Table of Contents

Unmatched Customization: Tailored Carbon Fiber Hydrofoils for Every Surfer

Why Customization Matters for Every Surfer

At JCSPORTLINE, we understand that no two surfers are the same. Every surfer has unique preferences and requirements, whether they’re a professional pushing the limits of speed and maneuverability or a recreational surfer looking for stability and ease. Customization allows us to tailor every aspect of the carbon fiber hydrofoil to fit your exact needs, enhancing both performance and comfort. By customizing the design, weight, and strength of the hydrofoil, we ensure that each surfer experiences optimal performance in every wave, regardless of their skill level or conditions.

JCSPORTLINE’s Expertise in Tailoring Hydrofoils to Your Needs

Our expertise lies in our ability to listen to our customers and turn their preferences into precise design specifications. JCSPORTLINE offers a range of customization options that take into account the surfer’s experience, weight, preferred riding conditions, and even personal style. Whether you’re seeking a lightweight foil for speed or a more robust design for stability, we have the knowledge and technology to craft the perfect hydrofoil for you. Our team uses cutting-edge tools and production methods, ensuring every hydrofoil is engineered for superior performance.

The Impact of Customization on Performance and Comfort

Customization plays a vital role in improving both performance and comfort when using a hydrofoil. By adjusting the hydrofoil’s shape, size, and material, we can create a foil that matches your riding style, making it easier to maneuver, improve stability, and increase speed. For professional surfers, this can mean gaining that extra edge in competition, while for leisure surfers, it ensures a comfortable and enjoyable experience in various water conditions. JCSPORTLINE’s tailored approach ensures that your hydrofoil will always meet your specific requirements, enhancing your time on the water.

Advanced Technology in Carbon Fiber Manufacturing: Precision and Durability

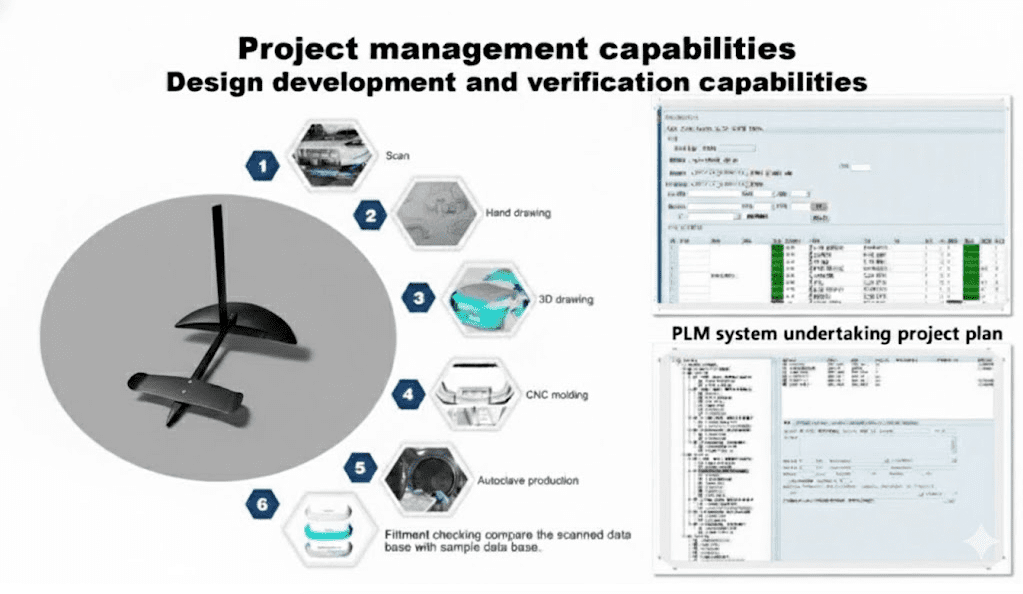

High-Precision CNC Machining for Flawless Hydrofoil Design

At JCSPORTLINE, precision is at the heart of our manufacturing process. Using high-precision 5-axis CNC machining, we can ensure that every carbon fiber hydrofoil is crafted with absolute accuracy. This technology allows us to shape the hydrofoil to the exact specifications needed for optimal performance. The precise cuts and smooth surfaces produced by the CNC machine help reduce air resistance, enhance maneuverability, and improve the overall strength of the hydrofoil.

