Table of Contents

Why One-Piece Compression Molding Changes Everything for You

Surfing enthusiasts know all too well the frustrations of traditional surfboards: heavy weight, delamination issues, water absorption, and inconsistent flex. These pain points not only compromise performance but also shorten the lifespan of your board. Enter JCSPORTLINE’s one-piece compression-molded carbon fiber surfboard—a revolutionary solution designed to address these challenges head-on. With a board that is 30% lighter than PU foam boards, 5× more impact-resistant, and built with factory-sealed precision, this innovation redefines what you can expect from a high-performance surfboard. Let’s explore how this cutting-edge technology transforms your surfing experience.

The Problem with Traditional Surfboards

Traditional surfboards are often constructed using a polyurethane (PU) foam core wrapped in fiberglass. While this method has been the industry standard for decades, it comes with significant drawbacks:

- Weight: PU boards tend to be heavier, making them harder to maneuver, especially in challenging wave conditions.

- Delamination: Over time, the bond between the fiberglass and foam weakens, leading to separation and structural failure.

- Water Logging: Once water penetrates the board through cracks or dings, it compromises buoyancy and performance.

- Inconsistent Flex: Variations in hand-laid fiberglass layers result in uneven flex patterns, affecting control and responsiveness.

These limitations have long plagued surfers, leaving them searching for a better alternative.

The JCSPORTLINE Solution: One-Piece Compression-Molded Carbon Fiber

JCSPORTLINE’s one-piece compression-molded carbon fiber surfboard eliminates these issues by leveraging advanced materials and manufacturing techniques. Here’s how it stands out:

