Table of Contents

Why Most Prototypes Never Reach the Water—And How Yours Will

The journey from concept to production is fraught with challenges, especially in the world of composite water-sport equipment. Statistics reveal a sobering reality: 70% of prototypes fail to make it past the first 1,000 units. For many innovators, this gap between “looks right” and “rides right” becomes an insurmountable hurdle. At JCSPORTLINE, we’ve identified the three critical gaps that cause these failures—and developed a gated process to ensure your prototype not only reaches the water but excels globally.

The 3 Critical Gaps Between “Looks Right” and “Rides Right”

When designing carbon fiber fins, achieving the perfect balance between aesthetics and functionality is no small feat. There are three key areas where most prototypes falter: bio-fit, hydrodynamic load, and supply-chain readiness.

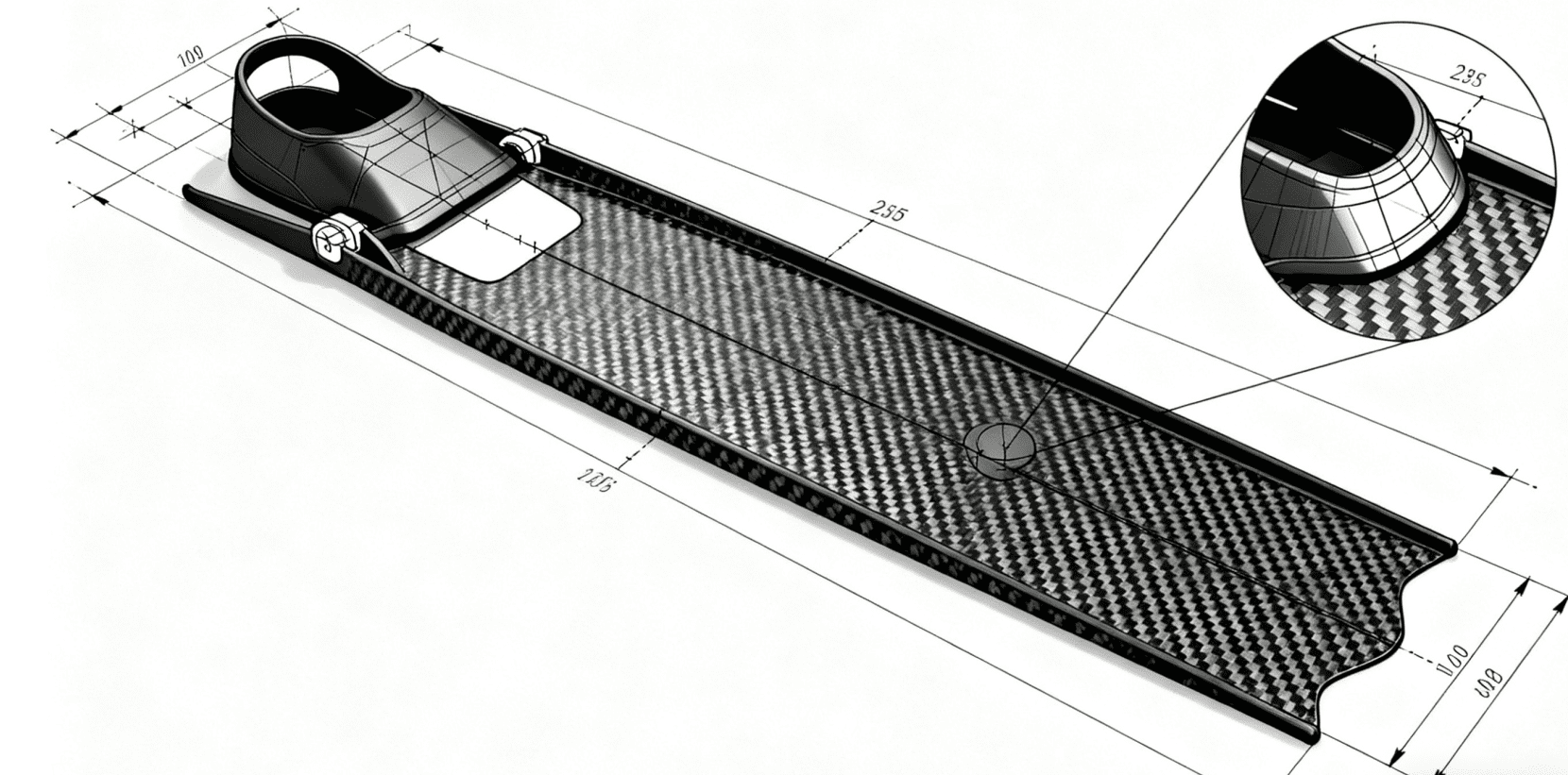

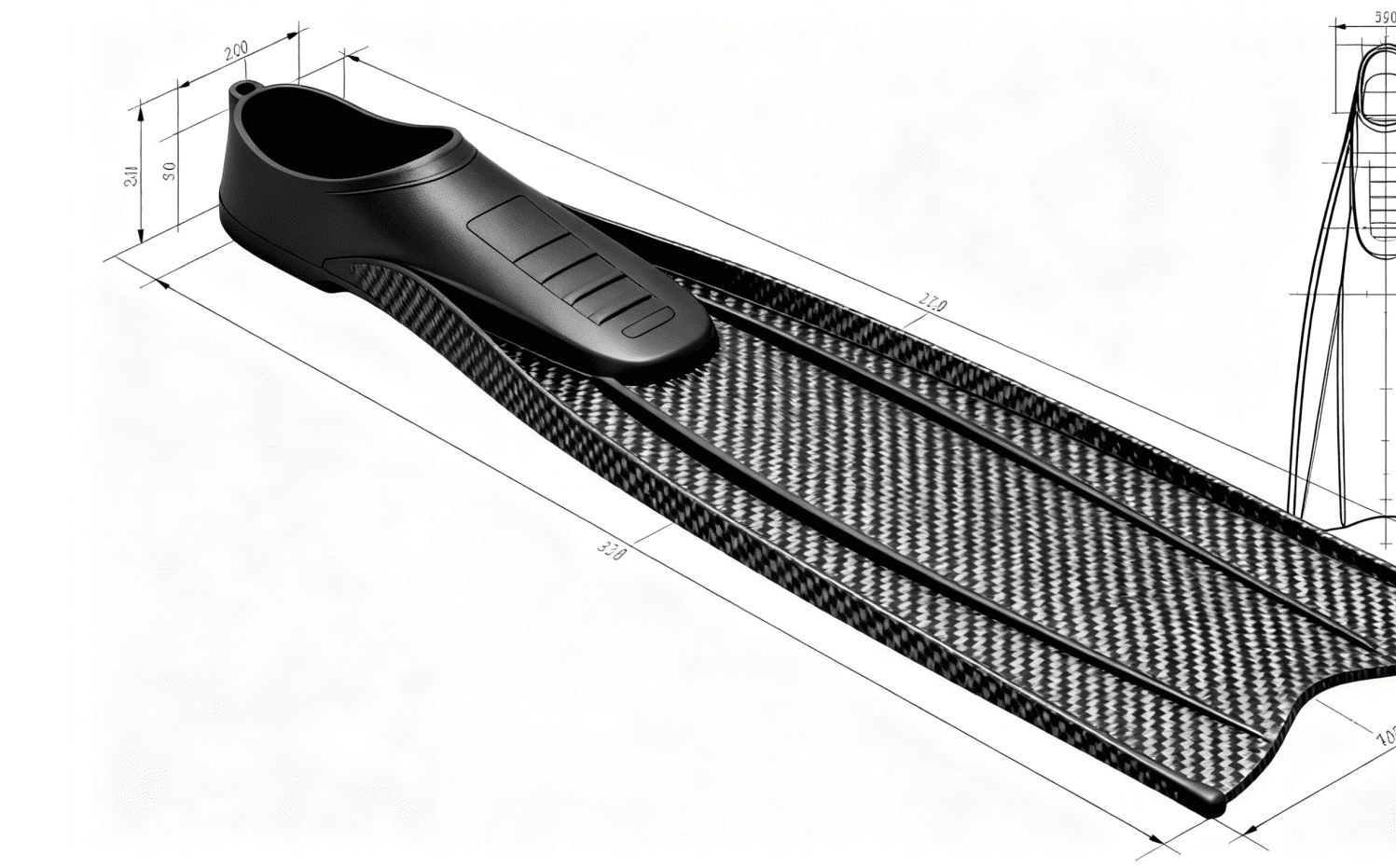

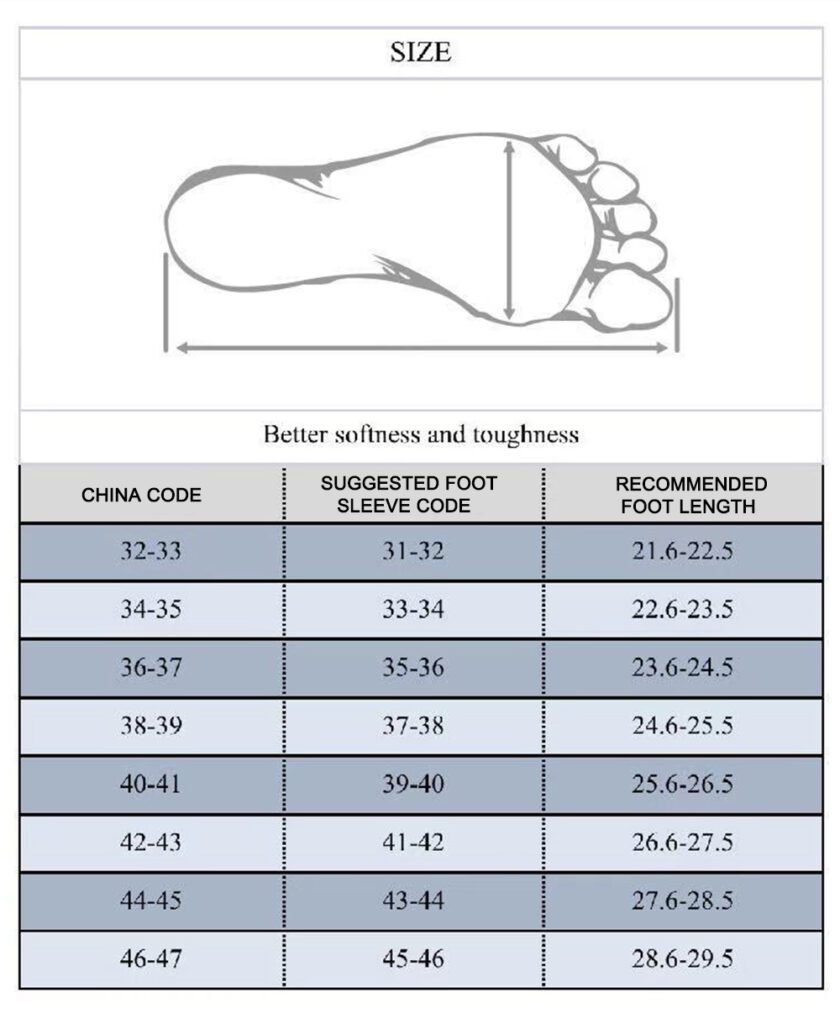

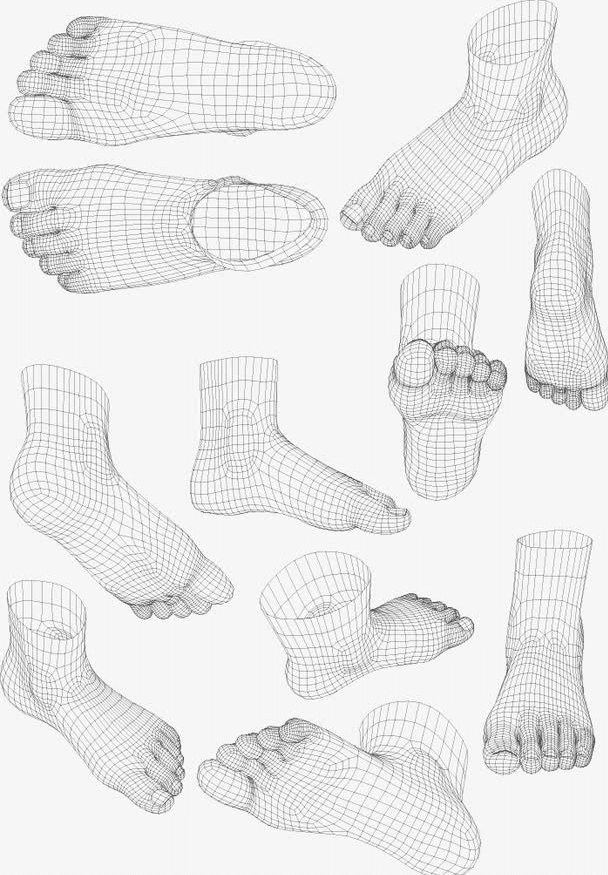

Bio-Fit: A fin might look sleek on paper, but if it doesn’t align with the biomechanics of the human foot, it’s destined to fail. Poor ergonomics can lead to discomfort, reduced performance, and even injury. JCSPORTLINE addresses this through advanced bio-scanning technology, ensuring every fin design matches the natural movement patterns of its users.

