- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Prototyping Process

Prototyping is an important part of the product development process, involving the creation of an initial version of a product to validate design ideas and functional requirements. It not only helps verify design assumptions and gather user feedback but also serves as an effective communication tool, reducing development risks and costs. Through continuous iteration and optimization of prototypes, the team can ensure that the final product meets user needs and provides a good user experience. The main steps in the prototyping process are as follows:

Advantages of vacuum evacuation process

Requirement Gathering and Analysis

- Define Goals: Clearly define the product’s goals, user needs, and functional requirements.

- User Research: Understand target users’ needs and behaviors through interviews, surveys, and observations.

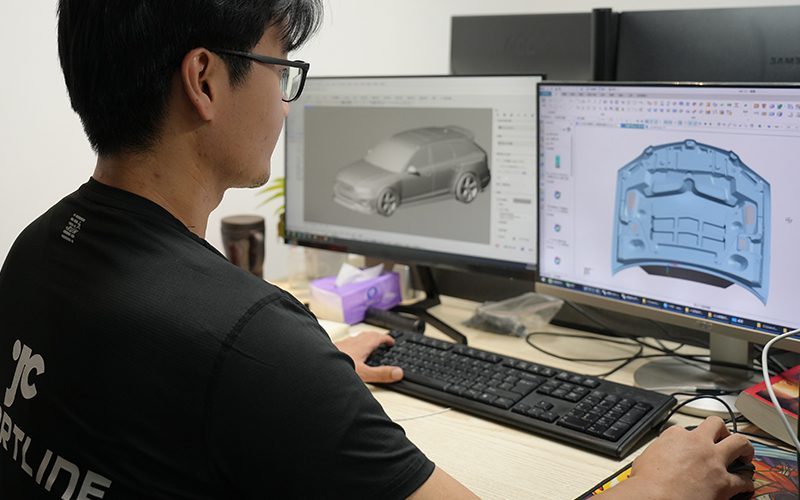

3D Design

- Brainstorming: Team members collaborate to come up with design ideas and concepts.

- Sketching: Use pen and paper or digital tools to create a preliminary design sketch showing the main interface and layout.

- Design: Through 3D design, designers are able to better realise ideas and concepts.

3D printing

- Proof of Concept: 3D printing can quickly turn design ideas into physical models, helping designers and engineers validate concepts and functionality.

- Iterative design: By rapidly producing prototypes, design teams can quickly test and modify them, improving design efficiency and quality.

Alignment And Prototype

Better quality, efficiency, and applications.

Discover how to apply these advantages to your project