Table of Contents

From Raw Carbon to Ride-Ready Core: Material Prep & Lay-Up

The journey of crafting a high-performance electric surfboard begins with precision and innovation. At JCSPORTLINE, every step in the process—from material preparation to the final lay-up—is designed to deliver an unparalleled riding experience. Let’s take a closer look at how aerospace-grade materials are transformed into the core of your dream board.

Precision Cutting: The Art of Pre-Preg Carbon Fiber

Laser-Cut Accuracy for Maximum Performance

At the heart of every JCSPORTLINE electric surfboard lies pre-preg carbon fiber, renowned for its exceptional strength-to-weight ratio. This advanced material is meticulously prepared using state-of-the-art laser-cutting technology. Each sheet is cut with an astonishing edge precision of ±0.2 mm, ensuring that every piece fits perfectly during assembly.

This level of accuracy isn’t just about aesthetics—it’s about performance. By cutting each ply to exact specifications, we ensure that the carbon fiber layers align perfectly to optimize flex, pop, and overall board stiffness. What’s more, our AI-driven nesting program ensures minimal waste during the cutting process. This not only reduces environmental impact but also maximizes the stiffness-to-weight ratio of your board, making it lighter and more responsive on the water.

| Material | Cutting Precision | Key Benefits |

|---|---|---|

| Pre-Preg Carbon | ±0.2 mm | Enhanced stiffness, reduced weight, zero defects |

| PU Core | One-shot foaming | Zero water absorption, consistent density |

The Perfect Core: Closed-Cell PU Foam

One-Shot Foaming for Unmatched Durability

While the carbon fiber provides the outer shell’s strength, the core of the surfboard plays an equally critical role. JCSPORTLINE uses closed-cell polyurethane (PU) foam, which is foamed in a single shot to achieve uniform density and zero water absorption. This process eliminates the risk of delamination or waterlogging, ensuring your board remains lightweight and durable over time.

The PU core is engineered to balance rigidity and flexibility, providing the ideal foundation for the carbon fiber layers. Its density, typically ranging from 60-120 kg/m³, is carefully calibrated to meet the demands of modern electric surfboards. Whether you’re carving sharp turns or gliding across calm waters, the PU core ensures consistent performance under all conditions.

Hand-Laid Perfection: Crafting Your Custom Board

Tailored Lay-Up for Optimal Performance

Once the materials are prepared, skilled technicians hand-lay each ply of carbon fiber at precise angles—typically ±45°—to achieve the desired mechanical properties. This meticulous process ensures that every board delivers the perfect combination of pop, flex, and strength tailored to your riding style.

For instance, if you’re looking for a board with explosive pop for aerial tricks, the lay-up will prioritize stiffness. On the other hand, if you prefer smooth, controlled flex for carving waves, the lay-up will emphasize elasticity. This “made-for-you” approach ensures that every JCSPORTLINE board is as unique as its rider.

Advanced Techniques: Molding and Curing

High-Temperature Curing for Ultimate Strength

After the lay-up is complete, the assembled board is placed in a mold and cured at 150°C for 90 minutes. This curing process activates the resin in the pre-preg carbon fiber, bonding the layers together to create a monolithic structure. The result is a board that’s not only incredibly strong but also remarkably lightweight.

To ensure quality, each board undergoes rigorous testing, including ultrasonic scanning (UT) and industrial CT scans. These advanced techniques detect even the smallest internal defects, ensuring that every board leaving the factory meets JCSPORTLINE’s exacting standards. With a defect rate of less than 0.5%, you can trust that your board is built to last.

Sustainability in Action

Eco-Friendly Practices for a Greener Future

At JCSPORTLINE, sustainability is more than just a buzzword—it’s a core value. Our production process incorporates several eco-friendly practices, such as recycling carbon fiber scraps through carbonization, achieving a recovery rate of 90% or higher. Additionally, our curing ovens are powered by solar energy, reducing energy consumption by 30%.

