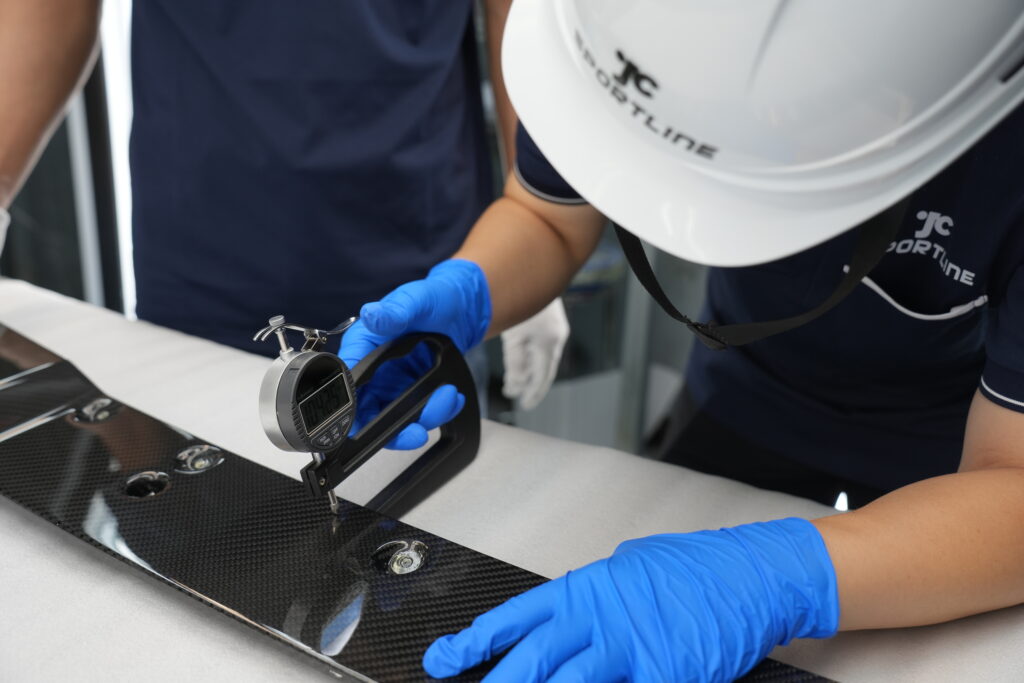

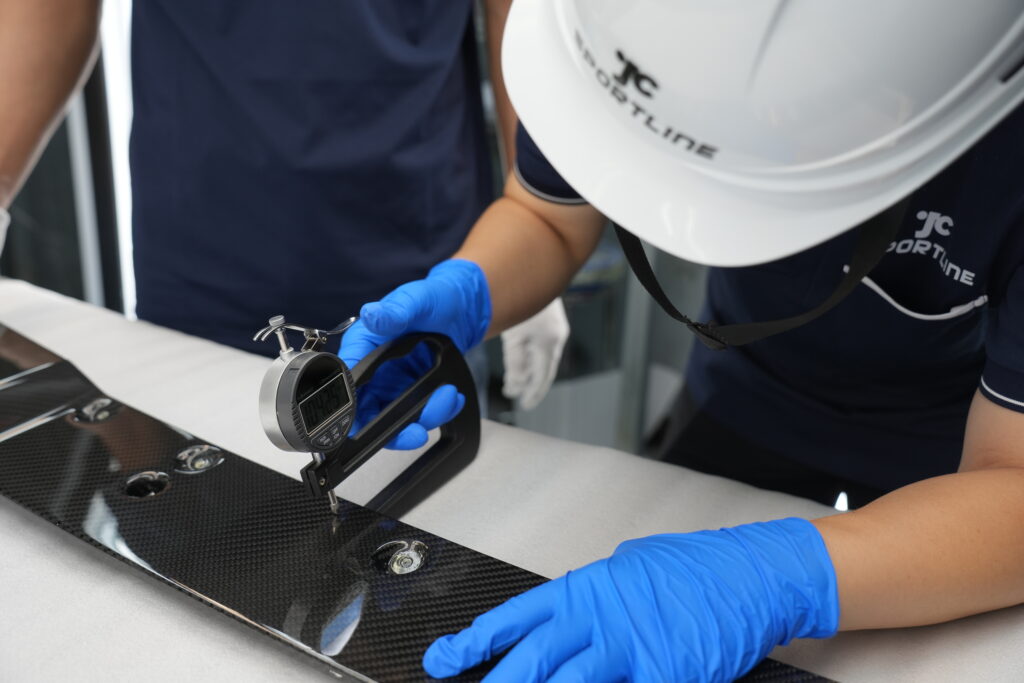

IPQC — Real-Time Quality Control During Production

IPQC monitors critical process points in real time, ensuring on-site execution follows approved standards and SOPs.

At JCSPORTLINE, consistent quality is built into every stage of carbon fiber manufacturing.

From raw material control to process execution and final validation, our quality management system is designed to support stable, repeatable results across long-term production programs.

At JCSPORTLINE, consistent product quality is achieved through a structured quality management system rather than isolated inspections.

Our system integrates product development, process control, testing, and continuous improvement to ensure long-term stability and reliability.

