Table of Contents

The Real Price of Perfection: What “Custom” Actually Means

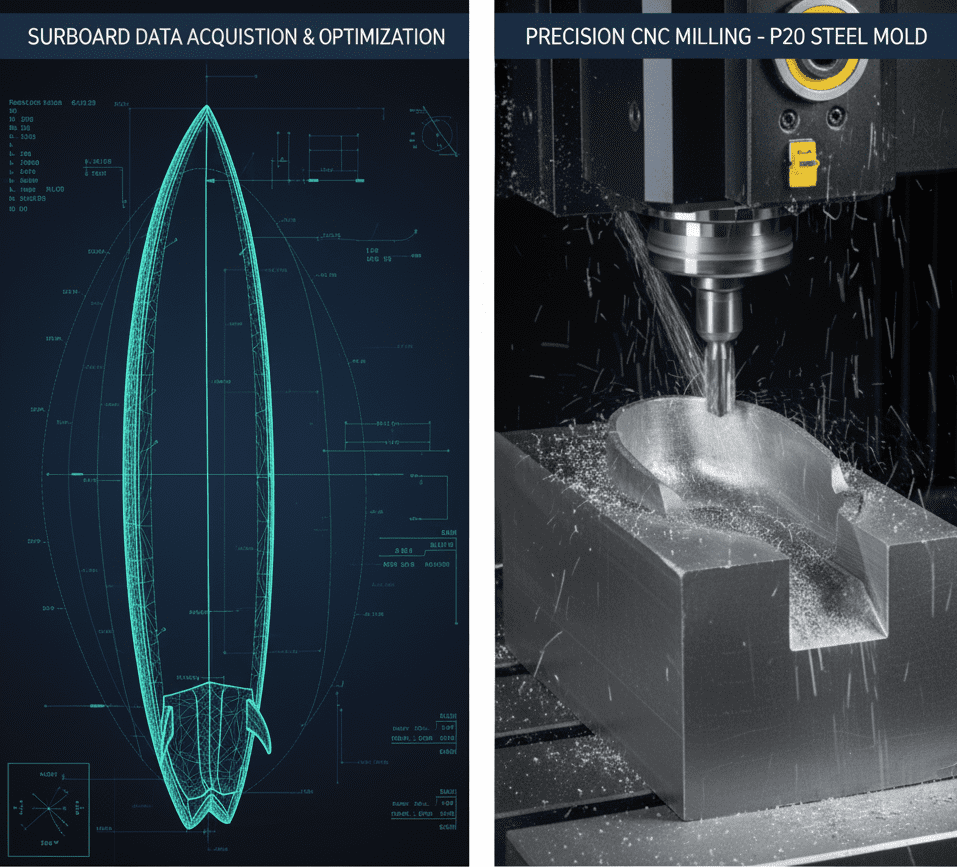

When it comes to high-performance surfboards, the term “custom” is often misunderstood. For many riders, a custom board isn’t just about aesthetics—it’s about performance tailored specifically to their needs. A board that matches your weight, stance, and local break can make all the difference between an average session and an unforgettable ride. At JCSPORTLINE, customization starts with precision engineering, not a stock blank or a simple paint job. Every custom surfboard begins its journey as a 3-D rider file, meticulously crafted to reflect the unique biomechanics and preferences of the surfer. This ensures that every detail, from the rocker curve to the fin placement, aligns perfectly with how you ride.

