Table of Contents

An Engineering-Driven Workflow for OEM Carbon Fiber Projects

Bringing a carbon fiber product from an initial idea to a manufacturable reality is rarely simple.

For OEM brands and product teams, the challenge is not only performance—but predictability.

Many carbon fiber projects fail not because of material limitations, but because key engineering decisions are made too late, risks are discovered during mass production, or prototypes are treated as cosmetic samples rather than validation tools.

At JCSPORTLINE, we address these challenges with a structured 58-day engineering workflow—designed to transform early concepts into production-ready carbon fiber components with controlled risk, validated performance, and clear decision checkpoints.

This article breaks down each stage of that workflow and explains what happens, why it matters, and what risks it eliminates.

D1–D7 | Idea & Planning

Defining Feasibility Before Design Begins

The first week is not about drawings—it is about clarity.

At this stage, we work with clients to define the real objectives of the project:

- What is the functional role of the part?

- What loads, environments, or user interactions will it experience?

- What constraints exist in weight, stiffness, cost, and volume?

This early planning phase prevents a common OEM mistake: designing an attractive part that cannot be manufactured reliably or economically.

By aligning application requirements, performance targets, and manufacturing constraints from the start, we eliminate infeasible concepts before time and budget are consumed.

Why this stage matters:

Projects that skip early feasibility discussions often encounter redesign loops later—when changes are far more expensive and disruptive.

