- Home

- Services

- Industries

- Capabilities

- Resources

- Company

CFD-Optimized Forged Wheels & Carbon Fiber Wheels Engineering Case Study

This engineering case study shows how JCSPORTLINE develops forged wheels and carbon fiber wheels with a simulation-driven workflow combining CFD aerodynamic analysis, FEA structural validation, and manufacturing-ready CAD engineering.

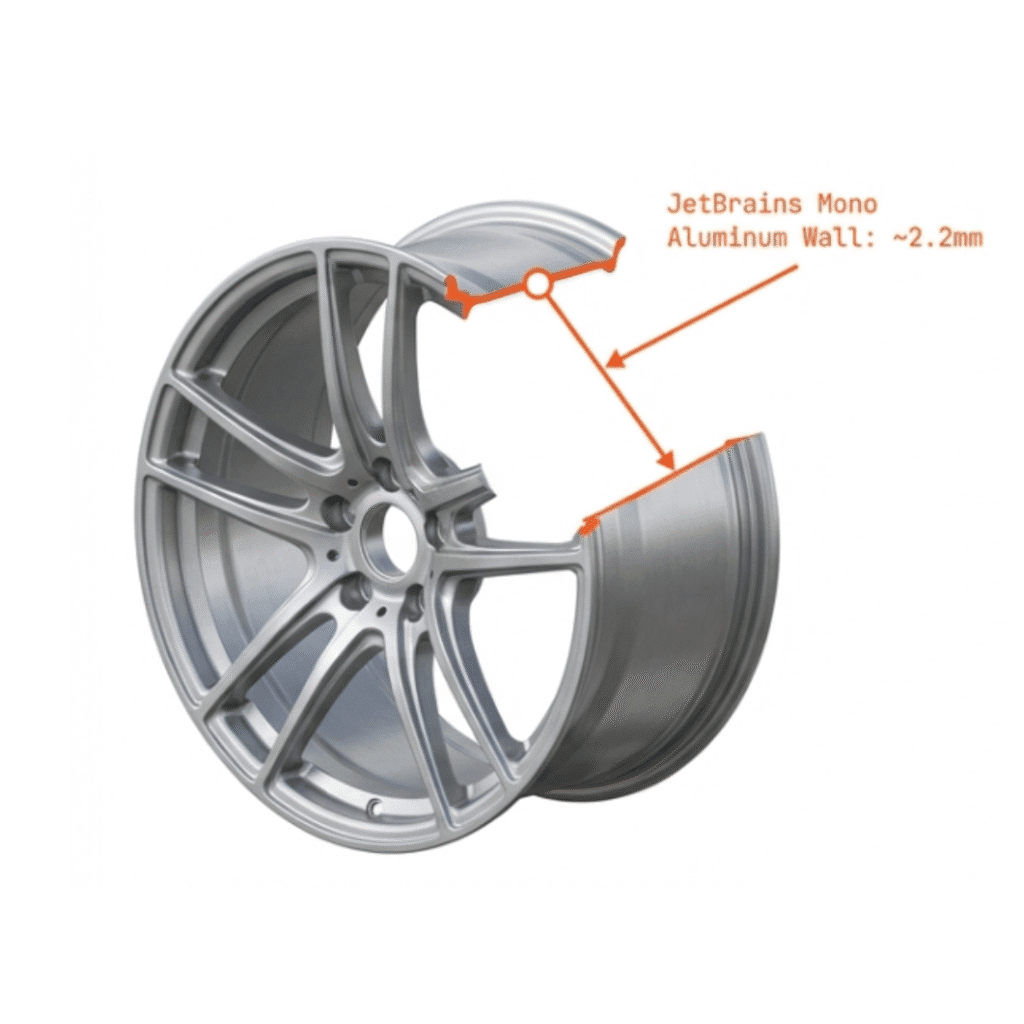

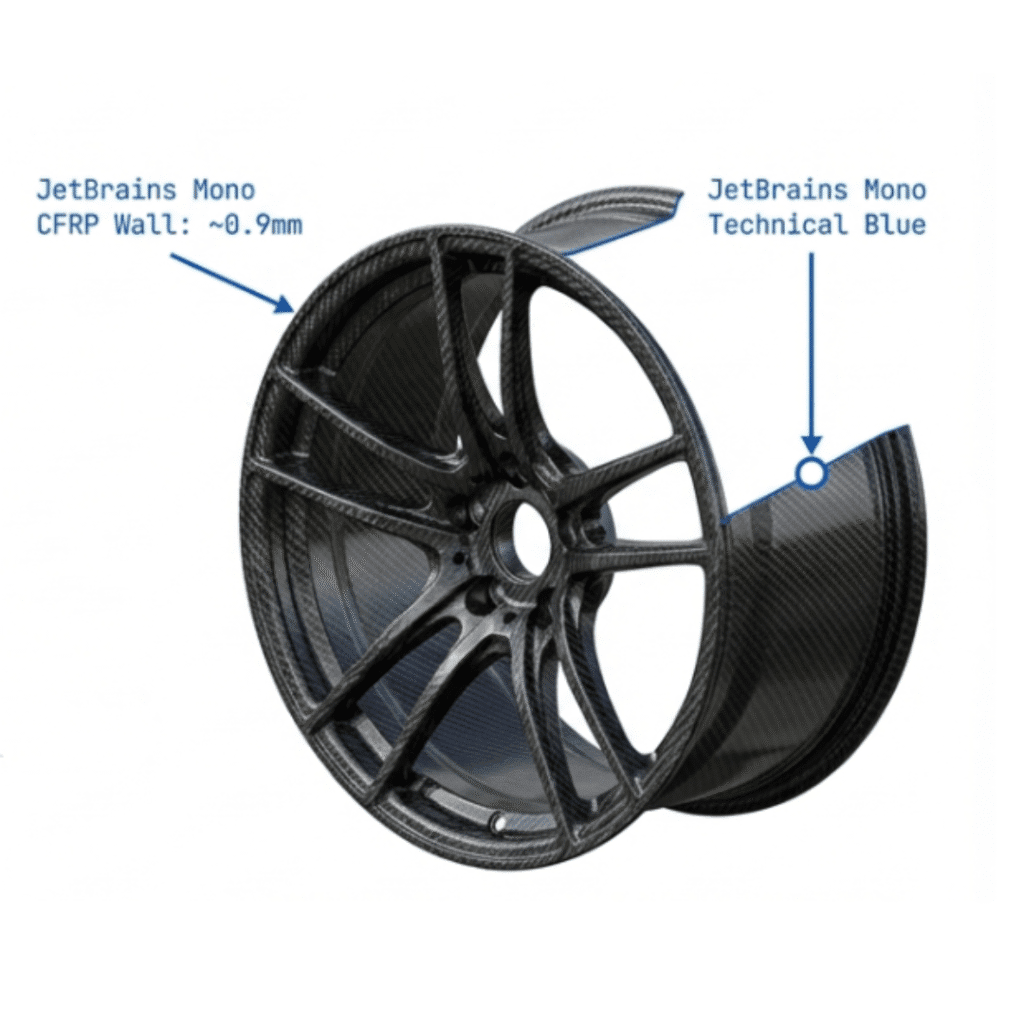

The featured model—a lightweight split-Y 10-spoke forged wheel—was created not only for aesthetics, but to deliver measurable aerodynamic, thermal, and structural improvements proven through simulation.

The Science Behind High-Performance Forged Wheels

High-performance wheels—whether traditional forged wheels or advanced carbon fiber wheels—directly influence a vehicle’s unsprung mass, stiffness, energy efficiency, and brake-cooling behavior. JCSPORTLINE focuses on engineering the physics behind these performance gains.

Weight Reduction

40–50% lighter

(Carbon vs Alloy)

Specific Stiffness

9.1/10 (Carbon) vs 4.2/10 (Aluminum)

Structure

Autoclave-cured Prepreg

Impact: Improved acceleration, braking distance, and EV range.

