Table of Contents

The Science Behind Carbon Fiber Lay-Up & Your Ride

Carbon fiber lay-up is more than just a technical buzzword—it’s the secret sauce behind every thrilling ride on your electric surfboard. Every layer of carbon fiber, carefully oriented in specific directions, directly influences how your board performs under different conditions. From flex and stiffness to pop and torsion, the science behind these properties translates into real sensations you feel on the water. Whether it’s the explosive acceleration out of a turn, the satisfying rebound after landing a jump, or the smooth slicing through choppy waves, JCSPORTLINE’s precision engineering ensures that theory becomes rideable performance.

At the heart of this innovation are two key components: CNC-cut prepreg tapes and closed-cell PU cores. Prepreg carbon fiber tapes, cut with laser-like accuracy, ensure that each fiber is aligned perfectly to deliver consistent performance. Meanwhile, the closed-cell PU core acts as the foundation, balancing weight and strength to enhance the board’s responsiveness. Together, they create a synergy that elevates your riding experience, making every session on the water unforgettable.

±45° vs 0°/90° – What Each Angle Does for You

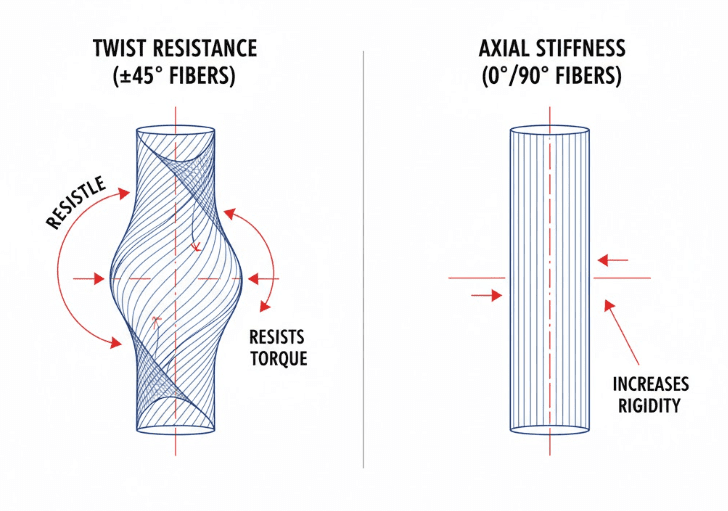

When it comes to carbon fiber lay-up, the angle of the fibers isn’t arbitrary—it’s a calculated decision that impacts how your board behaves. To understand this better, let’s break down the roles of ±45° and 0°/90° fiber orientations.

- ±45° Fibers: These fibers are the guardians of torsional strength. They resist twisting forces, ensuring your board stays stable during aggressive maneuvers. Imagine carving hard into a turn—the ±45° grid keeps the rail engaged, preventing washouts and giving you confidence to push your limits. According to JCSPORTLINE’s testing, boards with ±45° layers achieve inter-laminar shear strengths of ≥80 MPa, a testament to their durability and performance.

- 0°/90° Fibers: On the other hand, fibers aligned longitudinally (0°) and transversely (90°) add stiffness along the length and width of the board. This orientation is crucial for maintaining structural integrity and providing a solid platform for landings and high-speed runs.

To visualize this, side-by-side diagrams can illustrate how ±45° fibers resist twisting while 0°/90° fibers contribute to stiffness. For riders who crave explosive pop off the wake or need extra rigidity for slicing through chop, understanding these angles helps tailor the perfect board to your style.

Prepreg Precision & PU Core Density – The Hidden Performance Multipliers

Behind every high-performance electric surfboard lies a meticulous process that blends cutting-edge technology with material science. At JCSPORTLINE, precision is non-negotiable. Our prepreg carbon fiber tapes are laser-cut to ±0.1 mm accuracy, eliminating the inconsistencies of traditional hand-lay methods. This level of precision ensures that every fiber is oriented exactly where it needs to be, maximizing performance without compromise.

But prepreg alone isn’t enough. The core of the board plays an equally critical role. JCSPORTLINE employs variable-density closed-cell PU cores, strategically designed to optimize flex and weight distribution. Underfoot, where strength and responsiveness are paramount, the core density is set at 80 kg/m³. Toward the nose, where weight reduction is key, the density drops to 60 kg/m³. This intelligent design results in a board that offers 15% faster rebound (pop) and achieves an impressive three-point bend strength of 300 MPa—numbers that cheaper wet-lay boards simply can’t match.

