Table of Contents

Industrial equipment manufacturers are under increasing pressure to deliver machines that are lighter, more durable, easier to maintain, and adaptable to complex operating environments. From automated production lines to precision inspection instruments and outdoor industrial systems, traditional metal housings are becoming a limiting factor in performance, cost efficiency, and design flexibility.

This article explores how carbon fiber machinery equipment shells offer a practical, production-ready alternative to conventional metal enclosures. Based on JCSPORTLINE’s real development workflow and industrial manufacturing experience, we break down the market challenges, engineering solutions, manufacturing processes, and measurable value this next-generation enclosure brings to industrial equipment programs .

Why Traditional Metal Equipment Housings Are No Longer Enough

Weight, Corrosion, and Structural Limitations

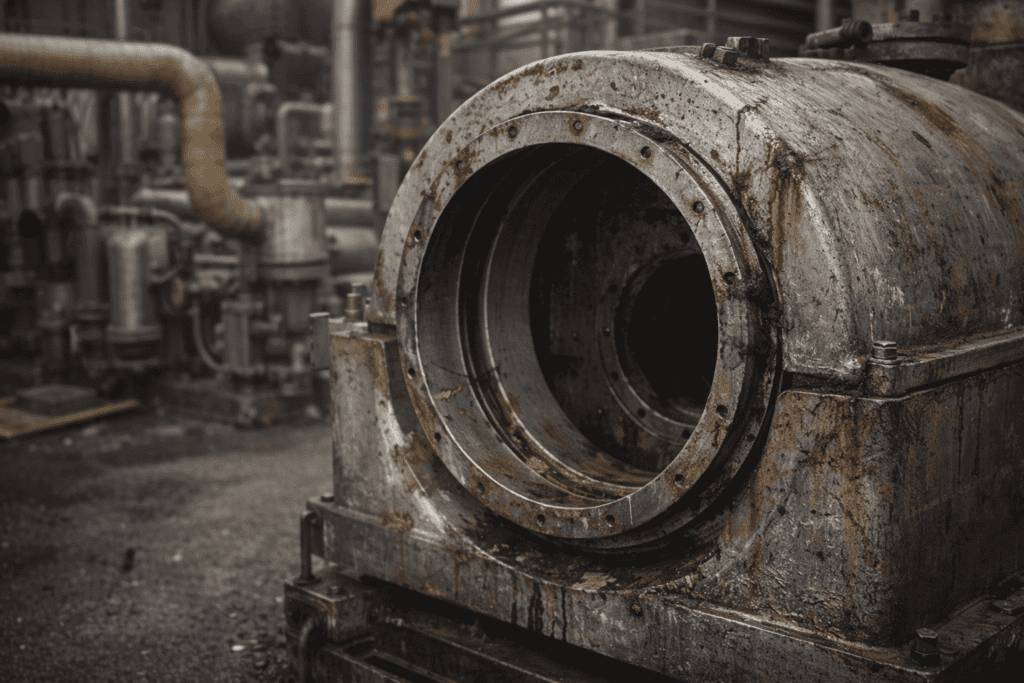

Metal housings—typically aluminum or steel—have long been the default choice for industrial equipment. However, as equipment becomes more modular, mobile, and performance-driven, these materials introduce several structural disadvantages.

First, excessive weight significantly increases transportation, installation, and handling costs. Heavy enclosures complicate on-site assembly and reduce flexibility when machines need to be relocated or reconfigured.

Second, corrosion resistance remains a persistent issue. In environments such as chemical workshops, outdoor installations, or high-humidity production floors, metal shells are prone to rust, surface degradation, and long-term deformation. Protective coatings can slow deterioration but add cost and maintenance requirements.

Third, impact resistance and surface durability are limited. Scratches, dents, and deformation not only affect appearance but can compromise internal component protection, especially in vibration-heavy or high-traffic industrial environments.

Poor Thermal Management and Maintenance Challenges

Another major limitation lies in heat dissipation efficiency. Many metal housings trap heat during long-term operation, leading to thermal buildup that shortens the service life of internal electronics and precision components.

