- Home

- Services

- Industries

- Capabilities

- Resources

- Company

Project Overview

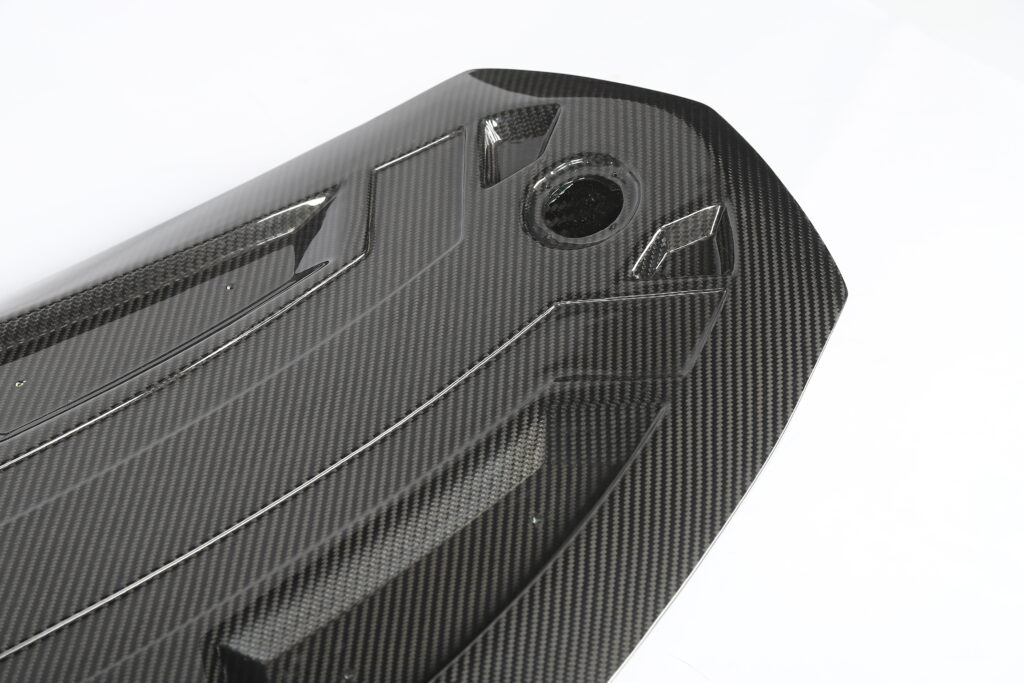

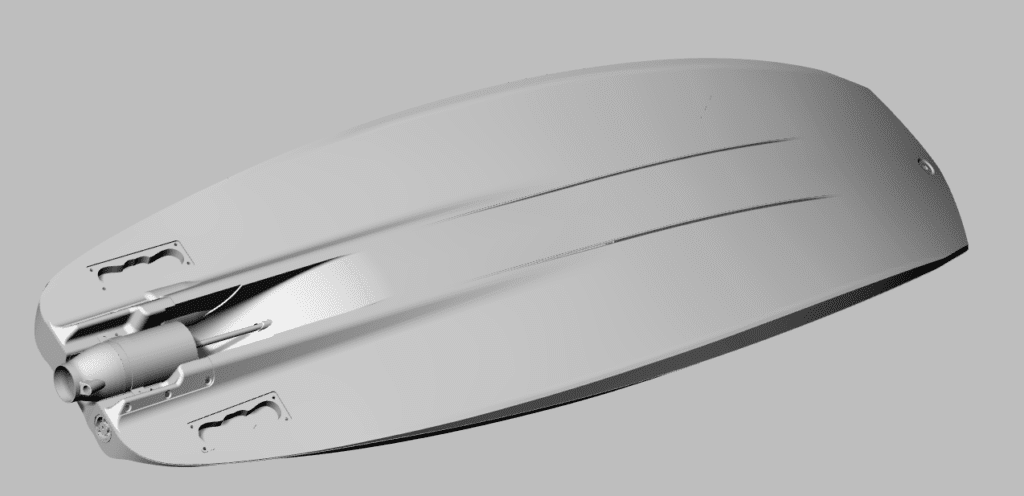

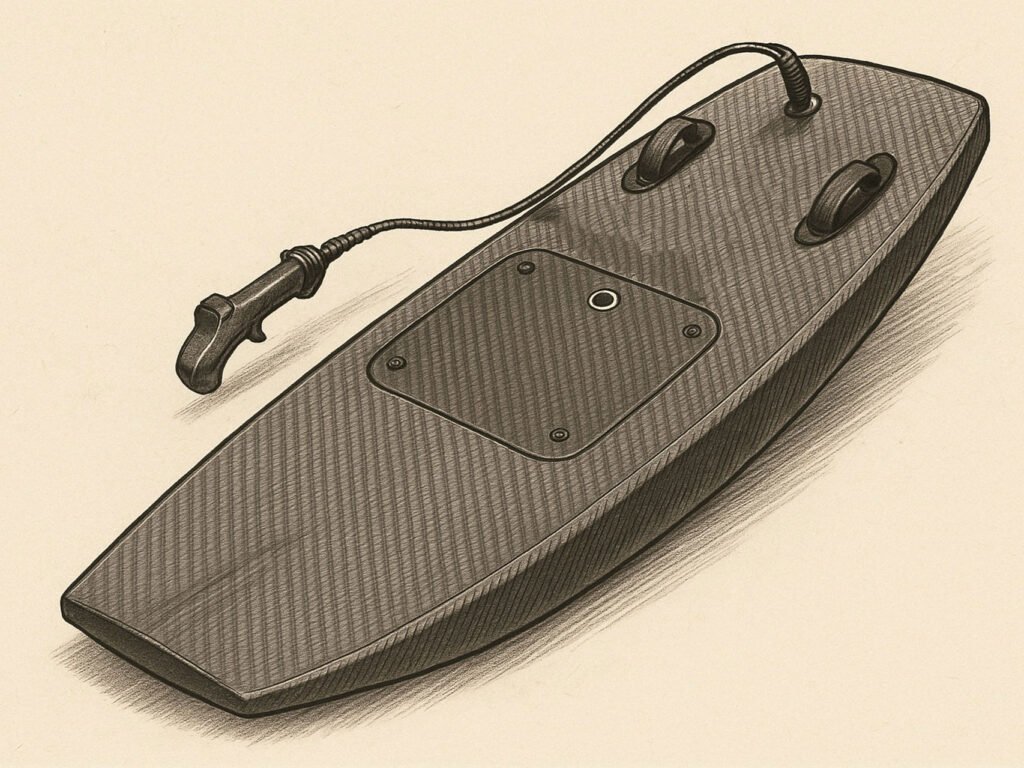

We developed a custom carbon fiber electric surfboard for a premium watersports brand, combining lightweight prepreg carbon construction, high-performance electric propulsion, and hydrodynamic design. From 3D modeling to autoclave production, JCSPORTLINE delivered a motorized surfboard with exceptional speed, agility, and durability — a scalable solution for marine sports brands and aftermarket innovators.