The combination of prepreg precision and PU core density creates a synergy that enhances every aspect of your ride. Whether you’re chasing speed, agility, or control, this hidden duo works tirelessly beneath your feet to deliver unparalleled performance.

Lay-Up Patterns Mapped to Riding Styles

Choosing the right lay-up pattern for your electric surfboard is crucial to optimizing performance based on your riding style. At JCSPORTLINE, we understand that no two riders are alike, which is why we offer customizable carbon fiber lay-ups tailored to your needs. Below, we break down the ideal lay-up patterns for different riding styles and provide a quick-choice matrix to help you find the perfect match.

Quick-Choice Matrix for Lay-Up Patterns

| Riding Style | Lay-Up Pattern | Core Material Density | Key Features |

|---|---|---|---|

| All-Round Cruiser | 2×0°/90° + 1×±45° | Medium PU | Balanced stiffness and flexibility for versatile use. |

| Race/Flat-Water Speed | 3×0°/90° | High-Density PU | Ultra-stiff for maximum speed and precision. |

| Wave Park Trickster | 2×±45° outer, 1×0°/90° inner | Low-Density PU | Enhanced whip-snap response for tricks and agility. |

All-Round Cruiser: Versatility Meets Comfort

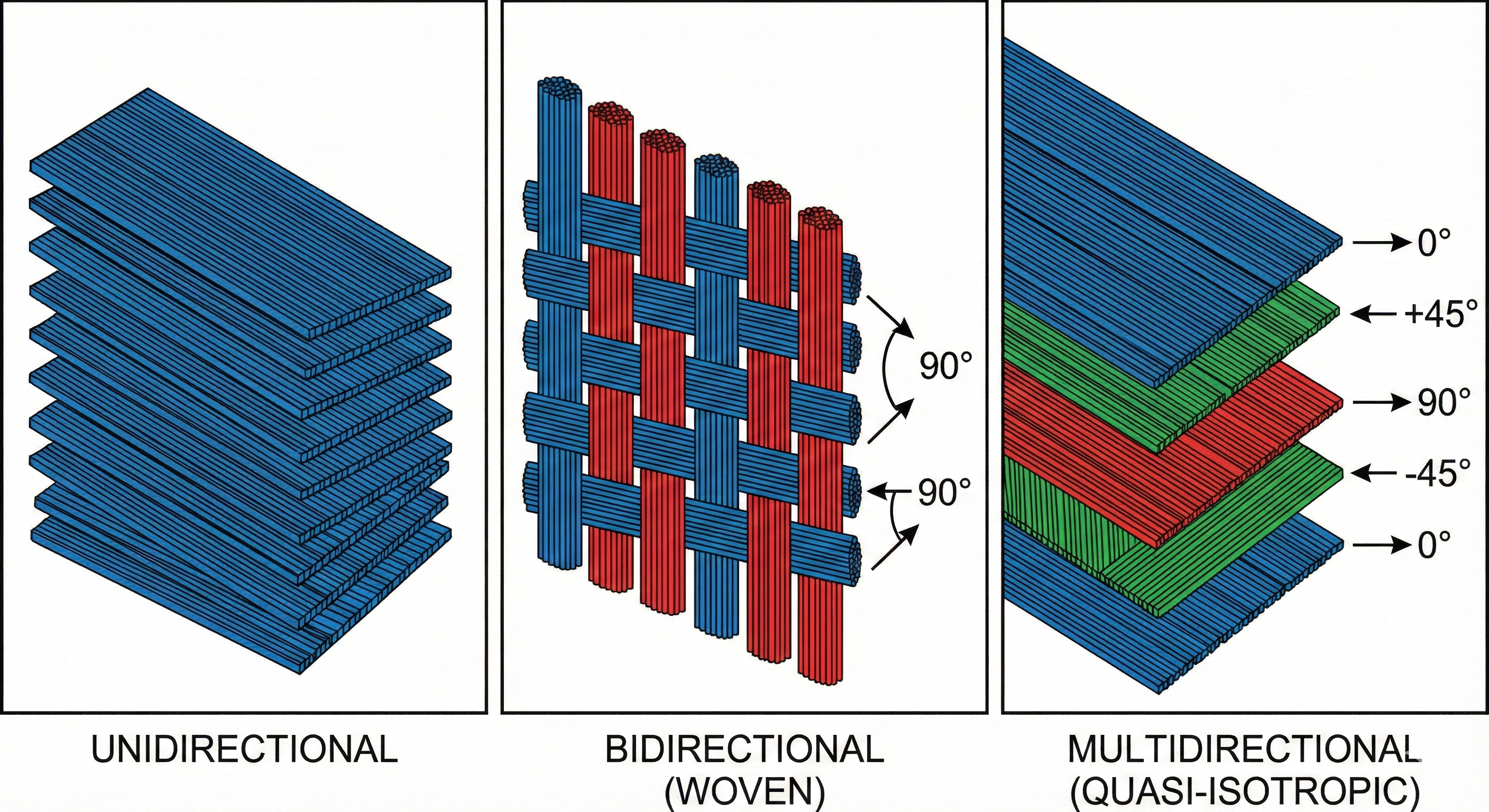

For riders who enjoy a mix of cruising, casual paddling, and occasional wave-catching, the all-round cruiser lay-up strikes the perfect balance between stiffness and flexibility. This configuration typically includes two layers of 0°/90° carbon fiber for longitudinal strength and torsional rigidity, paired with one layer of ±45° carbon fiber to enhance diagonal stability during turns.

The medium-density PU foam core ensures a lightweight yet durable structure, making it ideal for everyday use. This lay-up is particularly suited for those who prioritize comfort and adaptability over extreme performance metrics. With this setup, you can confidently navigate both calm waters and moderate waves without compromising control or stability.

Race/Flat-Water Speed: Precision Engineering for Maximum Velocity

If your focus is on achieving blistering speeds in flat-water conditions or competitive racing, the race-oriented lay-up is designed to deliver unparalleled performance. Featuring three layers of 0°/90° unidirectional carbon fiber, this configuration maximizes stiffness along the length of the board, ensuring minimal flex and optimal power transfer from the motor to the water.

