Table of Contents

Carbon fiber was not created for homes.

It was developed for aerospace, automotive, and industrial applications—fields where weight reduction, structural integrity, and manufacturing precision are critical.

However, as living spaces evolve and furniture requirements become more demanding, industrial carbon fiber manufacturing is increasingly being applied to home furniture.

This is not a design trend.

It is a manufacturing shift.

From Industrial Materials to Living Spaces

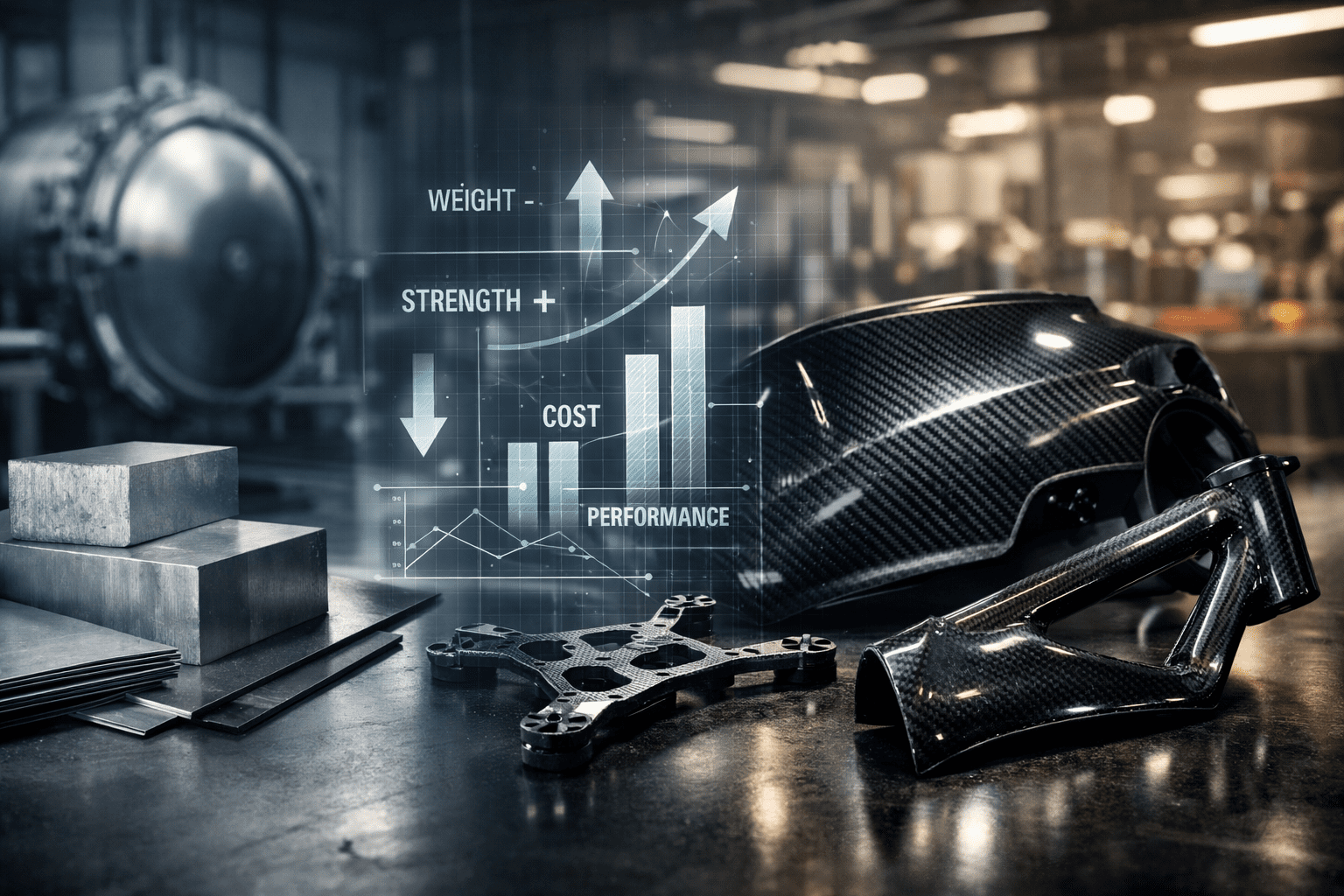

Industrial carbon fiber manufacturing focuses on three core objectives:

- Maximum strength with minimal material

- Predictable structural performance

- Repeatable, controlled production

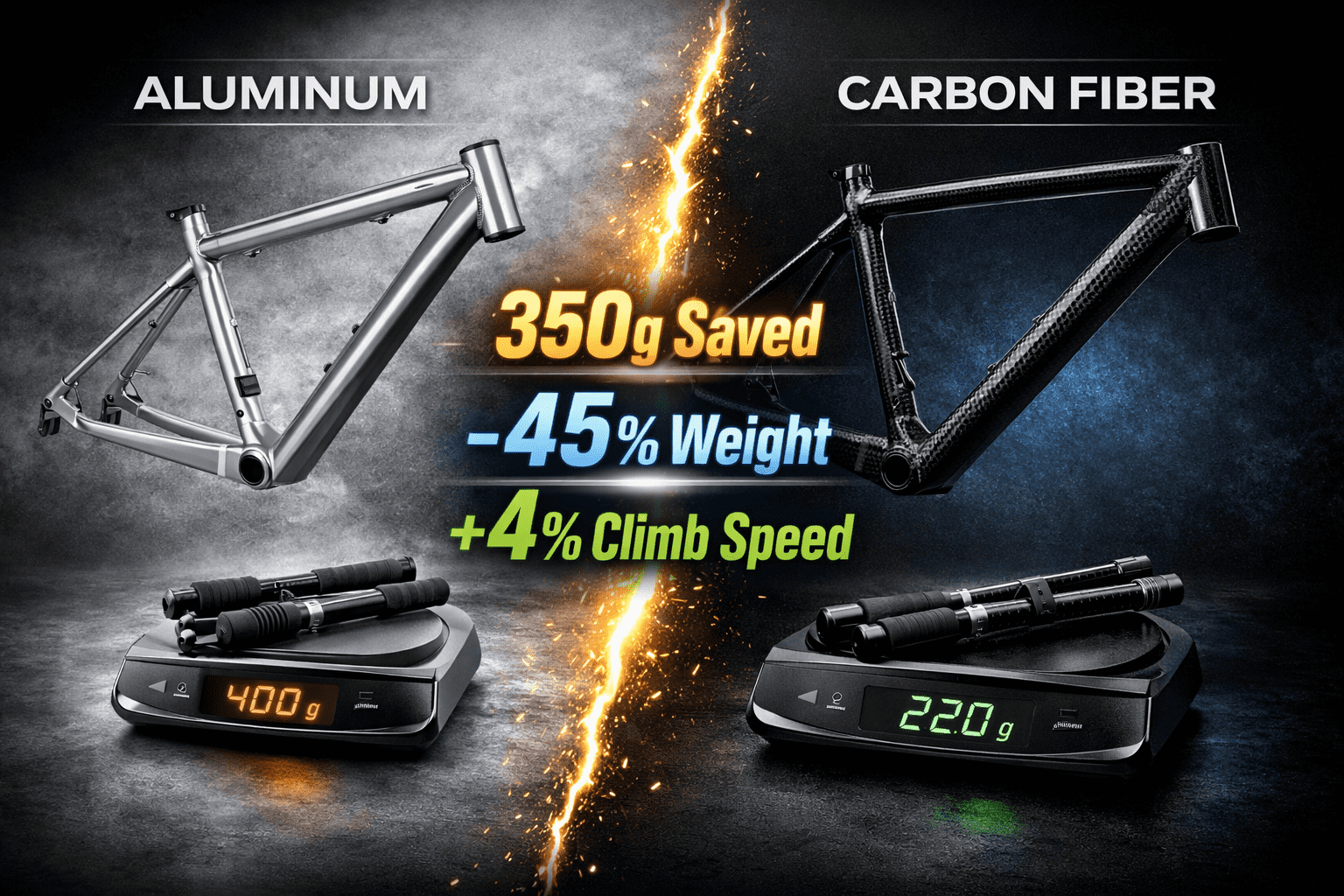

When these principles are applied to home furniture, the result is fundamentally different from traditional furniture manufacturing.

Instead of relying on wood joints, metal welds, or plastic reinforcements, carbon fiber furniture uses composite structures where the material itself carries the load.

This approach allows furniture to be:

- Significantly lighter

- Structurally stronger

- More stable over long-term use

Structural Engineering Comes Before Appearance

In industrial carbon fiber manufacturing, design does not begin with shape—it begins with load paths.