From CAD to Curl: How Your Personal Surf Geometry Is Born

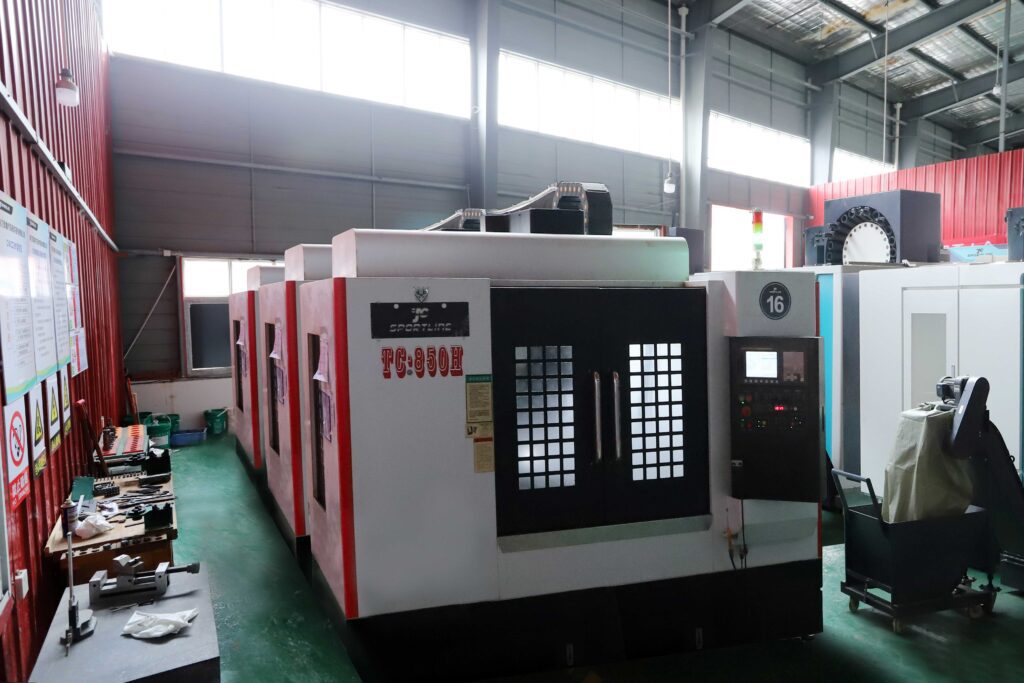

The process of creating a personalized surfboard shape begins long before the first layer of carbon fiber is laid. It starts with raw data—your weight, height, riding style, and even the characteristics of your local break. This information is fed into advanced CAD software, where engineers translate it into a digital blueprint. Using five-axis CNC machining, this blueprint is transformed into a P20 steel mold with tolerances as tight as ±0.1 mm. These molds are not only precise but also polished to a mirror finish (Ra ≤ 0.8 µm), ensuring that every board emerges flawless.

For example, consider a surfer who frequents a beach with fast-breaking waves. Their custom board might feature a steeper rocker and narrower tail for better control in sharp turns. Conversely, someone riding gentler swells might benefit from a flatter rocker and wider outline for enhanced glide. This level of personalization ensures that every JCSPORTLINE board is as unique as the rider it was made for.

One Board, One Mold: The Hidden $8k Block of Steel

Behind every custom surfboard lies a hidden hero: the P20 steel mold. These molds, which cost more than most off-the-rack boards, are the backbone of JCSPORTLINE’s customization process. Each mold is machined using state-of-the-art CNC technology, ensuring tolerances within ±0.1 mm. This precision eliminates common issues like resin-rich spots, which can add unnecessary weight and compromise performance.

But the value of these molds goes beyond their initial cost. JCSPORTLINE employs a reusable modular mold system, meaning your custom geometry is archived for future re-orders. Whether you want an identical board years later or a slight variation, your design is always accessible.

To put the quality of these molds into perspective, imagine a mirror-finish surface so smooth that it reflects light like glass. This level of craftsmanship ensures that every board produced meets the highest standards of durability and performance.

By integrating cutting-edge technology with meticulous craftsmanship, JCSPORTLINE redefines what it means to own a custom surfboard. Whether you’re chasing barrels or perfecting cutbacks, a board tailored to your exact specifications can elevate your surfing experience to new heights.

Inside the Black Fiber: Materials That Outperform (and Outprice) Foam

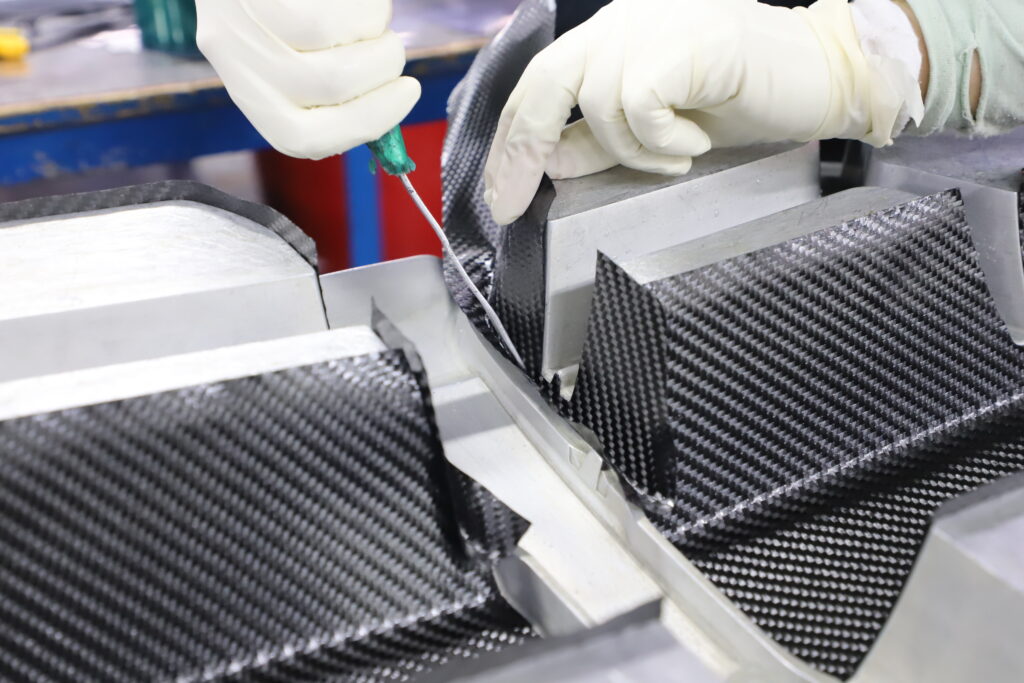

When it comes to high-performance surfboards, materials matter. The difference between a foam-based board and one made with advanced composites like prepreg carbon fiber is night and day. These cutting-edge materials are designed not just to outlast traditional options but to elevate your riding experience in ways that truly matter.

