Table of Contents

3D Design & Hydrodynamic Engineering

From Concept to 3D CAD Modeling

When a carbon fiber surfboard is born at JCSPORTLINE, everything begins with precision digital engineering.

Our design team transforms every concept into a 3D CAD model using SolidWorks and CATIA, two of the world’s most advanced engineering software platforms. These digital tools allow our engineers to fine-tune every contour — from the waterline profile to the tail curvature and center of gravity — ensuring the surfboard glides across waves with perfect balance and minimal hydrodynamic drag.

Through this stage, we combine the aerodynamic logic of a race car with the fluid dynamics of the ocean. Every curve, concave, and edge is analyzed for lift efficiency, stability, and agility. The result? A surfboard that doesn’t just float — it slices the water like a performance vehicle on the sea.

At JCSPORTLINE, 3D modeling is more than just design visualization — it’s engineering prediction. The model serves as the digital twin for later stages, guiding CNC mold machining, composite layup, and CFD (Computational Fluid Dynamics) simulations, ensuring the physical board perfectly matches the digital blueprint.

Hydrodynamic Optimization for Real Performance

Behind every high-performance carbon fiber surfboard, there is science in motion — the art of hydrodynamics.

Once the 3D CAD model is built, JCSPORTLINE engineers use CFD (Computational Fluid Dynamics) analysis to simulate how water flows beneath and around the board. These digital wave tunnels reveal how even the smallest curvature or concave pattern can affect lift, drag, and cornering stability.

To achieve maximum control on water, we adopt V-shaped and dual-concave hull designs.

The V-shaped bottom allows the board to cut through waves with greater precision, improving roll-to-roll transitions when turning. The dual-concave design, on the other hand, enhances lift and planing speed, creating a natural cushion of water beneath the board that boosts acceleration while maintaining smooth glide.

Every iteration is tested through simulation, and later validated in real-world conditions — calm lakes, test pools, and open sea runs. This process ensures that when you step on a JCSPORTLINE surfboard, every curve beneath your feet has been scientifically shaped for speed, agility, and balance.