By choosing a JCSPORTLINE electric surfboard, you’re not only investing in top-tier performance but also supporting a brand committed to protecting the planet.

Heat, Pressure & Precision: Curing, Machining & Surface Finish

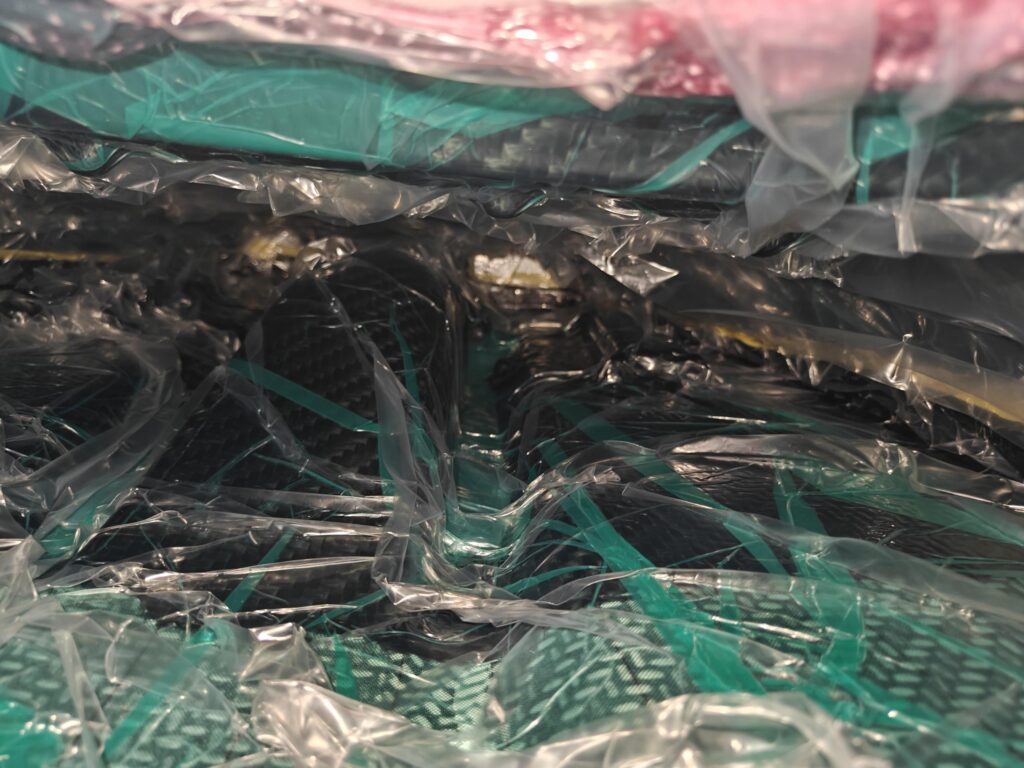

After the carbon fiber stack is carefully bagged and prepped, it enters the critical phase of curing, machining, and surface finishing. These steps define not only the structural integrity but also the aesthetic appeal and functionality of the final product. Let’s dive into how JCSPORTLINE masters these processes to deliver high-performance boards tailored to different riding styles.

The Science of Curing: Heat, Pressure, and Time

Curing is where the magic happens—transforming layers of carbon fiber pre-preg into a unified, ultra-strong structure. At JCSPORTLINE, this process involves precision-controlled heat and pressure within state-of-the-art molds.

The stack is subjected to a 150°C mold cure for 90 minutes, ensuring that the epoxy resin fully cures while maintaining optimal bonding between layers. This temperature is critical because it strikes the perfect balance between achieving maximum strength and avoiding thermal degradation of the materials. Once cured, the mold undergoes rapid cool-down to lock in the material properties and minimize residual stresses.

This meticulous curing process is complemented by advanced quality control measures. For instance, ultrasonic scanning (UT) and industrial CT detection are employed to identify any internal defects, keeping the defect rate below 0.5%. These technologies ensure every board leaving the production line meets JCSPORTLINE’s uncompromising standards.

