Table of Contents

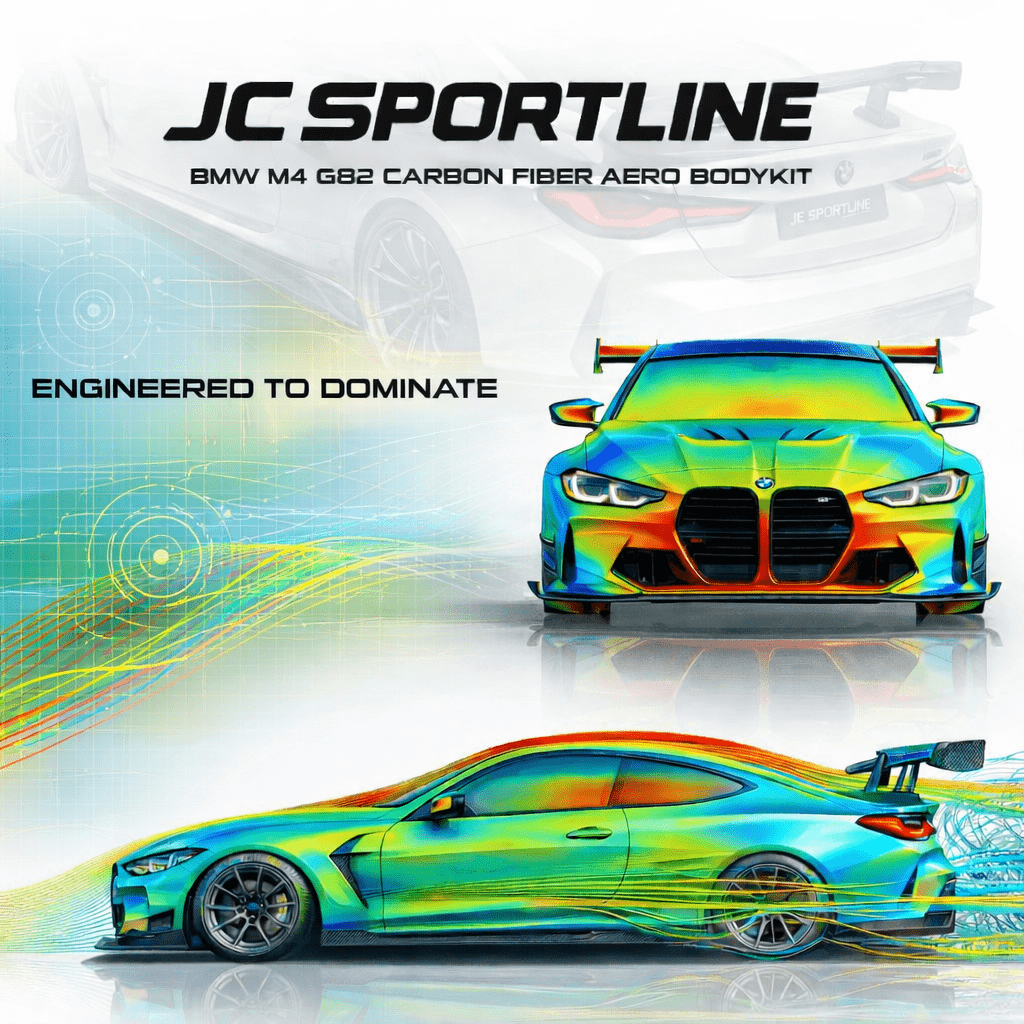

Developing a carbon fiber racing spoiler is far more than producing an attractive automotive accessory. Behind every lightweight, aerodynamic wing sits a complete engineering lifecycle—from concept validation to final installation. At JCSPORTLINE, this lifecycle follows a disciplined four-phase workflow: Design → Prototype → Production → Final Product. Each phase ensures structural reliability, aerodynamic performance, manufacturing repeatability, and long-term durability.

This article explains how a carbon fiber racing spoiler progresses through each stage, and how this workflow solves real market pain points—from traditional spoilers being too heavy, too fragile, or poorly fitted, to inconsistent quality and short lifespan. By integrating aerodynamic engineering, advanced composite manufacturing, and strict quality control, each spoiler becomes a performance component, not merely a styling accessory.