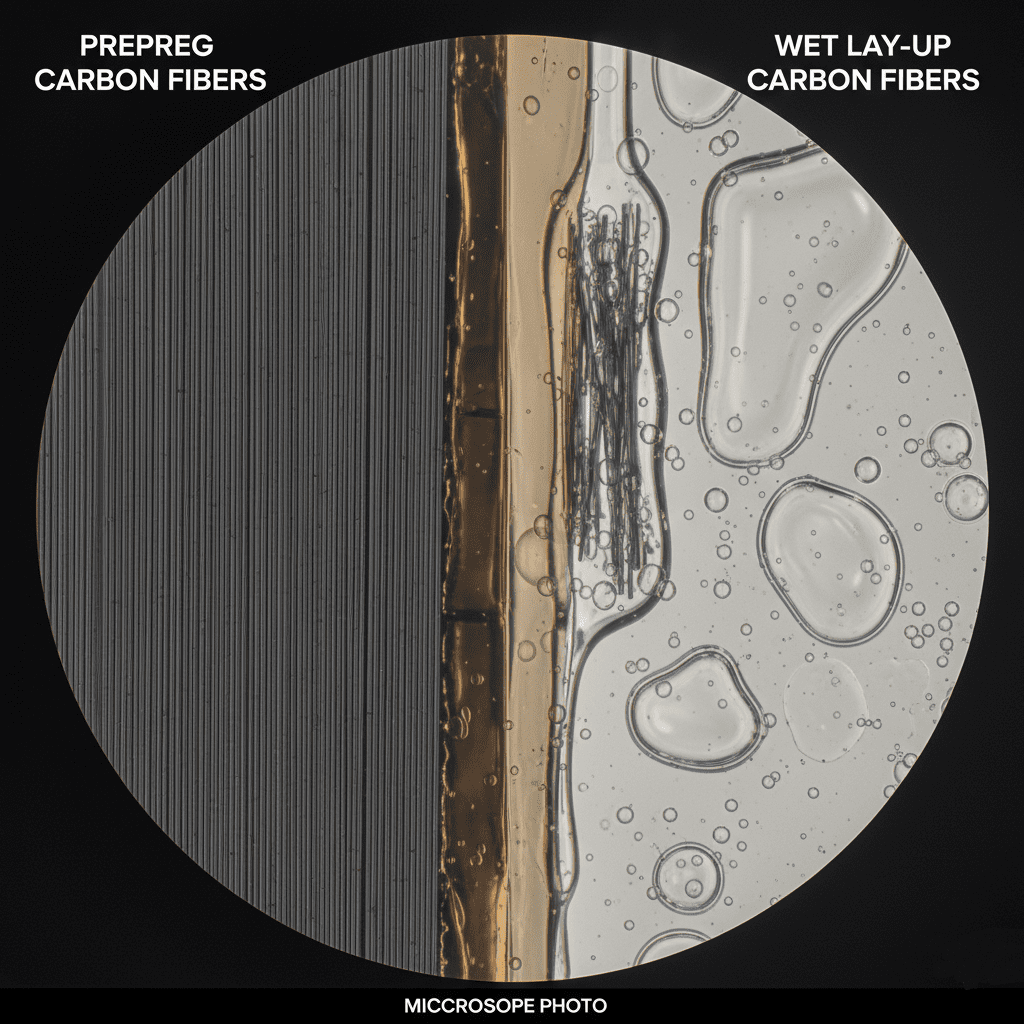

Aerospace-Grade Prepreg vs. Wet Lay-up: A 3× Price Jump

If you’re serious about performance, aerospace-grade prepreg carbon fiber is the gold standard. Unlike wet lay-up methods, which involve manually applying resin to fibers, prepreg carbon is pre-impregnated with precise amounts of resin under controlled conditions. This ensures consistent quality and unmatched performance. For riders, this translates into 20% more tensile strength at 30% less weight, allowing for quicker pop-ups and smoother transitions on the wave.

At JCSPORTLINE, we take prepreg technology to the next level by vacuum-consolidating our boards at 120°C to achieve a void content of less than 1%. This process, borrowed from Formula 1 monocoque construction, eliminates air pockets and ensures maximum structural integrity. The result? A board that feels lighter underfoot yet performs with unparalleled rigidity and responsiveness.