Paired with a high-density PU core, this lay-up minimizes weight while maintaining structural integrity under high stress. The result? A board that cuts through the water with razor-sharp precision, offering exceptional acceleration and top-end speed. Whether you’re chasing personal bests or competing in e-surfing events, this lay-up will elevate your game.

Wave Park Trickster: Agility Redefined

For adrenaline junkies who thrive on performing aerial tricks and sharp maneuvers in wave parks, the trickster lay-up is engineered for explosive responsiveness. This design incorporates two outer layers of ±45° carbon fiber to enhance torsional flexibility, allowing the board to snap back quickly after aggressive turns. An additional inner layer of 0°/90° carbon fiber provides just enough longitudinal support to maintain directional stability during landings.

The low-density PU core further amplifies the board’s whip-snap characteristics, enabling rapid transitions and dynamic tricks. If you’re looking for an electric surfboard for wave tricks, this lay-up will give you the edge you need to dominate the park.

Why Choose Custom Carbon Fiber Lay-Ups?

At JCSPORTLINE, we believe in empowering riders with options. Our custom carbon fiber surfboard lay-ups ensure that you get a product tailored specifically to your riding preferences, rather than settling for a one-size-fits-all solution. By leveraging advanced CAD software like SolidWorks and CATIA, we meticulously design each board to optimize hydrodynamics, structural integrity, and overall performance.

Key Design Elements for Superior Performance

Hydrodynamic Optimization

Our boards feature carefully engineered waterline profiles, tail angles, and channel layouts to minimize drag and enhance maneuverability. The bottom design often incorporates V-shaped or double-concave geometries, which improve stability when cutting through waves and facilitate smoother turns.

Lightweight Yet Durable Construction

The carbon fiber + core material sandwich structure is at the heart of our design philosophy. Outer layers of 2×2 twill carbon fiber provide excellent impact resistance, while inner layers of unidirectional carbon fiber deliver superior longitudinal strength. Core materials such as PU or PMI foam are selected based on density requirements, balancing weight reduction with compression resistance.