Phase 1 — Design: Turning Performance Requirements Into Engineering Blueprints

Aerodynamic & Structural Requirement Definition

Every racing spoiler begins with a clear definition of aerodynamic and structural goals. Traditional plastic or metal spoilers suffer from high weight, poor stiffness, and unpredictable drag. At high speeds, these materials flex under load, causing the spoiler to lose its intended downforce and destabilize the rear axle.

JCSPORTLINE begins with key aerodynamic parameters:

- Required downforce across speed ranges

- Vehicle-specific airflow behavior

- Angle-of-attack (AOA) constraints

- Structural load paths through brackets and trunk mounting points

- Fitment geometry matching the OEM trunk lid

Wind tunnel data from past motorsport projects helps guide selection of wing camber, chord length, mounting angle, endplate geometry, and wing height. The goal is simple: stable downforce, reduced lift, and improved high-speed control.

⭐ CFD Simulation: Validating Airflow Before Physical Prototyping

Before modeling the spoiler in CAD, JCSPORTLINE conducts CFD (Computational Fluid Dynamics) simulations to verify the aerodynamic concept and replace guesswork with measurable performance data.

This carbon fiber aero bodykit is designed using advanced Computational Fluid Dynamics (CFD) to deliver over 2,500 lbs (1,100+ kg) of downforce at 180 mph (290 km/h).

Every component has been optimized to enhance high-speed stability and cornering precision, making it an essential upgrade for serious racers.

CFD helps engineers analyze:

- Pressure distribution over the wing

- Airflow attachment & separation regions

- Efficiency at different AOAs

- Drag vs downforce balance

- Endplate vortex behavior

- Spoiler height interaction with trunk airflow

- Stability under crosswind turbulence

Engineers then iterate wing geometry to optimize:

- Wing curvature

- Camber ratio

- Chord length

- Endplate shape

- AOA presets

- Mounting height

CFD results directly inform CAD modeling, ensuring the first 3D model is already a data-validated aerodynamic structure.

CAD Modeling & Fitment Accuracy

Once aerodynamic targets pass CFD validation, engineers convert concepts into detailed CAD models. Using high-resolution 3D scanning, the trunk surface of the target platform—such as BMW M2/M3/M4—is captured with sub-millimeter precision.

CAD ensures:

- Perfect mating between spoiler feet and trunk lid

- Correct hole alignment

- Balanced geometry left to right

- OEM-level panel gap consistency

Even a 0.5 mm deviation can introduce unwanted vibration or aerodynamic instability at speed. CAD modeling prevents these issues and guarantees a secure, vibration-free installation.

Material & Layup Strategy Planning

Next, engineers design the composite layup to achieve the desired stiffness and weight. To solve common aftermarket pain points—heavy spoilers, deformation under load, UV aging—JCSPORTLINE uses:

- 3K twill carbon for the visible outer layer

- Unidirectional carbon fiber for stiffness-critical load paths

- High-grade epoxy resin compatible with 120°C curing

- Internal ribs or spars for structural reinforcement

This ensures a racing spoiler weighing as little as 5 kg maintains exceptional rigidity and long-term durability.

Feasibility & Risk Assessment

Before building prototype tooling, engineers conduct a manufacturability review to identify:

- Tight radii where fibers may wrinkle

- Areas requiring additional draft

- Locations for embedded inserts

- Assembly tolerance zones

- Sharp transitions that may cause bridging or print-through

This eliminates problems early—avoiding deformation, voids, inconsistent weave flow, and delamination.

