Table of Contents

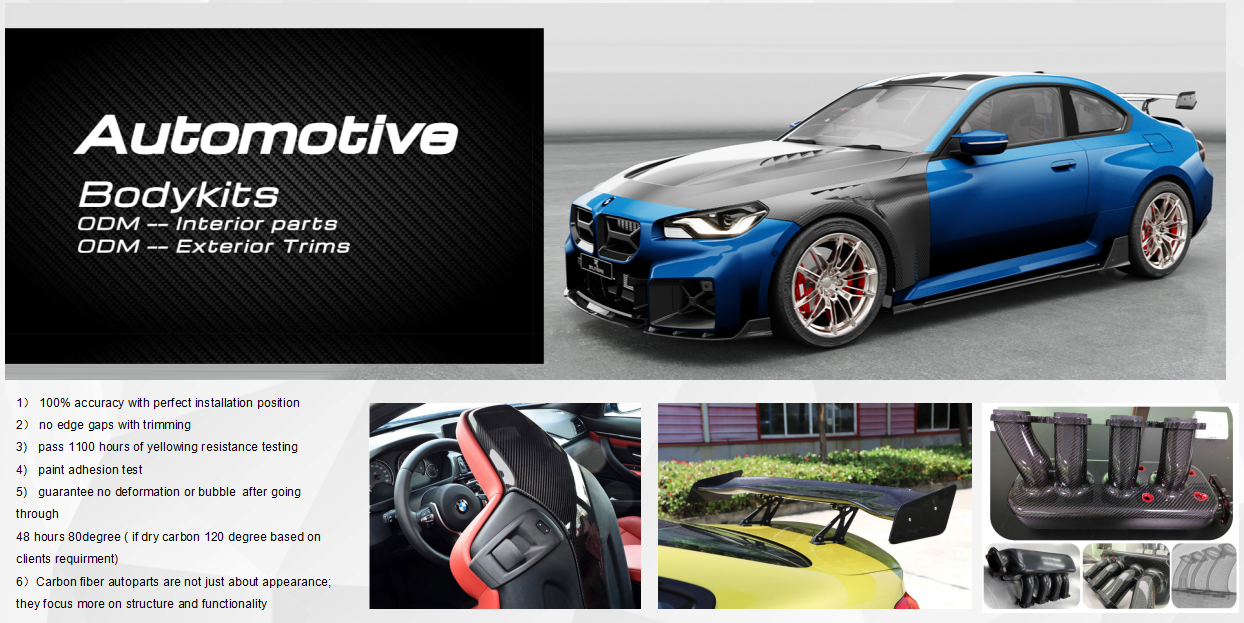

Are you part of a car club or a team of car enthusiasts? Looking for a way to stand out with a truly unique style? That’s where JCSPORTLINE comes in. With over 20 years in carbon fiber manufacturing and advanced precision engineering, we help clubs turn their ideas into custom carbon fiber parts that meet the most demanding technical requirements.

Whether you need lightweight carbon fiber composites, durable carbon fiber materials, or bulk carbon fiber products, our production line and engineering services ensure a professional solution from idea to final product.

Why Car Clubs & Teams Love Custom Carbon Fiber Parts & High Performance

Custom carbon fiber composite parts aren’t just for looks—they bring measurable benefits:

- Stand out in your community: A carbon fiber panel or kit makes your club recognizable.

- Performance edge: Thanks to carbon atoms arranged in tightly bonded structures, carbon fiber is considered one of the strongest materials in the automotive industry.

- Light weight: Helps reduce fuel consumption, improve high speeds, and reduce weight compared to metal, plastic, or aluminum.

- Cost effective: Group orders lower cost, while matched tooling and wet layup techniques optimize production.

- Durability: Superior mechanical properties provide resistance to heat, high temperatures, and many applications like cars, medical devices, and aerospace.