Composite Structure: Carbon Layers & Core Material

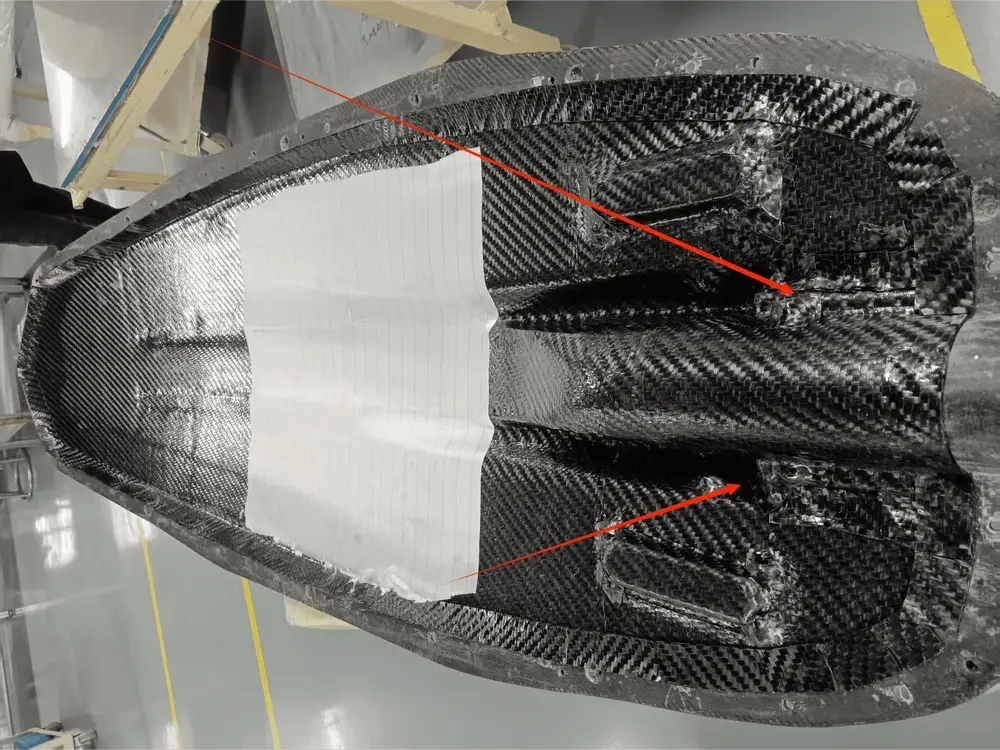

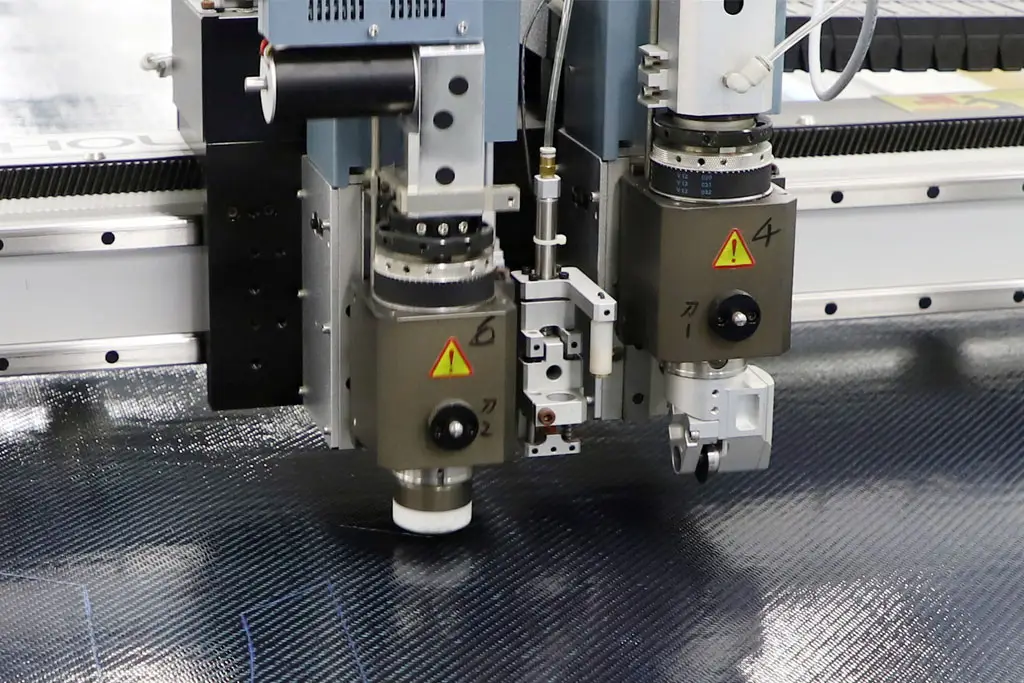

Multi-Layer Carbon Fiber Reinforcement

Every JCSPORTLINE carbon fiber surfboard begins with a carefully engineered multi-layer reinforcement system. The outer shell is crafted from 2×2 twill carbon fabric, providing superior impact resistance and a refined visual texture. Beneath it, unidirectional carbon layers are aligned for longitudinal strength, ensuring the board maintains its rigidity under dynamic loads. Each layer is laid at ±45° orientations, a method derived from aerospace composite design, to enhance torsional stiffness and prevent micro-cracks during high-speed maneuvers. This structural strategy not only reduces weight but also improves durability, giving riders unmatched stability and control on water.

High-Density PU / PMI Core for Lightweight Strength

At the heart of every JCSPORTLINE surfboard lies a high-density foam core designed for both lightness and strength. While PMI foam is recognized for its exceptional stiffness-to-weight ratio, JCSPORTLINE employs an optimized PU core as a cost-efficient alternative, offering nearly identical density (60–120 kg/m³) and compression resistance. This smart substitution achieves an overall board weight of ≤15 kg while sustaining dynamic loads exceeding 500 kg. The PU core is precisely bonded with pre-impregnated carbon layers during autoclave curing, forming a seamless sandwich structure that balances elasticity, toughness, and performance — a true expression of engineering efficiency and composite mastery.