Precision Machining: Trimming for Performance

Post-curing, the board moves to the machining stage, where precision is paramount. Using 5-axis CNC machines, key features such as fin boxes, mast tracks, and the magnetic battery hatch are trimmed with exacting accuracy.

Why does this matter? These components are crucial for performance. For example, the alignment of the fin box directly impacts hydrodynamics, while the battery hatch must fit seamlessly to maintain waterproof integrity. With tolerances as tight as ±0.2mm, CNC machining ensures that every detail aligns perfectly with the design specifications.

This level of precision is particularly important for electric surfboards, where even minor deviations can affect stability, speed, and overall ride quality. By integrating cutting-edge machining techniques, JCSPORTLINE guarantees a flawless transition from prototype to production-ready boards.

Surface Finish: Matte vs Gloss—A Matter of Style and Function

The final touch in the production process is the surface finish, which plays a dual role in both aesthetics and functionality. JCSPORTLINE offers two distinct options tailored to different rider preferences:

Matte Sanded Finish for Race Boards

Race boards feature a matte sanded finish, which provides an additional layer of grip without adding extra weight. This textured surface enhances control during high-speed maneuvers, making it ideal for competitive riders who demand precision and responsiveness.

UV-Stable Gloss Polish for Lifestyle Models

On the other hand, lifestyle models boast a UV-stable gloss polish that exudes elegance and durability. This glossy finish not only looks stunning but also resists fading under prolonged sun exposure, ensuring the board remains visually appealing over time.

By offering these two options, JCSPORTLINE allows riders to choose a finish that matches their personal style and riding goals. Whether you’re chasing podium finishes or cruising along the coastline, there’s a perfect match for you.

Sustainability in Production

Beyond performance and aesthetics, JCSPORTLINE prioritizes sustainability throughout the manufacturing process. For instance, cutting waste is recycled through carbonization, achieving a recovery rate of over 90%. Additionally, the curing ovens are powered by solar energy, reducing the carbon footprint of each board produced.

These eco-friendly practices underscore JCSPORTLINE’s commitment to innovation and responsibility, ensuring that high-performance products don’t come at the expense of the planet.

Why It Matters: Carbon Fiber Surfboard Production in 2025

As we look ahead to 2025, advancements in carbon fiber curing temperatures, CNC surfboard machining, and surface finish techniques will continue to shape the industry. Brands like JCSPORTLINE are leading the charge, setting new benchmarks for quality, customization, and sustainability.

Whether you’re a seasoned pro or a casual rider, understanding these processes helps you appreciate the craftsmanship behind every board. And with options like matte or gloss finishes, you can truly personalize your ride to reflect your unique style.

Planet-First Production: Recycling, Solar Power & 2025 Sustainability

Choosing a JCSPORTLINE board in 2025 means more than just owning a high-performance electric surfboard—it’s a commitment to supporting sustainable innovation. With closed-loop manufacturing processes, solar-powered production facilities, and an ambitious take-back program, we’re redefining eco-friendly carbon fiber production for the modern rider. Let’s dive into how our planet-first approach ensures that your upgrade never ends up in a landfill.

Carbon Fiber Recycling: Closing the Loop

At JCSPORTLINE, sustainability begins with material efficiency. Our advanced manufacturing process incorporates 90% recycled carbon fiber from off-cuts generated during production. These off-cuts are pyrolyzed—a thermal decomposition process that removes resin and restores the structural integrity of the fibers—allowing them to be reclaimed and reused in next year’s fins or other components.