While prepreg carbon surfboards come at a premium price—often three times that of wet lay-up alternatives—the benefits far outweigh the cost. Riders can expect superior durability, reduced fatigue during long sessions, and enhanced control in challenging conditions.

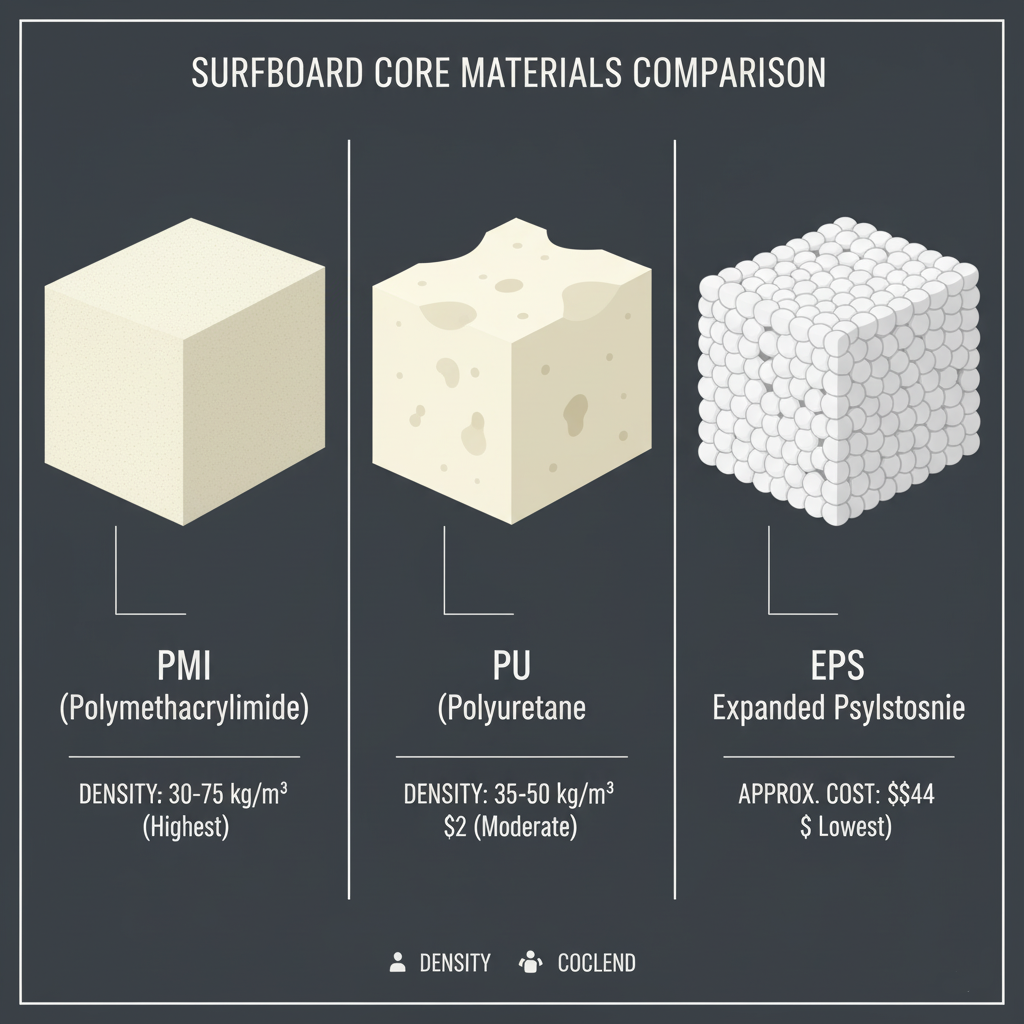

Core Choices: PMI vs. PU—Density, Dollars, Durability

The core material of a surfboard plays a critical role in its overall performance, influencing everything from buoyancy to flex characteristics. Two popular options dominate the market: PMI (polymethacrylimide) and PU (polyurethane). While PMI is often considered the “gold” core due to its exceptional density-to-weight ratio and durability, it comes with a steep price tag.

At JCSPORTLINE, we offer an innovative PU alternative that matches PMI’s density (approximately 40 kg/m³) while reducing costs by 60%. Our proprietary CNC shaping process ensures the core is machined to within ±0.2 mm tolerances. This precision allows the carbon skin to distribute loads evenly across the board, eliminating weak points and preventing issues like heel dents even after months of heavy use.

Our commitment to quality extends beyond affordability. Each board undergoes rigorous testing, including salt spray resistance and thermal cycling, to ensure it holds up in real-world conditions. Whether you’re carving through barreling waves or enduring a harsh winter session, our PU-core boards deliver reliable performance without breaking the bank.

By leveraging advanced materials and meticulous manufacturing processes, JCSPORTLINE redefines what’s possible in surfboard design. From aerospace-grade prepreg carbon to precision-engineered PU cores, every detail is crafted to enhance your ride while maintaining value for money.

Whether you’re chasing speed, agility, or longevity, these innovations ensure you’ll never have to compromise on performance again.