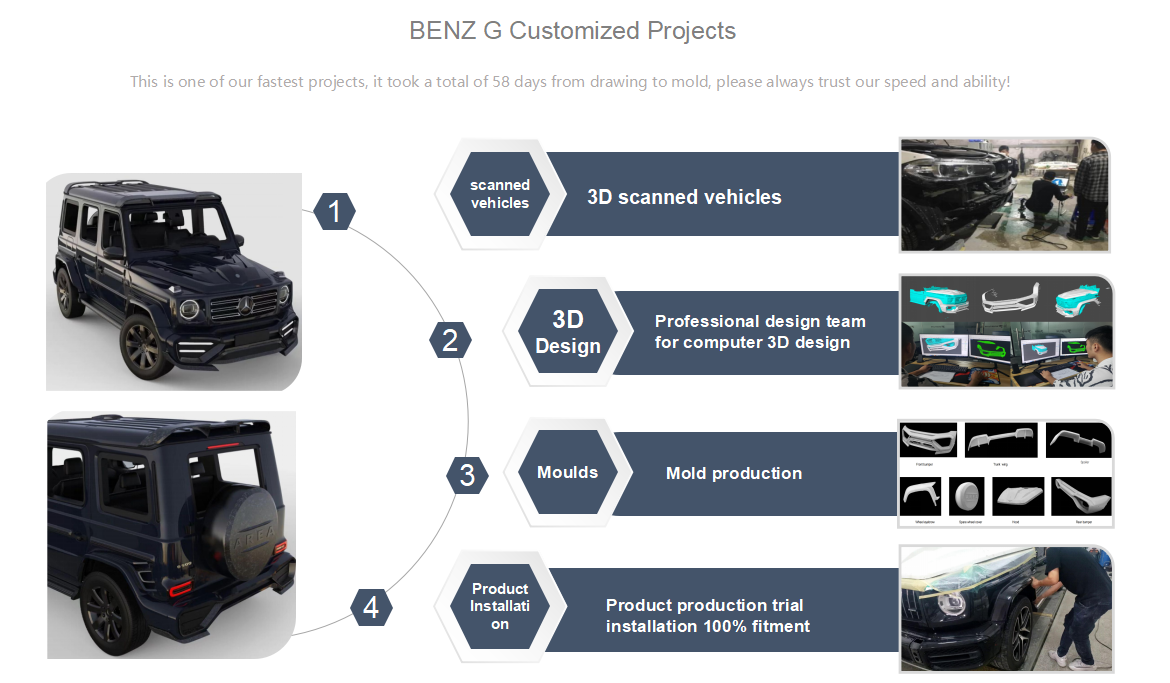

How JCSPORTLINE Works With Car Clubs – From Carbon Fiber Part Design to Custom Orders

We make the manufacturing processes simple, ensuring every step delivers quality services.

Collect Fan Suggestions

- Your members share custom orders ideas.

- Clubs usually request 20–100 sets of carbon fiber parts.

- Input can be sketches, CAD files, or even a short description of the project.

Design & Precision Engineering

- Our team translates your ideas into carbon fiber part design using CAD and matched tooling.

- Prototypes are shaped using advanced mold and vacuum bagging processes, ensuring high performance and technical requirements are met.

- This stage balances innovation with practical engineering services.

Production & Fabrication

- Once approved, the production line begins carbon fiber fabrication.

- We combine fibers, resin, and other materials in optimized manufacturing processes like wet layup or vacuum bagging.

- Bulk production makes it possible to deliver to customers quickly, meeting both market demand and club customization options.

Installation & Final Product

- Clubs showcase their final product at events, proving that composite material offers superior performance compared to other materials.

- The result: a unique, extremely strong and high strength solution that is cost effective and stylish.

Success Stories

- Tesla Club: Developed carbon fiber panels and aero kits using advanced production techniques.

- Audi S4/S5 Club: Customized interior components with carbon fiber parts manufacturing and premium quality control.

- Camaro Club: Ordered custom carbon fiber kits through a supplier partnership, improving brand exposure and fan loyalty.

These examples highlight how manufacturing innovation combined with custom carbon fiber solutions can transform components into a competitive advantage.

Why Choose JCSPORTLINE – Experts in Custom Carbon Fiber Solutions

- Experience: Over 20 years in carbon fiber parts manufacturing and composite development.

- High Performance Solutions: From carbon fiber materials to advanced production processes, every step is optimized for strength, rigidity, and stability.

- Engineering Services: We deliver precision engineering and technical solutions for automotive, aerospace, and even medical devices.

- Cost Effective Production: Using wet layup, vacuum bagging, and matched tooling, we produce components efficiently while meeting quality standards.

Get Started Today

If your car club or team is ready to explore carbon fiber fabrication, JCSPORTLINE is your trusted supplier. From raw materials and carbon atoms to non carbon atoms blended in composite material, we master the processes that lead to innovation and performance.

🚗 Contact us now to discuss your project and see how our engineering services and custom orders can deliver a final product that matches your vision.