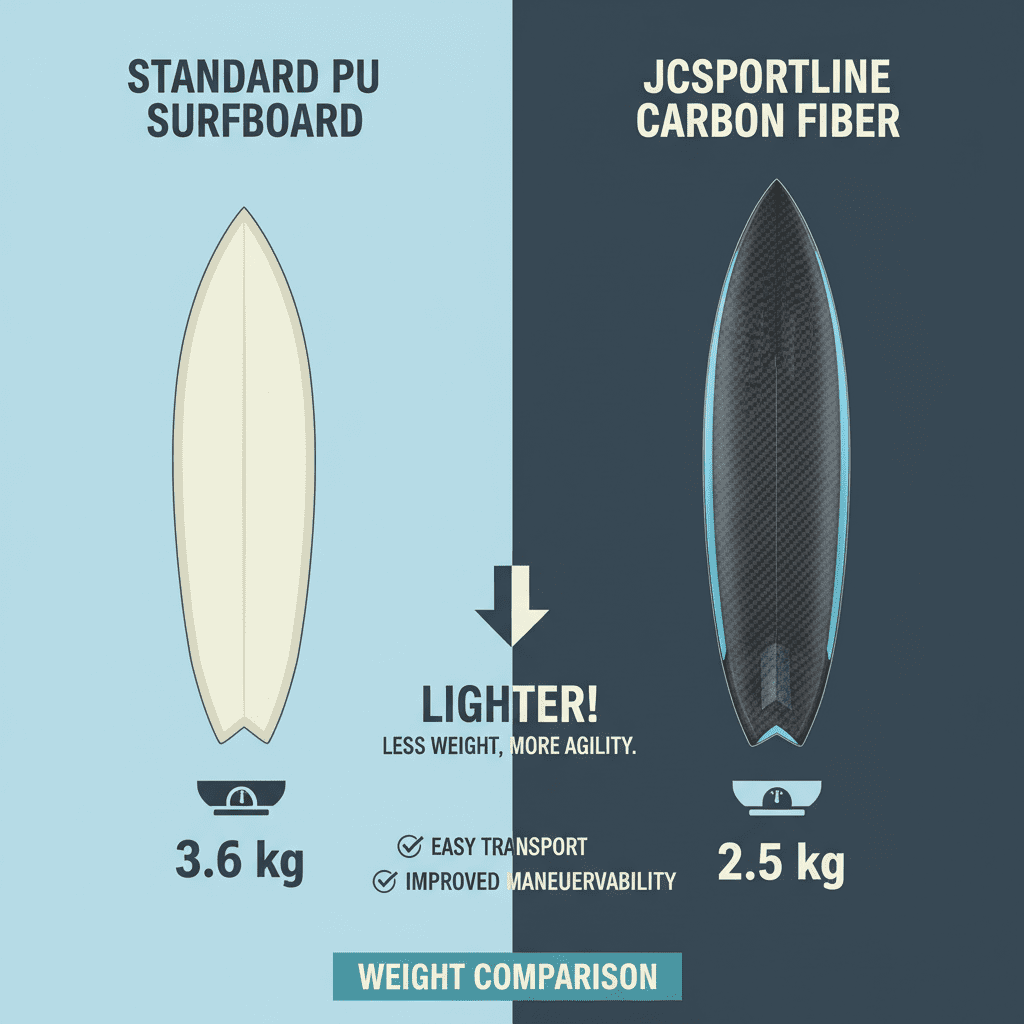

Lighter Than Ever

Using a combination of carbon fiber and PU foam core, JCSPORTLINE achieves an impressive weight reduction without sacrificing strength. A typical PU surfboard weighs around 3.6 kg, while the JCSPORTLINE model clocks in at just 2.5 kg. This 30% weight reduction makes paddling easier and enhances agility on the waves.

Unmatched Strength and Durability

The compression molding process ensures that the carbon fiber layers are perfectly bonded to the foam core under high heat and pressure. This results in a seamless, single-skin construction that is up to 5× more impact-resistant than traditional boards. Whether you’re navigating rocky shorelines or taking hard landings, this board can handle the abuse.

Factory-Sealed for Life

Unlike traditional boards prone to delamination and waterlogging, JCSPORTLINE’s one-piece design creates a hermetically sealed structure. There are no seams or joints where water can seep in, ensuring the board remains buoyant and structurally sound throughout its lifespan.

Precision Engineering

Every JCSPORTLINE board is crafted to exact specifications, ensuring consistent volume and flex characteristics across all units. This level of precision guarantees that every surfer receives a board tailored to their needs, whether they’re beginners or seasoned pros.

Backed by Rigorous Testing

To ensure the highest standards of quality, JCSPORTLINE subjects its boards to a battery of rigorous tests:

- Material Mechanics: The carbon fiber layer achieves a tensile strength of ≥80MPa, while the shear strength between the core and carbon fiber exceeds 15MPa.

- Environmental Resistance: Salt spray tests confirm corrosion resistance, and thermal cycling (-20°C to 60°C) validates structural stability.

- Fatigue Testing: Mechanical simulations replicate real-world use, ensuring the board withstands repeated stress without cracking.

These tests guarantee that every JCSPORTLINE board performs reliably in diverse conditions, from calm lakes to choppy ocean swells.

Why Choose Carbon Fiber?

Carbon fiber offers numerous advantages over traditional materials:

- Lightweight Construction: Its high strength-to-weight ratio makes it ideal for surfboards, reducing drag and improving speed.

- Aesthetic Appeal: The sleek, continuous surface of a one-piece carbon fiber board supports custom designs, including large logos and intricate patterns.

- Durability: Resistant to temperature fluctuations, UV exposure, and physical impacts, carbon fiber ensures longevity.