Before any furniture form is finalized, engineers analyze:

- Where weight is applied

- How forces move through the structure

- Which areas require reinforcement

- Which areas can remain thin

Using carbon fiber layup design, fiber orientation is adjusted by zone:

- High-stress areas receive directional reinforcement

- Low-stress areas remain minimal and lightweight

This engineering-first process ensures that material is used only where it is needed, improving efficiency without compromising safety.

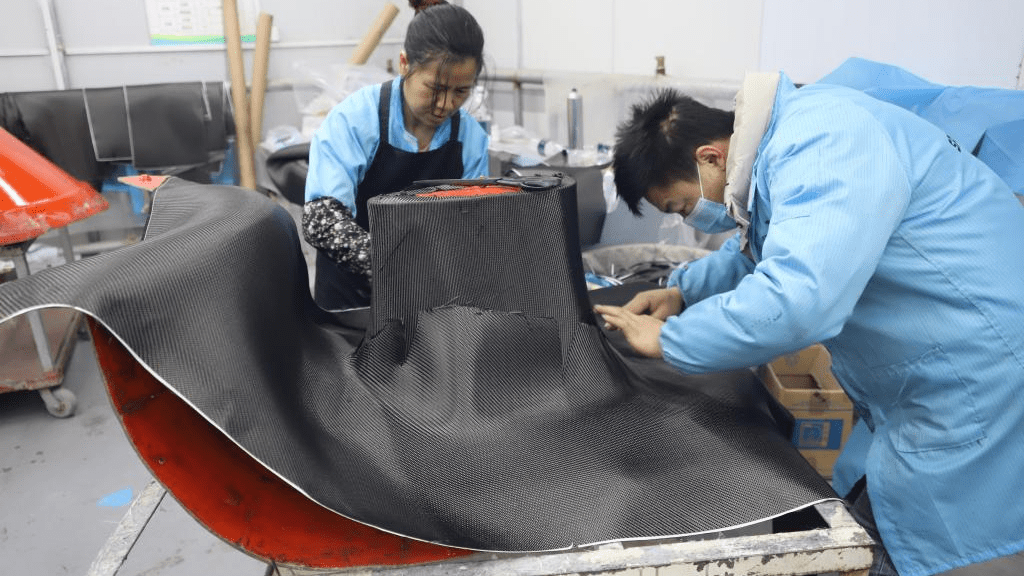

One-Piece Molding Replaces Traditional Assembly

One of the most important industrial techniques applied to home furniture is one-piece composite molding.

Instead of assembling multiple components, carbon fiber furniture parts can be formed as a single integrated structure.

This brings clear advantages:

- No mechanical joints that loosen over time

- Reduced fatigue and stress concentration

- Higher dimensional consistency

- Cleaner and more minimal visual lines

For home environments, this means furniture that feels solid, stable, and refined—without unnecessary weight.

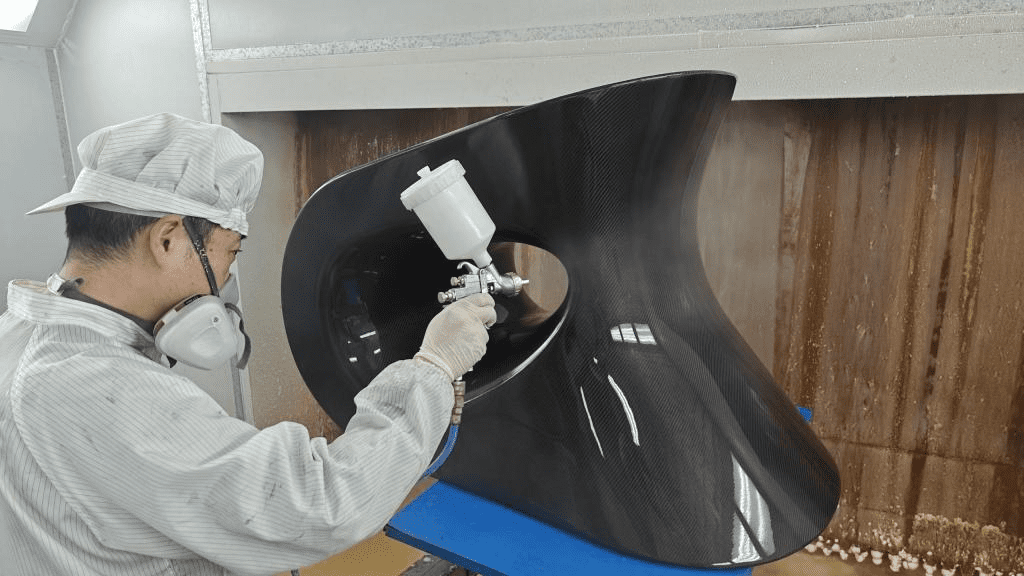

Surface Quality Is Engineered, Not Painted

In traditional furniture, surface appearance depends heavily on paint, veneer, or coatings.