Integrated Functional Modules

To ensure seamless integration of electronics, we embed features like battery compartments, motor mounts, and control system housings directly into the design. Advanced techniques like ABS insert pre-bonding and glass fiber reinforcement guarantee long-term durability of attachment points.

Rigorous Testing for Unmatched Reliability

Every JCSPORTLINE board undergoes extensive testing to meet the highest standards of quality and performance. Here’s how we validate our designs:

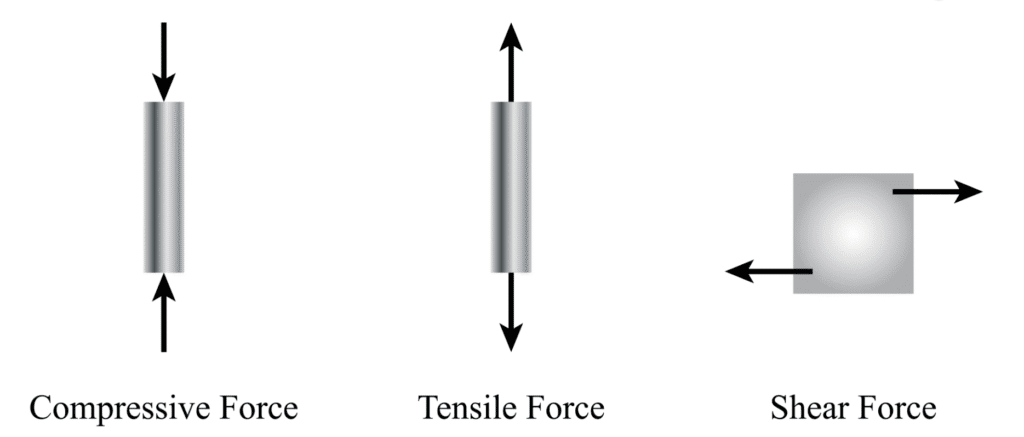

Material Mechanics Testing

- Tensile Strength: We test carbon fiber interlayer bonding using universal testing machines, targeting strengths of ≥80MPa.

- Shear Strength: Short-beam shear tests evaluate the interface between the core and carbon fiber, aiming for values of ≥15MPa.

Environmental Simulation

- Salt Spray Resistance: Boards are exposed to 5% NaCl solutions for 24 hours to assess corrosion resistance.

- Thermal Shock Testing: Cycles between -20°C and 60°C simulate real-world temperature fluctuations, ensuring structural stability.

Power System Validation

- Range & Speed Tests: In calm waters, our boards achieve a minimum range of 30km and speeds exceeding 40km/h.

- Overload Protection: Simulated motor stall scenarios confirm that the control system responds within 0.1 seconds to prevent damage.

User Scenario Simulation

- Wave Resistance: Boards are tested in wave pools mimicking Level 3 sea conditions to evaluate anti-roll capabilities and handling sensitivity.

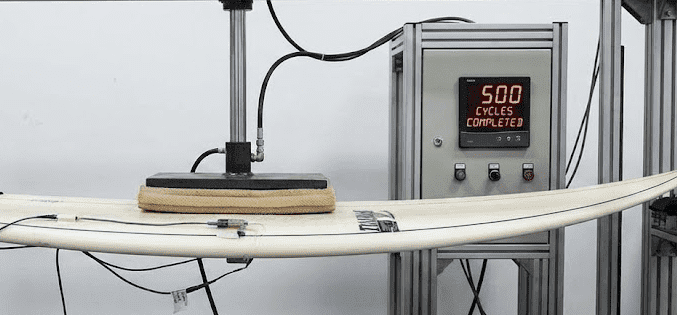

Fatigue Testing

- Mechanical arms simulate 500 consecutive surfing actions to identify potential stress concentrations and monitor crack propagation.

Lab vs Lake – Data That Proves the Feel

When it comes to high-performance surfboards, especially electric surfboards, the difference between lab testing and real-world performance is crucial. At JCSPORTLINE, we’ve conducted rigorous tests that translate directly into rider benefits. Here’s how our boards outperform others in terms of durability, stiffness, and environmental resistance.