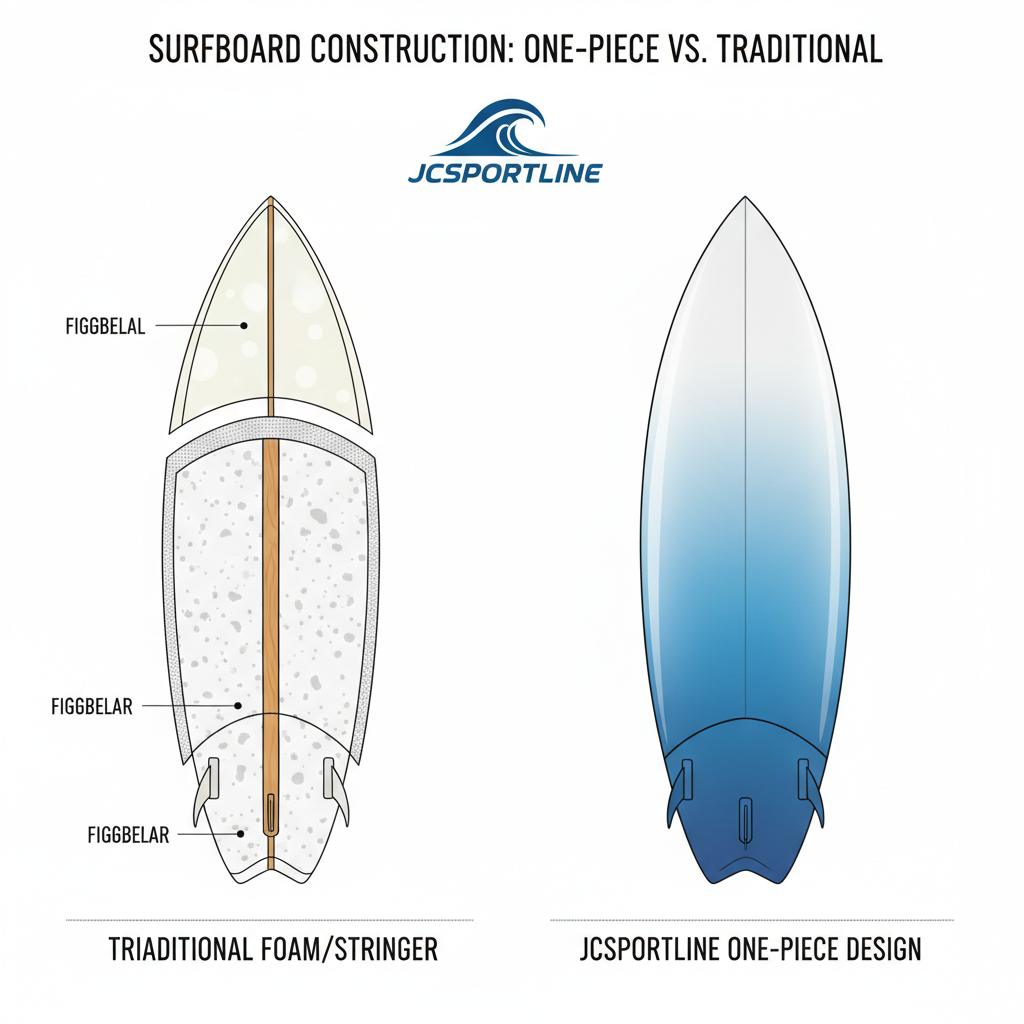

Visualizing the Difference

To truly appreciate the innovation behind JCSPORTLINE’s one-piece compression-molded surfboard, consider the following visuals:

JCSPORTLINE’s one-piece compression-molded carbon fiber surfboard represents a paradigm shift in surfboard manufacturing. By addressing the common pain points of traditional boards—weight, delamination, waterlogging, and inconsistent flex—it delivers a product that is lighter, stronger, and more reliable. Whether you’re chasing barreling waves or perfecting your cutbacks, this board empowers you to perform at your best.

Upgrade your surfing experience today with JCSPORTLINE’s cutting-edge technology and feel the difference for yourself.

From Aerospace Prepreg to Your Perfect Board—Material Stage

The foundation of a high-performance surfboard lies in its materials and the precision with which they are crafted. At JCSPORTLINE, we take inspiration from aerospace engineering to bring you a surfboard that combines strength, flexibility, and lightweight performance like no other. Let’s dive into the two critical steps that define our material stage: intelligent prepreg cutting and PU core casting.