Carbon fiber surfboard solutions

Advanced One-Piece Molding

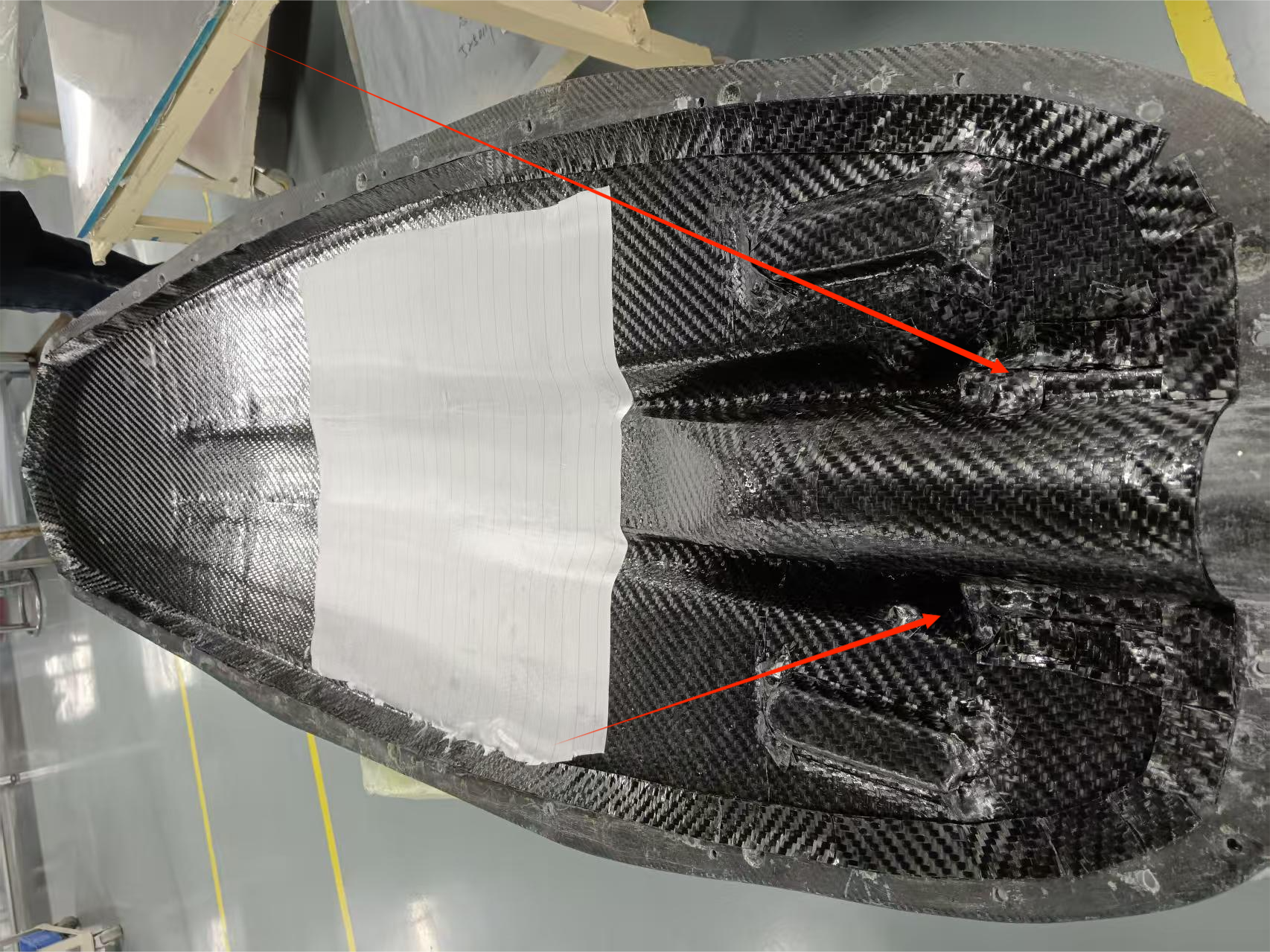

Unlike traditional split-mold or hand-layup boards that leave visible seam lines and rely on darkened finishes to hide imperfections, our one-piece molding process ensures:

- Seamless surface with continuous carbon weave flow

- Higher structural strength than conventional two-part boards

Premium Surface & Custom Finishing

Exceeding industry standards: Supports precise cutting of large-format designs over 1 meter. Offers diverse surface finishes, including clear carbon fiber, painted, or hybrid layers. Heat-resistant, peel-proof, and deformation-resistant.

