- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Carbon Fiber Mouse OEM

Carbon Fiber Mouse Manufacturing Project

Ultra-Lightweight, Rigid Carbon Shell Engineered for Premium Input Devices

The Problem with Traditional Mice

The Market Forces a Trade-Off Between Weight and Durability

Metal shells

Honeycomb plastics

ABS plastic

Not All Carbon Fiber Is Created Equal

Wet Carbon vs. JCSPORTLINE Dry Carbon

One-Piece Monocoque Construction

Our mouse shell is built using the same principles as a race car unibody

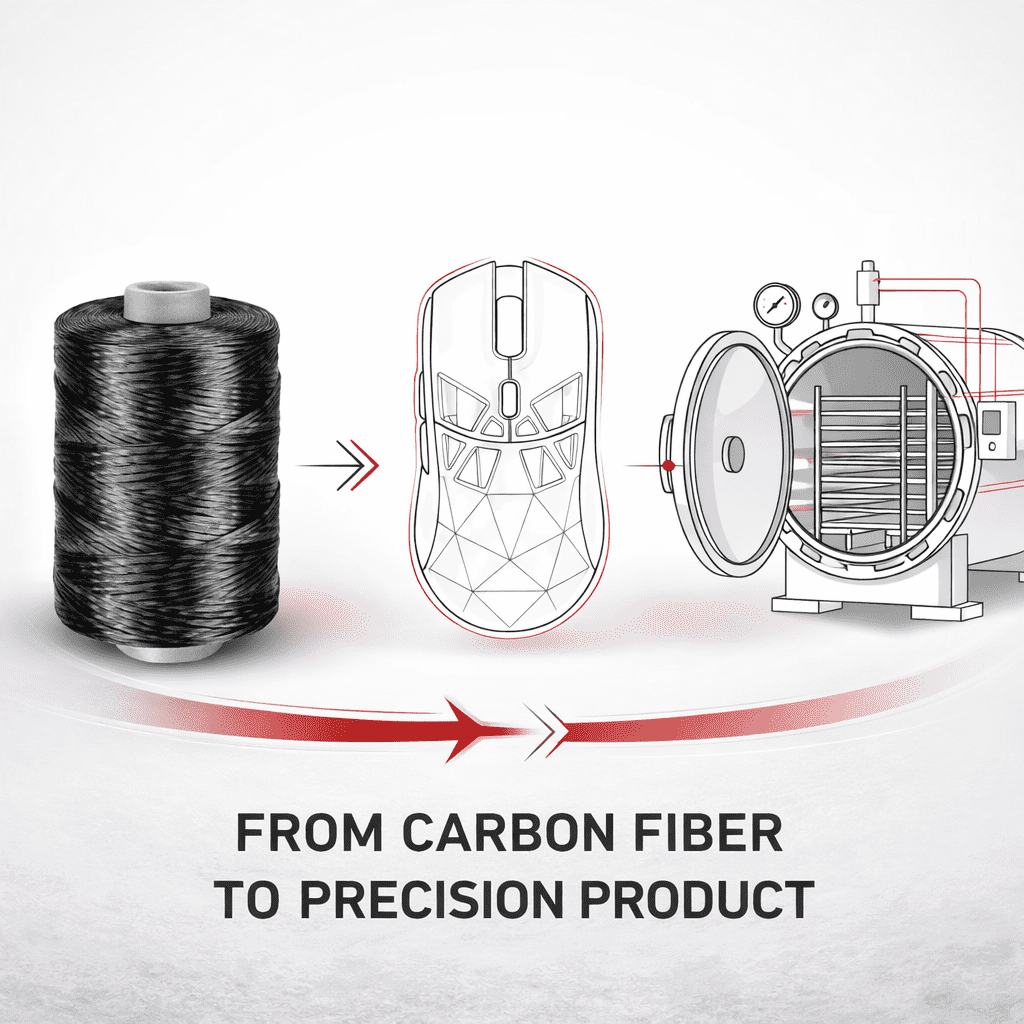

Raw Material

Toray T700/T800 carbon fiber filaments, woven in-house

One-Piece Molding

Complex geometry formed in a single structure

Autoclave Curing

High-pressure consolidation for optimal strength

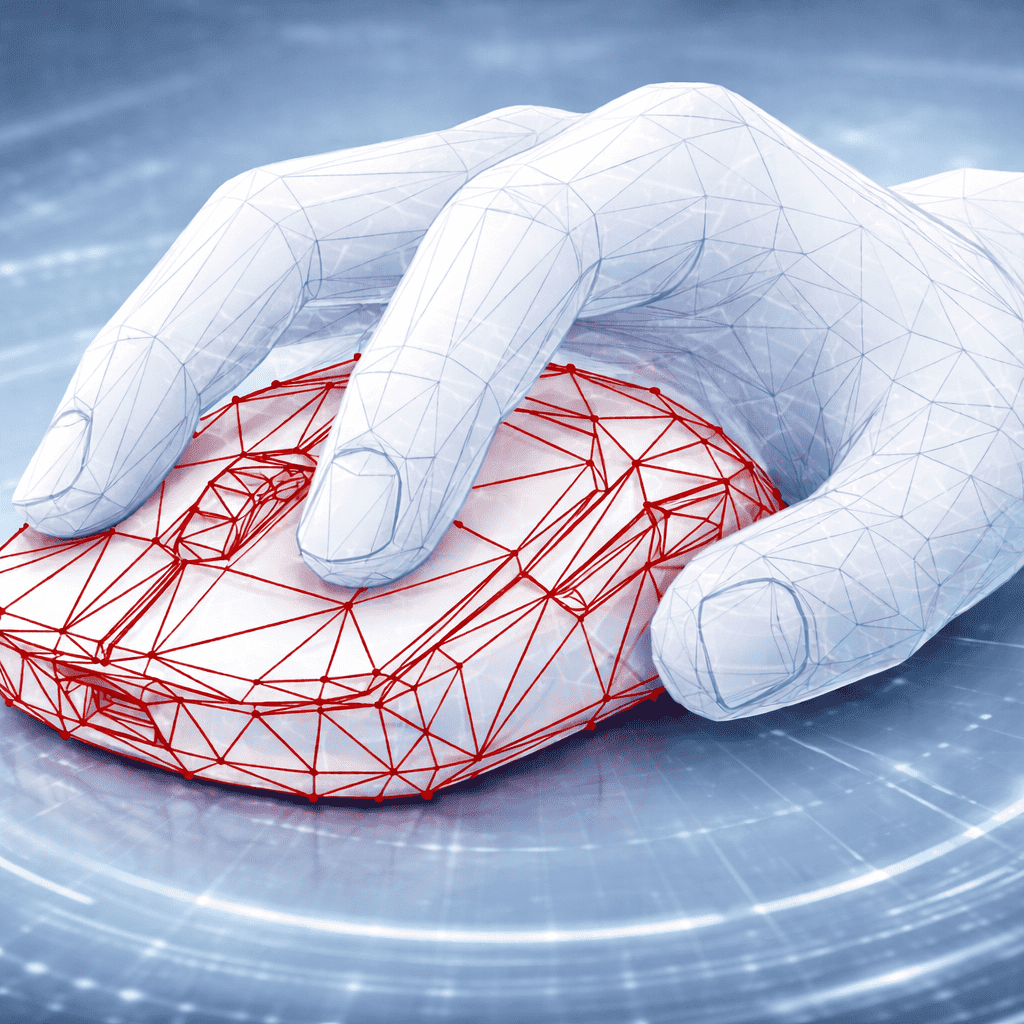

Engineered for Precision, Lightweight Performance, and Premium Touch

Through 3D-driven engineering, advanced lightweight carbon structures, and refined surface finishing, we deliver a mouse housing that fits perfectly, moves effortlessly, and feels exceptional over time.