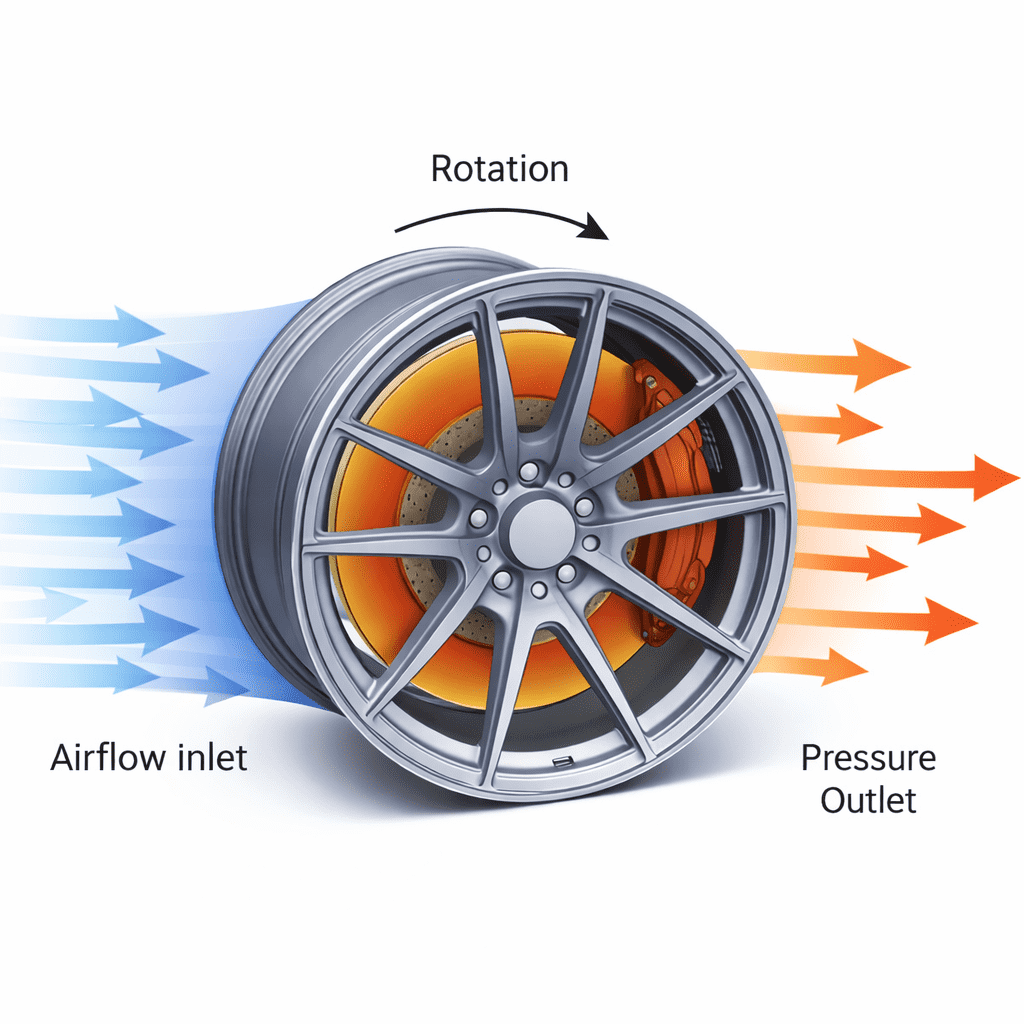

Why Aerodynamics Matter in Forged Wheel Design

At modern vehicle speeds—particularly in EVs—wheels behave as dynamic aerodynamic devices. Poorly optimized geometry can increase turbulence, raise drag, and reduce brake-cooling airflow.

