Table of Contents

How We Track and Fix Mistakes Fast with 1:1 Order Tracking

Who This Helps:

Wholesalers and Distributors

Brand and Private Label Customers

Small Batch and Project Orders

Cross-border Sellers (Amazon, eBay)

New Customers Thinking About Working with Us

When working with overseas customers, we often hear this worry:

“What if you print the wrong order?”

“What happens if the label is wrong or the product is mixed up?”

At JCSPORTLINE, we get it. Mistakes happen. But what matters is how fast and well you fix them. That’s why we have a strong system for 1:1 order tracking and fast error correction.

A Real Story: How We Saved a Customer from a Big Label Mistake

Last month, one customer ordered a BMW front lip — a popular carbon fiber part. But during packing, our system caught a problem: the label said “Audi spoiler.”

Because our picker double-checked the order screen and list, they stopped and told the manager right away. The manager checked the system and found it was a printing error. They canceled the wrong label, printed a new correct one, and the customer got exactly what they ordered — all before the package left the warehouse.

This quick catch saved the customer from frustration and a costly return. It also kept their Amazon FBA shipment smooth, without rejected packages or fees.

Why Is a Printing Mistake a Big Deal?

Even a small mistake in printing can cause big problems:

❌ Wrong products shipped → customers miss sales deadlines or need to return items

❌ Wrong labels → Amazon FBA rejects shipments or charges high fees

❌ Wrong brand info → hurts your brand’s reputation and customer trust

For big wholesalers, one mistake can affect many sellers down the line.

For brand owners, a label mistake can hurt your image in the market.

That’s why we say:

“Printing is the last step in making your order — and the first test of trust.”

How We Handle Printing Mistakes: 1:1 Order Tracking and Quick Fixes

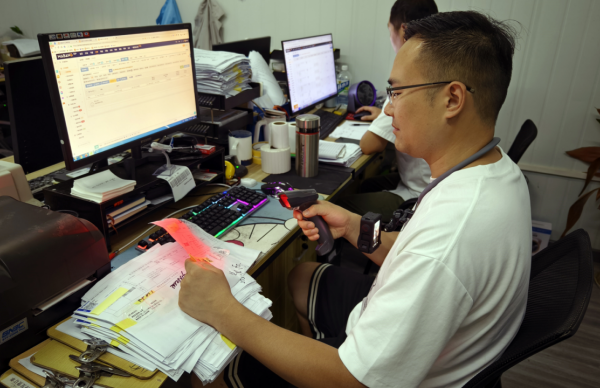

At JCSPORTLINE, we use a clear system to track every order and fix mistakes fast. Here’s how we do it in our warehouse:

Auto-Generated Order and Label

Our system creates the order and prints the label automatically.

Pickers check the order info on their screen and their picking list. If something is wrong, they stop and tell the warehouse manager right away.

Manager Checks and Fixes

The manager looks at the order in our ERP system:

If it’s a data error, they contact sales and the customer.

If it’s a printing mistake, they cancel the wrong label and print a new one.

Packaging Double Check

Packers scan the label’s QR code to make sure the product and order match.

Supervisor Spot Check

Before shipping, supervisors randomly check orders to make sure everything is right.

Thanks to this process, we find and fix mistakes in 15 minutes or less, cutting down customer complaints and returns.

For example, if a customer ordered a BMW front lip but got an Audi spoiler label, our system stops the mistake before it reaches them. This saves time, money, and trust.

Real Numbers: We Fix Mistakes Quickly

In the second quarter of 2025, JCSPORTLINE shipped over 4,300 orders with only 5 printing or label mistakes. All mistakes were fixed within 24 hours. That’s a 99.88% accuracy rate.

One European customer got the wrong SKU label. After checking, we reprinted the label and sent it by DHL free of charge. The customer was happy and kept ordering from us.

What We Promise You

1:1 Print Tracking: Every label shows who printed it and when

Free Re-shipment: If it’s our mistake, we pay all costs

Custom Label and Packaging Service: Fix label mistakes fast, no blaming customers

Monthly Reviews: We track and fix problems, and train our team regularly

Trust Is Not About Being Perfect—It’s About Owning Mistakes

We know customers don’t fear mistakes—they fear no one will fix them.

They don’t mind costs—they mind getting passed around with no clear answer.

JCSPORTLINE is not perfect, but we promise:

“Every mistake is tracked, fixed, and controlled.”

Got Questions or Worries?

Contact us for our shipping process charts and packaging standards.

Add us on WeChat or WhatsApp for quick support.

Send order numbers or photos—we reply in 1 hour.

Click “Online Chat” at the bottom right for real case help.