This closed-loop system not only reduces waste but also minimizes the need for virgin carbon fiber, which is energy-intensive to produce. By integrating recycled materials into new products, we significantly lower the environmental footprint of each surfboard. For example, a single board made with reclaimed carbon fiber can save up to 15 kg of CO₂ emissions compared to traditional manufacturing methods.

| Material | Recycling Rate | CO₂ Savings per Board |

|---|---|---|

| Virgin Carbon Fiber | 0% | N/A |

| Reclaimed Carbon Fiber | ≥ 90% | ~15 kg |

Solar-Powered Manufacturing: Cutting Emissions by 30%

Energy consumption is one of the largest contributors to a product’s carbon footprint. To address this, JCSPORTLINE has implemented solar-powered autoclaves in our production facilities. These state-of-the-art machines cure carbon fiber composites at temperatures of 150°C while running entirely on renewable energy.

The result? A 30% reduction in CO₂ emissions per board compared to conventional curing methods. This shift not only aligns with global efforts to combat climate change but also sets a new standard for sustainable electric surfboards.

For instance, consider the lifecycle of a typical surfboard. Traditional boards often rely on fossil fuels for energy-intensive processes like molding and curing. In contrast, our solar-powered approach ensures that every step—from pre-preg cutting to final assembly—is as green as possible.

Take-Back Program: From Old Boards to New Aerospace Parts

What happens when you’re ready to upgrade your surfboard? At JCSPORTLINE, we believe in a circular economy where nothing goes to waste. Through our innovative take-back program, old boards are shredded and repurposed into raw materials for aerospace parts and other high-performance applications.

Here’s how it works:

- Customers return their used boards through designated collection points.

- The boards undergo shredding and separation processes to extract usable materials.

- These materials are then reintegrated into manufacturing streams for industries like aviation and automotive engineering.

This initiative ensures that even end-of-life products contribute to future innovations, keeping valuable resources out of landfills. It’s a win-win solution for both consumers and the planet.

Rigorous Testing for Durability and Performance

Sustainability doesn’t mean compromising on quality. Every JCSPORTLINE board undergoes rigorous testing to ensure it meets the highest standards of performance and durability.

Material Strength and Environmental Resilience

Our carbon fiber composites are subjected to tensile strength tests (target ≥ 80 MPa) and shear strength evaluations (target ≥ 15 MPa). Additionally, boards are exposed to extreme conditions such as salt spray corrosion tests and thermal cycling between -20°C and 60°C to validate their longevity.

Real-World Simulations

To mimic real-world scenarios, we conduct anti-wave tests in controlled wave pools and simulate 500 consecutive surfing motions using mechanical arms. These tests help identify potential stress points and ensure the board remains robust under heavy use.

Why Choose JCSPORTLINE in 2025?

By choosing a JCSPORTLINE board, you’re not just investing in cutting-edge technology—you’re supporting a movement toward a more sustainable future. Our commitment to carbon fiber recycling, solar-powered manufacturing, and closed-loop systems makes us a leader in eco-friendly surfboard production.

Whether you’re an avid surfer or a casual rider, every purchase contributes to reducing waste, lowering emissions, and advancing green technologies. Together, we can ride the waves while protecting the planet.

FAQ – Everything You Still Wonder About Carbon E-Surfboard Build

Can a Carbon E-Surfboard Be Repaired?

Yes, but repairs depend on damage severity. The carbon fiber exterior and foam core structure allow localized fixes. For optimal results, professional servicing is recommended to ensure structural integrity and waterproofing.

How Does the Weight Compare to Fiberglass Boards?

Carbon boards are lighter and stronger than fiberglass. With weights around 8kg, they offer superior handling and durability. The advanced materials reduce fatigue during use while enhancing overall performance.

What is the Expected Lifespan?

With proper care, carbon e-surfboards last 5+ years. Rigorous testing—like salt spray for corrosion resistance and mechanical fatigue simulations—ensures longevity. Components such as stainless screws resist rust for over 3 years in marine environments.

Can I Visit JCSPORTLINE for a Custom Factory Tour?

Yes! JCSPORTLINE welcomes visitors to explore our factory. Witness the molding process, including prepreg layup and heat pressing. Our team provides insights into custom builds tailored to your needs.