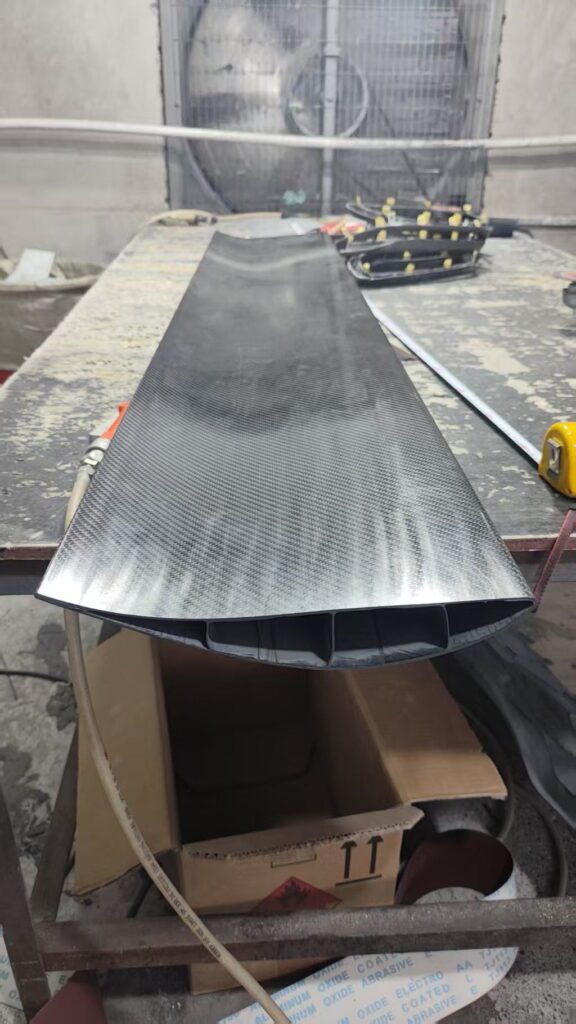

Phase 2 — Prototype: Building and Testing the First Functional Sample

Simplified Mold & First Layup

Prototyping transforms the digital design into a physical part. A simplified mold—faster to produce and less expensive than full production tooling—is created to validate geometry, surface quality, and structural behavior.

For a racing spoiler, the first layup checks:

- Accuracy of wing curvature

- Correct alignment of mounting legs

- Feasibility of achieving a seamless one-piece appearance

- Structural feel under manual torque testing

This prototype resolves early issues before investing in production-grade molds.

Fitment & Dimensional Verification

One of the key benefits of the prototype stage is ensuring the spoiler matches the targeted vehicle perfectly. Poor fitment is one of the biggest complaints in the aftermarket industry.

During this phase, engineers verify:

- Bolt-on alignment

- Contact surface match with trunk lid curvature

- Endplate alignment

- Symmetry and level across the vehicle’s rear axis

JCSPORTLINE aims for 99% fitment accuracy, solving the “hard to install” problem typical of universal or low-precision spoilers.

Surface & Structural Evaluation

Beyond geometry, the prototype undergoes detailed inspection for structural integrity and visual quality. Engineers check:

- Weave distortion

- Print-through

- Curing uniformity

- Early signs of vibration or flex

Because spoilers must withstand strong forces at high speeds, torsional stiffness is evaluated. This ensures the spoiler will not twist, flutter, or deform under downforce.

Prototype Approval & Improvement Loop

With data collected, the engineering team refines:

- Layup thickness

- Internal reinforcement

- Mold geometry

- Insert locations

- Endplate transitions

This iteration loop eliminates risks related to durability, installation difficulty, or aerodynamic inefficiency. Only when the prototype’s performance and appearance meet expectations does the project enter production.

