Table of Contents

Intro — High-Performance Carbon Fiber, Now for Consumer Electronics

Carbon fiber is synonymous with supercars, aerospace, and elite performance engineering. Today, JCSPORTLINE is bringing this material—and its engineering logic—from the racetrack to the workspace.

👉 Learn more about our full carbon fiber engineering capabilities.

As a global composite manufacturer specializing in full-process OEM/ODM carbon fiber engineering, we apply aerospace-grade production methods to solve long-standing weaknesses in traditional mice and high-end peripherals.

Why Traditional Mice Fail: Structural Weaknesses of Plastic and Thin Metal Shells

Mass-market materials limit long-term performance. Standard mouse shells suffer from:

• Poor Click Rebound Consistency

ABS and thin aluminum lack structural rigidity, causing button wobble, fatigue, and “mushy” degradation over time.

• Aesthetic Fatigue Among High-End Users

Plastic cannot deliver premium surface depth, pattern consistency, or the tactile experience demanded by professionals and gamers.

• Dimensional Instability

Traditional shells deform, leading to inconsistent gaps, uneven curves, and poor internal fitment.

👉 Explore how carbon fiber is transforming consumer electronics engineering.

The JCSPORTLINE Engineering Difference

We do not simply replace plastic with carbon fiber—we rebuild the product at the engineering level.

1. Autoclave Aerospace Molding for Superior Structural Integrity

Most consumer products use basic PMC (compression molding).

JCSPORTLINE uses:

Autoclave Vacuum Forming

- Uniform pressure up to 6–8 bar

- Maximum fiber-resin consolidation

- No voids, no wrinkles

- Deep 3D weave clarity

- Superior rigidity and heat stability (TG > 120°C)

👉 See our full autoclave composite manufacturing process.

This is the same technology used in racing components, drone arms, aircraft interiors, and medical robotics.

2. Micron-Level Precision Using Imported 5-Axis CNC

To achieve perfect assembly with internal ABS parts, we apply:

- ±0.02mm tolerance

- Perfect continuity in curved surfaces

- Zero-gap top/bottom shell integration

- Smoother mating between internal pillars and switch housings

This solves the #1 issue of “inconsistent gap lines” common in mass-market shells.

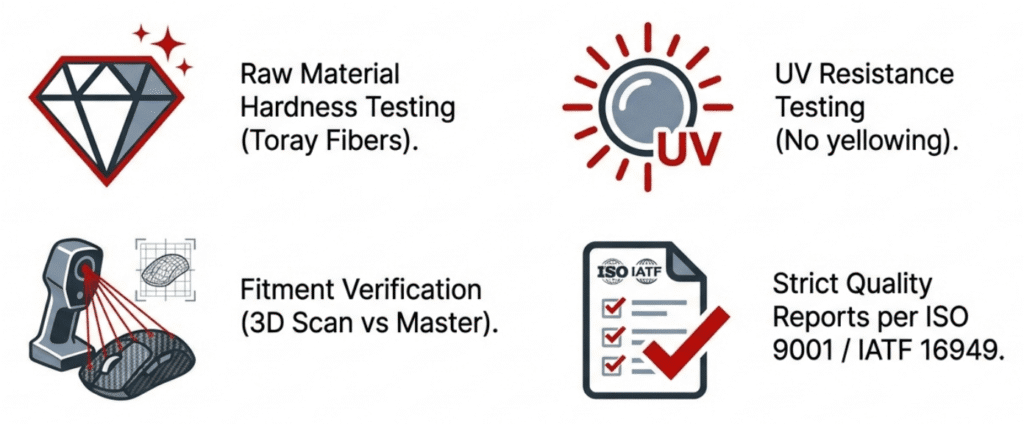

3. Ergonomic Validation Through 3D Scanning & Prototyping

Before entering composite production, every design undergoes:

- 3D data scanning

- Visual & tactile ergonomic verification

- Rapid 3D-printed hand-fit prototypes

- Structural stiffness tuning based on user grip profile

The result is a mouse that feels engineered—not just assembled.

Core Advantages: What Carbon Fiber Enables That Plastic Cannot

• Strength-to-Weight Performance

Reduced inertia improves targeting speed and reduces wrist fatigue.

• Automotive-Grade Finishing

High-gloss piano clear coat, matte micro-texture, or forged-carbon visual depth.

• Extreme Durability

Carbon fiber maintains geometry even under impact or long-term load.

• Premium Sensory Touch

Cool, smooth, high-density feel—instantly different from plastic or metal.

• Custom OEM/ODM Options

Textures, coatings, shapes, logos, weight tuning, and stiffness optimization.

From Concept to Mass Production in 58 Days

JCSPORTLINE’s structured 58-Day Workflow accelerates your product from idea to market:

| Stage | Duration | Output |

|---|---|---|

| Concept Feasibility | 3–7 days | CAD review & recommendations |

| Prototype Development | 7–15 days | CNC-trimmed functional prototypes |

| Mold Manufacturing | 10–18 days | Autoclave, compression, or hybrid mold |

| Pre-Production | 10–18 days | Small-batch refinement |

| Mass Production | Flexible | Autoclave composite manufacturing |

Material Chain Control

We source original fibers from Toray Japan, weave in-house, and maintain quality consistency from filament to final product.

IP Protection & NDA Support

All client designs are protected through strict confidentiality and design-patent filing support.

FAQ

Q1: Can carbon fiber mouse shells be mass-produced?

Yes. JCSPORTLINE offers autoclave, compression, and hybrid processes suitable for small-batch and large-scale OEM production.

Q2: What is the typical weight reduction compared to plastic?

A carbon fiber shell can reduce overall weight by 20–50% while increasing stiffness.

Q3: Can you customize the shape, texture, or thickness?

Absolutely. We support custom mold design, ergonomic shaping, forged carbon, matte, and multi-material hybrid structures.

Q4: Do you offer NDA protection?

Yes. All projects can be protected under NDA with full IP confidentiality.

Ready to Build the Next High-End Peripheral?

Get a Free Engineering Feasibility Report within 24 hours.

Let our R&D team evaluate manufacturability, structural design, mold feasibility, and production cost.

👉 Instant Quote

📧 info@jcsportline.com

📍 Los Angeles | Netherlands | Vancouver | Shenzhen