High-Performance Core & Structure

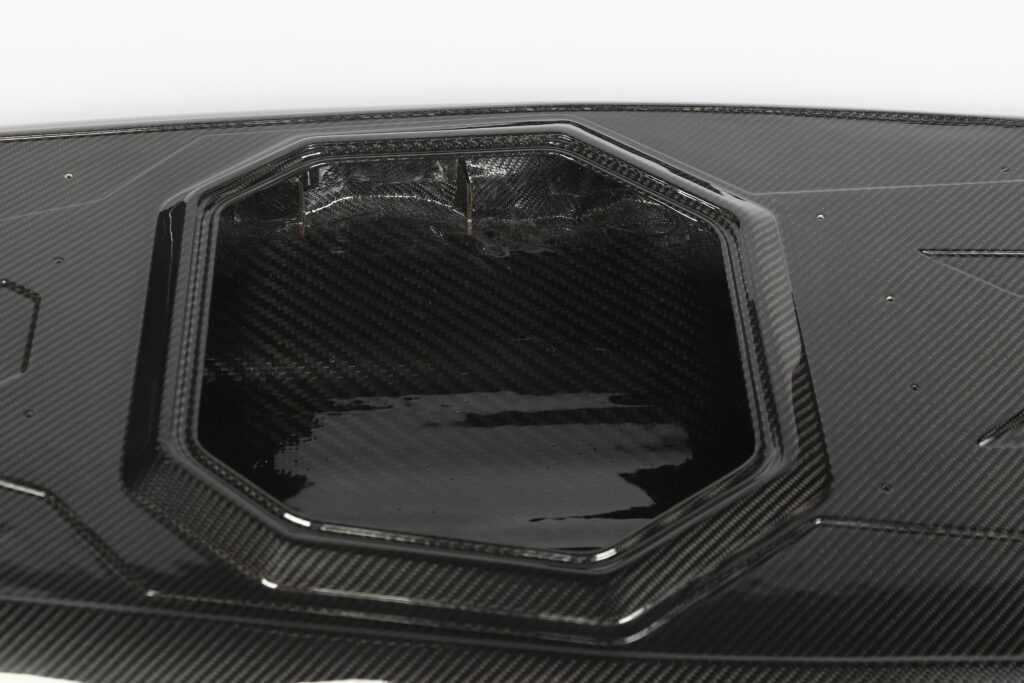

Carbon fiber outer layer combined with PU foam core, lightweight yet strong, approaching PMI-level performance. Built-in battery compartment, compatible with both hot press and mold press manufacturing processes.

Optimized Weight & Reinforcement

Approximately 8 kg. Strength and carbon fiber layup can be customized to achieve the ideal balance of lightness and durability.

Marine-Grade Hardware & Protection

Corrosion-resistant stainless steel screws and nuts, designed for marine environments. Guaranteed to resist rust and leakage for over 3 years.

Manufacturing process

Our carbon fiber electric surfboards are crafted using aerospace-grade prepreg carbon fiber with two advanced manufacturing methods: autoclave curing for maximum strength and precision, and mold press forming for efficient, high-quality production. These processes create an ultra-lightweight yet incredibly strong structure, optimized for hydrodynamic efficiency and stability.

The result is a high-speed, highly controllable motorized surfboard with a sleek, UV-resistant finish, ensuring long-lasting beauty and durability even in harsh marine environments. Perfect for watersports enthusiasts and brands seeking lightweight electric surfboards, custom carbon fiber boards, and high-performance motorized boards, JCSPORTLINE delivers expertly manufactured solutions that combine style, performance, and engineering excellence.

Design and engineering

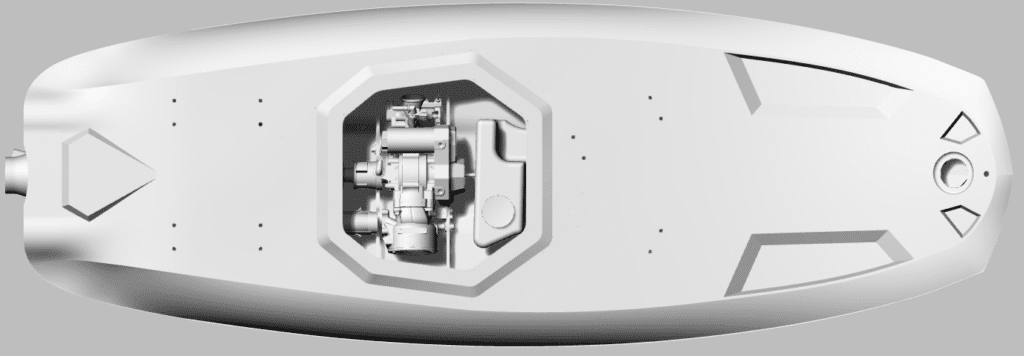

Our global 3D scanning capabilities capture precise digital models of each surfboard, ensuring accuracy and speeding up the initial design phase. Paired with our expert design team, this process guarantees high-quality, efficient development, providing a solid foundation for customization and performance optimization.