Maintenance also becomes problematic. Metal surfaces easily attract oil, dust, and industrial residues, making cleaning time-consuming and increasing downtime. Sharp edges and rigid structures further introduce safety risks during servicing and installation.

Customization Constraints and Long Development Cycles

For OEMs managing multiple machine models, metal housings present a significant bottleneck. Each variation typically requires new tooling, long lead times, and high mold costs. Small-batch customization or rapid prototyping is often economically unfeasible, slowing down product iteration and market response.

These limitations explain why many equipment manufacturers are actively seeking alternative enclosure materials that balance strength, weight, durability, and customization flexibility.

Engineering a Carbon Fiber Machinery Equipment Shell

Material Architecture: Strength Without Excess Weight

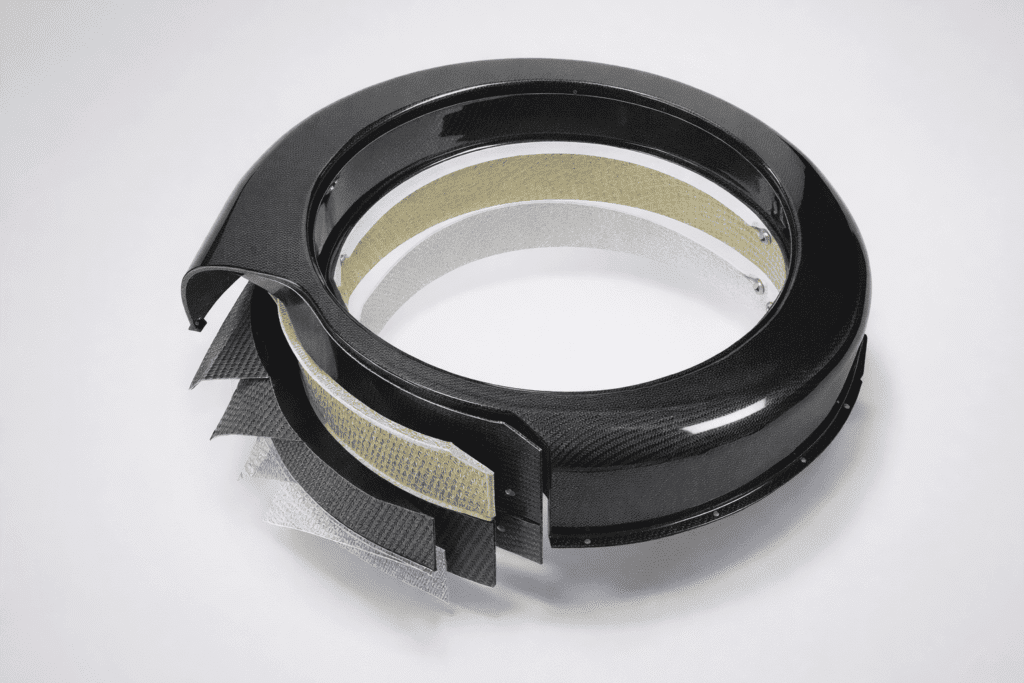

JCSPORTLINE’s carbon fiber machinery equipment shell is engineered using a hybrid composite structure, combining:

- 3K carbon fiber fabric

- Fiberglass reinforcement layers

- Industrial-grade unsaturated resin systems

This layered architecture allows engineers to precisely control stiffness, impact resistance, and load distribution. The result is a shell that weighs only 10.5 kg, delivering approximately 40% weight reduction compared to aluminum housings, while maintaining exceptional structural strength .

Carbon fiber’s high specific strength enables the enclosure to withstand compressive loads up to 50 times its own weight, making it suitable for both static installations and dynamic operating conditions.