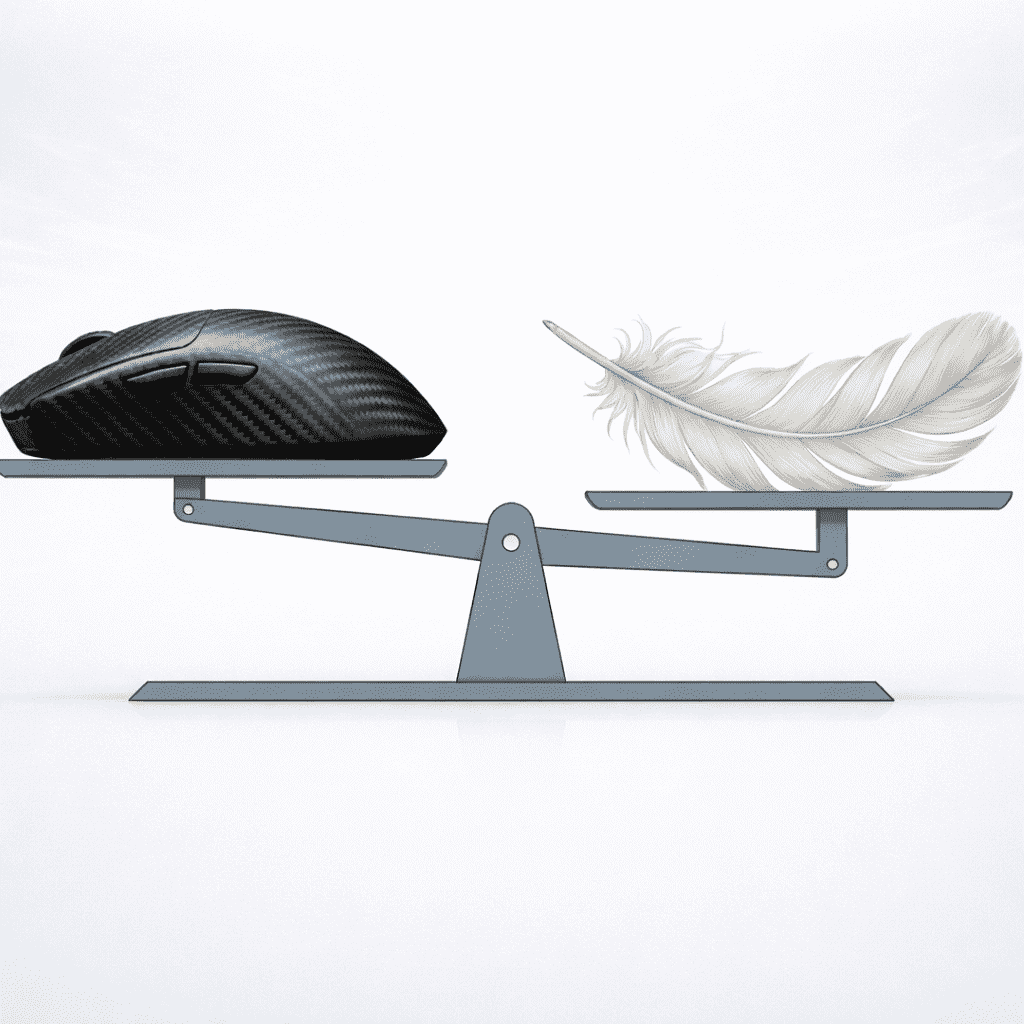

Unlike competitors who drill holes to save weight, we deliver: Fully enclosed solid carbon shell Lower inertia for faster, more precise movements Zero structural flex under pressure Superior balance between speed and control Lightweight doesn’t have to feel fragile.

Extreme Lightweighting Without Compromise 50% Weight Reduction — Without Structural Loss