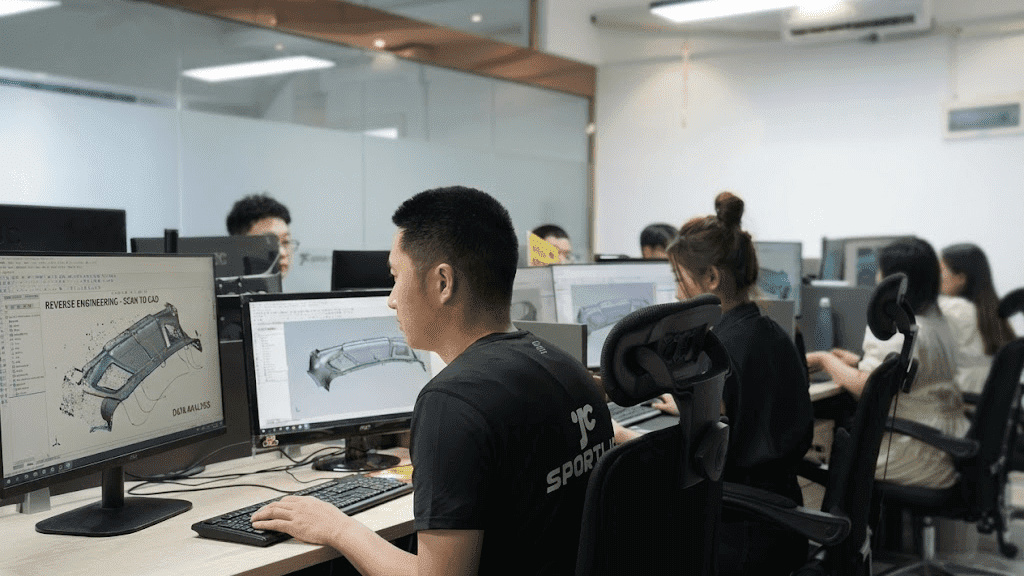

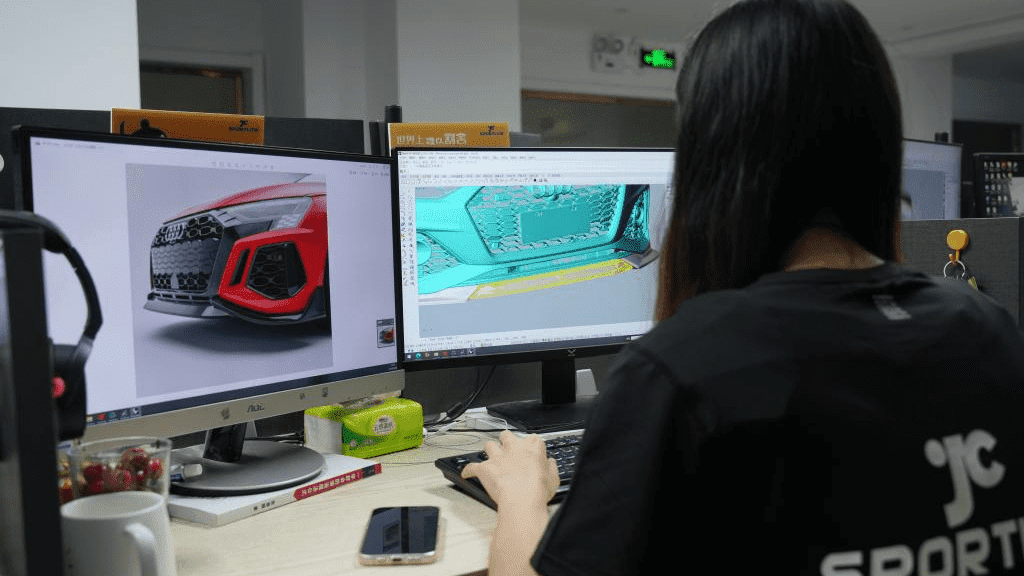

D8–D14 | Design & Evaluation

Engineering Decisions That Shape Cost and Performance

Once feasibility is established, the project moves into structured engineering evaluation.

During this phase, we focus on:

- Structural layout and geometry optimization

- Carbon fiber layup strategy (fiber orientation, layer count, reinforcement zones)

- Manufacturing route selection (prepreg vs wet layup, mold type, curing method)

Design is evaluated not only for strength and weight, but also for repeatability and scalability.

At this stage, we also identify:

- Potential weak points or stress concentrations

- Tolerance sensitivity and assembly risks

- Cost drivers that may affect future production volumes

Why this stage matters:

Most cost overruns in carbon fiber projects are locked in during design—not during production.

Early evaluation ensures performance targets are achieved without introducing hidden manufacturing risks.

D15–D30 | Prototype & Testing

Turning Concepts into Functional Validation

Prototypes are often misunderstood.

A prototype is not a display piece—it is a decision-making tool.

In this phase, functional prototypes are produced using near-production processes. These parts are tested for:

- Structural behavior under load

- Weight accuracy and balance

- Assembly compatibility

- User interaction or handling characteristics (when applicable)

Test results are fed directly back into design refinement.

If adjustments are required, they are made before tooling and production setup, when changes are still manageable.

Why this stage matters:

Skipping functional validation shifts risk to mass production—where corrections are slow, costly, and disruptive.

