Table of Contents

Avoid Costly Mistakes with JCSPORTLINE’s Expert Support

The Challenge: “Perfect Data” That Doesn’t Fit

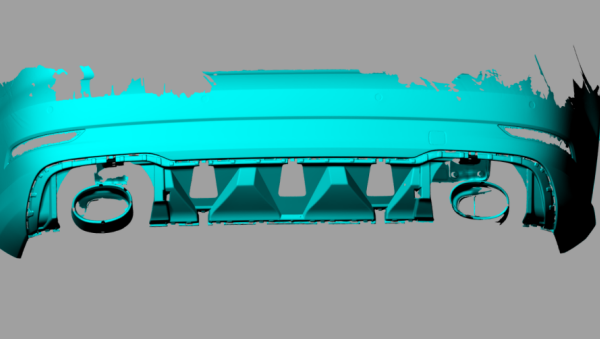

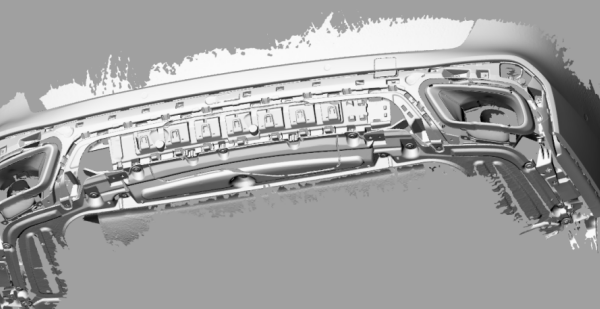

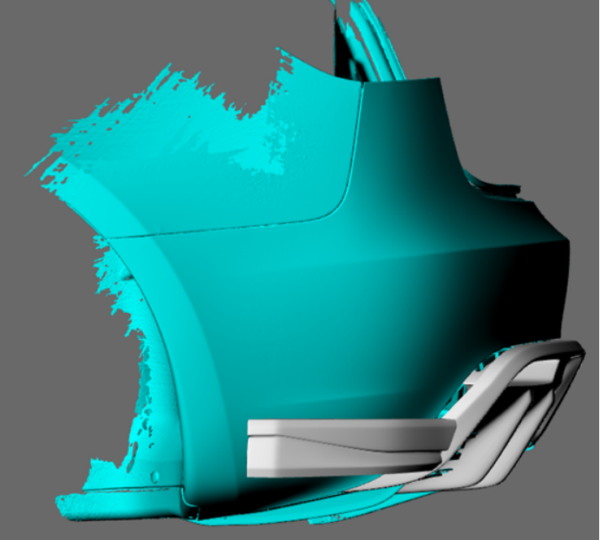

Across the globe, more customers are using 3D scanners to speed up the development of custom carbon fiber parts. Sounds great in theory — but in practice, poor scanning accuracy often leads to huge fitment problems.

Let’s look at who’s affected:

- Tuning shops with in-house scanning tools looking to develop new products fast

- Auto design firms outsourcing scan work with mixed data quality

- Overseas distributors needing precise specs to ensure compatibility across markets

- High-end car owners who expect millimeter-perfect custom parts

Real Story: When “High-Tech” Becomes a Headache

Tom, a respected tuning shop owner in the UK, reached out to us after struggling with a new carbon fiber project. He had scanned a vehicle using his own 3D equipment to develop a front lip and rear spoiler.

Here’s what went wrong:

- The 3D data had rough edges and missing areas

- The parts based on that data had visible gaps when installed

- Even 3D-printed samples didn’t match — fitment failed repeatedly

- The project faced cost overruns and delays due to constant rework

When Tom asked JCSPORTLINE for help, our engineers reviewed his scan files and quickly identified the root issues: low scan accuracy and inconsistent scan methods.

JCSPORTLINE’s Solution: Precision from Start to Finish

1. 20 Years of Carbon Fiber Expertise

We helped Tom improve his scan process by:

- Identifying critical measurement zones

- Recommending best angles for key areas

- Making sure all essential points for carbon fiber mounting were captured correctly

2. Easy-to-Follow 3D Scan Guide

Our clients receive a full guide including:

- Scanner setup and calibration tips

- Multi-angle scanning strategies

- Where and how to measure mounting holes and edges

- Visual examples to ensure data quality before modeling

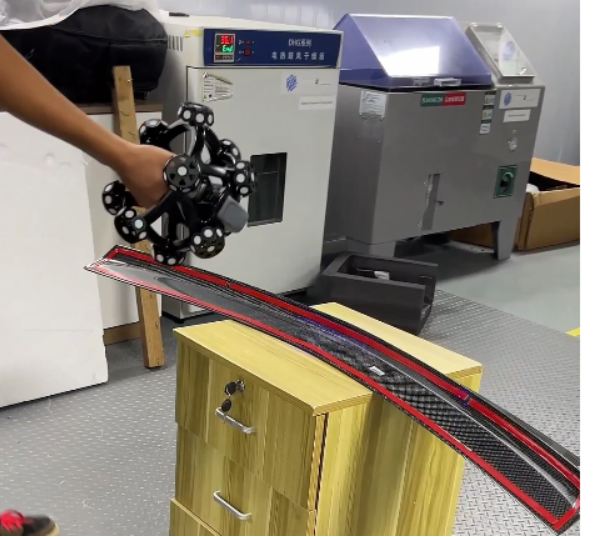

3. Access to Global 3D Scanning Equipment

4.Don’t have access to high-end scanning tools? No problem.

JCSPORTLINE offers scanning services from our labs in Canada, UK, Thailand, and China, with support for:

- Full vehicle scans

- Localized part scans

- Real-time technical support

5. One-Stop Design & Manufacturing

From accurate scan data to mold design, carbon fiber production, and installation advice — we handle the full process.

This ensures:

- Better fitment

- No guesswork

- No costly rework

Why Scan Accuracy Is Everything in Carbon Fiber

Imprecise scan data can cause:

| Problem | Impact |

| Jagged or warped edges | Gaps in fit, poor aesthetics |

| Missing geometry | Incorrect hole locations, failed installations |

| Distorted models | Mold misalignment, costly delays |

In carbon fiber, 1mm off can ruin the entire product — both in looks and function.

Are You Facing These Issues Too?

Whether you’re a:

- Tuning shop with scanners but limited carbon fiber experience

- Distributor needing help with accurate 3D data

- Car owner looking for custom parts that fit perfectly

JCSPORTLINE can support your project with:

- Remote technical guidance

- High-accuracy scan services

- Professional design and manufacturing follow-up

Let’s Make 3D Data Work for You — Not Against You

Don’t let bad scan data ruin a great product idea.

Contact JCSPORTLINE today and get expert help, global scanning resources, and decades of experience — all working to make your carbon fiber project faster, cleaner, and more accurate.