Table of Contents

When it comes to designing and producing carbon fiber car parts, precise fitment isn’t just about aesthetics — it directly affects user experience and driving safety. Yet, many customers face recurring pain points during installation:

- Excessive gaps that compromise the overall appearance and may cause safety risks

- Improper clip thickness leading to loose installation

- Bumper modifications required on some models, increasing labor and cost

- Complicated installation processes that take hours and add labor expense

Who Needs Perfect Installation?

- Tuning brands: Require consistent fitment across multiple vehicle models to avoid after-sales issues

- Car dealerships and distributors: Value easy installation to enhance customer satisfaction

- High-end vehicle owners and custom clients: Expect seamless fitment and flawless aesthetics

- Professional body shops: Want to reduce installation time, complexity, and overhead

Customer Story: From Frustration to Flawless

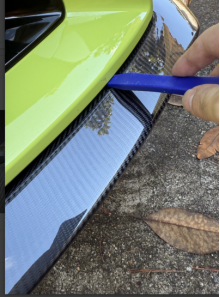

A well-known European tuning shop, Lucas, faced recurring issues while installing a carbon fiber side skirt for a popular model. The first sample had poorly designed clips and visible edge gaps, resulting in negative customer feedback.

By collaborating with JCSPORTLINE, they implemented vehicle-based testing and dimensional data comparison — leading to a perfectly fitting product.

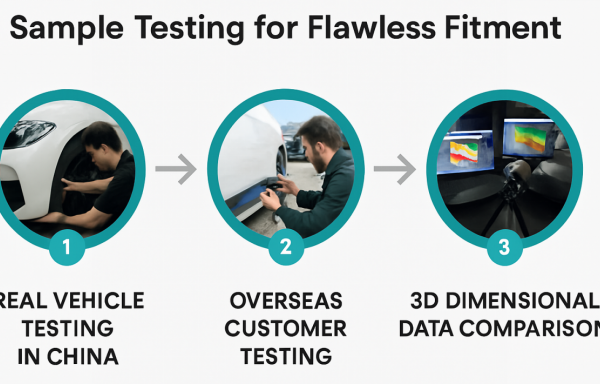

How JCSPORTLINE Tests for Perfect Installation

We use three levels of sample testing to ensure that our parts fit right — every time.

1. Real Vehicle Testing in China

We locate the target model and conduct direct on-car testing. This allows us to adjust clips and edges in real time, ensuring compatibility with OEM structures.

2. Overseas Customer Testing

For models not available domestically, we partner with international clients by shipping samples to them. Their installation feedback is used to make product improvements.

3. 3D Dimensional Data Comparison

We cross-reference vehicle scan data, mold scan data, and part scan data. This triple-layer check helps us optimize the mold for accurate fitment.

🛠️ Results that Matter

Thanks to our rigorous testing, we’ve helped clients:

- Minimize panel gaps and clip issues, improving both visual quality and safety

- Avoid unnecessary bumper cutting, simplifying the installation process

- Reduce installation time and cost, increasing workshop efficiency

- Continuously improve product quality, building long-term customer trust

Our Mission: The Best-Fitting Carbon Fiber Parts on the Market

At JCSPORTLINE, we believe that product quality and installation experience must go hand-in-hand. Only through strict testing and technical refinement can we deliver carbon fiber parts that truly stand out — not only in performance, but also in ease of use.

Facing Installation Issues? Talk to Us.

If you’re struggling with carbon fiber part installation — or simply want to improve the fitment, efficiency, and user experience — we’re here to help.

Let’s work together to make your carbon fiber upgrades easier, better, and more professional.

[Contact us today for personalized installation support and testing solutions]