- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Custom 400Z body kits concept to delivery

The creation of a high-performance dry carbon fiber body kit for the Nissan 400Z involves several intricate steps. This case study outlines the detailed process from initial concept to final production.

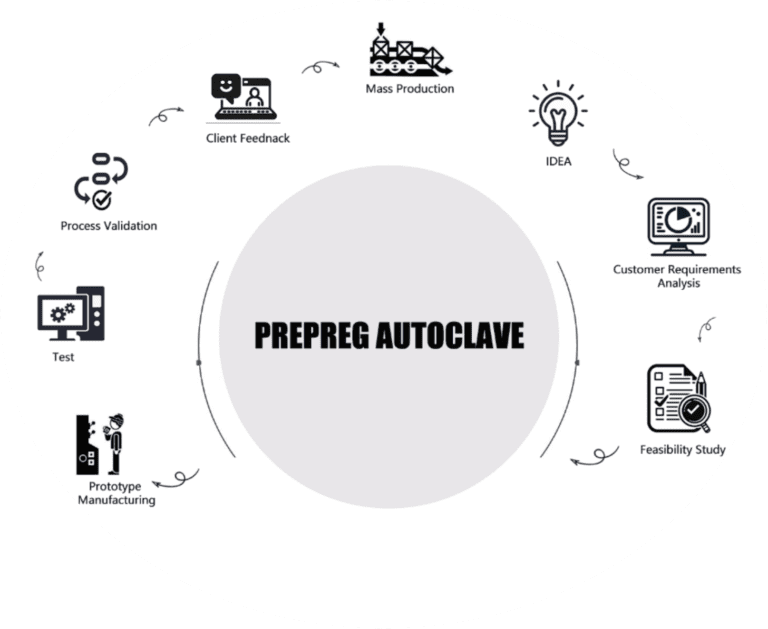

400Z development process and verification capabilities

The development of the Nissan 400Z body kit is a meticulously planned and executed process, leveraging advanced technologies and industry expertise to ensure the highest quality and performance standards.

Efficient development cycle plan

Our project design development and management capabilities are structured to ensure that we deliver on budget, on time, and with the highest quality standards. By combining advanced development processes with robust verification capabilities, we ensure that the Nissan 400Z body kit meets and exceeds customer expectations in terms of quality, performance, and aesthetic appeal. This comprehensive approach provides customers with the assurance of a meticulously crafted product that adheres to the highest industry standards and delivers superior performance and visual satisfaction.

Design and engineering for the 400Z project

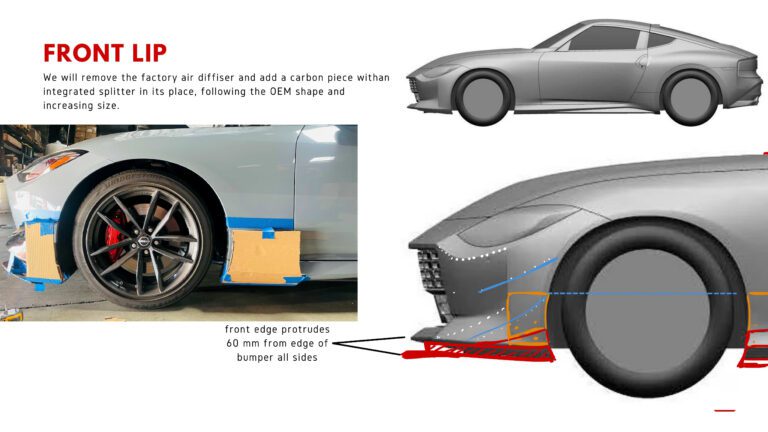

For the 400Z project, hand sketches evolve into precise CAD models and undergo FEA to ensure strength, lightness, and aerodynamic optimization.

Personalized Design Exploration

Hand sketching

The initial phase involves creating hand sketches to visualize the basic concepts and design ideas for the 400Z body kit. These sketches help in exploring different styles and features, providing a foundation for further refinement.

Creative Flexibility

Clients can explore various styles and features early in the design process, facilitating informed decisions and ensuring the final product meets their preferences.

Foundation for Refinement

These sketches serve as a foundational starting point, guiding the iterative design process towards achieving a refined and optimized 400Z body kit design.