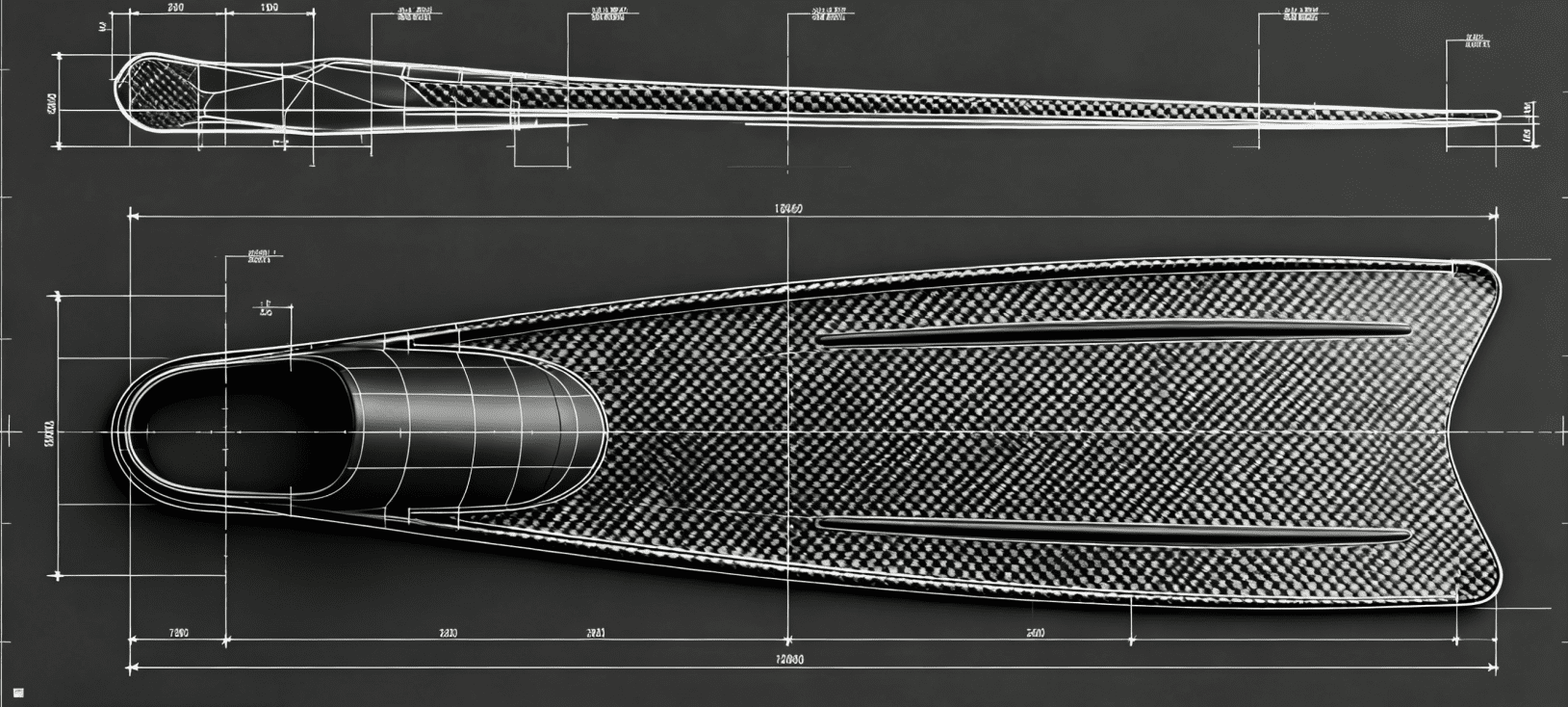

Hydrodynamic Load: Even the most visually appealing fins can crumble under pressure—literally. Hydrodynamic forces exert immense stress on materials, and without rigorous testing, prototypes often buckle. Our computational fluid dynamics (CFD) and finite element analysis (FEA) simulations identify weak points early, allowing us to refine designs before they hit the water.

Supply-Chain Readiness: Many projects stall because manufacturers underestimate the complexities of scaling production. From sourcing high-quality carbon fiber to mastering the mold-making process, every step requires precision. JCSPORTLINE’s expertise in carbon fiber fin manufacturing ensures seamless transitions from prototype to mass production, complete with region-specific sizing data to eliminate the need for costly re-tooling.

By closing these gaps, JCSPORTLINE empowers innovators to retain full intellectual property rights while confidently taking their products global.

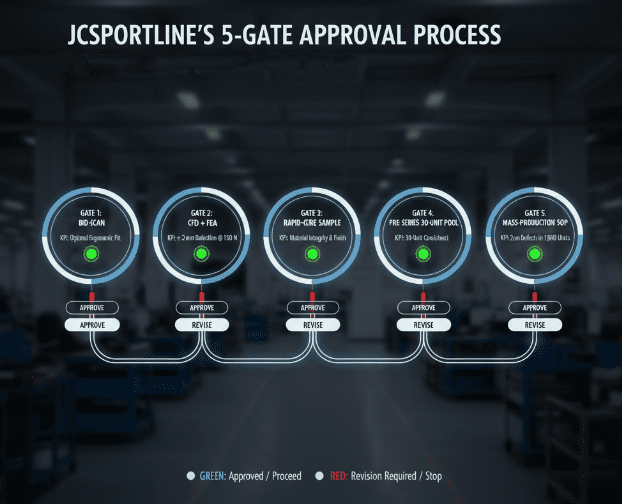

JCSPORTLINE’s 5-Gate Road-Map (and the KPI You Sign Off at Each Gate)

Navigating the path from prototype to production requires more than just vision—it demands a structured approach. JCSPORTLINE’s 5-Gate Road-Map provides a clear framework, ensuring every step is validated before moving forward. This gated workflow not only minimizes risk but also maximizes efficiency, giving you peace of mind throughout the development process.

