Table of Contents

When your car reaches high speeds, every curve and angle of its body influences performance. That’s where CFD (Computational Fluid Dynamics) comes in — a science-driven approach that helps you understand how air flows around your vehicle and how a precisely designed rear wing can dramatically improve stability, efficiency, and control.

What Is CFD and Why It Matters for Aerodynamic Design

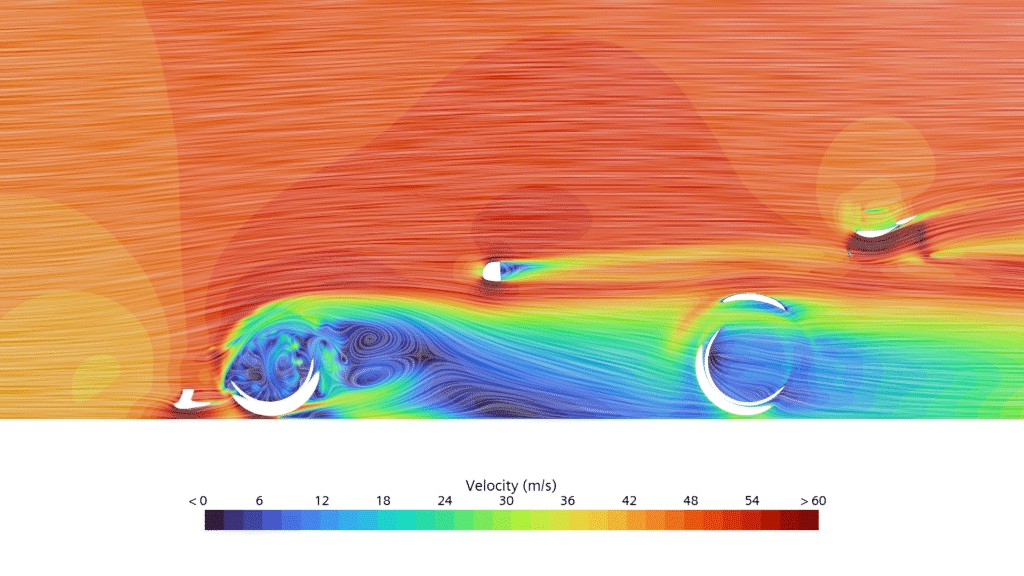

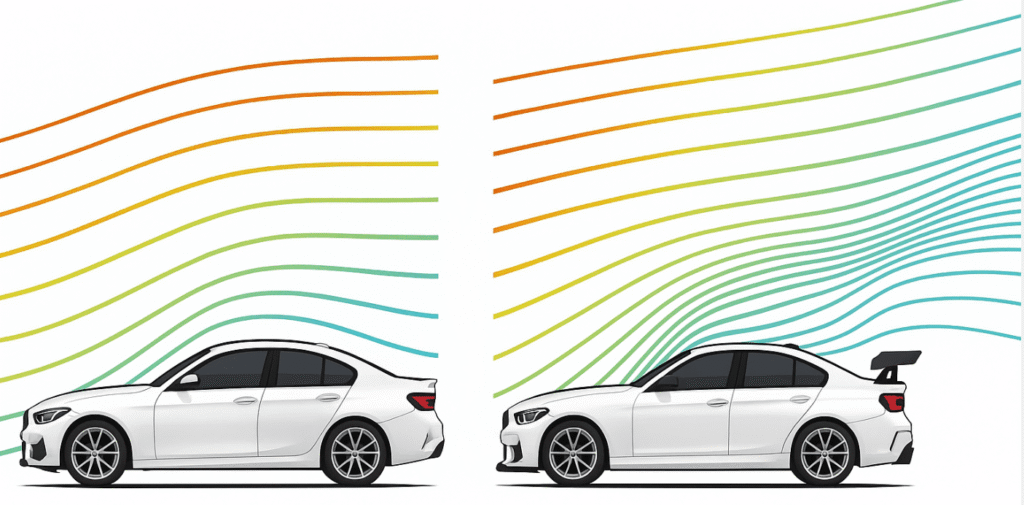

CFD simulates airflow around complex surfaces to analyze how lift, drag, and pressure behave in real time. Instead of relying only on expensive wind tunnel tests, CFD enables engineers to visualize air movement digitally — identifying how a car’s design affects downforce, drag, and stability at different speeds.