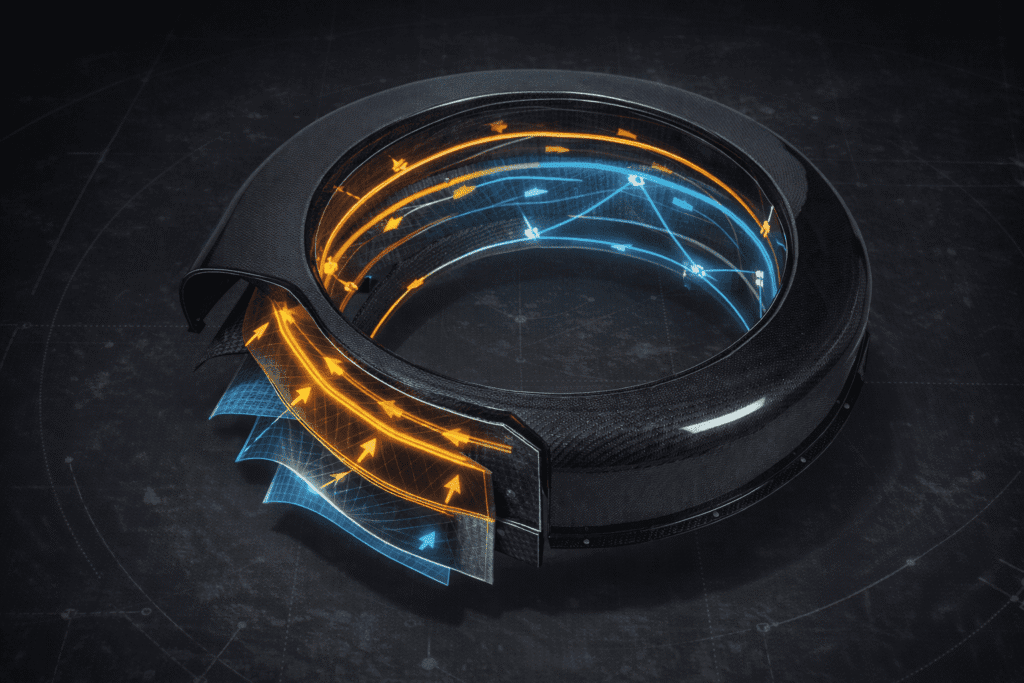

Structural Optimization Through Layup Design

Unlike isotropic metals, composite materials allow engineers to tailor strength exactly where it is needed. Through optimized ply orientation and thickness distribution, the shell achieves:

- High rigidity around mounting points

- Reinforced protection zones for sensitive components

- Weight reduction in non-critical areas

This structural optimization ensures that lightweight design does not compromise mechanical reliability or safety.

Integrated Functional Design

Beyond structural strength, the shell is designed to integrate multiple functional requirements directly into the enclosure:

- Rounded edges for improved safety and ergonomics

- Customizable mounting holes and interface cutouts

- Anti-static and corrosion-resistant surface properties

- Modular geometry adaptable to different machine platforms

This approach eliminates the need for secondary add-ons such as external shielding or protective brackets, simplifying system integration.