3 Engineering Tricks That Keep You in the Water, Not the Repair Shop

When it comes to high-performance surfboards, durability and design go hand in hand. At JCSPORTLINE, we’ve engineered three key innovations that ensure your board stays in the water—and out of the repair shop. From seamless construction to corrosion-resistant hardware, these tricks are game-changers for surfers who demand reliability and performance.

Seamless Monocoque: Why You Won’t Find a Rail Line

The secret to a truly durable surfboard lies in its construction process. Traditional boards often rely on secondary rail tape to seal seams, which can lead to weak points prone to leaks and delamination. At JCSPORTLINE, we’ve eliminated this vulnerability with our one-shot compression-mold process. This advanced technique fuses the deck, rails, and hull into a single, cohesive unit—creating a monocoque carbon surfboard that’s as strong as it is sleek.

By integrating all components in one step, we eliminate the need for secondary rail tape entirely. This seamless design ensures there are no weak seams or potential leak points, making the board not only more durable but also lighter and faster in the water. Additionally, we’ve taken extra care to hide the vent valve inside the handle, removing the need for additional holes that could compromise structural integrity.

This innovative approach isn’t just about aesthetics—it’s about performance. The absence of stress concentrations along the rail ensures consistent flex and responsiveness, giving surfers unmatched control.

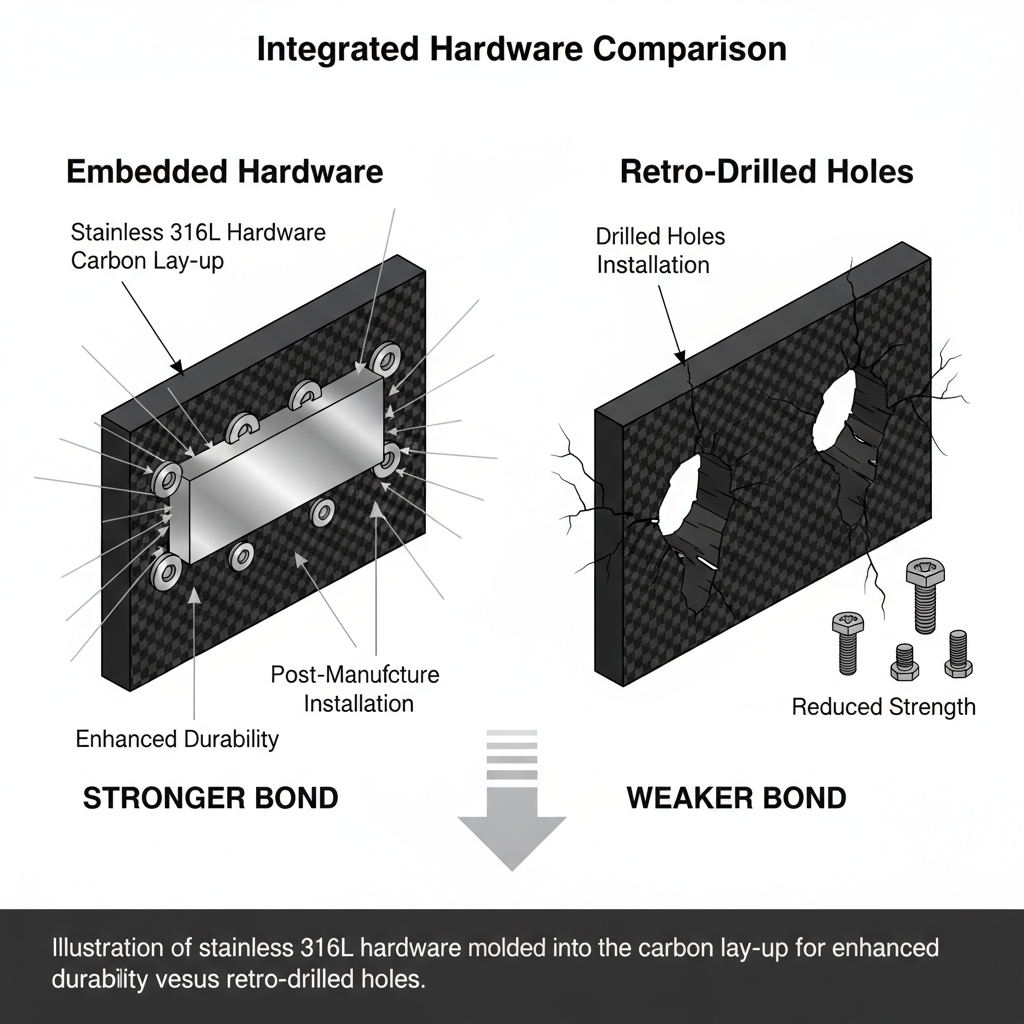

Stainless 316L Hardware: 1,000-Day Salt-Water Warranty

Another critical factor in surfboard longevity is the quality of its hardware. At JCSPORTLINE, we’ve invested in custom-machined 316L stainless steel components, including fin boxes, leash plugs, and waterproof M6 screws. These parts are specifically designed to withstand the harsh conditions of saltwater environments, offering a 1,000-day salt-water warranty—a testament to their durability.