Gate 1: Bio-Scan

The journey begins with a detailed bio-scan. This stage ensures the fin’s design aligns perfectly with the user’s anatomy. The KPI here? Achieving optimal ergonomic fit, measured by factors like pressure distribution and comfort scores. Only when these metrics meet our standards do we proceed to the next gate.

Gate 2: CFD + FEA

Once the design passes the bio-scan, it undergoes rigorous computational testing. Using CFD and FEA, we simulate real-world conditions to evaluate how the fin performs under hydrodynamic load. The KPI for this gate is ≤ 2 mm deflection at 150 N—a benchmark that guarantees durability and performance.

Gate 3: Rapid-Cure Sample

With virtual testing complete, we move to physical prototyping. Our rapid-cure samples allow for quick iterations, ensuring the design meets both aesthetic and functional requirements. At this stage, the KPI focuses on material integrity and surface finish quality.

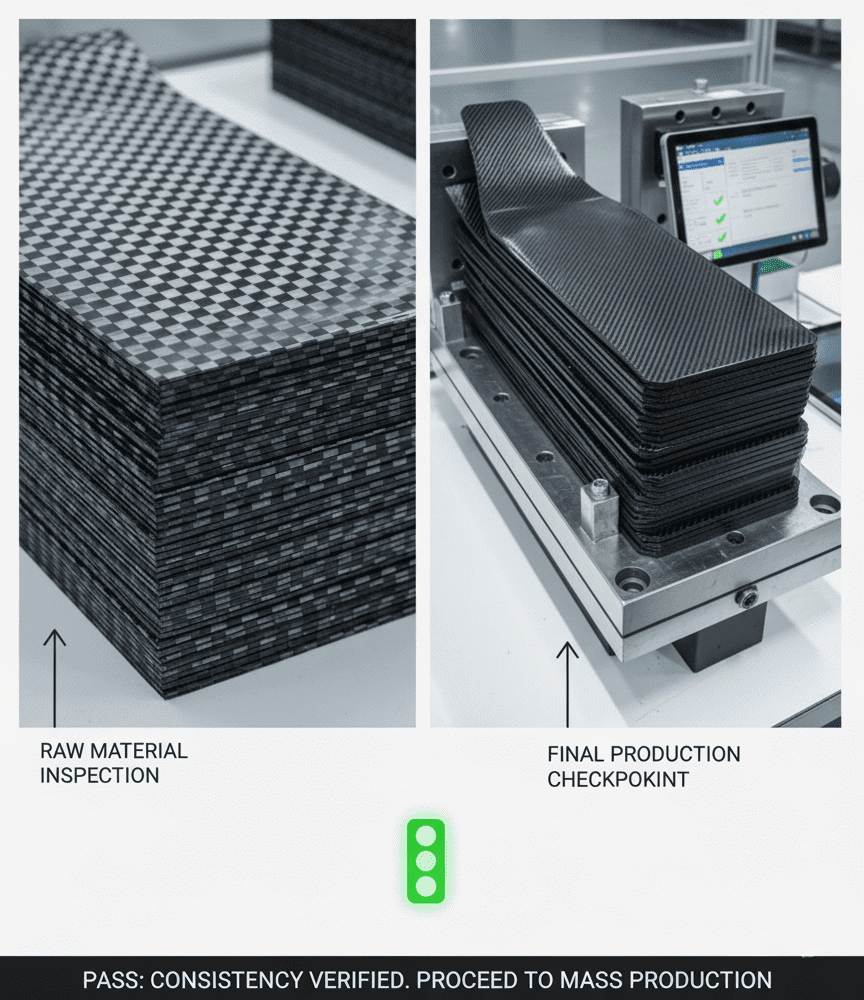

Gate 4: Pre-Series 30-Unit Pool

Before full-scale production, we create a pre-series pool of 30 units. This small batch serves as a final checkpoint, allowing us to test assembly processes, identify potential bottlenecks, and fine-tune the supply chain. The KPI here revolves around consistency—ensuring all 30 units meet identical standards.

Gate 5: Mass-Production SOP

The final gate establishes the standard operating procedures (SOP) for mass production. By this point, every aspect of the design and manufacturing process has been validated. The KPI for this stage is achieving zero defects in the first 1,000 units—a testament to the robustness of our gated workflow.

At each gate, you have the authority to approve or request revisions before any tooling budget is spent. This transparency ensures you remain in control, minimizing risks and maximizing ROI.

Designing for Humans, Not for CAD: Custom Geometry That Scales

In the world of high-performance freediving and spearfishing fins, one size does not fit all. At JCSPORTLINE, we’ve revolutionized fin design by focusing on human anatomy rather than rigid CAD constraints. Our approach ensures that every fin is tailored to meet the unique needs of diverse demographics, delivering unparalleled comfort and performance.

From Hip-Width Databases to Regional Lasts—How We Eliminate “One-Size-Fails-All”