Precision Mold Manufacturing

5-Axis CNC Machining & P20 Steel Molds

JCSPORTLINE’s mold manufacturing process is built on the foundation of 5-axis CNC machining and P20 tool steel precision. Each mold is processed to achieve a ±0.1 mm dimensional tolerance and a mirror-grade surface finish of Ra ≤ 0.8 μm, ensuring both aerodynamic smoothness and flawless surface reflections. Unlike traditional aluminum molds that deform easily under repeated heat cycles, P20 steel molds maintain dimensional stability over 5,000+ production cycles, guaranteeing consistent gloss and fit across every surfboard. This precision-driven approach not only enhances production efficiency but also defines JCSPORTLINE’s standard for world-class composite craftsmanship.

Mold Design for Accuracy & Easy Release

To achieve flawless carbon surfaces and reliable production consistency, JCSPORTLINE employs an advanced split mold structure integrated with precision alignment pins and sealed grooves. This design ensures upper and lower mold halves align perfectly during compression, preserving the surfboard’s aerodynamic contours. A thin Teflon-based release coating is applied to the mold surface to prevent bonding between resin and steel, enabling effortless demolding without surface damage. For complex geometries, an additional removable cap system allows internal structures to be formed and extracted cleanly. Every detail reflects JCSPORTLINE’s engineering discipline — precision at every step for perfection in every board.

Prototype Testing & Performance Validation

Static & Dynamic Testing

Before entering mass production, every JCSPORTLINE carbon fiber surfboard undergoes a series of static and dynamic strength tests to verify structural reliability and hydrodynamic balance. Using a three-point bending test, the flexural strength must reach ≥300 MPa, ensuring the board can withstand extreme loads without deformation. Impact resistance is assessed through drop and compression tests, followed by water pool dynamic trials that evaluate balance, turning response, and buoyancy stability. To guarantee dimensional accuracy, 3D scanning technology is applied to compare the prototype against the CAD model — any deviation exceeding 0.5 mm triggers mold refinement. These precision-driven validation steps ensure each surfboard performs exactly as engineered — strong, stable, and streamlined.

Waterproof & Corrosion Resistance Verification

Marine performance depends not only on strength but also on durability against saltwater exposure. JCSPORTLINE integrates marine-grade stainless steel screws and nuts, each pre-treated for anti-rust and corrosion resistance, ensuring longevity even after prolonged ocean use. The surfboard’s entire assembly follows IPX7 waterproofing standards, employing precision-sealed battery compartments, reinforced inserts, and insulated connectors to prevent any leakage or oxidation. This combination of advanced materials and precision engineering allows every JCSPORTLINE board to maintain structural integrity and appearance for over three years of continuous marine use, making it a trusted companion for both enthusiasts and professionals.

Mass Production & Quality Control

Automated Molding & Smart Inspection

In JCSPORTLINE’s production lines, precision and consistency are achieved through vacuum molding combined with autoclave curing at 150°C for 90 minutes. This process ensures optimal fiber consolidation, eliminating voids and guaranteeing a smooth, high-gloss surface finish. Every surfboard undergoes ultrasonic (UT) and industrial CT scanning to detect internal air pockets, delamination, or micro-defects invisible to the naked eye. With a rejection rate controlled below 0.5%, JCSPORTLINE delivers aerospace-grade quality to the water sports industry. By merging automation with data-driven inspection, each board that leaves the factory meets exacting structural and aesthetic standards — a testament to precision manufacturing excellence.

Sustainability & Energy Efficiency

Sustainability lies at the core of JCSPORTLINE’s manufacturing philosophy. Every stage of production is designed to minimize environmental impact — from thermal carbonization recycling, which achieves a ≥90% carbon fiber recovery rate, to solar-powered curing ovens that reduce total energy consumption by up to 30%. Offcut materials from trimming are reprocessed and reused in lower-grade composite applications, ensuring zero waste across production cycles. This closed-loop system not only reflects JCSPORTLINE’s commitment to eco-friendly innovation but also sets a benchmark for responsible, next-generation composite manufacturing.

