Table of Contents

Introduction: Not All Carbon Fiber Is Real

If you’ve ever shopped for car parts online, you’ve probably seen tons of parts labeled as “carbon fiber.” But here’s the truth: a lot of them are fake. The growing popularity of carbon fibre as a popular material in the automotive world has led to an increase in fake and wrapped products on the market.

Some parts only look like carbon fiber because of a printed pattern called water transfer printing. Others are simply wrapped with a film or sticker to mimic the appearance of real carbon fibre. These parts may seem cool at first, but they don’t have the strength, durability, or weight savings of real dry carbon fiber.

So how can you tell the difference? Let’s break it down.

Why It Matters: Real vs. Fake Carbon Fiber

Real carbon fiber parts aren’t just for looks. In high-performance cars, the appearance and material choice are crucial factors for both function and style. They’re strong, light, and performance-focused. Fake parts might look similar but are made of plastic or fiberglass with a carbon sticker on top.

Fake carbon fiber:

🚫 Just a film on top of plastic

🚫 Cracks or peels easily

🚫 Adds weight instead of reducing it

🚫 Poor fit, short lifespan

🚫 Choosing fake carbon fiber is often a compromise on durability and performance, sometimes made for price or appearance.

Real carbon fiber:

✅ Layers of carbon fiber cloth

✅ High-temperature, high-pressure cured

✅ Extremely light and strong

✅ Designed to last and fit perfectly

Many consumers are drawn to the look of carbon fiber stuff for their cars, but should consider the factors that affect quality and price before buying.

The Real Process: How Dry Carbon Fiber Is Made

Real carbon fiber (also called dry carbon fiber) is made using multiple steps:

- Pre-preg sheets: Carbon fiber fabric is pre-impregnated with epoxy resin to create consistent, high-quality carbon fiber sheets.

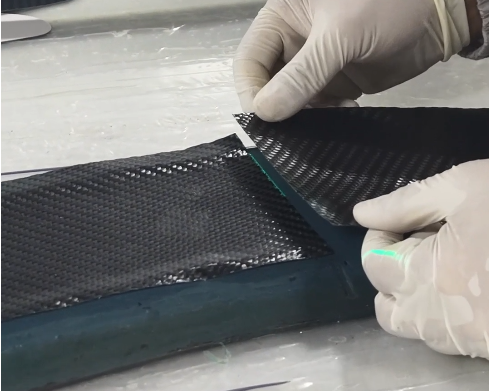

- Hand layering: Sheets are laid by hand in the correct direction, with careful attention to the weave and the shape of complex parts, ensuring the materials fit precisely and maintain superior strength and rigidity.

- Vacuum-sealed and placed in an autoclave to cure the composites under controlled conditions. The backside of genuine carbon fiber parts will have a smooth, high-quality surface due to this process.

- Cured under heat and pressure to form a solid, lightweight, and durable part with high stiffness and resistant properties.

- Checked with tools like infrared detection to find hidden flaws, ensuring only completely flawless carbon fiber parts are used.

- Precision fit test — any part with a 0.3mm error goes back for rework, maintaining the superior standards set by manufacturers.

Manufacturers use both wet and dry methods to produce carbon fiber composites. The wet lay-up process involves applying epoxy resin by hand to the carbon fiber fabric, while dry carbon fiber uses pre-impregnated sheets for a more consistent and superior result. The use of epoxy is crucial in both wet and dry processes to create a strong, high-quality material.

The weave of quality carbon fiber sheets is a key indicator of authenticity, and the shape of complex parts requires careful layering of materials to maintain structural integrity. Real carbon fiber composites are used in industries like automotive, aerospace, and sporting goods for their high strength, lighter weight, stiffness, rigidity, and resistant, durable properties.

Story: A Customer’s Costly Mistake

One of our wholesale clients ordered “carbon fiber” spoilers from another supplier. In today’s market, it’s easy to be misled when sourcing materials for a project. They looked good at first. But after just a few weeks, they began cracking and peeling.

Turns out, the spoilers were just water transfer printed plastic. The client lost money on returns and hurt their brand’s reputation.

After switching to our dry carbon fiber parts, they saw a huge improvement:

✅ Lower return rates

✅ Happier customers

✅ Real carbon fiber that performs under stress

How to Spot Real Carbon Fiber

Here are some tips to tell real carbon fiber from fake:

🔍 Check the back of the part — real carbon fiber has a woven texture all the way through, not just a surface layer, and the backside will have a smooth, high-quality finish due to the vacuum process

📏 Feel the weight — real carbon fiber is light but stiff

💥 Bend it — fake parts often flex too much or feel soft; if you gently push on the part, real carbon fiber will resist flexing, while fake parts may bend easily

🔥 Ask about the process — dry carbon is always cured in a mold or autoclave, not just painted

For example, one buyer tested a carbon fiber panel by pushing on it with their thumb. The real carbon fiber part stayed rigid, while a cheaper imitation flexed noticeably under the same pressure.

If the seller can’t explain how it was made, chances are it’s not real carbon fiber. If you’re still unsure, seek the expertise of a professional to verify authenticity.

What Our Customers Say

“I used to buy cheap carbon parts, but they always failed fast. Once I tried real dry carbon, I never went back.”

— Mike, Subaru WRX owner

“The fit was perfect, and I could tell the strength right away. Totally worth the upgrade.”

— Sarah, BMW M3 driver

Final Thoughts: Don’t Just Buy the Look

Real carbon fiber costs more, but it gives you:

✅ Real strength

✅ Better looks over time

✅ Proper fit and safety

✅ Long-term value

Fake parts may look good for a few weeks, but they’ll cost you more in the long run. If you’re serious about car performance and quality, always ask: is it real carbon fiber?

Ready to Upgrade?

👉 Looking for real carbon fiber body kits, spoilers, or interior parts?

👉 Want help checking if your current parts are genuine?

Contact our team today. We’ll walk you through how our carbon fiber parts are made — and why you’ll feel the difference the moment you install them.