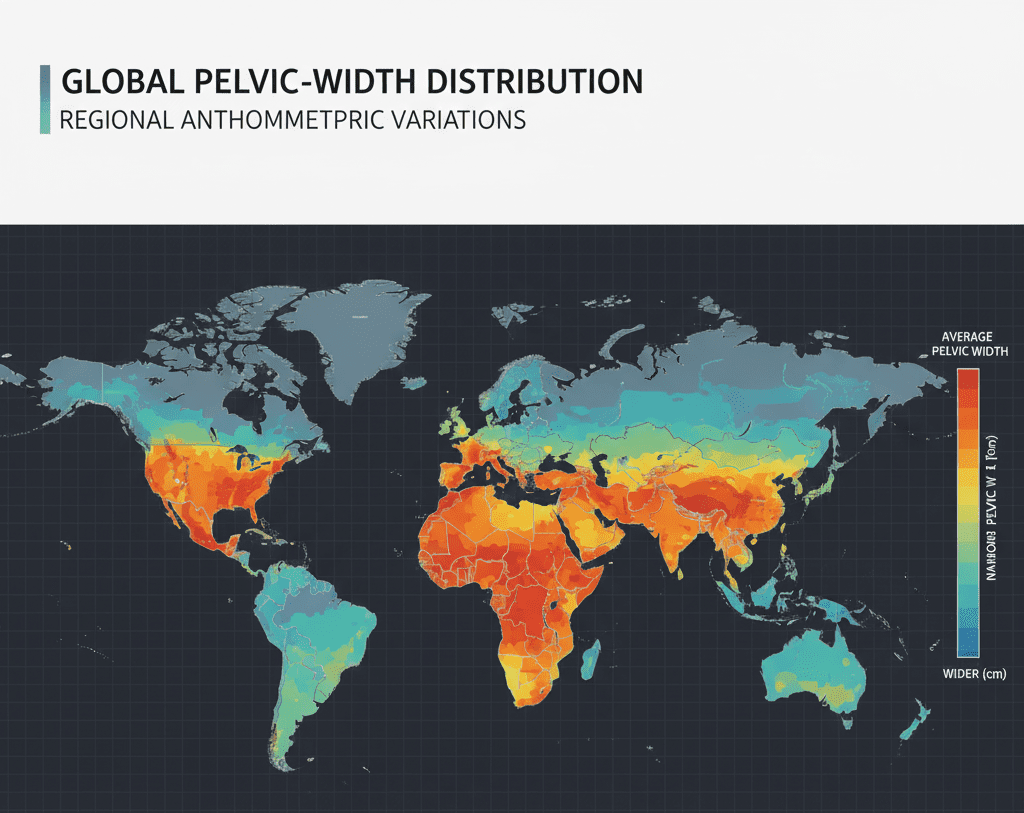

Off-the-shelf fins often fail to account for significant variations in pelvic width across populations. For instance, the average pelvic width difference between Asian and European populations is approximately 38 mm—a gap that can drastically affect fit and performance. Traditional designs ignore these nuances, leading to discomfort and inefficiency.

At JCSPORTLINE, we’ve addressed this issue head-on by building a comprehensive database of human anatomy. Our library includes over 1,200 optical body scans, capturing detailed measurements from diverse demographics. Using advanced algorithms, we automatically adjust critical design parameters such as blade angle, foot-pocket draft, and stiffness index. This ensures that our fins fit 90% of target users without the need for additional moulds. By leveraging custom carbon fiber technology, we create tailored fin geometry that scales seamlessly across regions and body types.

Parametric Lay-Up Schedules: Same Mould, Three Stiffness Levels

Creating multiple stiffness levels traditionally requires separate moulds, driving up costs and production time. At JCSPORTLINE, we’ve developed an innovative solution using parametric lay-up schedules. This technique allows us to produce Soft, Race, and Freediver versions from a single master mould, saving you 42% in tooling costs.

Our process involves differential ply drops and localized 3-K twill inserts. These techniques enable precise control over the stiffness profile of the blade. For example, softer versions use fewer layers of carbon fiber, while race-oriented fins incorporate additional reinforcement in high-stress zones. The result is a line of fins that cater to different skill levels and preferences without compromising structural integrity.

This approach not only reduces waste but also enhances customization. Whether you’re a beginner seeking flexibility or a professional requiring maximum propulsion, our parametric lay-up system ensures optimal performance for every user.

By combining cutting-edge technology with a deep understanding of human anatomy, JCSPORTLINE sets a new standard for custom carbon fiber fins. Our commitment to innovation ensures that every diver experiences unmatched comfort, performance, and personalization.

Prototype Testing That Predicts Real-Ocean Life—In 14 Days

Developing high-performance fins requires not only innovation but also rigorous testing to ensure they perform reliably in real-world conditions. Traditional prototyping methods often take weeks or even months, delaying critical feedback loops. At JCSPORTLINE, we’ve revolutionized this process with rapid prototyping techniques that deliver actionable insights within just 14 days—without compromising accuracy.

Rapid-Cure Carbon & 3-D Printed Cores: Cut Iteration Time by 60%

One of the most significant advancements in our prototyping workflow is the use of out-of-autoclave prepreg carbon fiber and dissolvable PLA cores. This combination allows us to drastically reduce iteration times while maintaining structural integrity close enough for validation purposes.

The out-of-autoclave prepreg cures at a relatively low temperature of 90°C over 45 minutes, eliminating the need for expensive autoclave equipment and reducing energy consumption. Meanwhile, the dissolvable PLA cores enable quick removal after curing, allowing swim tests as early as day three instead of waiting until week three. Our internal testing has shown that these prototypes exhibit an 18% drop in modulus compared to production autoclave parts—a difference small enough to validate design assumptions before moving into full-scale manufacturing.

This approach cuts iteration time by 60%, enabling faster refinement cycles and more efficient development. Whether you’re designing fins for competitive freediving or recreational snorkeling, rapid carbon fiber prototyping ensures your designs are both innovative and functional.