Manufacturing Process and Quality Control

Vacuum Infusion Molding for Industrial Consistency

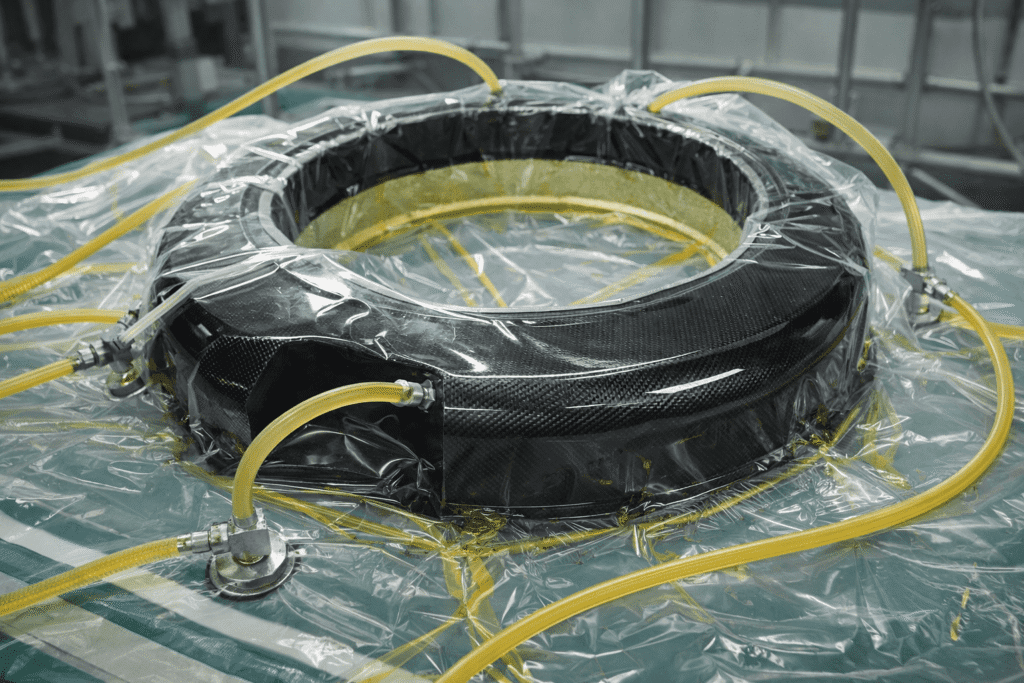

The shell is produced using vacuum infusion molding, a process well-suited for industrial composite components requiring uniform quality and scalable production.

During infusion, resin is evenly drawn through the fiber layers under controlled vacuum pressure, ensuring:

- Complete fiber wet-out

- Dense, void-free internal structure

- Consistent mechanical performance across batches

Compared to hand layup or basic compression methods, vacuum infusion delivers superior repeatability for OEM-level production.

Precision Finishing and Surface Treatment

After curing, each shell undergoes CNC trimming and surface refinement. A high-gloss or matte clear-coat finish is applied to enhance:

- Surface hardness and scratch resistance

- Visual consistency and industrial aesthetics

- Ease of cleaning and maintenance

The finished surface resists oil stains, dust adhesion, and chemical exposure, significantly reducing long-term maintenance effort.

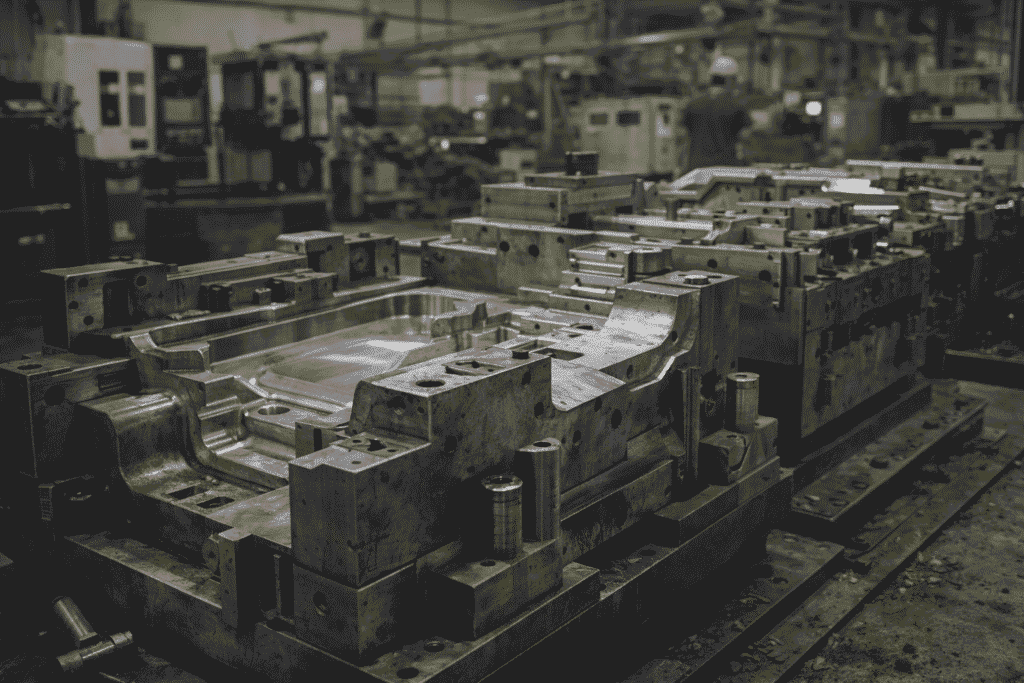

Equipment, Tooling, and Process Accuracy

JCSPORTLINE supports production with advanced manufacturing infrastructure, including:

- High-precision CNC machining centers with ±0.02 mm accuracy

- Intelligent automated fabric cutting systems for batch consistency

- Industrial inspection equipment for dimensional and performance verification

This tooling ecosystem ensures that both prototype and mass-production shells meet the same engineering standards.

End-to-End Quality Control System

All carbon fiber equipment housings are produced under a validated manufacturing framework, aligned with our Material Manufacturing & Validation standards.

Quality assurance is embedded throughout the entire workflow:

- Raw material inspection – fiber strength, resin purity

- Process monitoring – temperature, humidity, and infusion parameters

- Finished product testing – dimensional accuracy, compression strength, impact resistance, corrosion performance

With a 99.5% pass rate and full product traceability, the system supports long-term reliability and post-delivery quality tracking .

Solving Industrial Pain Points and Delivering Measurable Value

Addressing Core Industry Challenges

The housing is designed not only for performance, but also for scalable production—bridging the gap between prototype development and Prototype Mass Production.

The carbon fiber machinery equipment shell directly resolves five critical problems associated with metal enclosures:

- Excessive weight

- Corrosion and environmental degradation

- Poor heat dissipation

- Limited customization flexibility

- High tooling cost and long development cycles

By replacing metal with engineered composites, manufacturers gain a housing solution designed for modern industrial demands.

Quantifiable Performance Improvements

The benefits are not theoretical—they are measurable:

| Performance Area | Result |

|---|---|

| Weight | 10.5 kg (≈40% lighter than aluminum) |

| Durability | 5+ years service life in harsh environments |

| Heat Dissipation | ~40% improvement |

| Tooling Cost | ~30% reduction |

| Customization Lead Time | ~50% shorter |

These improvements translate directly into lower logistics costs, longer equipment lifespan, and faster product iteration.

Application Versatility Across Industrial Scenarios

Thanks to modular design and composite adaptability, the shell supports more than 10 industrial application scenarios, including:

- Automated production lines

- Precision testing and inspection equipment

- Outdoor industrial systems

- Chemical processing environments

A single shell platform can be adapted across multiple equipment models, maximizing ROI and simplifying inventory management.

Efficient Delivery and Production Planning

Leveraging AI-assisted production scheduling, JCSPORTLINE offers:

- Standard custom shell delivery in 10–15 days

- Expedited orders in as little as 7 days

- Small-batch prototyping with low mold investment

This agility allows OEMs to respond rapidly to market changes without sacrificing engineering quality.

FAQ: Carbon Fiber Machinery Equipment Shell

Can this carbon fiber shell be customized to fit my equipment dimensions?

Yes. The shell supports full dimensional customization based on your equipment geometry. JCSPORTLINE provides design drawings and develops small-batch tooling to minimize development cost while ensuring accurate fit.

What is the typical development and production timeline?

The process includes requirement confirmation, design and quotation, tooling development, prototyping, validation, and mass production. Prototyping typically takes 10–15 days, with timelines adjusted based on order volume and customization scope.

Are the materials environmentally compliant?

All materials comply with RoHS and REACH standards. The carbon fiber and resin systems use low-VOC formulations and meet international industrial environmental requirements.

What is the minimum order quantity for custom shells?

The initial tooling order requires a minimum of 30 units. After tooling is completed, repeat production does not require a minimum order quantity.

Can the appearance and branding be customized?

Yes. Customers may choose carbon fiber natural finishes (gloss or matte), solid color coatings, or custom corporate colors. Embedded or surface LOGO customization is also supported.

How is the shell protected during transportation?

Each shell is packed using multi-layer protective packaging, including non-woven fabric, bubble cushioning, reinforced cartons, and optional wooden frames for bulk shipments to ensure safe delivery.