- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Concept Consulting Engineering Manufacturing Marketing

Carbon fiber prototype development

Rapid prototype builds with controlled layup and curing parameters

Flexible tooling strategies from soft molds to pre-production tools

Functional validation for stiffness, weight targets, and cosmetic quality

Carbon Fiber Prototype Development

Turning carbon fiber designs into validated, production-ready prototypes.

Rapid Prototype Builds

Controlled layup and curing from day one.

Layup sequence defined early

Ply orientation verified on-tool

Autoclave or hot-press parameters

Tooling Options

Soft molds to pre-production tools.

Soft molds for fast iteration

Composite/aluminum for functional builds

Pre-production tools for pilot runs

Prototype Validation

Functional checks beyond surface finish.

Weight and stiffness targets

Fitment and assembly interfaces

Cosmetic quality inspection

When Does a Carbon Fiber Project Need Prototyping?

New carbon fiber part with unvalidated geometry

Tight weight or stiffness targets

Cosmetic surface requirements

Transitioning from design to production tooling

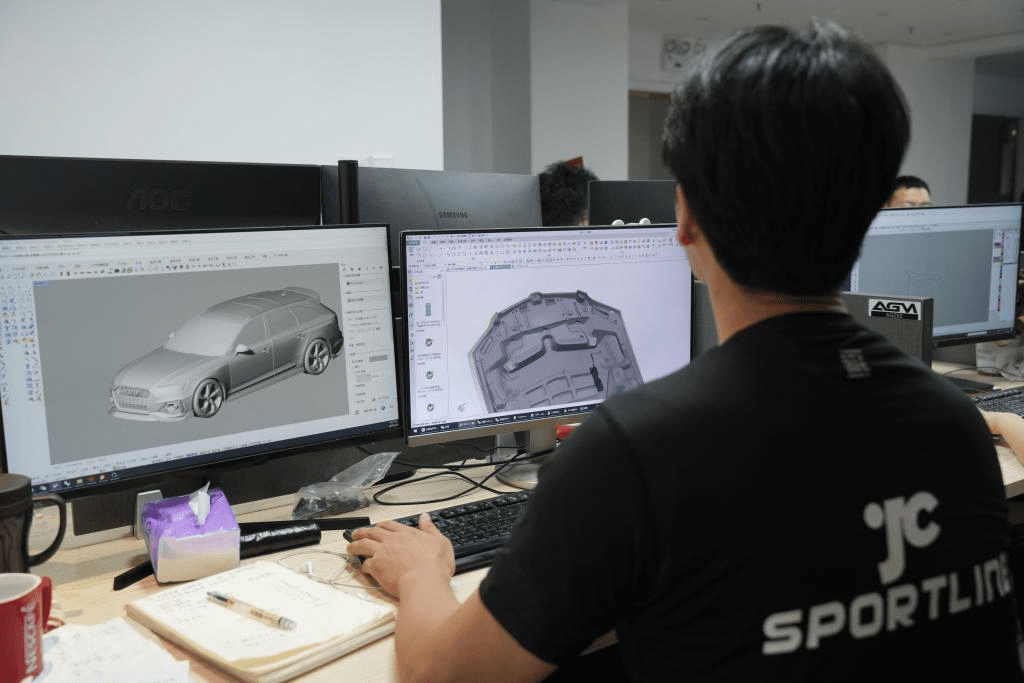

Our Prototype Development Workflow

From design validation to functional prototype readiness

STEP 01 — Design & DFM Review

Evaluate geometry, load paths, and manufacturability before tooling.

STEP 02 — Tooling Strategy Selection

Select soft molds, CNC tools, or pre-production tooling based on project goals.

STEP 03 — Prototype Build & Curing

Execute controlled layup, curing cycles, and material validation.

STEP 04 — Validation & Design Feedback

Test stiffness, weight, fitment, and refine the design for next iteration.

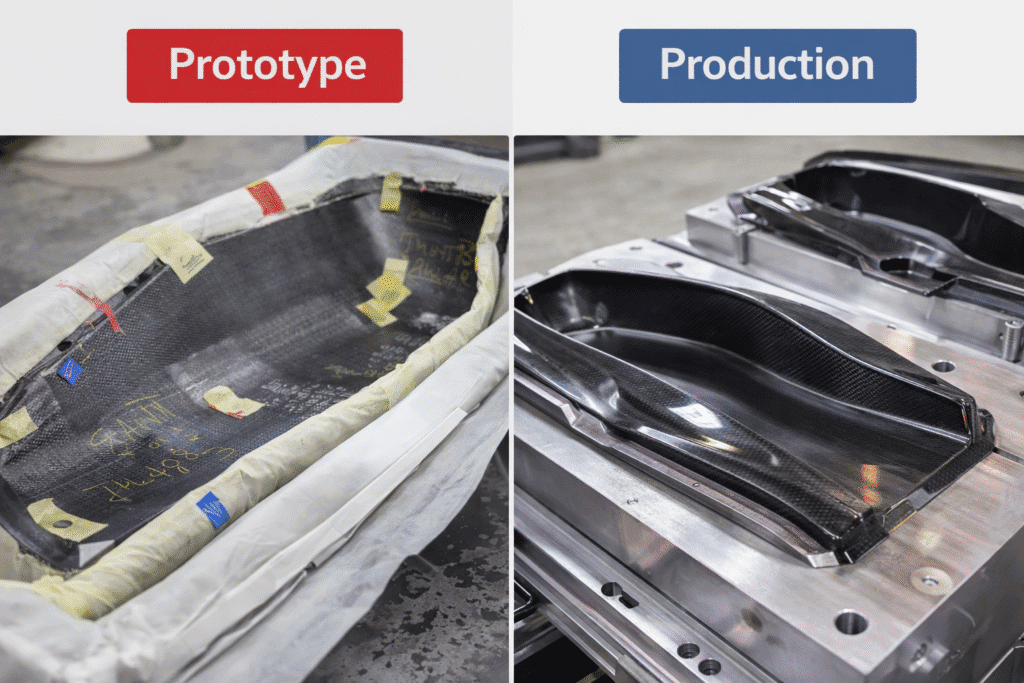

Prototype vs Production — What to Expect

Prototype focuses on validation

Production focuses on consistency & cost

Not all prototype tools are production tools

Prototype decisions influence production success

Prototype → Production

How Prototype Fits into the Full Development Process

Concept definition, surface development, and design intent creation

→ Feeds design intent into prototype feasibility

Structural logic, material strategy, and manufacturability validation

→ Defines how the prototype should be built

Prototype Development ( Current Stage )

Validated builds with controlled layup, tooling, and curing parameters.

→ Bridges design intent with production reality.

Production tooling transfer, process locking, and quality consistency control

→ Scales validated prototypes into stable, repeatable production

Free Technical Evaluation

Ask for a Free Carbon Fiber Project Review

Our engineers will review your concept and provide suggestions on materials, structure, and manufacturability – tailored to your carbon fiber application.

Response within 24 hours by our engineering team

OEM/ODM support for wheelchairs and other mobility devices

NDA and confidential review available on request

Start Your Carbon Fiber Project

Get expert guidance on materials, structure, and feasibility.