Table of Contents

1. Project Background & Market Pain Points

The gaming and creative-product market has reached the limits of what standard plastics and metals can deliver. Users increasingly feel the drawbacks of conventional materials—poor rebound consistency, aesthetic fatigue, and long-term structural instability.

The problems with traditional mouse shells

Most mass-market mice suffer from several recurring issues:

- Inconsistent click rebound caused by uneven stiffness between left and right buttons.

- Dimensional deformation from thin plastic walls or metal fatigue.

- Mismatched tolerance that leads to dead zones or key travel deviation.

- Aesthetic sameness—plastics and metals no longer feel premium or unique.

These issues become more obvious in e-sports environments, where precision and tactile responsiveness determine performance.

Why the client turned to JCSPORTLINE

- Full in-house carbon fiber engineering capability

From concept → 2D/3D design → mechanical analysis → layup development → prototype → mass production. - Strong quality management system

Certified under IATF16949 and ISO9001, with complete traceability from material intake to shipment. - Deep experience in structural composites

Years of experience engineering carbon fiber for automotive and sports equipment enabled the team to avoid common failure modes and optimize performance from day one.

The goal was clear: create a mouse shell that is stronger, lighter, more stable, and aesthetically more premium than any plastic or metal alternative.

2. Engineering & Development Workflow

Transforming a carbon fiber concept into a production-ready mouse requires a multi-stage engineering process. The workflow follows the same principles used in automotive composite components: precise design, validated structure, robust molding, and repeatable mass production.

2.1 Ergonomic Design, Surface Modeling & 3D Validation

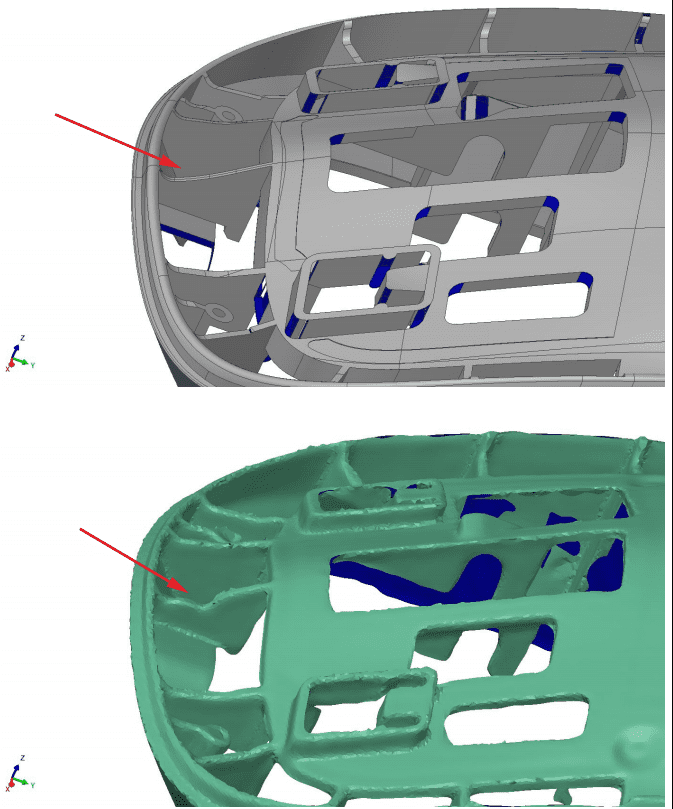

The project began with human-factor modeling—designing a curvature that supports long-term grip comfort and provides consistent click feedback.

- 3D scanning and reverse engineering ensured accurate reference data for mating parts.

- Ergonomic surface sculpting refined palm fit and fingertip angle.

- 3D printed prototypes were used to validate grip, button travel, and shell stiffness before moving into composite layup.

This early validation eliminated traditional problems such as uneven key pressure or misaligned internal structures.

2.2 Layup Design & Structural Optimization

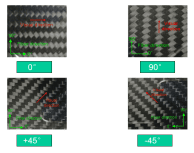

In composite engineering, strength is not defined by material thickness alone, but by fiber orientation, fabric selection, and resin system.