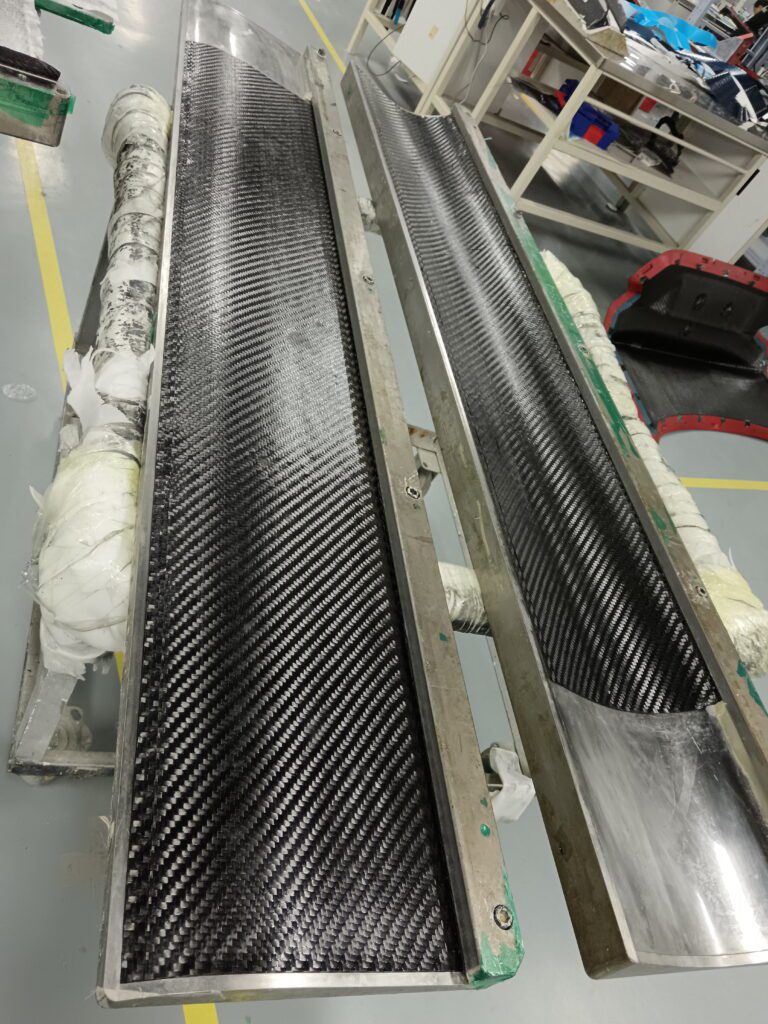

Phase 3 — Production: Scaling Into a Repeatable, High-Quality Manufacturing Process

Precision Mold Manufacturing

Production molds are CNC-machined from high-grade aluminum, achieving ±0.02 mm accuracy. This allows every unit to match the exact geometry validated during prototyping.

Key mold features include:

- Mirror-polished internal surfaces

- Multi-piece design for complex spoiler shapes

- Built-in alignment keys

- Draft angles optimized for layup stability

High-precision tooling eliminates warping, uneven surfaces, and inconsistent fitment—major complaints common in lower-end spoilers.

Layup, Curing & Process Control

Production layup is performed using a combination of automated cutting and controlled manual placement to preserve fiber orientation. Spoilers benefit from:

- Vacuum-assisted forming

- Consistent resin distribution

- Controlled curing at 120°C

- Use of large autoclaves or vacuum ovens

JCSPORTLINE’s process creates parts with dense composite structures and minimal voids. Internal ribs further enhance rigidity, preventing deformation at high speeds.

Batch Quality Assurance

Every unit undergoes strict QC inspection, ensuring 99.8% pass rate. Tests include:

- Dimensional scanning

- Impact resistance

- -40°C to 80°C thermal cycling

- 1000-hour UV exposure

- Surface finish inspection

- Insert strength testing

These checks guarantee long-term durability—solving the market problem of spoilers that crack, fade, or delaminate after exposure to harsh environments.

Packaging & Logistics Planning

To maintain the premium finish, the spoiler is packaged using:

- Multi-layer protective coverings

- Foam mold supports

- Hard-shell export-grade boxes

- Separate compartments for brackets and bolts

This ensures the product arrives scratch-free, even during long-distance international shipping.