The high-resolution 3D scans of each surfboard are transformed into detailed CAD models using advanced software like SolidWorks or AutoCAD, ensuring precise dimensions and perfect integration of structural and aerodynamic features. These CAD models undergo Finite Element Analysis (FEA) to simulate and evaluate the mechanical performance under various conditions, guaranteeing that each board is both strong and lightweight. This process optimizes the strength-to-weight ratio and enhances overall performance, durability, and rider safety.

Mold Press Mold

Designed for rapid, repeatable production of complex shapes, ensuring consistent dimensions and smooth surfaces.

Hot Press Mold

Ideal for high-strength, lightweight boards, applying uniform heat and pressure to achieve optimal fiber consolidation.

Both molds

Hot Press & Mold Press

We use two types of precision molds for carbon fiber surfboards: •

Both molds guarantee structural integrity, perfect fit, and high-quality finishes for every board.

Implementation process

Pushing Boundaries with Carbon Fiber for High-Performance E-Surfboards

Design & Engineering Optimization —Collaborate closely with clients to create precise 3D CAD models and detailed engineering plans tailored for custom electric surfboards and lightweight e-boards, ensuring optimal strength, weight balance, and hydrodynamic performance.

Premium Carbon Fiber Layup & Material Preparation — Use high-grade carbon fiber prepreg materials combined with advanced hand layup and automated processes to ensure maximum strength, durability, and ultra-lightweight construction.

Autoclave Curing & Comprehensive Quality Control — Perform high-pressure autoclave curing followed by thorough inspections and mechanical testing to deliver durable, impact-resistant, and corrosion-proof carbon fiber surfboards.

Trimming & Edge Finishing

Precisely trim excess material and refine edges to ensure perfect fit and smooth contours.

Sanding & Surface Polishing

Multi-step sanding and polishing to achieve a flawless, high-gloss finish while preserving the carbon fiber pattern.

Quality Inspection & Final Touches

Thorough inspection for surface defects, dimensional accuracy, and durability. Apply final protective coatings if needed for long-lasting performance.

Performance and efficiency

Enhanced Performance through Carbon Fiber Strength

The high stiffness and strength of premium carbon fiber composites provide superior rigidity for electric surfboards and lightweight e-boards, enabling faster response and efficient power transfer during sharp maneuvers, significantly boosting overall surfing performance and rider control.

Improved Efficiency with Ultra-Lightweight Carbon Fiber

The ultra-lightweight nature of advanced carbon fiber materials reduces the overall board weight, decreasing energy consumption of electric motors and lithium-ion batteries, resulting in longer ride times and enhanced battery efficiency for electric surfboards and high-performance watercraft.

Project achievements

Our carbon fiber electric surfboards combine innovative design and premium materials to deliver unmatched performance, durability, and lightweight agility. Engineered for riders who demand excellence, these boards showcase advanced carbon fiber technology that ensures strength, responsiveness, and long-lasting corrosion resistance in all water conditions.

Lightweight Carbon Fiber Construction

Crafted from high-quality carbon fiber composites, our boards provide superior strength while significantly reducing weight for enhanced control and faster maneuvers.

Exceptional Durability and Impact Resistance

Designed to withstand rigorous use, the carbon fiber structure offers excellent impact absorption and fatigue resistance, ensuring reliability and longevity.

Advanced Water and Corrosion Resistance

Natural resistance to saltwater and moisture extends the lifespan of the boards, maintaining consistent performance in harsh marine environments.