Final Assembly & User Experience

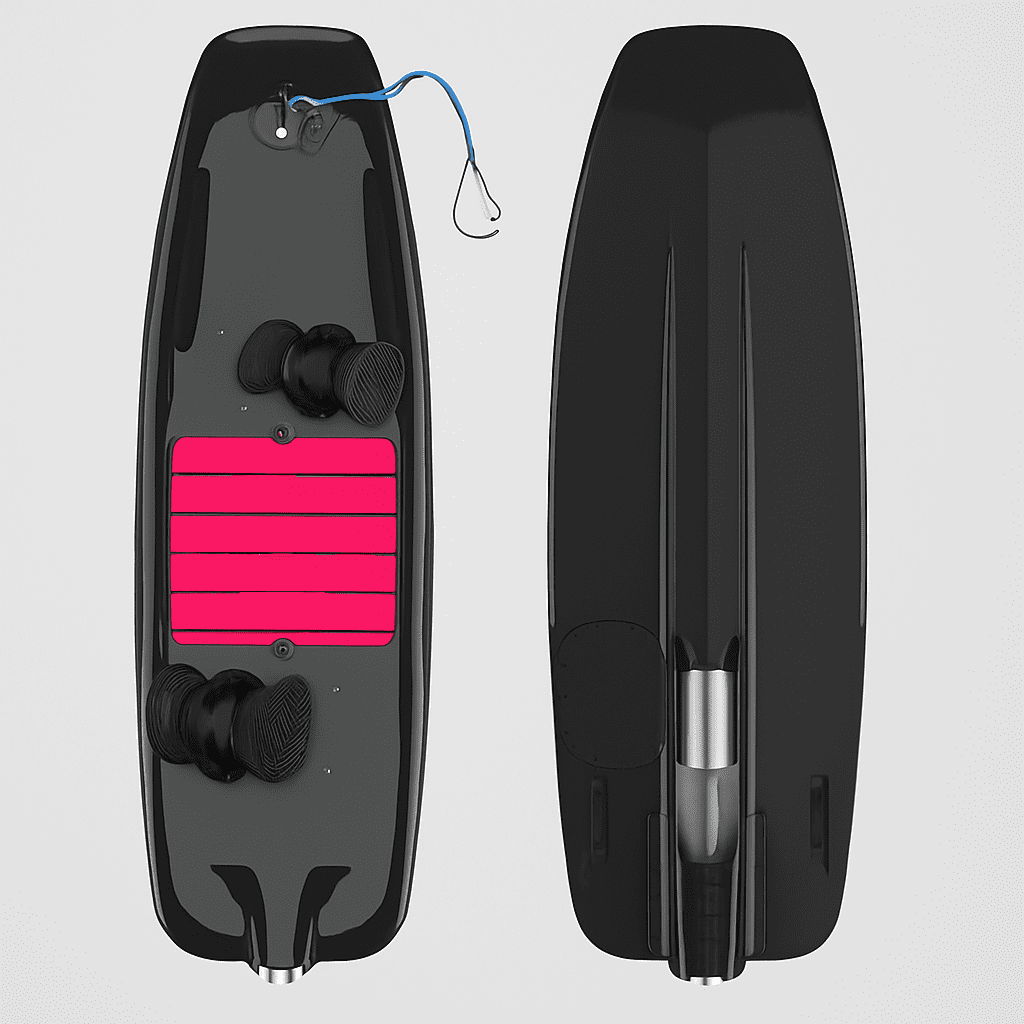

Modular Assembly for Efficiency

JCSPORTLINE’s electric surfboards are designed for seamless modular assembly, integrating quick-release battery compartments and pre-drilled motor mount interfaces for unmatched production efficiency. Each unit can be fully assembled and quality-checked in as little as 15 minutes, drastically reducing labor time and enabling scalable manufacturing for OEM and ODM partners. The precision pre-fit components ensure every electrical connector, seal, and bracket aligns perfectly without adjustment, maintaining waterproof integrity and mechanical reliability. This system embodies JCSPORTLINE’s engineering philosophy — efficiency without compromise — ensuring every board leaves the production line ready for adventure.

Performance on the Water: Real Rider Feedback

When tested in real marine conditions, JCSPORTLINE’s carbon fiber electric surfboards deliver exhilarating yet stable performance. Powered by an optimized propulsion system, each board reaches top speeds of ≥40 km/h with a cruising range of 30 km on a single charge. During trials under level-3 wave conditions, riders reported exceptional control, responsive turning, and minimal vibration — a result of the board’s finely tuned balance between stiffness and flexibility. The fusion of aerodynamic design, lightweight carbon construction, and waterproof reliability ensures every ride feels smooth, powerful, and precise — transforming engineering excellence into pure ocean freedom.