High turbulence between spokes increases drag and energy loss

Insufficient brakecooling airflow leads to thermal fade

Negative pressure zones around the barrel reduce flow efficiency

Unoptimized spoke profiles generate unwanted noise and vortex buildup

Lack of directional airflow guidance reduces highspeed stability

The JCSPORTLINE wheel was designed to provide:

- Lower turbulence & controlled airflow channels

- Stronger brake-cooling airflow volume

- Reduced aerodynamic drag

- Stable pressure distribution at high speed

- Improved weight-to-stiffness ratio

OEM-Ready Engineering Deliverables

JCSPORTLINE supports OEMs and performance brands with complete production-ready wheel engineering packages, including:

- Full 3D CAD (STEP / IGES)

- CFD aerodynamic analysis

- FEA structural and fatigue validation

- Forging-ready design files and CNC machining references

- Material, process, and manufacturing recommendations

- Surface and mold-flow optimization

- Custom branding & scalable production support

These deliverables ensure that both forged wheel and carbon fiber wheel programs move smoothly from concept to tool design and serial manufacturing.

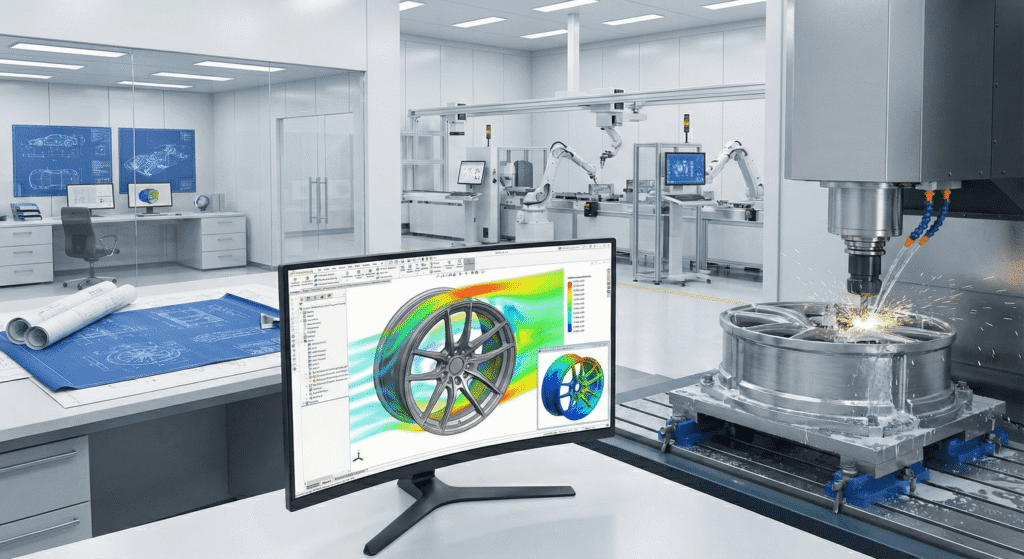

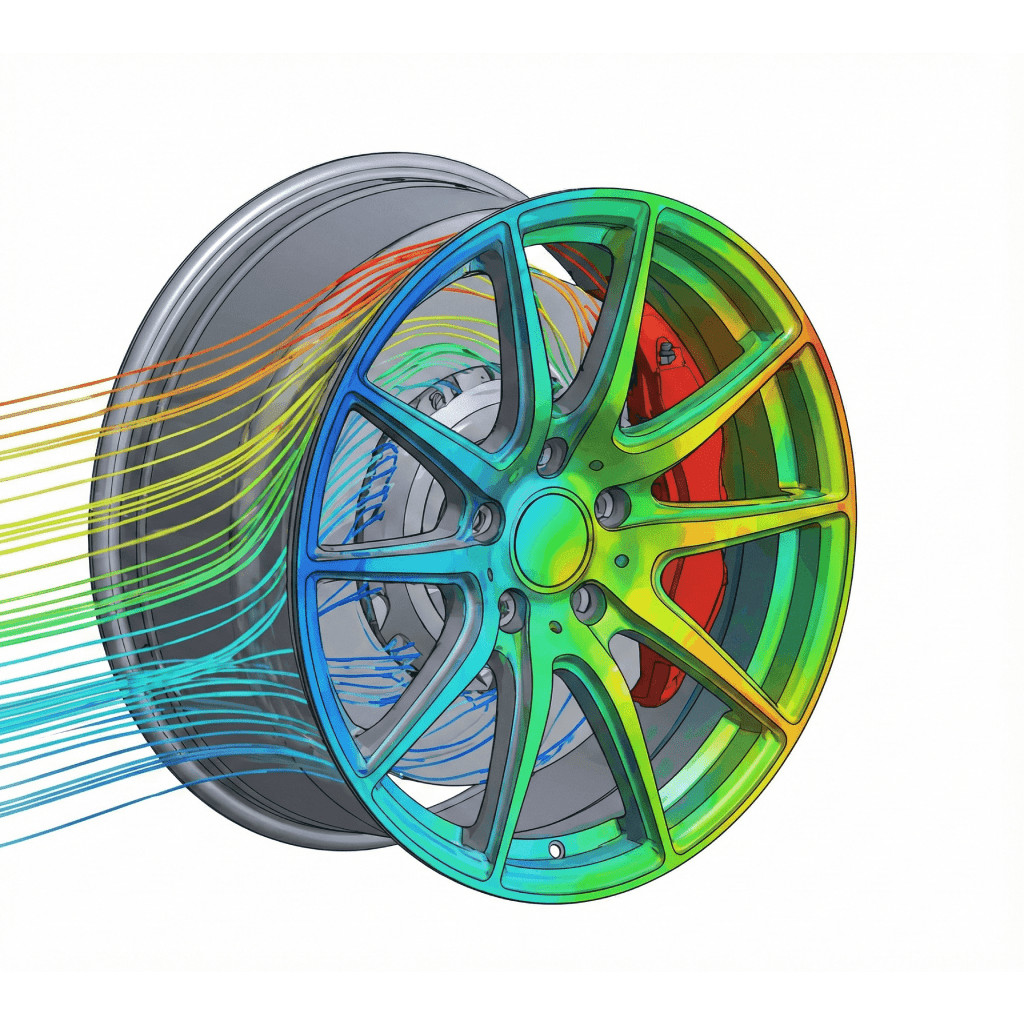

Our CFD Simulation Workflow

JCSPORTLINE integrates aerodynamic simulation directly into the wheel-development pipeline, ensuring engineering decisions guide both design and manufacturing.

