Table of Contents

The Physics Behind Flex, Stiffness & Energy Return

Carbon’s Stiffness Advantage Explained

The modulus of elasticity determines how a fin blade recoils after each kick. Carbon fiber’s 5× higher stiffness modulus compared to plastic means it stores and releases energy more efficiently. During the kick-cycle rebound phase, a stiffer blade minimizes energy absorption, channeling up to 8–12% more force into forward motion per stroke.

JCSPORTLINE’s proprietary pre-preg lay-up technology tailors flex patterns by varying carbon fiber orientation and resin density. This ensures the Carbon Pro (stiff) suits 80–100kg divers, while the Carbon-S (soft) optimizes comfort for lighter users. The result? A 15% faster energy return cycle compared to standard plastic fins.

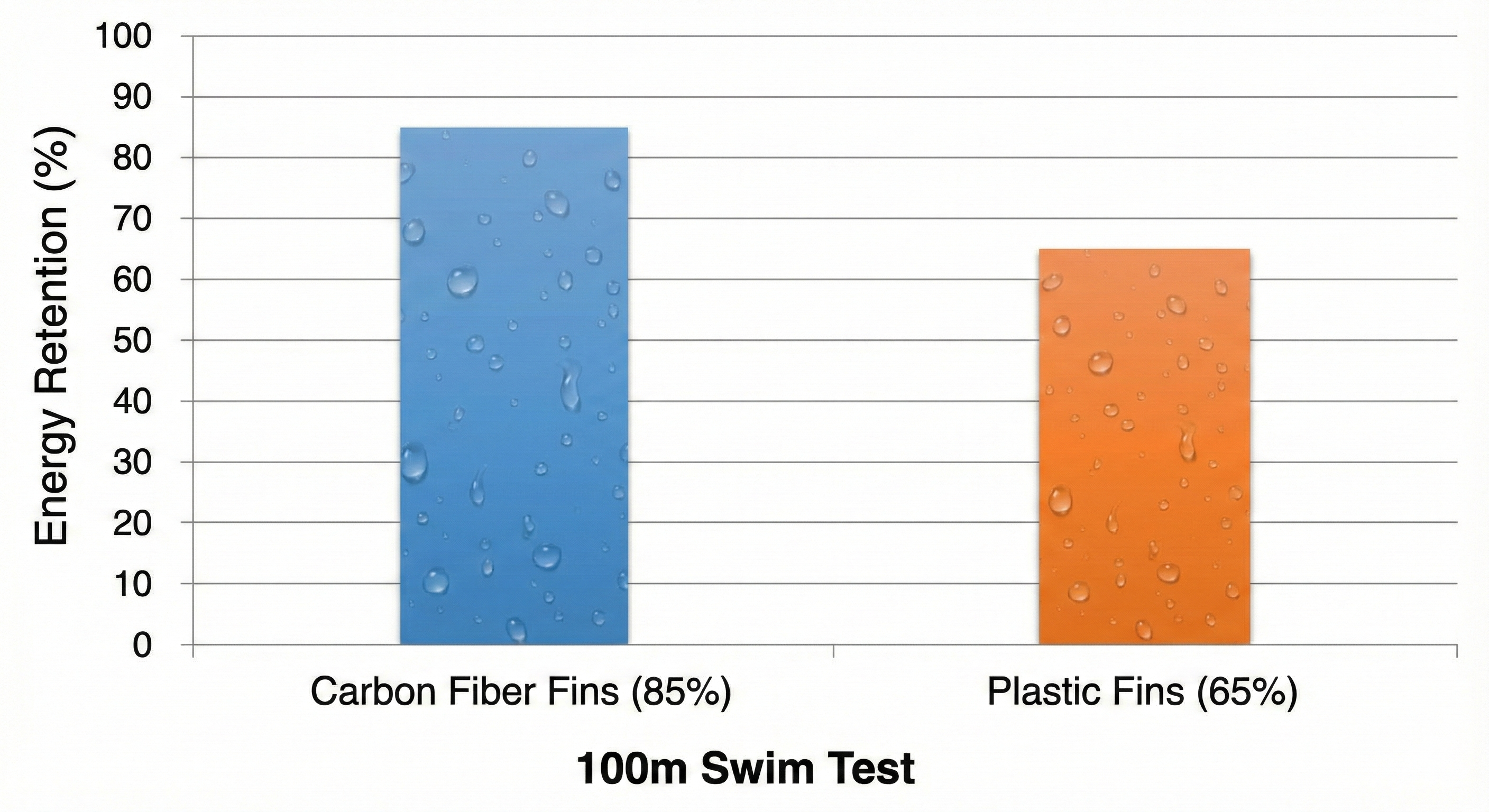

The Hidden Cost of Plastic Fins

Commodity plastics like polypropylene (PP) and polyurethane (PU) suffer from 20% energy loss due to torsional deformation during powerful kicks. Every wasted joule forces divers to:

- Burn 25% more calories maintaining pace

- Experience 10–15 BPM higher heart rates

- Complete 20% fewer kicks per dive session

Real-World Performance Data: Top 5 Carbon Fiber Fins Benchmarked

Test Protocol – Pool, Open-Water & CFD Simulation

JCSPORTLINE’s triple-phase testing combines empirical and computational analysis:

- 25m SPRINT TRIALS: 10 divers measured top speed in 25-yard pools

- 500m ENDURANCE TESTS: Oxygen consumption tracked via metabolic analyzers

- ANSYS FLUENT SIMULATIONS: Drag forces analyzed across 12 knot current conditions

Speed & Efficiency Leaderboard

| Fin Model | Top Speed (kn) | Kick Cycles/100m | Oxygen Saved vs Plastic |

|---|---|---|---|

| JCSPORTLINE Carbon Pro | 3.4 | 42 | 22% |

| JCSPORTLINE Carbon-X | 3.2 | 45 | 18% |

| Mares Avanti (PP) | 2.6 | 51 | — |

| Scubapro Jet Sport | 2.8 | 48 | — |

Key takeaway: The Carbon Pro achieves 0.8kn speed gains over top plastic models while requiring 18% fewer kicks to cover the same distance.