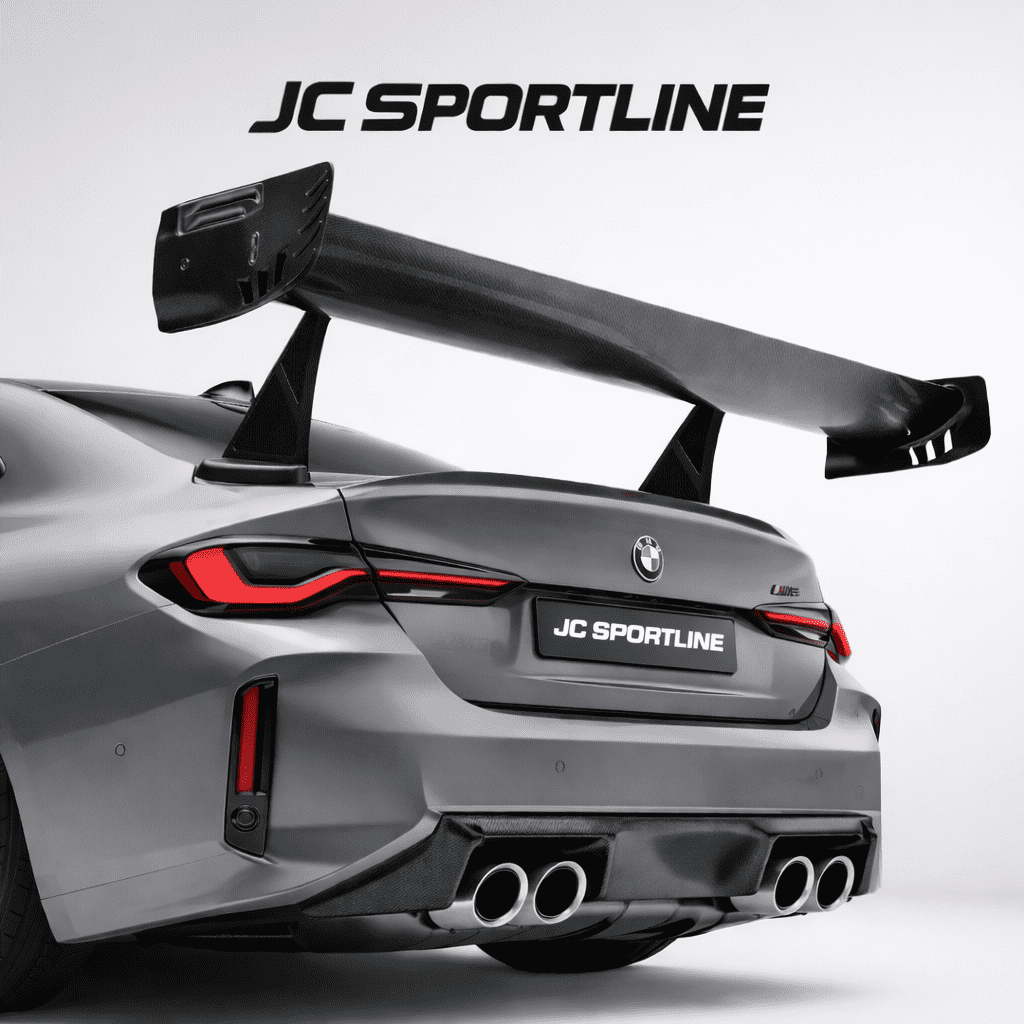

Phase 4 — Final Product: Validation, Installation, and Real-World Performance

Surface Finishing & Coating

Final appearance matters greatly in performance carbon fiber parts. JCSPORTLINE applies:

- High-gloss or matte clear coats

- UV-resistant protective layers

- Precision polishing

- Finish inspection with ≤0.1 mm flatness tolerance

This achieves a smooth, premium surface free of defects—resolving the “ugly texture” problem often associated with inferior spoilers.

Installation Accuracy & Accessories

The spoiler comes with dedicated, vehicle-specific mounting hardware:

- Model-matched brackets

- Pre-threaded inserts

- Torque-rated bolts

- Full installation manual and tutorial video

This solves the biggest customer complaint after receiving a spoiler: difficult or inaccurate installation.

Most users can install the spoiler using simple tools such as wrenches and screwdrivers. Professional help is optional—not mandatory.

Real-World Performance Validation

Before launch, the spoiler undergoes street and track validation to confirm:

- Rear-end stability at high speeds

- Downforce retention during cornering

- No vibration or flex

- Good behavior in crosswinds

- No coating discoloration or deformation under heat

The results show improvements such as:

- +40% cornering stability

- Reduced drag due to optimized aero design

- Balanced vehicle feel at highway and track speeds

After-Sales Support & Traceability

Each spoiler includes:

- Serial number

- QC pass certificate

- Warranty documentation

- Support access

This ensures customers can always receive service, spare parts, or installation guidance.

FAQ: Carbon Fiber Racing Spoiler Development & Use

1. Is this carbon fiber racing spoiler compatible with my car?

Currently, the spoiler fits BMW M2, M3, and M4 models. If your vehicle is not listed, you can provide model year and trunk dimensions—custom mold development is available.

2. Does installation require a professional shop?

Basic automotive shops can install the spoiler easily. It includes dedicated brackets, hardware, and a detailed step-by-step installation guide with photos and videos. Most users can complete the installation with standard tools such as wrenches and screwdrivers. Online support is available if needed.

3. How durable is the spoiler in extreme weather conditions?

The spoiler has passed -40°C to 80°C temperature cycling, 72-hour continuous rain simulation, and 1000-hour UV exposure. It includes a 2-year warranty against fading, cracking, or delamination.