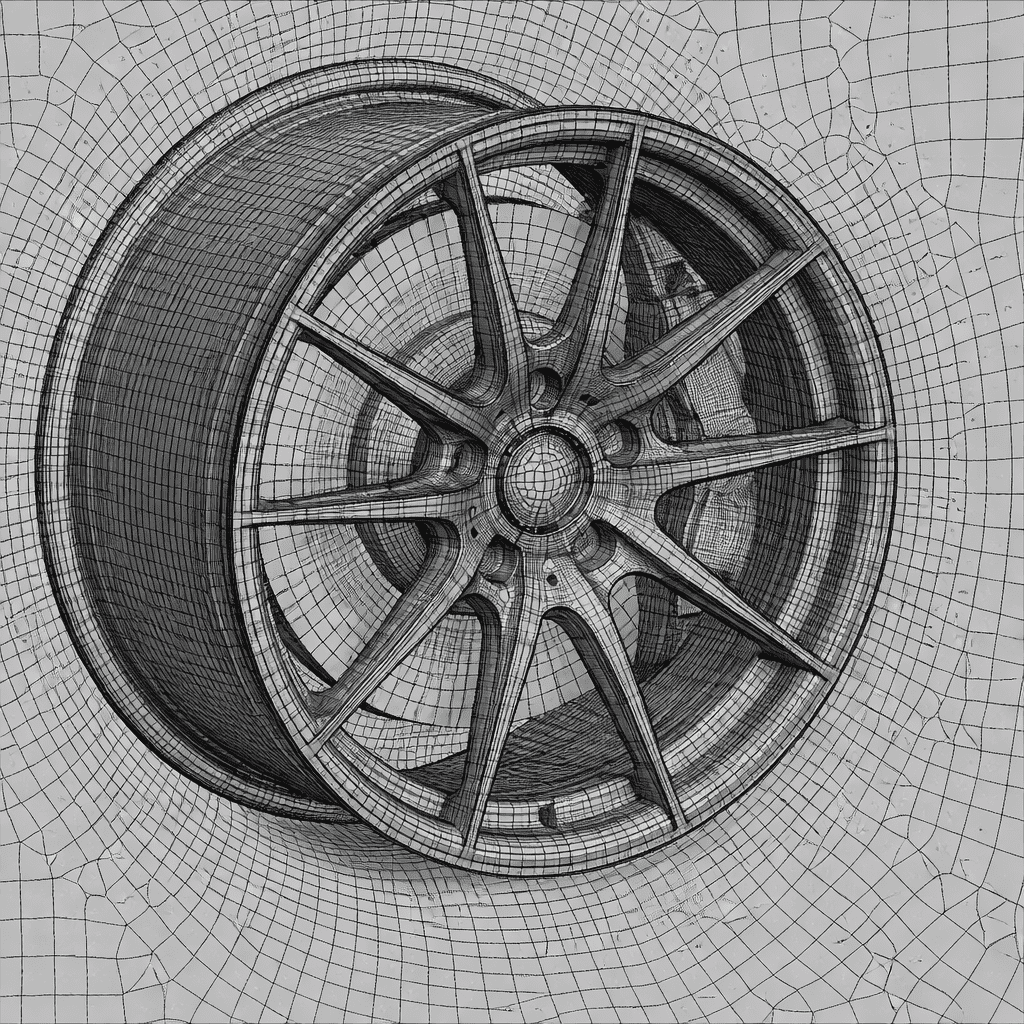

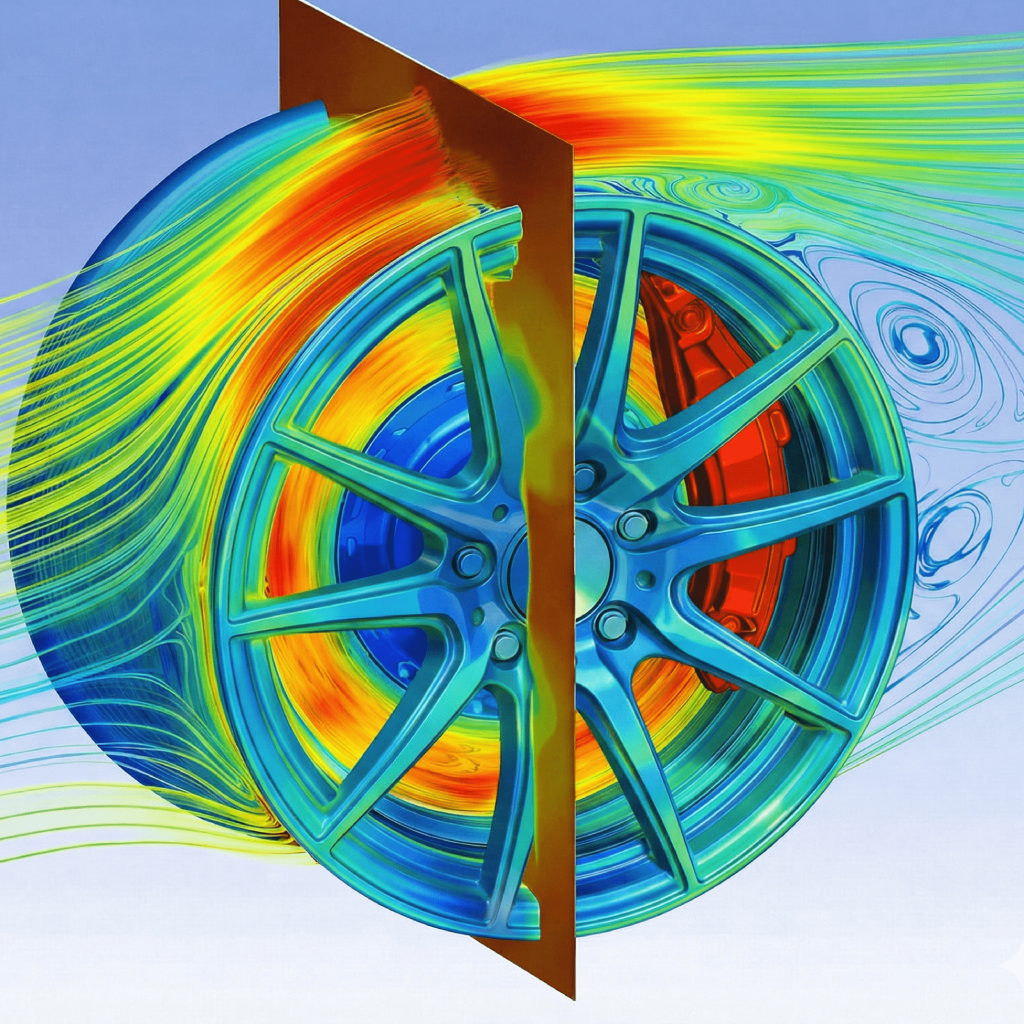

A detailed multi-layer mesh captured boundary layers and rotor airflow, totaling around 18–22 million cells for accurate aerodynamic behavior.

Mesh Generation High-resolution mesh for precision

Simulations applied 120–240 km/h rotation, 20–38 m/s airflow, and realistic brake-heat loads to match both ICE and EV high-speed scenarios.

Boundary Conditions Real-world speed and airflow inputs

The model was tested under rotating conditions to observe velocity, pressure, vortex formation, flow separation, cooling airflow, and drag behavior.

CFD Simulation Runs Steady and transient flow analysis

Final evaluation focused on cooling airflow, drag reduction, pressure balance, vortex intensity, and flow-through efficiency between spokes.

Result Evaluation Key aerodynamic performance indicatorsAerodynamic Performance Outcomes

The final wheel design—optimized using CFD—achieved measurable improvements over a conventional 5-spoke forged wheel

Frequently Asked Questions

These frequently asked questions address common engineering, manufacturing, and integration considerations when developing CFD-optimized forged wheels. They are intended to clarify how simulation-driven design translates into reliable, production-ready solutions for OEM and performance-oriented programs.

No. While aerodynamic effects become more pronounced at higher speeds, CFD optimization is equally valuable for road vehicles, EV platforms, and performance-oriented OEM programs. Improved airflow control benefits brake cooling, energy efficiency, noise reduction, and overall vehicle stability across a wide range of use cases.