Mold Design and Materials for Ultimate Strength and Durability

The next crucial step in the production process is mold design. At JCSPORTLINE, we use high-quality P20 steel molds that are built for precision and longevity. The surface roughness of the mold is maintained to Ra ≤ 0.8μm, ensuring that the final hydrofoil has a smooth and polished surface. The molds are designed using advanced CAD technology, and our engineers ensure that each component fits together perfectly for the strongest possible bond between the carbon fiber layers.

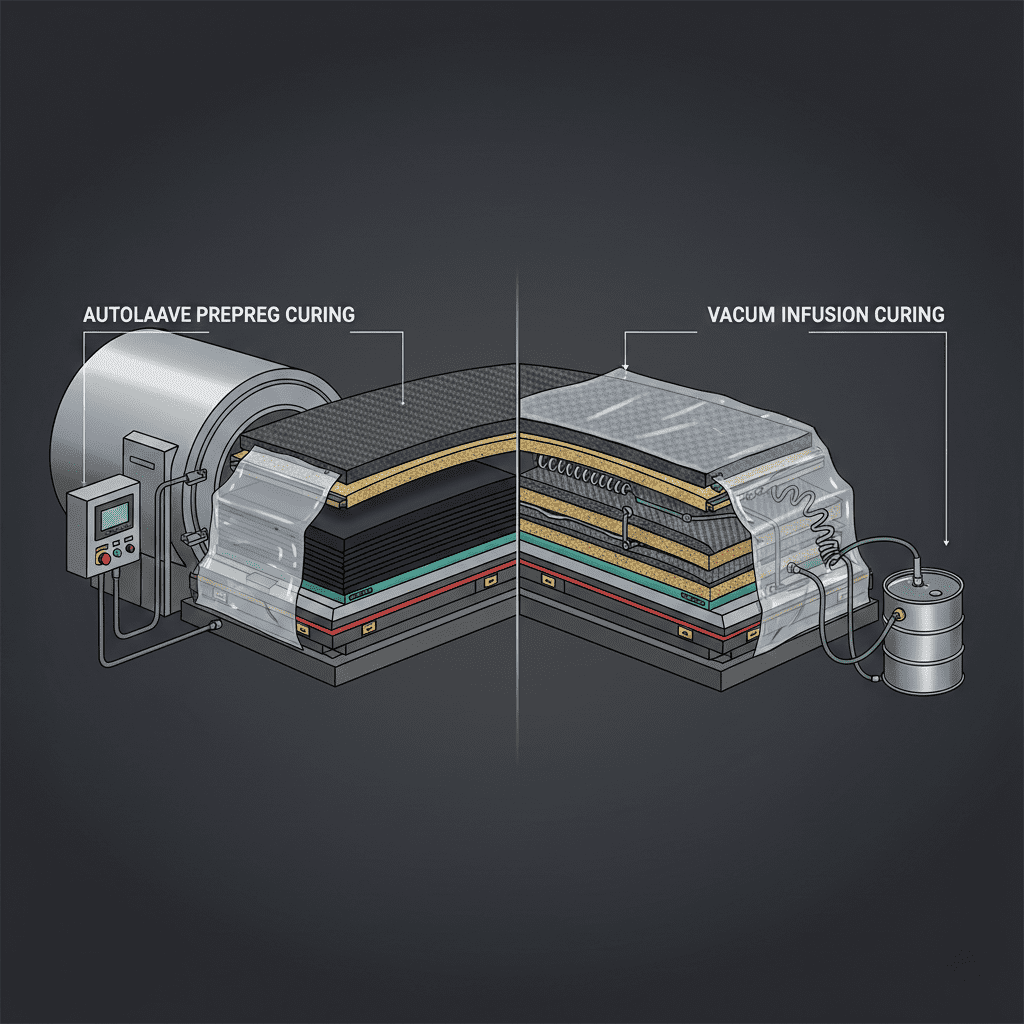

High-Temperature Curing and Intelligent Detection for Consistent Quality

Once the hydrofoil is molded, we apply a high-temperature curing process that ensures a strong and durable bond between the layers of carbon fiber. The curing process is carried out under controlled conditions, which allow the resin to fully bond with the carbon fiber layers, enhancing strength and resilience. To guarantee consistency and performance, we use intelligent detection systems such as ultrasonic scans and industrial CT scans to check for any internal defects. This rigorous testing process ensures that every hydrofoil leaving our factory is up to the highest standard of quality.