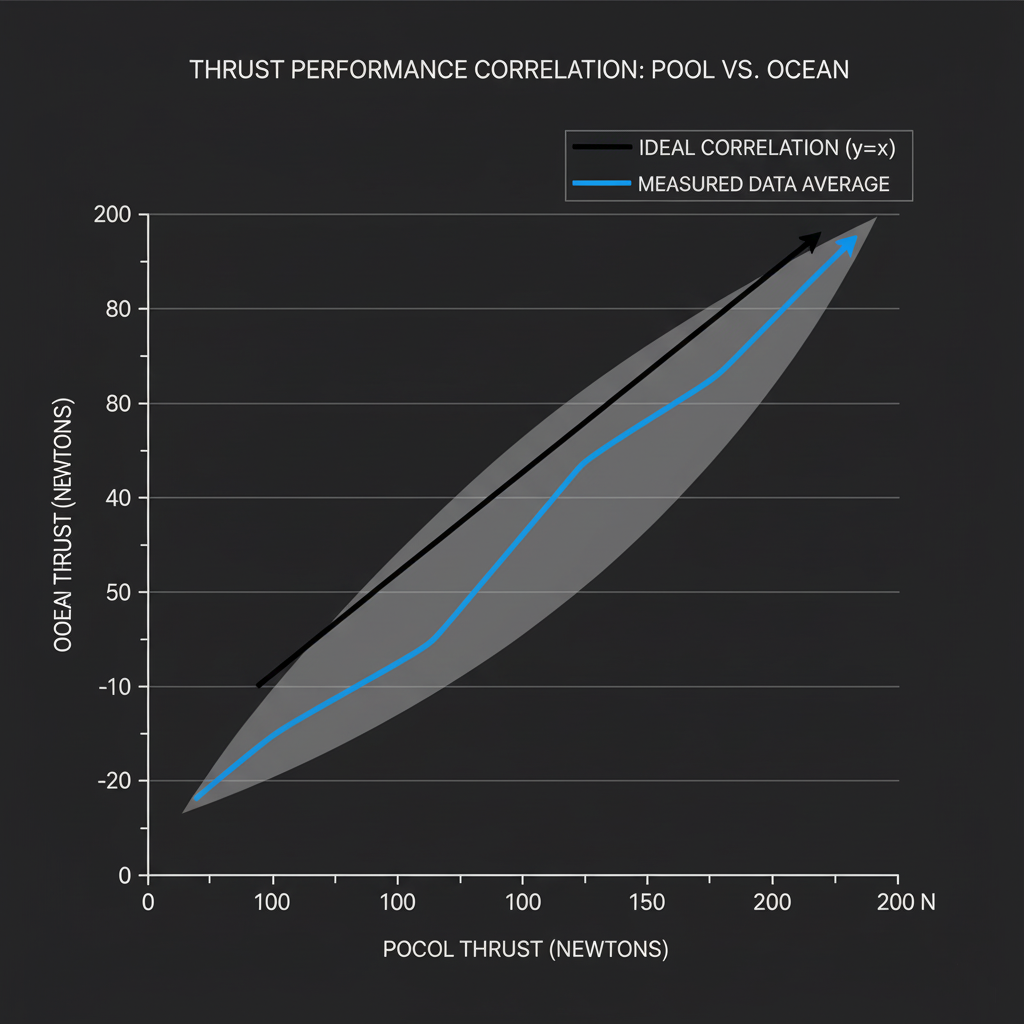

Pool-to-Open-Water Correlation Matrix—How We De-Risk Your Field Trials

Translating controlled pool test results to unpredictable open-water conditions can be challenging. To address this, we’ve developed a proprietary Pool-to-Open-Water Correlation Matrix that helps de-risk field trials by providing reliable correction factors. These factors allow you to adjust data collected in a 25-meter pool to simulate performance in 2-meter ocean chop effectively.

Our matrix includes a lookup table that readers can use to refine their own testing protocols. For example, if your pool thrust measurements indicate a specific force output, our correction factors will help predict how that same fin will perform in rougher waters. The correlation is backed by extensive testing, ensuring a high degree of confidence in its accuracy.

By leveraging this tool, designers and engineers can minimize uncertainties associated with transitioning from lab settings to real-world applications. This ensures that every fin meets the highest standards of performance and reliability, whether it’s used in calm pools or turbulent seas.

Tooling & Supply-Chain Engineering: The Moment Your Fin Becomes a Business

When it comes to scaling your carbon fiber fin production, the choice of tooling and supply-chain engineering can make or break your business. High-quality tooling not only ensures precision but also reduces long-term costs, making it a critical investment for any serious manufacturer. Below, we explore two key aspects that define successful production: high-performance moulds and compliance documentation.

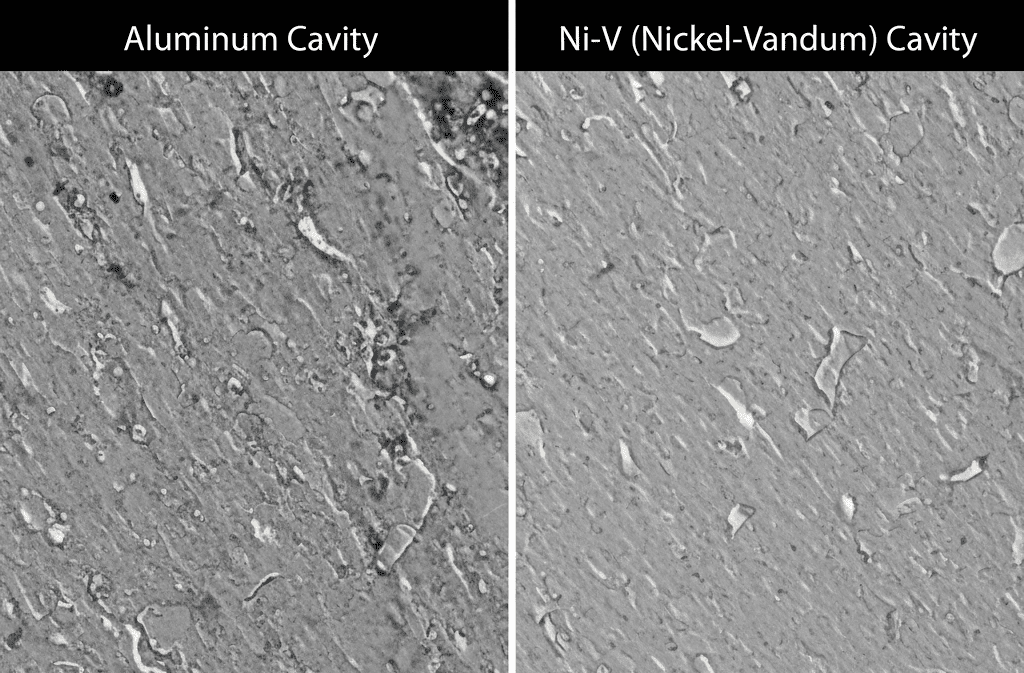

Nickel-Vanadium Moulds: 5,000 Shots, Zero Warp, <0.05 mm Tolerance

Investing in premium tooling is often seen as a significant upfront cost, but the long-term benefits far outweigh the initial expense. Nickel-Vanadium (Ni-V) moulds are a prime example of this principle in action. While an aluminum mould might cost around $1,000, a Ni-V mould comes with a price tag of approximately $8,000. However, the superior durability and precision of Ni-V moulds quickly justify their cost.

For instance, after producing just 500 units, the cost-per-shot drops dramatically from $3.20 with aluminum moulds to $0.80 with Ni-V moulds. This reduction is due to the Ni-V mould’s ability to deliver up to 5,000 shots without warping, all while maintaining tolerances below 0.05 mm. In contrast, aluminum moulds often begin to degrade after 1,000 cycles, leading to increased maintenance costs and inconsistent product quality.