CFD delivers the greatest value when integrated at the early design stage. Introducing simulation during initial CAD development allows spoke geometry, vent paths, and structural decisions to be optimized before tooling, reducing redesign cycles and development risk later in the project.

Yes. All CFD-driven design iterations at JCSPORTLINE are developed with forging feasibility and CNC machining constraints in mind. Aerodynamic optimization is validated alongside structural and manufacturing requirements to ensure the final design is production-ready.

Aerodynamic improvements are always validated through FEA structural analysis. Any geometry changes introduced for airflow control are evaluated for fatigue, impact resistance, and load capacity to ensure compliance with automotive safety standards.

No. While the results shown are based on a specific split-Y forged wheel configuration, the underlying CFD methodology and optimization logic are transferable to other spoke layouts, sizes, and vehicle platforms. Each project is adapted based on vehicle requirements and usage conditions.

This level of engineering support is commonly used by OEM programs, performance brands, EV startups, and technical partners that require validated performance, predictable manufacturing outcomes, and long-term development collaboration.

Start Your Forged Wheel Engineering Program

From early-stage simulation to forging and serial production, JCSPORTLINE works as a long-term engineering and manufacturing partner—supporting brands that require precision, consistency, and scalable performance.

A complete 3D model was built, including spokes, hub, barrel surfaces, vent paths, and brake-system surroundings to ensure accurate simulation conditions.

CAD Modeling Full 3D geometry preparation