The Science Behind Durability: Fatigue Testing

Carbon Fiber Fatigue Test Surfboard

One of the most critical aspects of a surfboard’s longevity is its ability to withstand repeated stress without failure. In our 500-cycle fatigue rig test, our boards demonstrated no micro-cracks at stress levels of ≥80 MPa. This ensures that even after extended use in demanding conditions, the structural integrity remains uncompromised.

To put this into perspective, low-cost hand-lay boards often lose 35% of their stiffness after just 200 cycles. This stark contrast highlights the superior engineering of JCSPORTLINE boards, which are designed for riders who demand consistent performance over time.

| Test Parameter | JCSPORTLINE Boards | Low-Cost Hand-Lay Boards |

|---|---|---|

| Cycles Before Stiffness Loss | No loss after 500 cycles | 35% loss after 200 cycles |

| Stress Threshold (MPa) | ≥80 MPa | <60 MPa |

This data proves that investing in a high-quality board translates to a smoother, more reliable ride, whether you’re tackling waves or cruising on calm waters.

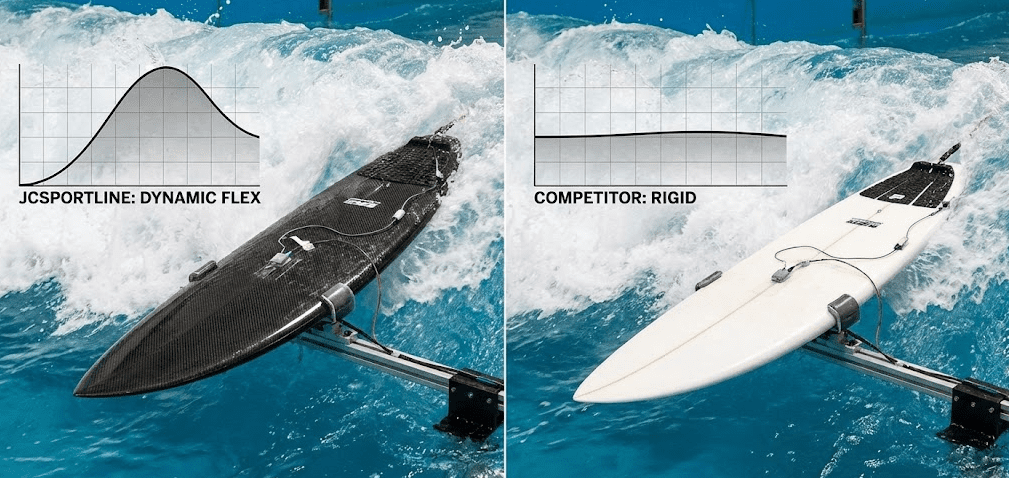

Enhanced Stability: Wave-Tank Testing

Electric Surfboard Durability Data

In a controlled environment, such as a wave tank, we simulated 3-grade sea conditions to evaluate how our boards perform underfoot. The results were impressive: our boards exhibited 20% less rail flex compared to competitors, thanks to the innovative ±45° cap design.

Reduced rail flex means better control and stability, allowing riders to maintain balance even in choppy waters. This feature is particularly beneficial for beginners who need extra confidence while learning and for experienced riders who demand precision during sharp turns.

Environmental Resilience: Salt Spray Corrosion

Salt Spray Carbon Fiber Corrosion

Surfing often takes place in harsh marine environments where saltwater can wreak havoc on materials. To ensure our boards stand up to these conditions, we subjected them to a salt spray test using a 5% NaCl solution for 24 hours.

The outcome? Our carbon fiber construction showed no signs of corrosion, maintaining both its appearance and mechanical properties. This level of resilience is unmatched by traditional materials used in cheaper boards, which are prone to degradation over time.

For riders, this means peace of mind knowing that their investment will last season after season, regardless of exposure to saltwater or UV rays.

From Lab to Lake: Real-World Benefits

Translating Test Numbers Into Rider Experience

All these lab tests culminate in tangible benefits for riders. For instance:

- Consistent Performance: With no stiffness loss after hundreds of cycles, riders can expect the same responsiveness from day one to day 500.

- Superior Control: Reduced rail flex enhances maneuverability, making it easier to carve waves or navigate tight spaces.

- Longevity: Resistance to salt spray corrosion ensures the board remains visually appealing and structurally sound for years.