Performance Testing: Ensuring the Ultimate Surfing Experience

Testing Stability and Maneuverability in Real-World Conditions

At JCSPORTLINE, we understand that a hydrofoil’s stability and maneuverability are crucial for an exceptional surfing experience. That’s why we conduct extensive performance tests to simulate various water conditions, including calm waters, choppy waves, and even high winds. These tests allow us to assess how the hydrofoil handles in different environments, ensuring that surfers can enjoy a smooth ride no matter the conditions. Our testing focuses on how well the hydrofoil maintains stability during high-speed runs, sharp turns, and difficult wave encounters. By putting the hydrofoils through these real-world conditions, we ensure that each product is finely tuned for top-tier performance.

Durability Testing: Ensuring Long-Lasting Performance

We believe that a high-quality hydrofoil should not only perform well but also withstand the test of time. To ensure that our carbon fiber hydrofoils maintain their integrity over extended use, we perform a variety of durability tests. These tests include stress simulations, material fatigue testing, and repeated exposure to harsh environmental conditions such as saltwater and extreme temperatures. By subjecting the hydrofoils to these rigorous tests, we ensure that they will continue to perform at their best for years to come, providing you with a reliable and durable product for your surfing adventures.

Simulating Wave Conditions: Perfecting Performance in Every Scenario

One of the most critical aspects of performance testing is simulating wave conditions. At JCSPORTLINE, we use advanced wave tanks to mimic real-world surfing environments, allowing us to test how the hydrofoils react to different wave heights and types. From small, gentle waves to larger, more powerful swells, each hydrofoil is tested to ensure that it performs optimally, providing smooth and stable rides across various wave conditions. We also analyze how the hydrofoils perform in both calm water and turbulent surf, ensuring that surfers can enjoy precise control and agility, regardless of the environment.

Sustainable Manufacturing: Eco-Friendly Solutions for Surfing Products

Eco-Friendly Materials for Carbon Fiber Hydrofoils

At JCSPORTLINE, sustainability starts with the materials we choose. We prioritize eco-friendly carbon fiber alternatives that reduce the environmental impact of our production. By selecting carbon fibers with lower environmental footprints and utilizing recyclable resins, we ensure that each hydrofoil is not only high-performing but also responsible. Our approach involves sourcing sustainable raw materials without compromising on strength, durability, or overall performance. This commitment to using green materials makes our products more environmentally friendly while maintaining the premium quality that surfers expect.

Energy-Efficient Manufacturing Processes

Reducing energy consumption is a key factor in our commitment to sustainability. JCSPORTLINE has implemented energy-efficient manufacturing techniques to lower the carbon footprint of our production process. We utilize advanced technologies such as solar-powered curing ovens and automated systems that optimize energy use throughout the production process. These innovations help minimize waste and energy consumption while ensuring the production of high-quality hydrofoils. By continually improving our energy efficiency, we contribute to the reduction of environmental impact in the surfing industry.

Waste Recycling and Process Optimization for Sustainable Production

Another critical aspect of our sustainable manufacturing process is waste management. We actively recycle production waste, including carbon fiber scraps, and repurpose them for lower-tier products or use in other industries. This waste recycling system reduces the amount of waste sent to landfills and helps us minimize our environmental footprint. Additionally, we continue to optimize our production line for better efficiency, which allows us to reduce material waste and further decrease our overall environmental impact. By integrating waste recycling and process optimization, we are making strides toward a more sustainable and eco-conscious future in hydrofoil production.