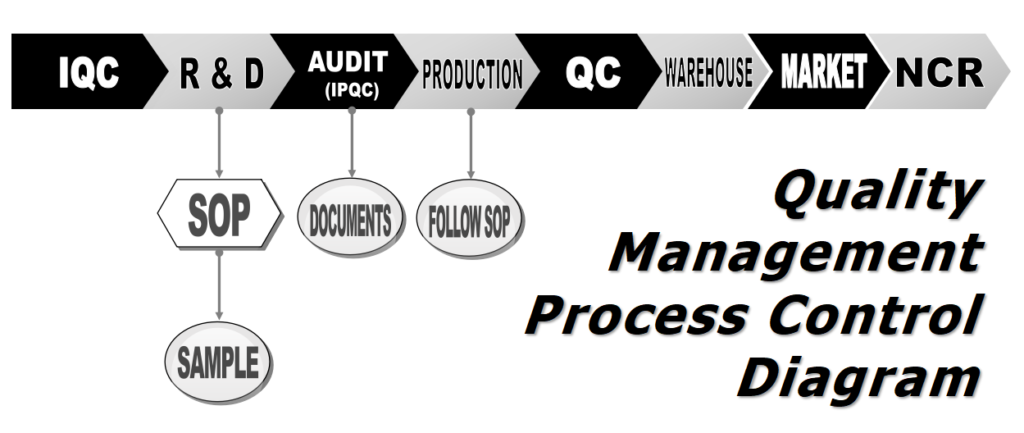

To ensure consistent carbon fiber quality from development to mass production, JCSPORTLINE operates a comprehensive quality management system built around seven key stages.

Consistent quality starts with controlled raw materials. All incoming materials are inspected to ensure they meet defined standards before entering production.

Ensures Surface Durability

Verifies resistance to scratches and wear, supporting long-term appearance and protection.

Ensures Stable Bonding

Confirms strong adhesion between paint and carbon fiber surfaces, preventing peeling or flaking.

Ensures Process Integrity

Detects leaks that could affect curing quality and structural performance.

Ensures Long-Term Visual Stability

Validates UV resistance to prevent discoloration over time.

Quality is not inspected; quality is designed and produced

At JCSPORTLINE, our Quality Management System is overseen through the following seven stages.

Quality Management System

Our R&D team defines quality standards at the earliest stage of each project, ensuring designs are stable, repeatable, and ready for mass production.

Mold design definition

Surface texture criteria

Installation and interface standards

Screw hole size and tolerance

Trimming location control

Validate design intent

Test performance

Integrate feedback

Ensure consistency

Optimize processes

Maintain quality stability

The production team executes approved SOPs with controlled parameters, ensuring that every part produced matches validated samples in structure and appearance.

Verifies the accuracy and completeness of IPQC records through daily inspections.

Ensures immediate detection and correction of process deviations.

Responsible for final quality assurance, testing, and continuous improvement.

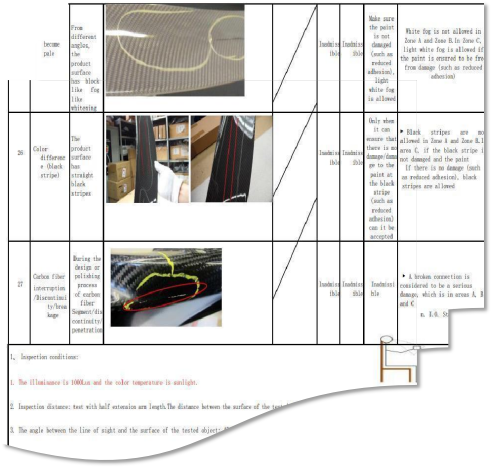

Adopts customer FQC standards, transforming them into internal standards. For example, for OEM products, this may involve exterior inspection standards obtained from a primary supplier for a project supplied to BMW. Even for BMW, recognizing the difficulty of defining 100% perfection in the carbon fiber industry, they set acceptable ranges for features such as the pattern at the corners of carbon fiber fabric, the diameter of white spots, and different quality standards for ABC surfaces.

Helps improve products by addressing customer concerns and suggesting enhancements based on feedback.

Assures customers of quality and compliance through detailed information on product specifications and rigorous testing.

Testing equipment meets diverse application needs, such as BMW's requirement for 2000 hours of xenon gas resistance to yellowing, and the aftermarket's requirement for 900 hours. Standard tests include high and low-temperature tests, stone impact tests, acid tests, auxiliary tests, tensile tests, xenon tests, etc.

Ensures products meet stringent industry standards and specific customer requirements, enhancing reliability and longevity.

Validates product performance under various environmental conditions, assuring customers of durability and resilience.

Provides assurance that products comply with regulatory and customer-specified standards, facilitating smoother market entry and acceptance.

Reduces the risk of product failures or defects, leading to fewer returns and customer complaints.

Demonstrates commitment to quality and customer satisfaction, enhancing brand reputation and customer loyalty.

Helps identify potential issues early in the development process, reducing overall costs associated with product recalls or rework.

Even with rigorous controls, non-conformances may occur. Customer-provided NCRs are actively integrated into our quality management system to update standards, SOPs, and control points, ensuring long-term improvement and consistency.

Talk to our engineering team and start a project where quality is predictable, repeatable, and scalable.

Our engineers will review your concept and provide materials, structure, and feasibility suggestions.