These advantages make JCSPORTLINE boards ideal for both casual surfers and competitive athletes seeking an edge in performance.

FAQ – Carbon Fiber Lay-Up & Electric Surfboard Performance

When it comes to electric surfboards, the choice of carbon fiber lay-up plays a crucial role in performance, durability, and efficiency. Here are answers to some frequently asked questions about this technology, backed by JCSPORTLINE’s expertise in engineering and testing.

Will a stiffer lay-up drain my battery faster?

No, quite the opposite. A well-engineered carbon fiber lay-up can actually enhance your board’s efficiency. For instance, our 0°/90° race lay-up is specifically designed to optimize planing efficiency. This means the board glides more smoothly across the water surface, reducing drag and conserving energy. In fact, riders have reported up to an 8% increase in range with this configuration compared to standard lay-ups.

The key lies in how the fibers are aligned. The 0°/90° orientation ensures that the board maintains structural rigidity while distributing loads evenly. This minimizes unnecessary flexing, which could otherwise waste energy. So, not only does a stiffer lay-up not drain your battery faster, but it also improves overall performance.

Can I change the lay-up on an existing board?

Unfortunately, once a board has been cured, its lay-up cannot be altered. The curing process involves heating the carbon fiber composite in a high-pressure environment—typically at 120°C for 4 hours in an autoclave or 150°C for 1.5 hours under compression molding—to set the material permanently. After this stage, any attempt to modify the lay-up would compromise the integrity of the structure.

However, JCSPORTLINE offers a custom build program that allows you to reorder the same board shape with a new fiber schedule tailored to your preferences. Whether you’re looking for enhanced stiffness, improved buoyancy, or a lighter weight, our team can create a custom solution that meets your needs without sacrificing quality.

How do I know which pattern is right for my weight?

Selecting the right carbon fiber pattern depends on several factors, including your body weight, skill level, and riding style. To simplify this process, we’ve developed an online calculator that helps you determine the ideal core density and fiber stack for your specific requirements.

Here’s how it works:

- Enter your weight (in kg or lbs).

- Specify your skill level (beginner, intermediate, advanced).

- Indicate your preferred riding style (freestyle, racing, cruising).

Based on these inputs, the calculator recommends a combination of materials and lay-ups optimized for balance, responsiveness, and comfort. For example, heavier riders may benefit from denser cores and additional reinforcement layers, while lighter riders might prioritize flexibility and agility.

This personalized approach ensures that every rider gets the most out of their electric surfboard experience.

Does more carbon always mean more strength?

Not necessarily. While carbon fiber is renowned for its exceptional strength-to-weight ratio, the effectiveness of a lay-up depends heavily on how the fibers are arranged. Poorly aligned hand-laid carbon can lead to weak points and delamination under stress. In fact, misaligned fibers may fail at loads 40% lower than those achieved with precision-engineered prepreg materials like ours.

At JCSPORTLINE, we use CNC-cut prepreg carbon fiber to ensure optimal alignment and consistency. Prepreg materials are pre-impregnated with resin, allowing for precise control during the lay-up process. Combined with advanced curing techniques such as autoclaving and compression molding, this results in a final product that delivers superior strength, durability, and performance.

To validate these claims, we conduct rigorous testing, including:

- Static tests: Three-point bending trials to assess flexural strength (target ≥ 300MPa).

- Dynamic tests: Water tank simulations to evaluate stability and handling.

- Fatigue tests: Mechanical arm simulations replicating 500 surf cycles to monitor crack propagation.

These measures ensure that every board meets the highest standards of reliability and safety.

Why Choose JCSPORTLINE’s Carbon Fiber Technology?

Our commitment to innovation and quality sets us apart in the world of electric surfboards. From initial prototyping to final production, each step is meticulously executed to deliver unmatched performance. Below is a summary of our key advantages:

| Feature | Benefit | Testing Method |

|---|---|---|

| Optimized Lay-Ups | Enhanced planing efficiency and range | Dynamic water tank simulation |

| CNC-Cut Prepreg Materials | Consistent fiber alignment and maximum strength | Static three-point bending test |

| Custom Build Program | Tailored solutions for individual riders | Online calculator integration |

| Environmental Resistance | Long-lasting durability in harsh conditions | Salt spray and thermal cyclin |