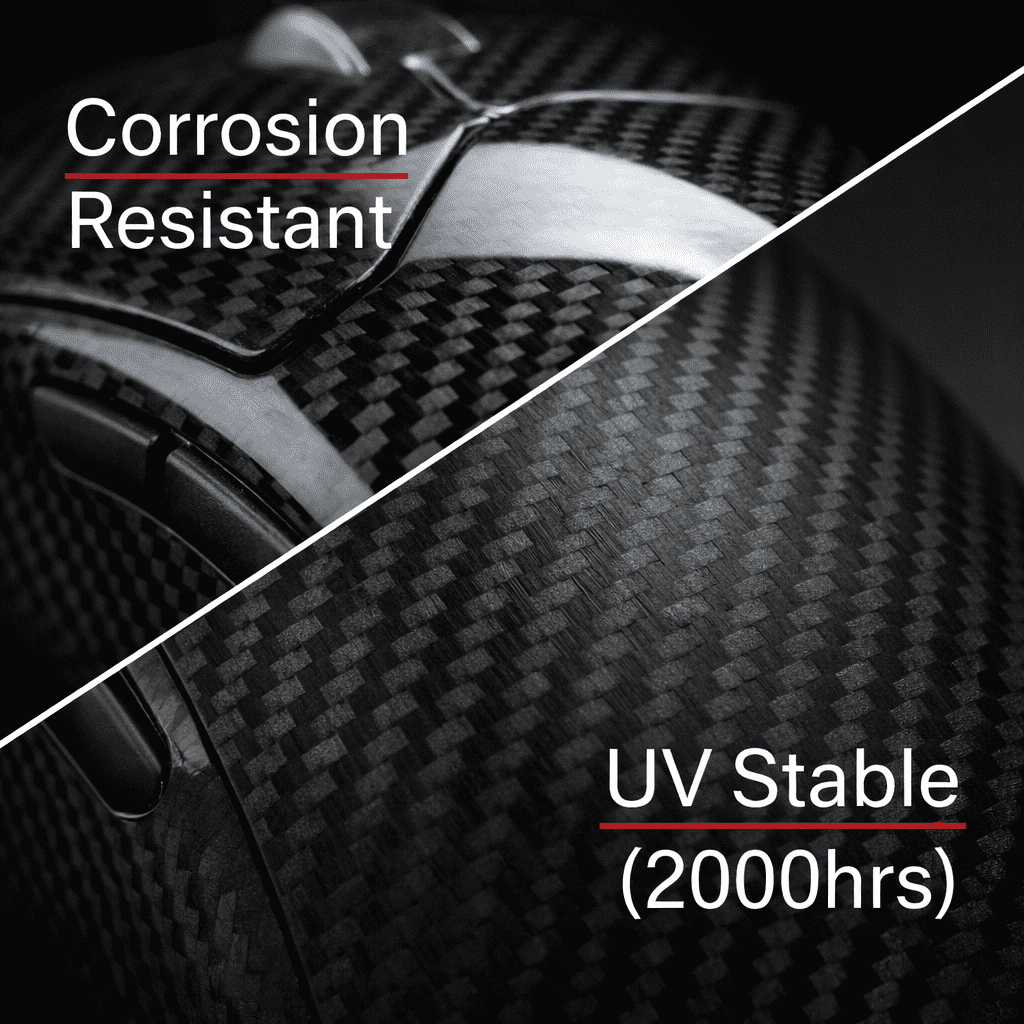

Cool-to-touch carbon texture with secure grip Resistant to sweat, oils, and corrosion UV-stable coating tested up to 2000 hours No yellowing, no surface degradation “A symbol of freedom and individuality.” — JCSPORTLINE Design Vision

An Unmatched Sensory Experience Premium Touch, Built to Last

Inconsistent Click Feel and Structural Weakness

From click feel to assembly precision and brand differentiation, we remove the most common failure points in mouse housing development.

Click Feel Fails Over Time

Gaps and Fitment Inconsistency

Designs Look the Same

Frequently Asked Questions

Common Technical Questions About Carbon Fiber Mouse Development and Manufacturing

We support multiple carbon fiber weave options, including standard carbon weave, forged carbon patterns, and special custom textures to match different design requirements.

We can create hybrid material designs, such as carbon fiber combined with aramid fiber or other composite patterns, allowing greater visual differentiation and brand identity.

We use high-strength carbon fiber materials combined with structural adhesives from globally recognized brands. The resulting structure offers higher strength and durability than conventional plastic or metal housings.

We use dedicated fixtures, five-axis CNC machining, and 100% inspection.

Both parts and tooling are verified through 3D surface scanning and comparison to master data, ensuring consistent alignment and gap control during assembly.

We apply high-alloy cutting tools, optimized tool paths, and high-speed CNC machining parameters.

This ensures clean edges, smooth curves, and eliminates chipping or fiber breakout.

We use intelligent fabric cutting systems and AI-assisted layout planning to maintain consistent fiber orientation and pattern alignment.

Anti-error markings on forming tools further ensure visual consistency across batches.

Make Carbon Fiber Your Signature

Lightweight. Durable. Distinctive.Elevate your product line with JCSPORTLINE.

Benefits: Seamless button integration Smooth internal wall clearance Zero-gap construction Exterior form and internal architecture perfectly aligned

Perfect Fit Through 3D Data Acquisition Automotive-Level Ergonomic Engineering Using the same technology applied in vehicle aerodynamics, we perform: 3D dimensional scanning Reverse engineering & data comparison Ergonomic surface optimization