Why Choose JCSPORTLINE: Factory Expertise and Commitment to Quality

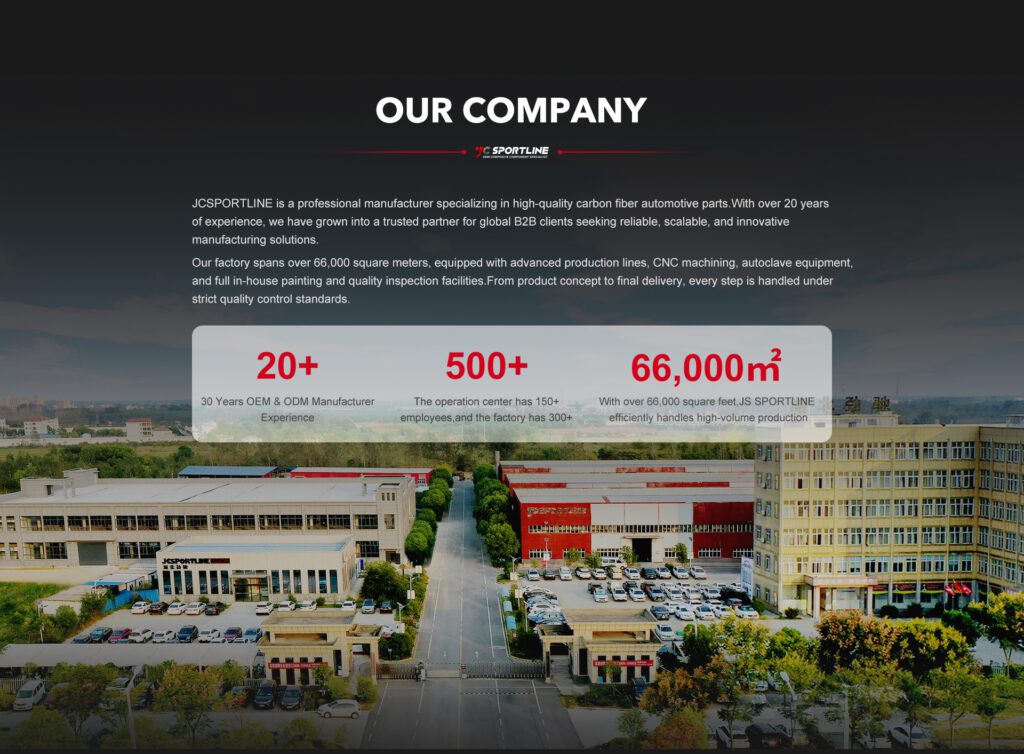

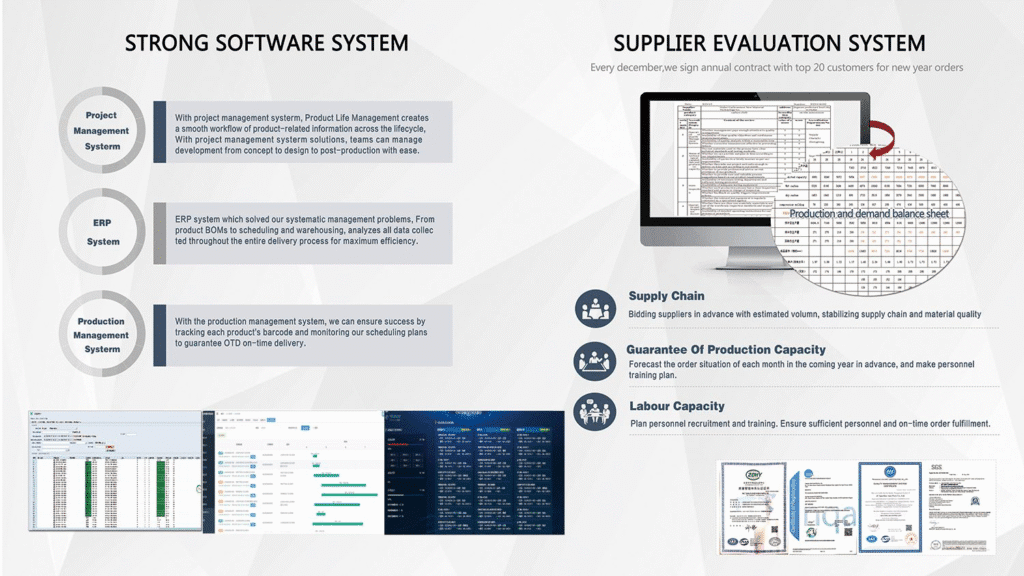

Expert Manufacturing and Cutting-Edge Technology

At JCSPORTLINE, we pride ourselves on our expertise in carbon fiber hydrofoil manufacturing. Our factory is equipped with state-of-the-art technology that allows us to produce hydrofoils that exceed industry standards. From precision CNC machining to advanced carbon fiber layering techniques, we use only the most advanced tools and processes to ensure the highest quality. Our dedicated engineering team works relentlessly to improve and innovate, ensuring that every hydrofoil we produce is designed for performance, durability, and efficiency.

Stringent Quality Control and International Certifications

Quality is at the core of everything we do at JCSPORTLINE. We employ a stringent quality control process that begins from the selection of raw materials to the final testing of every finished hydrofoil. Each hydrofoil undergoes rigorous testing to ensure it meets the highest standards of performance and durability. In addition to our in-house quality checks, we are proud to hold international certifications, including ISO 9001 and IATF 16949, which further validate our commitment to producing only the best products for our customers.

Global Leadership and Industry Trust

As a leading brand in the carbon fiber hydrofoil industry, JCSPORTLINE has earned the trust and respect of surfers around the world. Our commitment to innovation, performance, and sustainability has positioned us as an industry leader, and our products are trusted by professional surfers, enthusiasts, and recreational riders alike. With decades of experience in carbon fiber manufacturing and a dedication to pushing the limits of what’s possible, JCSPORTLINE continues to set the standard for high-quality hydrofoils in the surfing world.

FAQ – Frequently Asked Questions About Our Custom Carbon Fiber Hydrofoils

What Makes JCSPORTLINE Hydrofoils Different from Others?