Image Suggestion:

3D airflow visualization around a vehicle with and without a rear wing.

Alt Text: CFD airflow simulation comparing car aerodynamics.

How a CFD-Optimized Rear Wing Works

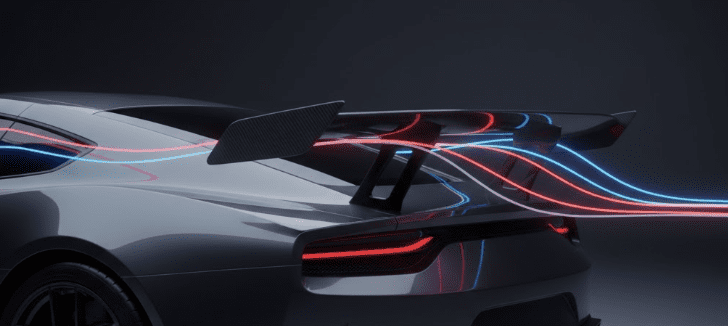

A CFD-designed rear wing helps your car stay planted on the road by redirecting airflow, creating negative lift (downforce) while minimizing aerodynamic drag.

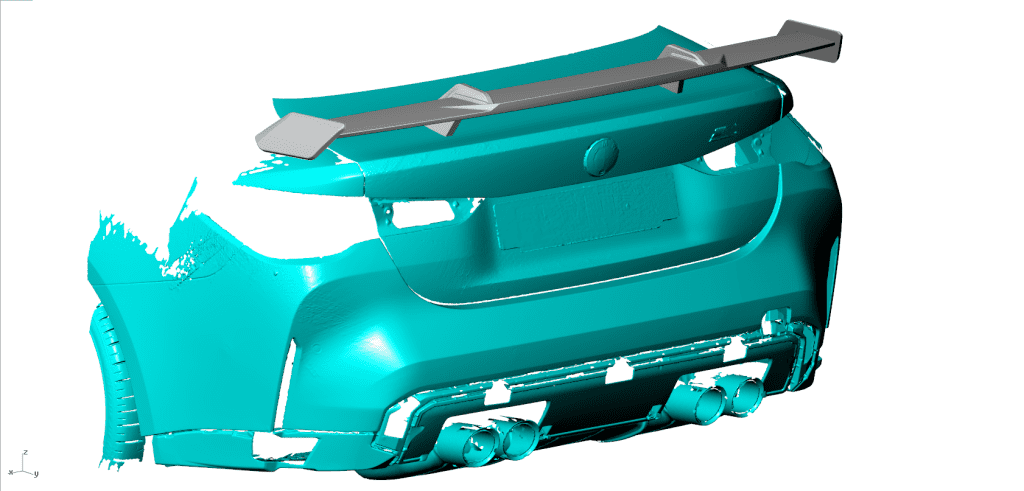

Every JCSPORTLINE rear wing is validated through the same CFD simulation process used by professional tuning brands and OEM partners. Using ANSYS Fluent and real vehicle 3D scans, each design is optimized for aerodynamic efficiency before production — ensuring that what you install on your car delivers measurable, track-proven results.

Unlike conventional designs, JCSPORTLINE’s CFD-tested rear wings are based on 3D scanning and ANSYS Fluent simulations, ensuring real aerodynamic balance — not just visual appeal.

Scientific Validation: Findings from Published CFD Research

According to a 2020 study published in the International Journal for Scientific Research and Technology (IJSART),

CFD analysis of a BMW sedan model revealed:

- A -15° rear wing angle achieved the lowest drag coefficient (Cd = 0.53).

- Drag reduction reached 64.57% compared to cars without a spoiler.

- The optimized setup improved fuel efficiency and high-speed stability.

This confirms what JCSPORTLINE’s in-house CFD simulations have long proven — that precise angle tuning is key to balancing downforce and efficiency.

