- Home

- Services

- Industries

- Capabilities

- Resources

- Company

58-Day Carbon Fiber Project Management

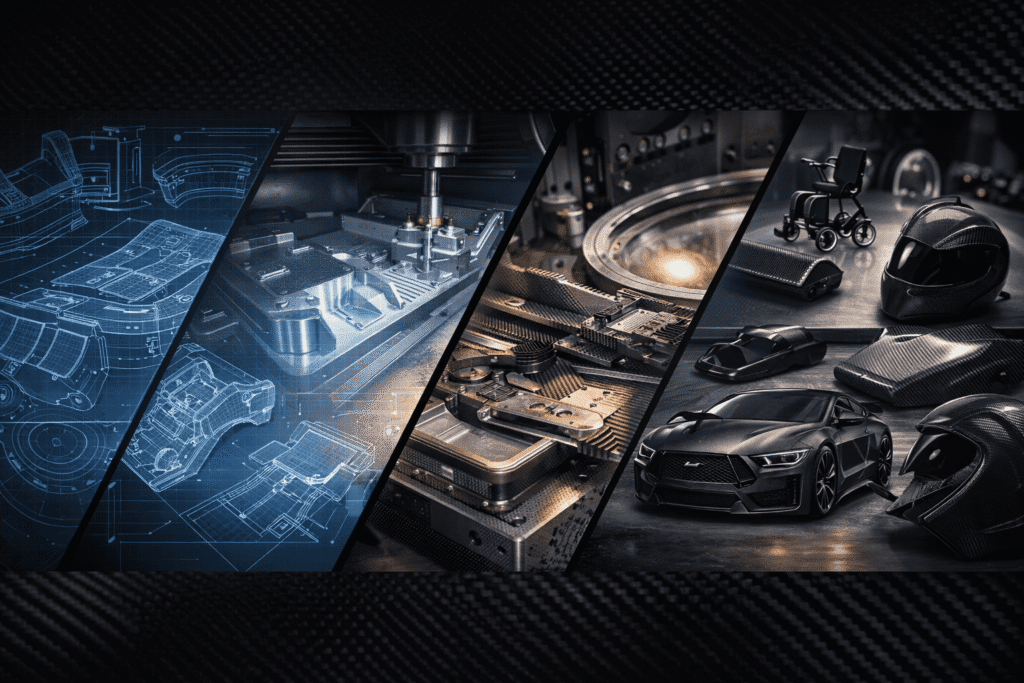

From concept sketches to real composite prototypes — delivered in as fast as 58 days

We turn your ideas into physical carbon-fiber parts through a fast, structured, engineering-driven workflow.

From drawing confirmation and CNC machining to mold tooling and sample production, every phase is optimized for speed, precision, and transparency.

Why Our 58-Day System Works

A fast, reliable project lifecycle built for brands that need speed, accuracy, and world-class composite production.

Rapid R&D Execution

We turn complex ideas into manufacturable designs quickly through experienced engineering and reverse-modeling teams.

Flexible Tooling Options

Choose from multiple mold types — rapid tooling, CNC prototype molds, or full production molds — depending on budget and timeline.

Full Transparency & Tracking

Our AI-integrated workflow system keeps every step visible: feasibility, tooling status, molding progress, sample reports.

How Our 58-Day Workflow Delivers Results

A proven step-by-step system that brings your carbon-fiber idea to life.

What Makes Our Process Different

A project-management system designed for high-speed engineering teams and OEM/ODM brands.

From Fabric to Finish — Your Part, Our Process

We manage everything others don’t show: engineering logic, mold construction, layup strategy, curing workflow, and full lifecycle quality control.

58-Day Delivery Rate

Projects Engineered

Global Clients Served

Tooling & Prototype Success Rate

Frequently Asked Questions

Clear answers to how our 58-day carbon-fiber project system works.

Our 58-day workflow covers the full lifecycle: requirement collection, feasibility evaluation, R&D modeling, CNC patterns, mold fabrication, prototype samples, and final QC. Each stage is pre-scheduled to ensure fast, predictable delivery.

You only need to submit your 2D/3D files, functional requirements, material preference, tolerance expectations, and usage scenario. Our engineering team will handle manufacturability analysis and complete the project plan.

Most prototypes and low-volume molds can be completed in 45–58 days. Extremely complex structures, multi-part assemblies, or aerospace-level tolerances may require additional time—your schedule will be confirmed before production begins.

We provide rapid prototype molds, CNC aluminum molds, P20 steel molds, and autoclave-ready composite molds. Our engineers will recommend the best option depending on geometry, surface requirements, and your budget.

Every stage includes:

• Manufacturability review

• Layup and curing simulation

• Dimensional inspection

• First-article report

• Final QC with professional measuring tools

This ensures your part matches the design intent and functional needs.

Automotive, aerospace, marine, medical mobility, sports equipment, robotics, UAVs, and consumer composite products. Any custom carbon-fiber part can fit into our workflow.

Ready to Turn Your Concept Into a Carbon-Fiber Prototype?

We help brands, engineers, and OEM teams develop custom carbon-fiber parts through a fast, transparent, and engineering-driven 58-day workflow.

Accelerate Your Development with Our 58-Day Project System

From manufacturability review to CNC patterns, mold fabrication, layup strategy, and prototype delivery — every step is optimized for speed, precision, and reliability.

Start your project today and see how quickly your ideas become real composite components.