Unlike traditional boards where hardware is retro-drilled into the structure, our 316L components are molded directly into the carbon lay-up. This integration ensures there are no “soft spots” or weak areas around the hardware, maintaining the board’s structural integrity over time. Each piece is precision-engineered to meet a 3-year anti-corrosion specification, ensuring long-term performance even in the most demanding conditions.

The Cost of Quality

While the cost of custom-machined 316L hardware is higher than standard alternatives, the investment pays off in reliability and longevity. For example, our corrosion-resistant fin boxes and leash plugs are built to last, reducing the need for frequent replacements and repairs.

A Closer Look

An exploded view illustration can help visualize the difference between our embedded hardware and retro-drilled alternatives. In our design, you’ll see how each component is seamlessly integrated into the carbon stack, eliminating the risk of water ingress or structural failure.

Digital Precision and Sustainable Production

Behind every JCSPORTLINE surfboard is a commitment to precision engineering and sustainability. Our production process leverages cutting-edge technologies to ensure consistency and minimize environmental impact.

Advanced Manufacturing Techniques

- Prepreg Layup: Using intelligent cutting systems, we achieve edge precision of ±0.2mm for carbon fiber prepreg materials. This accuracy ensures optimal weight distribution and structural strength.

- High-Temperature Curing: The mold is cured at 150°C for 90 minutes, ensuring maximum bonding strength and eliminating air pockets or defects.

- Quality Control: Every board undergoes ultrasonic scanning (UT) and industrial CT detection to identify internal flaws. With a defect rate below 0.5%, our boards meet the highest standards of quality.

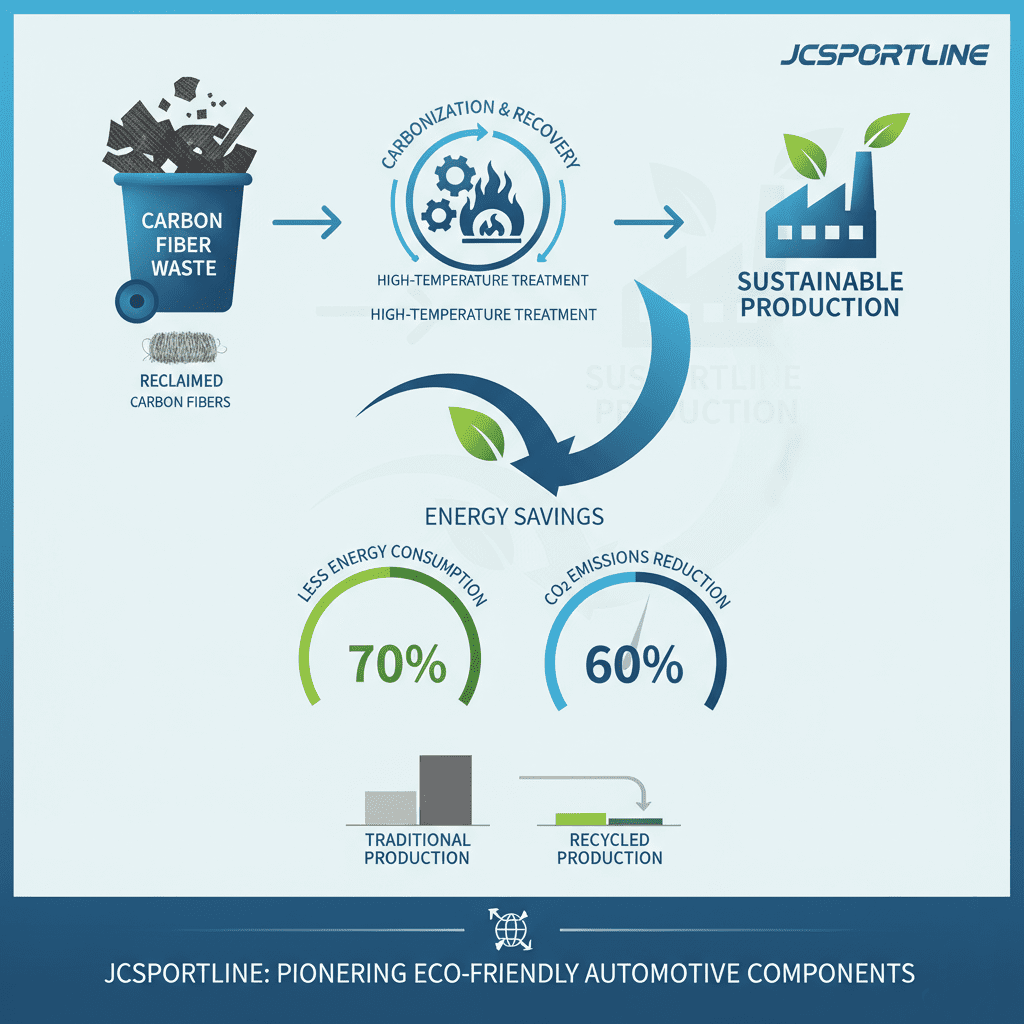

Eco-Friendly Innovations

Sustainability is at the heart of our operations. We recycle over 90% of carbon fiber waste through carbonization processes and use solar-powered curing ovens to reduce energy consumption by 30%. These efforts not only protect the planet but also enhance the efficiency of our production line.