Behind Every Design — Professional Engineering Support

What you see on your Model Y or M4 is more than a styling upgrade. Each JCSPORTLINE rear wing is engineered under a CFD-validated R&D framework — the same system used in motorsport and OEM aerodynamic development.

With a fully digitalized AI-powered OTD production system, JCSPORTLINE ensures consistent quality and on-time delivery — from prototype to global distribution.

JCSPORTLINE CFD-Validated Rear Wing Advantages

1. Track-Tested Aerodynamics for Real Performance

You get race-proven aerodynamic efficiency without compromising street legality.

Every JCSPORTLINE CFD wing is verified both digitally and physically, ensuring stable airflow and predictable handling.

2. Lightweight Dry Carbon Fiber Construction

Crafted using autoclave-cured dry carbon, the rear wing combines strength, stiffness, and minimal weight — enhancing acceleration and high-speed response.

3. Precision Fitment via 3D Scanning

Each product is developed using real vehicle data.

You’ll enjoy an exact OEM fit with zero need for trimming or adjustment.

🔘 Get Your Personalized Quote Now

🔘 Get Your Aerodynamic Upgrade Plan

CFD Workflow: From Simulation to Real-World Testing

- 3D Vehicle Modeling – Engineers create a digital twin of the car for analysis.

- Flow Simulation (ANSYS Fluent) – Airflow, drag, and lift are simulated at different speeds and wing angles.

- Prototype Validation – CFD findings are confirmed via on-road and track testing.

- Production – Verified data is used to shape molds through CNC machining and autoclave production.

These technologies not only enhance your driving experience but are also trusted by automotive brands, tuning houses, and OEM partners worldwide.

Results You Can Feel

A CFD-validated rear wing offers measurable benefits:

- Reduced aerodynamic drag for better fuel economy

- Enhanced downforce for stable cornering

- Improved high-speed grip and driver confidence

Whether for a race track or a tuned street build, a CFD-engineered rear wing transforms how your car performs.

Why JCSPORTLINE Makes the Difference

Every aerodynamic product starts with engineering precision, but what truly defines performance is how it’s built.

JCSPORTLINE integrates advanced manufacturing and intelligent management to deliver results that go beyond expectations.

1. AI-Powered OTD System

Our AI-driven On-Time Delivery system tracks every production stage in real time — from CNC mold cutting to surface finishing — ensuring your order stays on schedule with full transparency.

2. 58-Day Development Cycle

From concept design to mass production, each project follows a 58-day timeline. This accelerated process allows dealers and tuners to bring new products to market faster than ever.

3. Consistent Quality Control

Every carbon fiber part is produced under ISO9001 and IATF16949-certified standards. JCSPORTLINE guarantees stable weave alignment, precise fitment, and flawless finish — batch after batch.

4. Advanced Carbon Fiber Technology

Using autoclave-cured dry carbon and CNC aluminum molds, we achieve lightweight strength and visual perfection that outperforms conventional wet carbon parts.

5. Global OEM & Dealer Support

JCSPORTLINE partners with tuning brands and OEMs worldwide, offering engineering files, branding customization, and global logistics coordination.

6. Data-Driven Improvement

Through AI analysis and digital tracking, our production system continuously refines accuracy, efficiency, and repeatability — ensuring long-term reliability for every project.

FAQ

Q1: What makes a CFD rear wing different from regular spoilers?

CFD wings are developed using fluid dynamic simulation, providing data-backed aerodynamic improvements instead of purely aesthetic designs.

Q2: Can a CFD wing be used on a street car?

Yes. JCSPORTLINE designs its CFD rear wings for both track and road use with perfect balance between performance and daily drivability.

Q3: How does wing angle affect performance?

Based on simulation data, a moderate negative angle (around -15°) offers optimal drag reduction and stability.

Q4: What’s the production lead time for a custom CFD wing?

JCSPORTLINE smart manufacturing system ensures concept-to-production in just 58 days.

Q5: Are these CFD wings tested to OEM standards?

A: Yes. All JCSPORTLINE aerodynamic parts are validated under ISO9001 and IATF16949-certified processes, combining simulation data with real-world testing to meet OEM-grade fitment and safety standards.