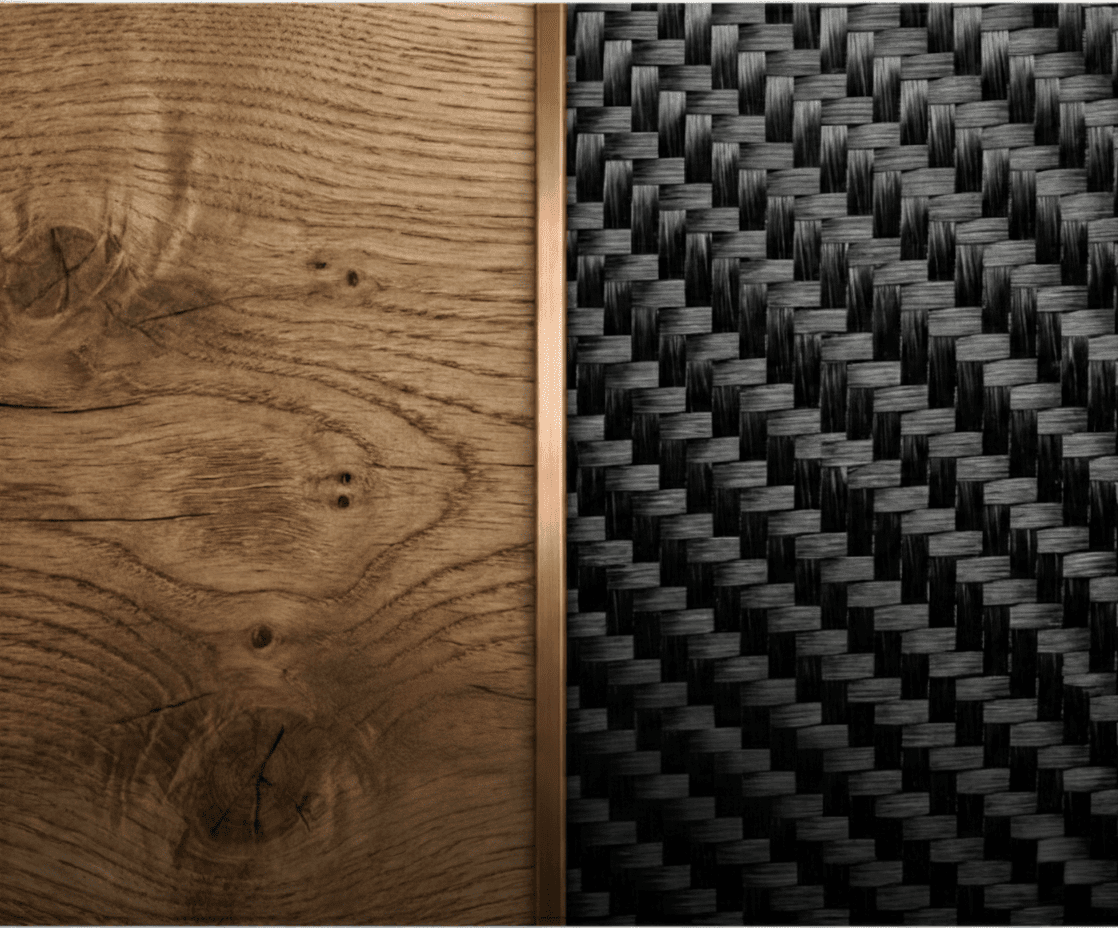

Not All Carbon Fiber Is Created Equal

Wet Carbon vs. JCSPORTLINE Dry Carbon

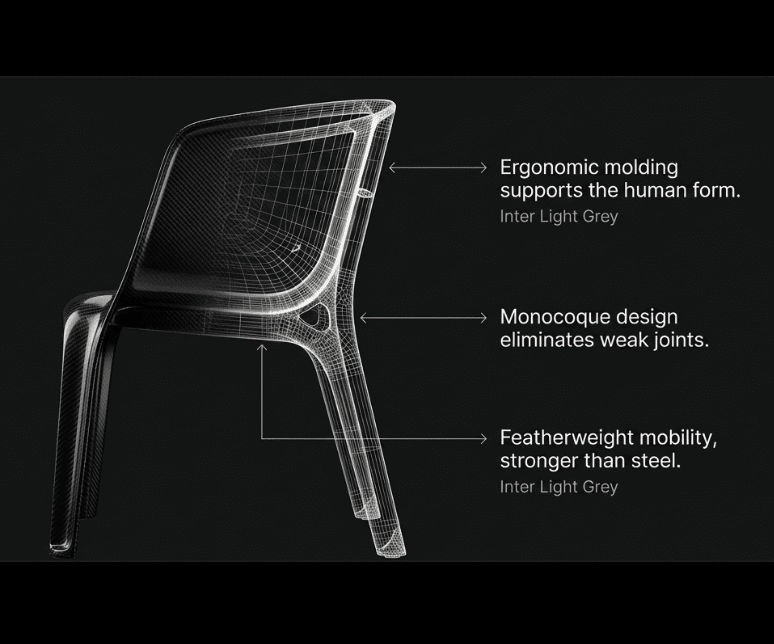

Engineering-Driven Excellence

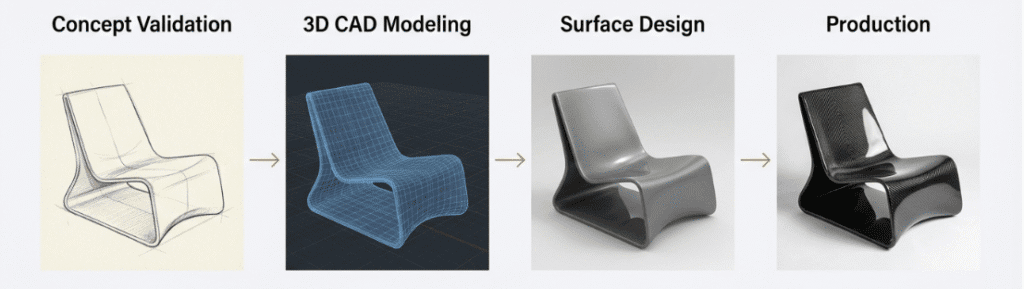

Every furniture design is evaluated by our engineers to optimize load paths and manufacturability

Precision CAD Modeling:High-accuracy 3D design structured specifically for carbon fiber layup logic

Material Validation:Rigorous testing including tensile, thermal, and impact performance to guarantee safety and durability

In-House Weaving:Complete control over fiber quality and custom patterns through our dedicated weaving factory

From Concept to Carbon Reality

We partner with designers to turn bold interior concepts into production-ready reality using our 58-day development framework.

Traditional furniture relies on wood andsteel. We are redefining interiors usingaerospace-grade composites. Carbonfiber offers a strength-to-weight ratiothat allows for gravity-defying shapesand thin profiles previously impossiblein furniture design.

Beyond Traditional Materials Turningadvancedmaterial science intoeveryday luxury.

Engineering-Driven Carbon Fiber Furniture

We design and manufacture carbon fiber furniture for brands that require lightweight structure, high strength, and premium surface quality—supporting OEM and custom development from concept to production.

Warp Chair

Bar Stool

Washbasin

Frequently Asked Questions

Common Technical Questions About Carbon Fiber Furniture Development and Manufacturing

It offers a superior strength-to-weight ratio, extreme durability, and a unique modern aesthetic that traditional materials cannot match.

Yes, we support fully customized manufacturing based on your CAD data, 3D scans, or physical samples.

Our standard framework targets 58 days from initial concept to a finished sample.

We offer various surface finishes, including UV-resistant gloss or matte clear coats, validated through strict dimensional and aesthetic inspections.

Absolutely. We support flexible production volumes, ranging from 1 to 500 pieces for niche or bespoke projects.

We use genuine Toray carbon fiber and provide material certifications and test documentation to verify quality.

Benefits: Seamless button integration Smooth internal wall clearance Zero-gap construction Exterior form and internal architecture perfectly aligned

Perfect Fit Through 3D Data Acquisition Structural Integrity, Designed for Comfort