JCSPORTLINE developed a multi-layer prepreg layup using:

- High-strength carbon fiber fabric

- Epoxy resin system designed for thermal stability

- TG120°C+ prepreg to ensure durability

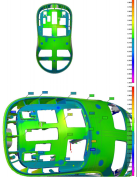

Each ply orientation was simulated and later validated through physical testing. This ensured the shell achieved:

- High rigidity to prevent flex under pressure

- Stable click rebound

- Weight reduction of up to 50% compared to metal or reinforced plastic

A critical advantage was the ability to engineer stiffness exactly where it influences click feel and durability.

2.3 Tooling, Autoclave Processing & 5-Axis CNC

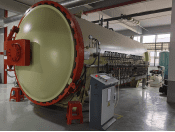

Tooling quality determines 70% of composite success:

- Molds were engineered for manual layup accessibility, stability, and anti-dummy design.

- Autoclave forming ensured uniform pressure, dense structure, and superior surface quality compared to standard compression molding.

- 5-axis CNC machining achieved ±0.02 mm accuracy, allowing perfectly matched left/right button gaps.

Fixtures and jigs were also developed to support:

- Precise trimming

- Repeatable assembly

- Dimensional consistency across batches

This guaranteed every unit maintained the same structural integrity as the original prototype.

2.4 Assembly, Bonding & Surface Finishing

Once trimmed, the shell entered assembly and finishing stages:

- Structural adhesive bonding (3M and equivalent brands) ensured high mechanical reliability.

- UV-resistant coating protected the surface from aging and yellowing.

- Manual polishing delivered ≤0.1 mm surface flatness and a premium gloss/matte finish.

- Aesthetic customization allowed twill, forged carbon, hybrid weave, Kevlar mix, and laser-engraved logos.

The final result achieved a balance of visual sophistication and functional performance—rare in consumer electronics housings.

3. Pain Point Solutions & Delivered Results

The project did more than replace plastic with carbon fiber—it systematically solved the engineering challenges that limit performance in conventional mice.

3.1 Improved Click Rebound & Structural Rigidity

The refined layup structure eliminated common issues such as:

- Button flex

- Asymmetric rebound

- Long-term deformation

The shell now provides consistent tactile feedback, even under intense gaming use.

3.2 Zero-Gap Curved Surface Fitment

Precision CNC machining and custom jigs ensured:

- Perfect alignment between upper and lower shells

- Symmetrical left/right button height

- Seamless appearance with zero edge mismatch

This directly elevated the perceived value of the product.

3.3 Premium Aesthetic with Material Differentiation

Compared to plastic, carbon fiber provided:

- Deep 3D woven visual texture

- Luxury automotive-grade finishing

- Multiple weave and coating options

The product visually stands out as a high-end device.

3.4 Verified Durability & Production Consistency

Quality testing (impact, temperature cycling from –40°C to 80°C) validated structural performance.

With intelligent prepreg cutting and standardized autoclave parameters, batch consistency reached 99.8%.

This level of reliability is critical for OEM clients seeking stable mass production.

4. FAQ: Common Questions About the Carbon Fiber Mouse Shell

Can the mouse shell support multiple carbon fiber textures?

Yes. Twill, forged carbon, hybrid fibers, and custom patterns are all available.

Can different materials be combined?

Yes. Carbon + Kevlar mix, special decorative weaves, and multi-texture combinations are supported.

Is the shell prone to cracking?

No. High-strength prepreg and premium structural adhesives provide superior impact resistance compared to plastic or metal.

How do you guarantee assembly precision?

5-axis CNC trimming, custom jigs, and 3D contour scanning ensure perfect alignment and consistent tolerances.

How do you prevent CNC edge chipping?

High-alloy tooling and ultra-high spindle speeds keep edges clean and smooth.

How do you maintain weave consistency?

AI-assisted cutting and smart nesting ensure every shell has aligned fiber patterns.

Conclusion

This carbon fiber gaming mouse project demonstrates how advanced composite engineering can reshape the expectations of modern electronic products. By combining autoclave molding, precision CNC machining, ergonomic design validation, and rigorous quality control, JCSPORTLINE delivered a mouse shell that is lighter, stronger, more precise, and visually superior.

For OEM/ODM brands looking to differentiate their products with premium materials and dependable engineering, carbon fiber offers a clear competitive advantage—and JCSPORTLINE provides the complete workflow to make it possible.