To better illustrate the return on investment (ROI), consider the following table:

| Units Produced | Aluminum Mould Cost/Shot | Ni-V Mould Cost/Shot | Savings per Shot |

|---|---|---|---|

| 500 | $3.20 | $0.80 | $2.40 |

| 1,000 | $1.60 | $0.80 | $0.80 |

| 5,000 | N/A (Mould Fails) | $0.80 | Significant |

By the time you reach 5,000 units, the Ni-V mould has paid for itself multiple times over, offering unmatched reliability and cost efficiency.

Regional Compliance Passport: CE, REACH, Prop 65 in One Data-Pack

Navigating global markets requires more than just a great product—it demands meticulous attention to regulatory compliance. For manufacturers of carbon fiber fins, having a comprehensive compliance package is essential to ensure smooth customs clearance in regions like the EU, US, and Australia.

Our folder 05_Documents serves as your “Regional Compliance Passport,” containing all necessary certifications neatly organized for easy access. These include:

- CE Certification: Ensures compliance with European safety, health, and environmental requirements.

- REACH Compliance: Verifies that materials used meet EU chemical regulations.

- Prop 65 Compliance: Guarantees products sold in California are free from harmful substances listed under Proposition 65.

Each certificate is indexed in a PDF portfolio, allowing quick verification during audits or inspections. With this data-pack in hand, you can confidently ship your containers without worrying about surprise tests or delays at customs.

The transition from prototype to full-scale production hinges on two critical factors: robust tooling solutions and seamless regulatory compliance. By choosing nickel-vanadium moulds, you ensure unparalleled precision and cost efficiency, while a well-organized compliance data-pack guarantees hassle-free global distribution. Together, these elements transform your carbon fiber fin project into a thriving business.

Costing Models That Protect Your Margin at 100, 1,000, and 10,000 Units

Understanding the cost dynamics of producing carbon fiber fins is crucial for maintaining healthy profit margins as your business scales. JCSPORTLINE’s modular lay-up system offers a unique approach to managing costs effectively across different production volumes.

The 70-20-10 Rule—Material, Labour, Amortisation

Breaking down the typical Cost of Goods Sold (COGS) reveals a common distribution: 70% material costs, 20% labor, and 10% amortization. However, this ratio can shift dramatically with scale. For instance, at low production volumes, labor costs tend to dominate due to manual processes involved in composite part manufacturing. JCSPORTLINE addresses this challenge through advanced automation techniques that significantly reduce labor costs while maintaining high-quality standards.

Our modular lay-up process ensures that material costs remain steady at approximately 70%, even when scaling up to 10,000 units. This consistency is achieved by optimizing material usage and minimizing waste. Furthermore, our automated systems trim labor expenses from the typical 20% down to just 9%. This reduction not only protects your margin but also enhances overall production efficiency.

MOQ Sweet Spots & Cash-Flow Scenarios

Navigating Minimum Order Quantities (MOQs) is essential for startups and established brands alike. JCSPORTLINE offers three strategic MOQ tiers designed to align with various stages of business growth:

- 100 Units (Prototype-Plus): Ideal for initial prototyping and testing phases. At this tier, you can refine your product design without committing to large-scale production.

- 500 Units (Market Test): Perfect for conducting market tests and gathering consumer feedback before full-scale launch.

- 2,000 Units (Retail Roll-Out): Suited for retail expansion, ensuring sufficient stock levels to meet anticipated demand.

To assist with financial planning, we provide cash-flow projection templates tailored to each MOQ tier. These templates are invaluable tools for CFOs, offering clear insights into potential revenue streams and expenditure patterns associated with different order quantities.

By leveraging these costing models and MOQ strategies, businesses can achieve economies of scale in composite part production while safeguarding their profit margins. Whether you’re launching a start-up fin brand or expanding an existing line, JCSPORTLINE provides the expertise and solutions needed to succeed in today’s competitive market.

Assembly, Finishing & Branding: Turning a Blade into Your Brand Signature

In the world of high-performance fins, assembly, finishing, and branding are not just final steps—they are opportunities to transform a functional blade into a signature piece that reflects your brand’s identity. Whether you’re targeting professional divers or recreational water sports enthusiasts, the right finishing techniques can elevate both the aesthetics and functionality of your product. Below, we explore advanced finishing options and anti-counterfeit technologies that will set your fins apart.