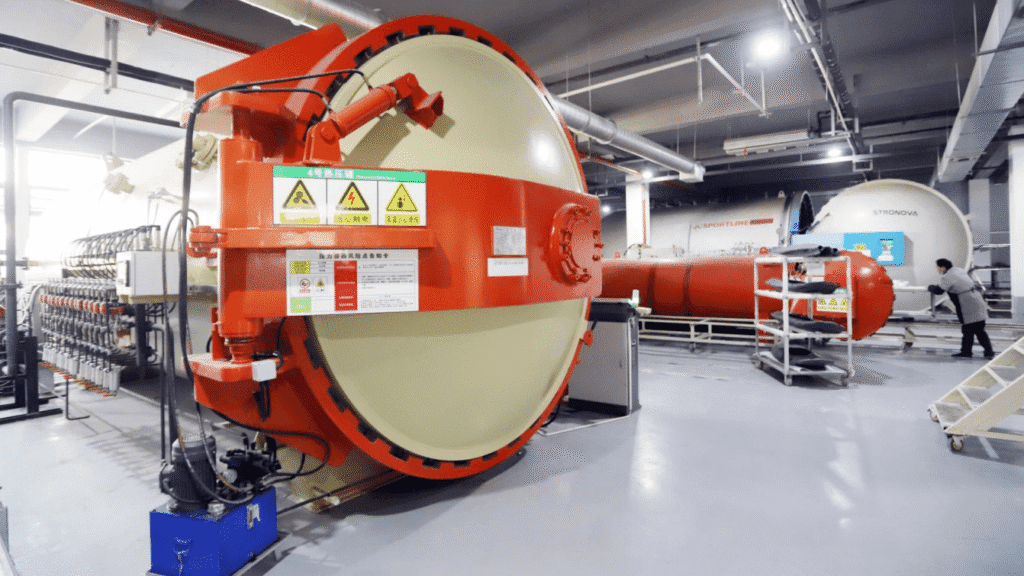

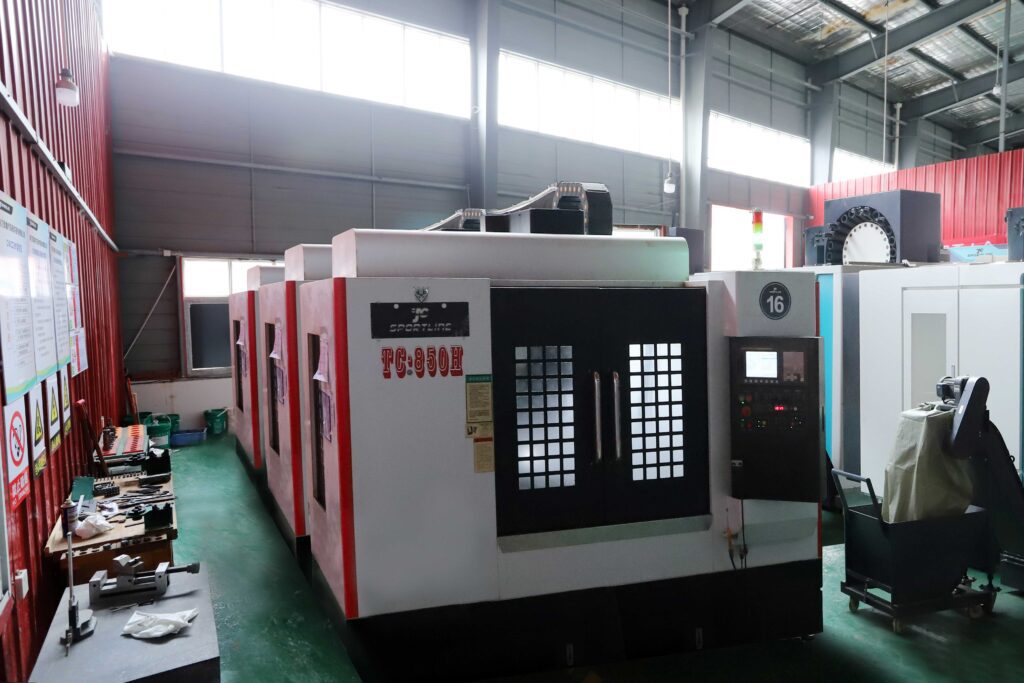

D31–D50 | Production Setup

Preparing for Repeatable Manufacturing

This phase is where many suppliers fall short.

Production setup is not about making parts quickly—it is about making them consistently.

During this stage, we focus on:

- Tooling validation and mold optimization

- Defining curing parameters and layup sequences

- Establishing inspection points and quality criteria

Process parameters are documented and stabilized to ensure that the results seen in prototypes can be repeated in production.

Why this stage matters:

A prototype proves that something can be made.

Production setup proves that it can be made again and again.

D51–D58 | Final Manufacturing & Quality Control

Delivering Production-Ready Results

The final stage focuses on controlled manufacturing using validated processes.

Key activities include:

- Production runs using established parameters

- Dimensional and structural quality checks

- Final surface and finish inspection

The goal is not only to deliver parts, but to deliver production confidence—components that meet specifications and are ready to scale.

Why this stage matters:

At day 58, clients are not receiving an experiment.

They are receiving a manufacturable result backed by engineering validation.

Who This 58-Day Workflow Is Designed For

This workflow is ideal for:

- OEM brands developing performance-driven products

- Engineering-led teams that value validation over guesswork

- Projects requiring predictable outcomes and scalable manufacturing

It may not be suitable for:

- Projects focused solely on lowest initial price

- Concepts unwilling to undergo functional testing

- Applications where engineering feedback is not valued

Clear alignment ensures better outcomes for both sides.

Engineering Certainty Over Speed Alone

Speed matters—but only when it is controlled.

This 58-day workflow is not designed to rush projects.

It is designed to prevent failure, reduce uncertainty, and create manufacturable success.

By combining early feasibility, structured evaluation, functional prototyping, and controlled production setup, we help OEM clients move forward with confidence—knowing that key decisions have been validated, not assumed.

FAQ – 58-Day Carbon Fiber OEM Manufacturing Process

Q1: Is the 58-day timeline fixed for all carbon fiber projects?

The 58-day timeline applies to projects with defined requirements and timely feedback.

Complex designs or major changes may extend the schedule, but the workflow ensures predictable engineering checkpoints.

Q2: Does the 58-day process include functional prototyping and testing?

Yes. Functional prototyping and validation are core parts of the workflow, used to verify structure, weight, and performance before production.

Q3: What types of projects benefit most from this workflow?

This workflow is designed for OEM and custom carbon fiber projects that require engineering validation, controlled manufacturing, and future scalability.

Q4: Can the workflow support both small batches and mass production?

Yes. It supports low-volume production while preparing processes, tooling, and quality controls for stable mass manufacturing.

Q5: How does the 58-day workflow reduce OEM manufacturing risk?

By validating feasibility, design, and process early, risks are identified before tooling and mass production—reducing cost, delays, and rework.