At JCSPORTLINE, we specialize in producing custom carbon fiber hydrofoils designed for ultimate performance, durability, and comfort. What sets us apart is our attention to detail, advanced manufacturing processes, and our commitment to using only the highest-quality materials. Each hydrofoil is tailored to meet the unique needs of every surfer, ensuring superior stability, maneuverability, and reliability in a variety of water conditions. Our hydrofoils are also tested rigorously to ensure consistency and longevity, making them a trusted choice for both professional surfers and recreational riders.

How Can I Customize My Hydrofoil?

Customizing your hydrofoil is simple with JCSPORTLINE. We offer a range of customization options, including choosing the size, shape, and material of the hydrofoil. You can select from different carbon fiber options for varying levels of strength and weight, and we also offer specific designs tailored to your riding style, whether you prefer speed, stability, or maneuverability. Our team works closely with you to understand your preferences and create the perfect hydrofoil to suit your needs.

How Do I Care for and Maintain My Carbon Fiber Hydrofoil?**

Proper care and maintenance are essential to keep your carbon fiber hydrofoil in top condition. To maintain its performance, it’s important to rinse the hydrofoil with fresh water after each use, especially if you’ve been in saltwater. Dry the hydrofoil thoroughly and store it in a cool, dry place away from direct sunlight. We also recommend periodically checking for any wear or damage, such as cracks or loose parts, and addressing any issues immediately. Following these simple maintenance tips will help ensure that your hydrofoil lasts for years while performing at its best.

What Is the Typical Lifespan of a Carbon Fiber Hydrofoil?

With proper care, a carbon fiber hydrofoil from JCSPORTLINE can last for many years. The lifespan largely depends on how frequently the hydrofoil is used, the conditions in which it’s used, and how well it’s maintained. In ideal conditions with regular maintenance, you can expect your hydrofoil to remain in top condition for 5-10 years. We recommend following our maintenance guidelines to ensure your hydrofoil performs optimally throughout its lifespan.