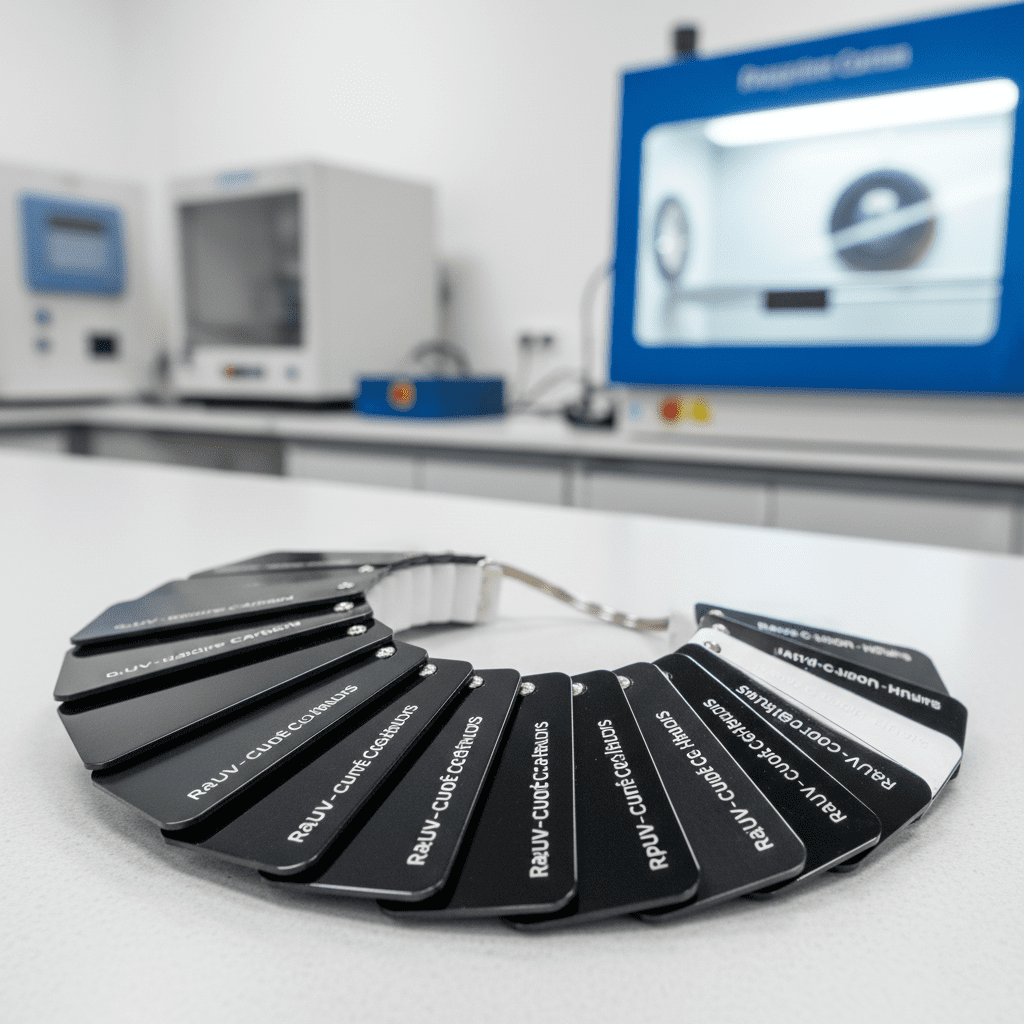

UV-Stable Matte, Gloss, and Hydrographic Finishes That Last 5 Years

When it comes to protecting your fins from environmental wear and tear while maintaining their visual appeal, choosing the right coating is crucial. Two popular options—PU clear-coat and epoxy nano-sealer—offer distinct advantages depending on your needs.

PU clear-coat is known for its durability and resistance to abrasion, making it ideal for high-impact activities like freediving or spearfishing. On the other hand, epoxy nano-sealer provides an ultra-smooth finish that enhances hydrodynamics while offering superior UV stability. Both coatings are engineered to resist fading under prolonged sun exposure, ensuring your fins retain their vibrant colors for up to five years.

For brands looking to create a unique visual identity, hydrographic transfer technology opens endless possibilities. This process allows for intricate designs such as camouflage patterns, carbon-fiber textures, or even custom Pantone-matched brand colors. Imagine a fin that not only performs exceptionally but also serves as a canvas for your brand story.

Laser Etching & RFID Inside the Fin—Anti-Counterfeit & Customer Engagement

In an era where counterfeit products flood the market, integrating advanced anti-counterfeit measures into your fins is more important than ever. One innovative solution is embedding NFC (Near Field Communication) tags directly into the fin structure. These tiny chips link to your registration page, enabling customers to verify authenticity simply by tapping their smartphones against the fin.

But the benefits don’t stop at authentication. NFC-enabled fins can also unlock exclusive content, such as care instructions, warranty details, or even personalized training tips. This interactive feature not only builds trust but also fosters deeper engagement between your brand and its users. Additionally, laser etching adds another layer of sophistication, allowing you to engrave serial numbers, logos, or design elements that are tamper-proof and permanent.

From a manufacturing perspective, incorporating RFID antennas within the fin ensures seamless integration without compromising structural integrity. The result? A cutting-edge product that combines security, convenience, and style.

By leveraging these advanced finishing techniques and anti-counterfeit technologies, you can create fins that are not only visually stunning but also highly functional and secure. For businesses seeking to differentiate themselves in a crowded marketplace, customization and innovation are key. Whether through UV-stable coatings, hydrographic designs, or embedded NFC tags, every detail contributes to crafting a product that truly embodies your brand’s values.

Ready to turn your vision into reality? Explore our range of customizable solutions tailored to meet the unique demands of your target audience. Together, let’s redefine what’s possible in the world of high-performance fins.

Shipping, Warranty & After-Sales: Protecting Your Reputation After the Sale

When it comes to high-performance carbon fiber fins, ensuring they arrive safely and remain reliable long after purchase is crucial for maintaining customer trust. JCSPORTLINE has developed a comprehensive approach to shipping, warranty, and after-sales support that not only safeguards your investment but also enhances brand loyalty.

Individual Foam Nest + VCI Film—0.3% Transit Damage Rate

Shipping composite materials like carbon fiber fins can be challenging due to their susceptibility to impact and environmental damage. At JCSPORTLINE, we’ve perfected a packaging SOP that balances efficiency with protection. Each fin is individually nestled in a custom foam insert, designed to absorb shocks during transit. This is further wrapped in VCI (Vapor Corrosion Inhibitor) film, which prevents oxidation and surface degradation caused by humidity or temperature fluctuations.

Our master carton holds 24 pairs of fins and has been rigorously tested to withstand a 1-meter drop without compromising the contents. This meticulous attention to detail results in an industry-leading transit damage rate of just 0.3%. By adhering to these standards, we ensure that every product reaches its destination in pristine condition, ready to perform.

FAQ

Q1: How many prototypes will I need before JCSPORTLINE approves mass production?

A1: Typically, you’ll go through 2–3 rapid prototypes followed by one pre-series batch of 30 units. Final approval occurs at Gate 4 when all specifications meet your requirements.

Q2: Can I mix stiffness levels in the same order?

A2: Absolutely! Thanks to our parametric lay-up technology, you can split your Minimum Order Quantity (MOQ) 50/50 between Soft and Race stiffness levels without requiring additional tooling costs.

Q3: What file formats do you accept for my custom foot-pocket scan?

A3: We accept STL, OBJ, or STEP files. If you only have a plaster cast, don’t worry—we offer free optical scanning during Gate 1 to digitize your design.

Q4: Does JCSPORTLINE keep my mould if I pause orders?

A4: Yes, we store and maintain your mould free of charge for up to 24 months. After this period, there’s a storage fee of USD 20 per month, or you can arrange to have it shipped back to you.

Q5: Are your carbon fins recyclable?

A5: Sustainability matters to us. Through our take-back program, returned fins are pyrolyzed to reclaim carbon fiber for industrial reuse. As a thank-you, you’ll receive a 5% credit toward your next order.

By addressing these frequently asked questions, we aim to provide transparency and build confidence in our processes. Whether you’re concerned about prototyping timelines, customization options, or environmental impact, JCSPORTLINE has solutions tailored to meet your needs.