Table of Contents

Crooked Logos Kill Brands. Here’s How We Fix That.

Three months ago, we got an angry email from a new German client:

“Every spoiler has a different logo position! Some are too far left, some too high. How can we sell these?”

This wasn’t just about appearance — it was about trust.

The product looked sloppy. The customer blamed us. But in truth, those parts were made by a third-party factory, with logos applied by hand after production.

Since then, that customer handed all logo work to JCSPORTLINE.

We told them:

“To us, logo placement is not an afterthought — it’s part of the production line.”

Why Do Custom Logos Go Wrong?

If you’ve ever dealt with poorly placed or peeling carbon fiber logos, you’ve probably experienced one of these:

- No proper process — logo placement done by eye

- Logo applied after clear coat — can peel or bubble

- Cheap sticker quality — inconsistent size or color

- No tracking — wrong logos placed on the wrong SKUs

- No positioning jig — every part looks slightly different

- That’s not “custom.” That’s chaos.

Our 4 Logo Solutions — Ranked by Effectiveness

✅ 1. Logo Under Clear Coat (Recommended)

- Logo is applied before clear coat

- Becomes part of the surface — no peeling or bubbles

- Every SKU has logo instructions in our MES system

Cost:

- Setup/sample fee: $150

- Per-part cost: $5 labor + sticker material

- Optional jig (for perfect alignment): $50 per car model

- Best For: Brands that care about long-term quality and consistency

✅ 2. Logo Built into Mold

- Logo shape is part of the mold — clean, permanent

- No color, but perfect consistency

- Great for subtle branding or structural parts

✅ 3. Logo on Packaging or Accessories

- Fastest, cheapest option

- No changes to production

- Great for online sellers or budget-sensitive clients

❌ 4. Logo Applied After Production

- Worst option. Most prone to peeling, errors, and complaints

- Not offered as a standard service by JCSPORTLINE

What Makes JCSPORTLINE’s Logo Process Different?

We built a complete system to control every step:

- ✅ SKU-level MES tracking

- ✅ +/- 1mm jigs for precise placement

- ✅ Trained workers with step-by-step SOPs

- ✅ QC process includes logo inspection

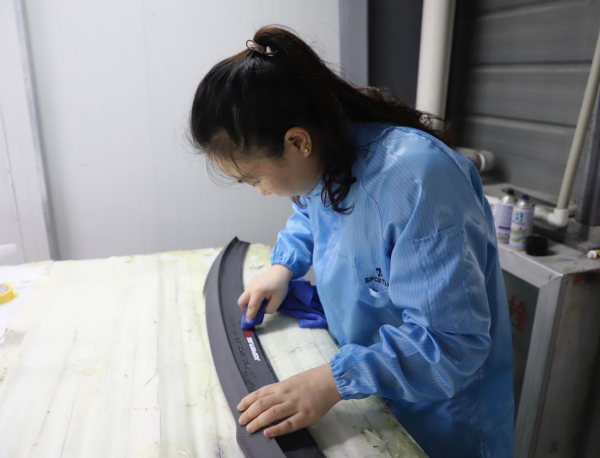

- ✅ Logo application is done in a clean room environment

What Do You Really Get?

- You don’t just get a part with a logo.

- You get a product that represents your brand — one you can proudly show on your website, display in a showroom, or ship to your top clients.

Who Should Do Logo Customization?

Logo branding is a smart choice for:

- Wholesalers and resellers with their own brand

- Performance shops building custom product lines

- 2B customers who care about consistency and resale value

- Brands trying to stand out in a competitive market

Ready to Customize Your Logo?

We make it easy:

- Send us your logo file + car model

- Get a full quote and layout within 3 business days

- Want to test on multiple models? We support combined sampling to save costs

Get Started Now

- Click Contact Us and send your logo + part info.

- Let’s make your carbon fiber parts look as professional as your brand deserves.

About JCSPORTLINE

With over 20 years of experience in carbon fiber manufacturing, JCSPORTLINE helps global clients turn ideas into high-quality car parts — from full kits to small details like logos.

We build for strength, precision, and style.