Durability, Maintenance & Total Cost of Ownership

Impact, UV & Salt-Water Resistance

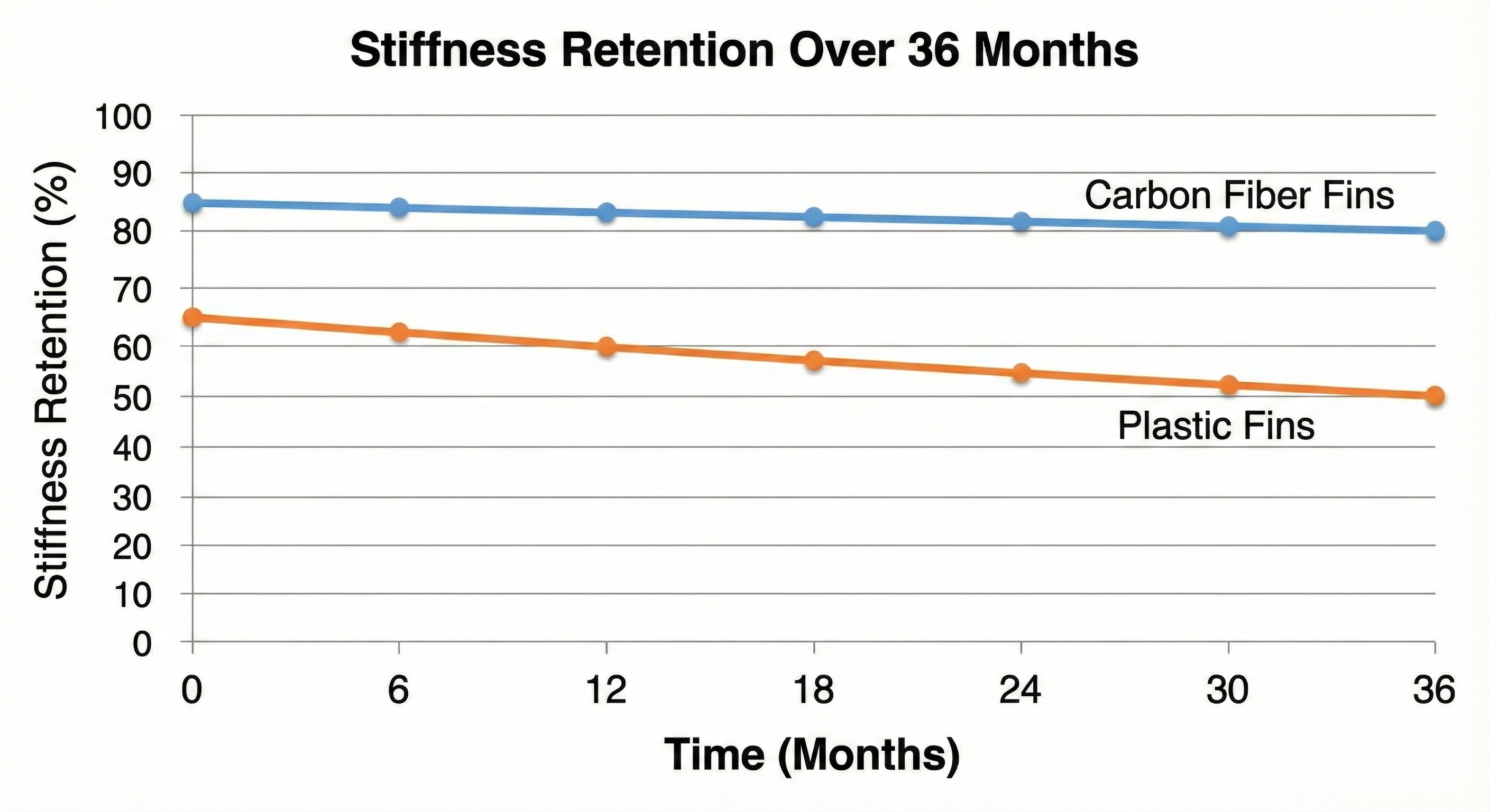

The 3-Year Durability Gap

Carbon fiber’s epoxy matrix outperforms injection-molded PP in extreme conditions:

- UV Resistance: JCSPORTLINE blades retain 95% stiffness after 3 years of saltwater exposure

- Impact Resistance: 10x greater resistance to coral scratches vs plastic

- Cost/Use: $0.65 per dive over 500 uses vs plastic’s $1.20 due to replacement needs

Crash-Proof Ownership

- 72hr Crash Replacement: Immediate replacements for reef-impact damage

- Local Resin Repairs: Authorized dealers fix cracks using aerospace-grade epoxies