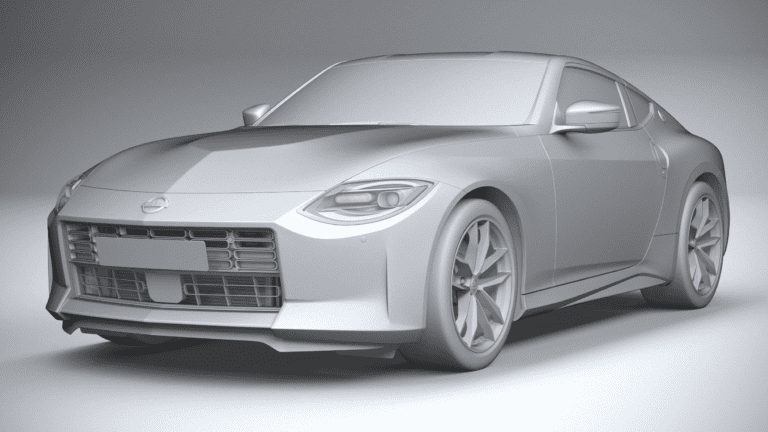

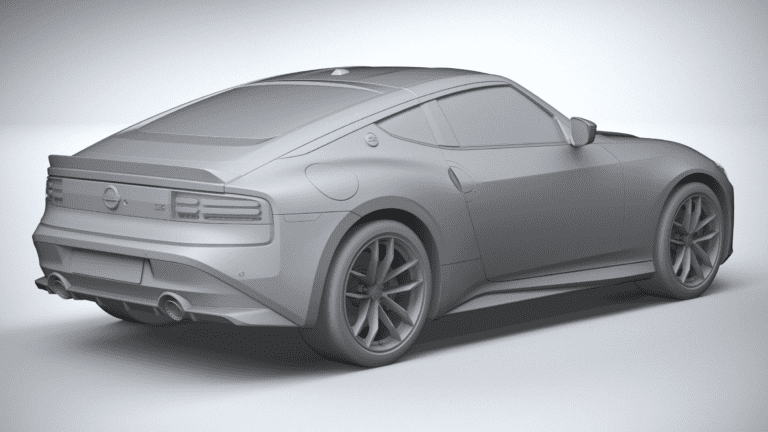

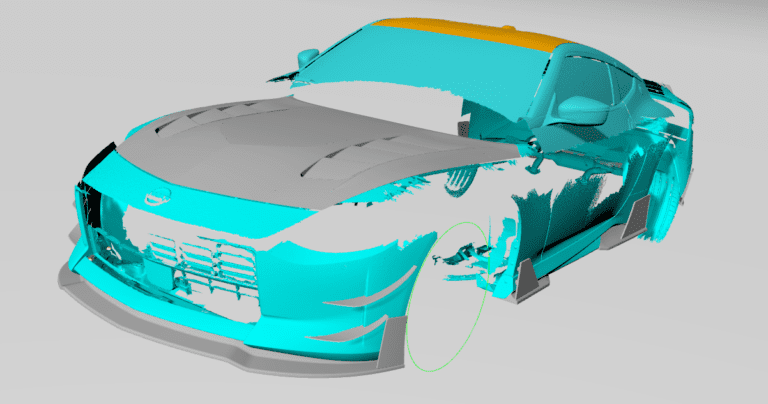

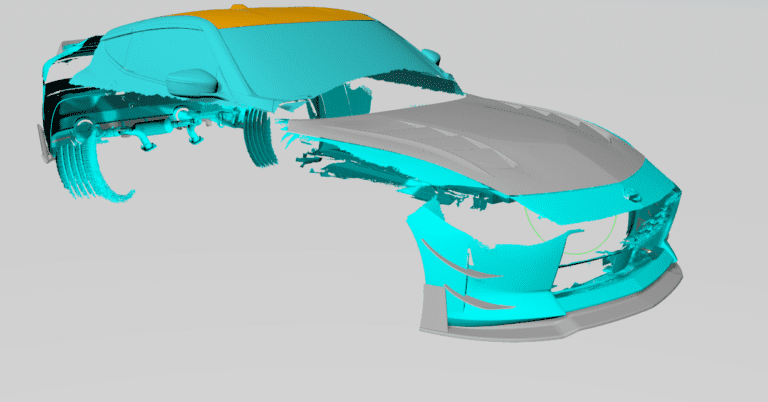

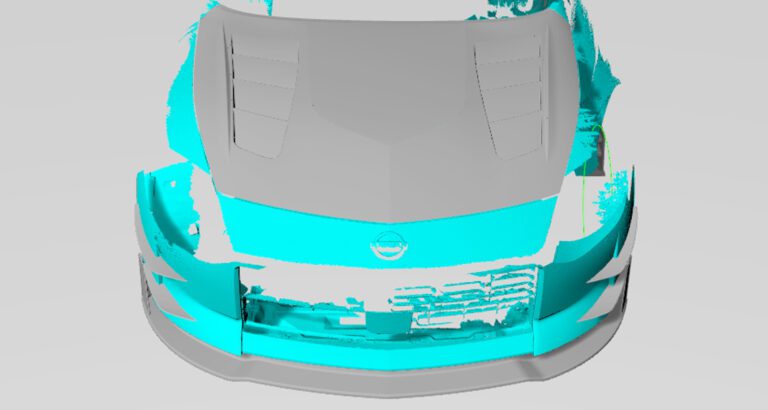

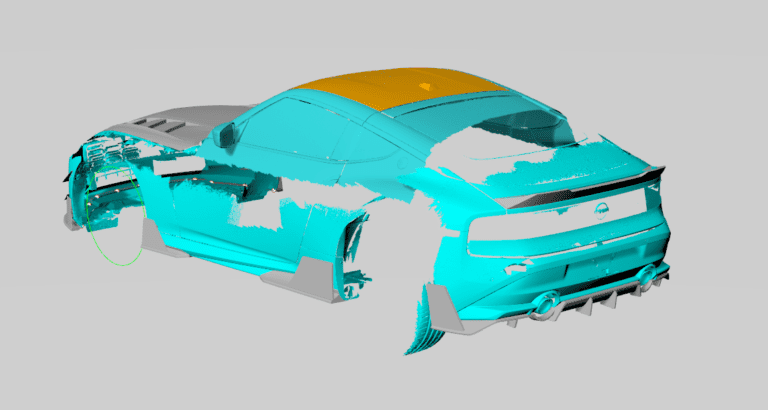

3D scanning and CAD modeling

Design and engineering

Our global 3D scanning resources provide detailed and accurate digital representations of the 400Z, ensuring precision and saving time in the initial design phase. Combined with our experienced design team, this process guarantees high-quality and efficient project completion, giving clients a solid foundation for further development.

CAD Modeling and FEA for Optimal 400Z Body Kit Design

The refined 3D scans of the 400Z are converted into detailed CAD models using advanced software like SolidWorks or AutoCAD, ensuring precise dimensional accuracy and seamless integration of aerodynamic features. These CAD models then undergo Finite Element Analysis (FEA) to simulate and analyze the mechanical behavior of the body kit components under various conditions. This crucial step ensures that each part is both strong and lightweight, optimizing the strength-to-weight ratio and enhancing the overall performance and durability of the 400Z body kit.

Advanced materials & processes

Advanced Production Process for High-Quality Carbon Fiber Parts

Mold Design and CNC Machining

Precision Mold Fabrication for 400z

Molds are created based on the final design to produce precise and consistent carbon fiber parts, utilizing advanced CNC machines for high-accuracy manufacturing. Specifically, the wind knife and mirror housing are aluminum molds, the engine cover is a resin mold, and the remaining components are carbon molds

Using 3D printing, initial prototypes allow us to evaluate fit and surface finish without full-scale production costs, ensuring high product quality. Our choice of dry carbon fiber enhances kit performance and fuel efficiency, supported by carefully selected resin systems ensuring durability across diverse conditions.

Jcsportline head engineer

Our Mold type

Application: Mirror covers and canards

Application: Engine hood

Resin Mold

Carbon Fiber Production Process for the 400Z Project

Through these meticulous processes, the Nissan 400Z dry carbon fiber body kit was developed to meet rigorous quality standards, enhancing both aesthetic appeal and vehicle performance.

Laying Up Carbon Fiber

Skilled technicians oriented carbon fiber sheets correctly in molds to maximize strength.

Autoclave Curing

Parts underwent high-pressure, high-temperature curing to eliminate voids and optimize mechanical properties.

Trimming and Finishing

After curing, parts were meticulously trimmed, sanded, and finished to achieve a high-quality surface.