In industrial carbon fiber manufacturing, surface quality is designed into the process.

Key factors include:

- Mold surface precision

- Fiber alignment control

- Curing pressure and temperature

- Resin distribution consistency

Because the surface is formed directly in the mold, carbon fiber furniture maintains:

- Consistent texture

- Stable color and gloss

- Resistance to peeling, cracking, or fading

This makes carbon fiber particularly suitable for long-term home use and design-driven spaces.

Why Industrial Manufacturing Matters for Home Furniture

Modern homes demand more from furniture than ever before.

Furniture must be:

- Lightweight yet durable

- Easy to move but structurally stable

- Visually minimal without feeling fragile

Industrial carbon fiber manufacturing meets these needs naturally.

Because carbon fiber is unaffected by humidity, temperature fluctuations, and material fatigue common in traditional furniture, it performs consistently across different living environments.

This makes it suitable for:

- High-end residential interiors

- Hospitality and commercial living spaces

- Design-focused showrooms

- Semi-outdoor or climate-sensitive areas

Manufacturing Capability Determines the Outcome

Applying industrial carbon fiber manufacturing to home furniture requires more than design expertise—it requires manufacturing discipline.

Key capabilities include:

- Precision mold development

- Controlled curing environments

- Repeatable fiber placement

- Consistent quality inspection

Without these, results become inconsistent—especially when production scales beyond prototypes.

Manufacturers such as JCSPORTLINE, with deep experience in automotive and industrial composites, apply the same process controls to furniture production, ensuring stability from prototype to volume manufacturing.

The Future of Home Furniture Manufacturing

Industrial carbon fiber manufacturing is not replacing traditional furniture materials everywhere.

Instead, it is expanding what home furniture can be:

- Lighter without sacrificing strength

- More durable without visual bulk

- Engineered for long-term performance

As living spaces continue to evolve, furniture is no longer just decorative—it becomes a functional structural element within the home.

This is how industrial carbon fiber manufacturing is shaping the next generation of home furniture.

FAQ

What does “industrial carbon fiber manufacturing” mean in home furniture applications?

At JCSPORTLINE, industrial carbon fiber manufacturing means applying composite processes originally developed for automotive and industrial components to furniture production.

Instead of focusing on decorative carbon fiber surfaces, we design furniture components as structural composite parts with controlled layup, molding, and curing processes suitable for commercial use.

How is carbon fiber furniture manufactured differently from traditional furniture?

Traditional furniture relies on joints, fasteners, or welded structures to achieve strength.

Our carbon fiber furniture is manufactured as a load-bearing composite structure, where the material itself provides strength and stability. This results in lighter weight, fewer connection points, and more consistent long-term performance compared to wood or metal furniture.

Can carbon fiber furniture be manufactured at commercial scale?

Yes. We support carbon fiber furniture projects from prototype validation through batch and scalable production.

With in-house tooling development, controlled curing environments, and standardized production workflows, we are able to maintain consistency as volumes increase, rather than limiting projects to one-off prototypes.

What manufacturing processes does JCSPORTLINE use for carbon fiber furniture?

Depending on structural requirements, surface quality expectations, and production volume, we use industrial composite processes such as prepreg carbon fiber layup, controlled oven or autoclave curing, and one-piece composite molding for large structural parts.

Process selection is always driven by performance and manufacturing feasibility, not appearance alone.

What types of furniture projects is JCSPORTLINE best suited for?

We typically work with furniture brands, designers, and OEM partners who require industrial-grade carbon fiber manufacturing for home and interior applications.

Our projects often involve structural components, new mold development, and long-term production planning rather than decorative carbon fiber products or single custom pieces.

Is carbon fiber furniture suitable for everyday home environments?

Yes. When manufactured using industrial composite processes, carbon fiber furniture offers excellent resistance to humidity, temperature variation, and long-term fatigue.

This makes it suitable for daily use in modern residential interiors as well as design-driven commercial living spaces.