Final Thoughts

At JCSPORTLINE, we believe that innovation should serve both performance and durability. By combining seamless monocoque construction, corrosion-resistant 316L hardware, and precision manufacturing, we’ve created surfboards that are built to last. Whether you’re tackling big waves or perfecting your turns, our boards are designed to keep you in the water—and out of the repair shop.

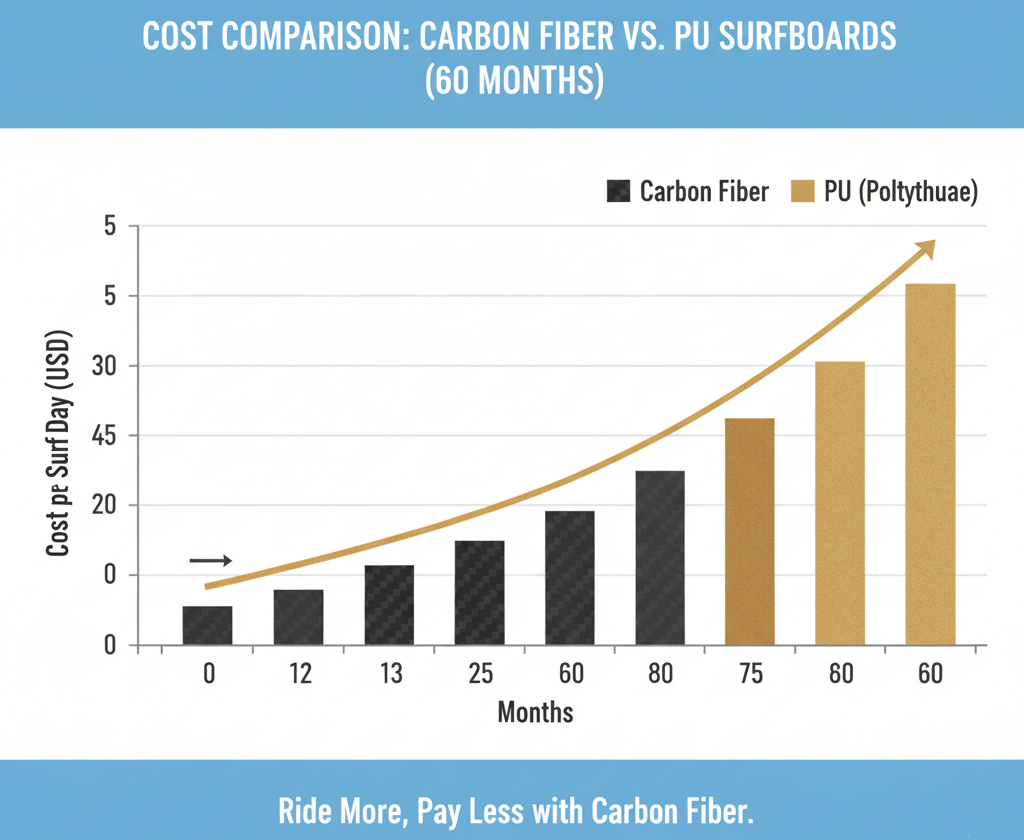

4 Value Math: Why a $3k Custom Saves You $1k per Year

Investing in a custom carbon surfboard isn’t just about performance—it’s also a smart financial decision. While the upfront cost of a premium carbon board might seem steep compared to traditional PU pop-out boards, the long-term savings and value are undeniable. Let’s break it down.

Lifespan Spreadsheet: Custom Carbon vs. PU Pop-Out

When evaluating surfboard options, durability is a key factor. A custom carbon surfboard can last 5+ seasons with proper care, thanks to its superior material properties. On the other hand, PU pop-out boards typically last only 2 seasons before showing significant wear and tear. This difference alone has a profound impact on your total cost of ownership.

To help you visualize this, we’ve created a downloadable Google Sheet template branded with JCSPORTLINE colors. This spreadsheet allows you to input variables like initial cost, airline fees, and resale value to calculate your personal ROI. Here’s what you’ll discover:

- Airline Fees: A lightweight carbon board weighs around 8 kg, while a PU board averages 12 kg. For frequent travelers, those extra kilos translate into higher baggage costs. Over multiple trips, these fees add up significantly.