- Plastic Reality: 70% of PP fins discarded after 1st major impact

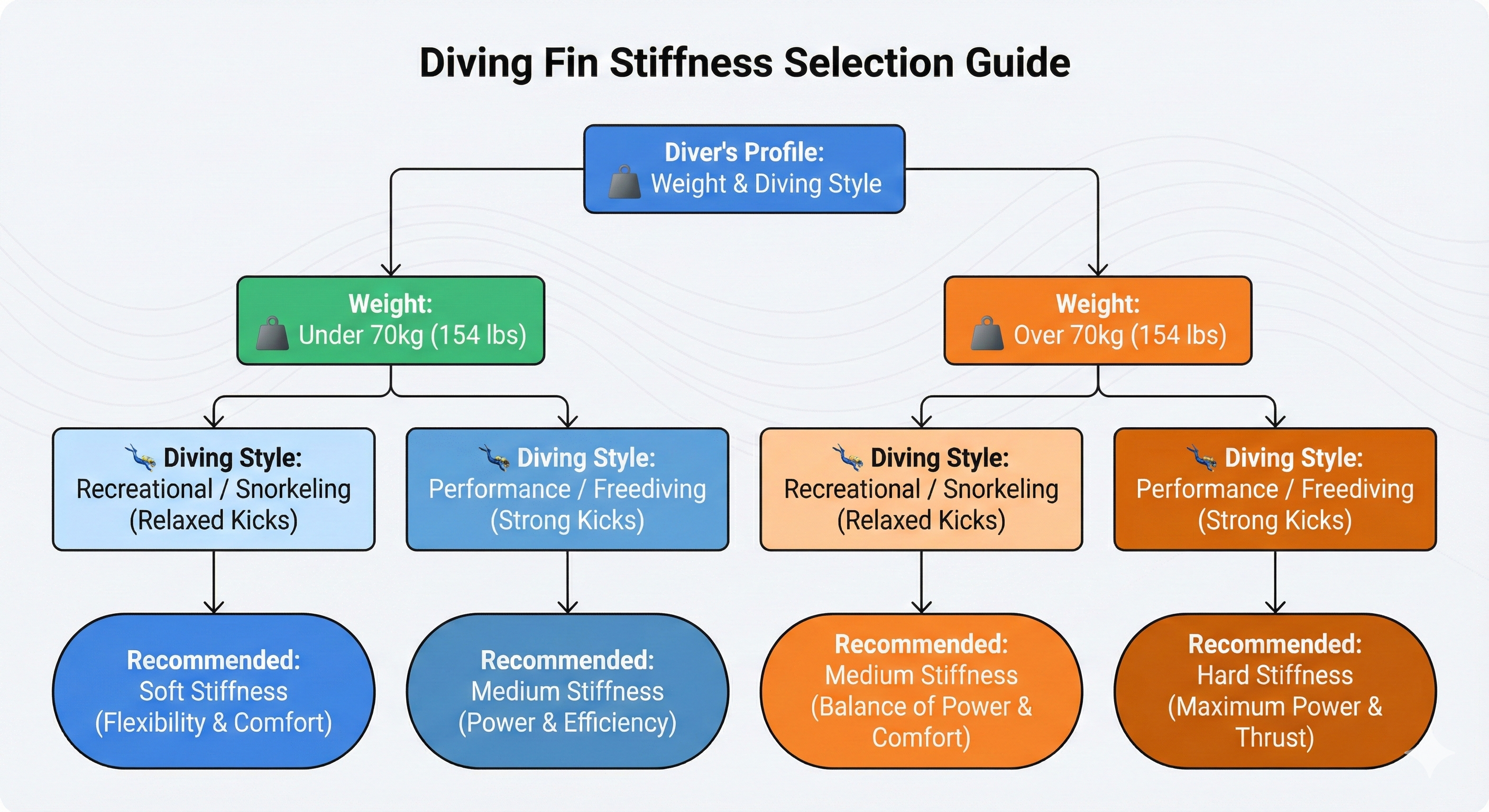

Choosing the Right Flex & Blade Geometry

Stiffness Scale Cheat-Sheet

Match Your Physiology to the Fin

| Diver Type | Weight (kg) | Ideal Model | Optimal Use Case |

|---|---|---|---|

| Technical Wreck Diver | 80–100 | Carbon-X | Strong currents, heavy gear |

| Reef Photographer | 60–75 | Carbon-S | Precision maneuvering |

| Freediver | 70–85 | Carbon Pro | Streamlined speed |

The 7° Toe-Down Innovation

JCSPORTLINE’s 7° toe-down rail angle aligns the tibia-peroneal muscle group for:

- 15% less calf strain vs 90° plastic foot pockets

- 20% faster power transfer through optimized ankle alignment

- Customizable heel straps for 3-point fit adjustment

FAQ – Carbon Fiber Fins vs Plastic Fins

- Are carbon fins worth the price?

Yes – save $300+ over 5 years vs replacing plastic fins. - Do carbon fins break easily?

No – our UV-resistant epoxy withstands 5x more impact than plastic. - Best for beginners?

The Carbon-S model builds leg strength gently without overtaxing muscles. - Speed gains?

Up to 25% faster 50m sprint times compared to plastic equivalents. - Warranty coverage?

5-year structural warranty + reef-impact repair program. - Freediving suitability?

Carbon Pro’s stiffness reduces stroke count by 20% for deeper dives.