- Resale Value: Carbon boards retain approximately 60% of their value, whereas PU boards often drop to just 20% after two seasons. Selling your carbon board later recoups more of your investment.

Cost Breakdown Table

| Factor | Carbon Board | PU Board | Savings (Carbon) |

|---|---|---|---|

| Initial Cost | $3,000 | $1,500 | – |

| Airline Fees (5 yrs) | $400 | $800 | $400 |

| Resale Value | $1,800 | $300 | $1,500 |

| Total Ownership Cost | $1,600 | $2,000 | $400 |

This table clearly shows how a carbon surfboard saves you money over time, even with a higher upfront investment.

Your Next Step: Locking in Your Mold Before Price Increases

With rising material costs, now is the perfect time to secure your custom carbon surfboard. Steel and prepreg prices have increased by 12% year-over-year, and these trends show no signs of slowing down. To ensure you lock in today’s pricing, JCSPORTLINE offers a convenient 10% deposit program that reserves your mold slot and freezes material costs until production begins.

How It Works

- Book a CAD Review: Click on our interactive calendar to schedule a 15-minute consultation with one of our expert surf engineers. They’ll guide you through the design process and answer any questions about customization options.

- Secure Your Slot: Pay a 10% deposit to reserve your place in the production queue. This guarantees your board will be crafted using current material prices, shielding you from future increases.

- Finalize Details: Work closely with our team to finalize dimensions, graphics, and additional features tailored to your riding style.

By acting now, you not only save money but also ensure timely delivery of your dream board.

In conclusion, investing in a custom carbon surfboard from JCSPORTLINE isn’t just about enjoying unparalleled performance—it’s about making a financially savvy choice. With extended lifespan, reduced airline fees, and better resale value, the numbers speak for themselves. Don’t wait—lock in your mold today and start saving tomorrow!

FAQ: Quick Answers to the Price Questions We Hear Every Day

When it comes to custom carbon surfboards, questions about pricing, durability, and performance are common. To help you make an informed decision, we’ve compiled this quick-reference FAQ section with clear answers to your most pressing concerns. Let’s dive in!

Why Does a Carbon Mold Cost More Than the Board Itself?

Creating a high-quality carbon mold is a meticulous process that involves advanced techniques like modular compression molding and high-temperature curing (up to 150°C). These molds are engineered for precision and longevity, ensuring every board produced meets exacting standards. Here’s why they come at a premium:

- Material Quality: The mold itself uses specialized materials capable of withstanding repeated thermal cycles without warping or degrading.

- Labor Intensive: Crafting a mold requires skilled technicians who meticulously layer carbon fiber and foam core structures by hand.

- Long-Term Value: While the initial cost may seem steep, a single mold can produce hundreds of boards, spreading its expense across multiple units.

For those seeking carbon surfboard mold reuse, rest assured that investing in a durable mold ensures consistent quality over time.

Can I Reuse My Custom Mold for a Different Size?

Unfortunately, custom molds are highly specific to the dimensions and design of the original board. Here’s why reusing them for different sizes isn’t feasible:

- Precision Fit: Each mold is tailored to match the exact curvature, rail shape, and thickness profile of the intended design. Altering these parameters would compromise structural integrity.

- Design Constraints: Adjustments to size often require changes to the internal structure, such as foam core placement or reinforcement layers, which cannot be retrofitted into existing molds.

If you’re considering a new size or design, our team can create a fresh mold optimized for your needs while maintaining the same level of craftsmanship.

How Much Lighter Will My Carbon Board Be Versus PU?

One of the standout advantages of carbon fiber construction is its exceptional strength-to-weight ratio. Compared to traditional PU (polyurethane) boards, carbon boards offer significant weight savings—up to 30% lighter, depending on the configuration.

Here’s a breakdown of typical weight differences:

| Material | Average Weight (kg) | Notes |

|---|---|---|

| PU Surfboard | 12–14 | Heavier but softer flex |

| Carbon Surfboard | 8–9 | Stiffer, more responsive |

This carbon board weight savings translates to enhanced maneuverability and reduced fatigue during long sessions. Plus, the added rigidity improves speed and control, making it ideal for competitive surfers.

Does the Seamless Rail Really Never Crack?

The claim of “never cracking” might sound bold, but it’s backed by cutting-edge manufacturing techniques and rigorous testing protocols. Here’s how we achieve unparalleled durability:

- One-Piece Molding: Our seamless rail design eliminates weak points caused by traditional seam lines, resulting in a uniform structure that resists stress fractures.

- High-Strength Coatings: Specialized finishes ensure resistance to environmental factors like UV exposure and temperature fluctuations, preventing delamination or chipping.

- Impact Testing: Boards undergo dynamic simulations to verify their ability to withstand impacts equivalent to real-world conditions.

While no product is entirely indestructible, our seamless rail technology minimizes the risk of cracks significantly better than conventional designs.