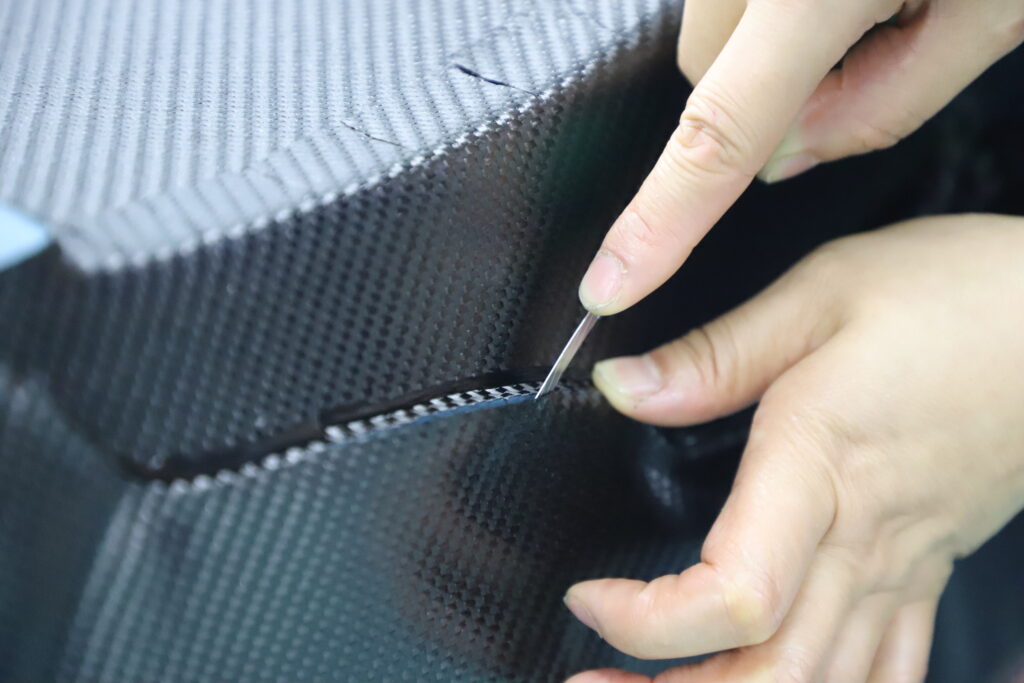

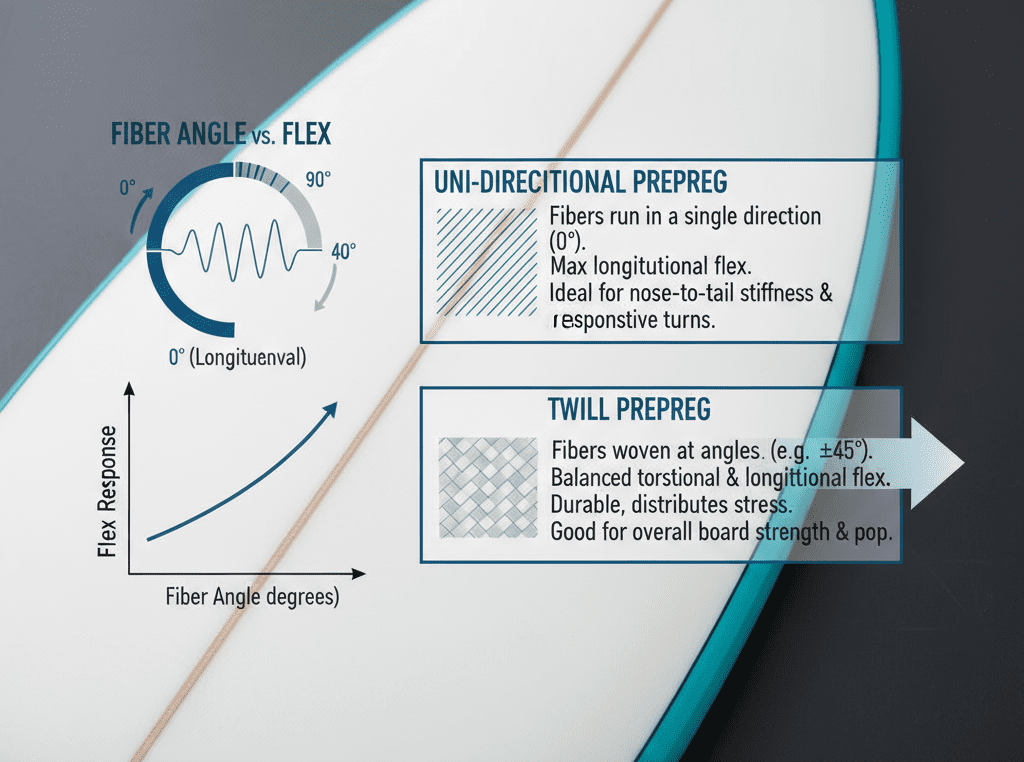

Intelligent Prepreg Cutting—Precision Down to 0.2 mm

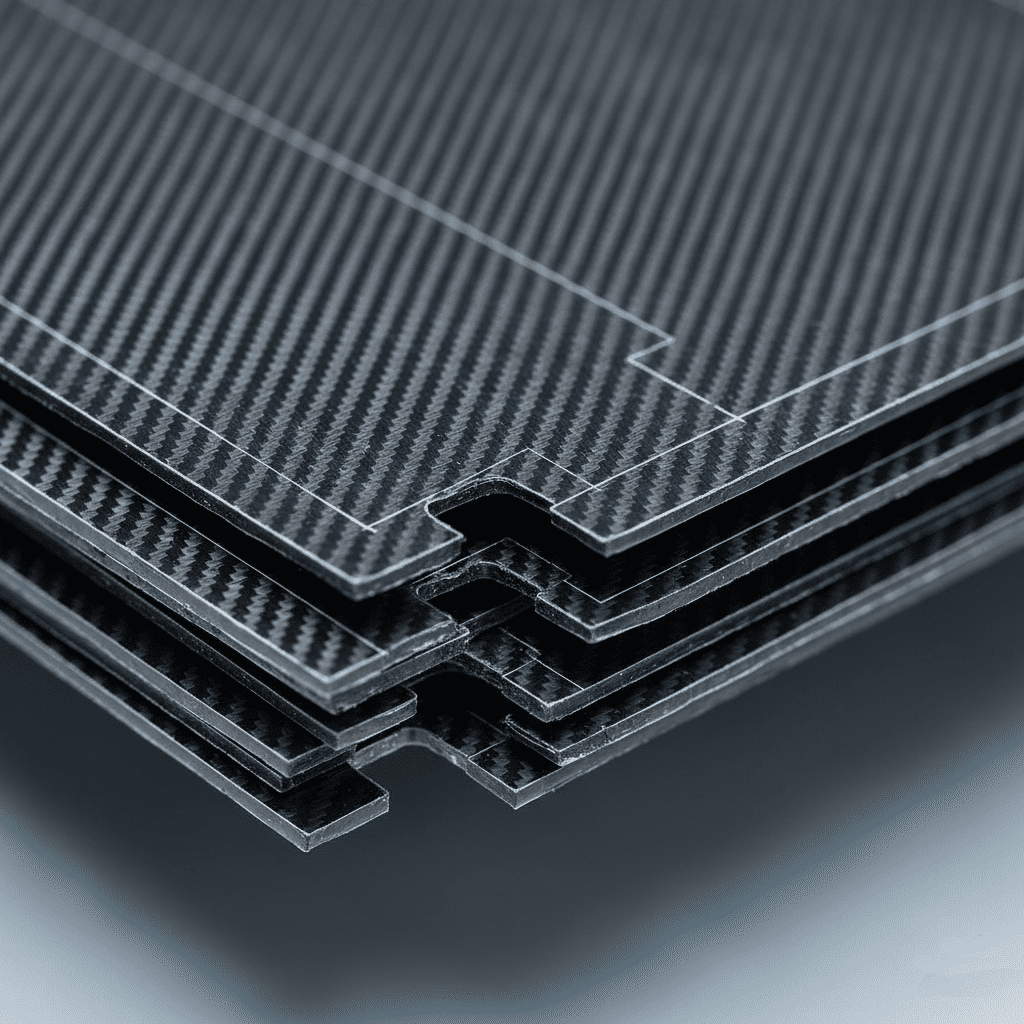

When it comes to crafting a surfboard that performs flawlessly under pressure, the devil is in the details—or more specifically, in the carbon fiber layup. JCSPORTLINE imports aviation-grade uni-directional and twill prepregs, materials renowned for their exceptional strength-to-weight ratio. These prepregs are not just any carbon fiber; they’re engineered to provide directional stiffness and controlled flex, making them ideal for surfboards that need to handle both power and finesse.

What sets us apart is our use of AI-guided cutters to map your board’s load paths with unparalleled precision. Each piece of prepreg is cut with edge accuracy down to ±0.2mm, ensuring that every fiber aligns perfectly with the intended stress points of the board. This meticulous process eliminates excess resin and unnecessary weight, giving you a lay-up that places carbon exactly where it’s needed. The result? A surfboard that feels lighter, responds faster, and delivers consistent performance wave after wave.

For surfers who demand the best, this technology ensures that no two boards are alike unless they’re meant to be. Whether you’re carving sharp turns or gliding smoothly across the face of a wave, the intelligent layup guarantees optimal energy transfer and responsiveness.

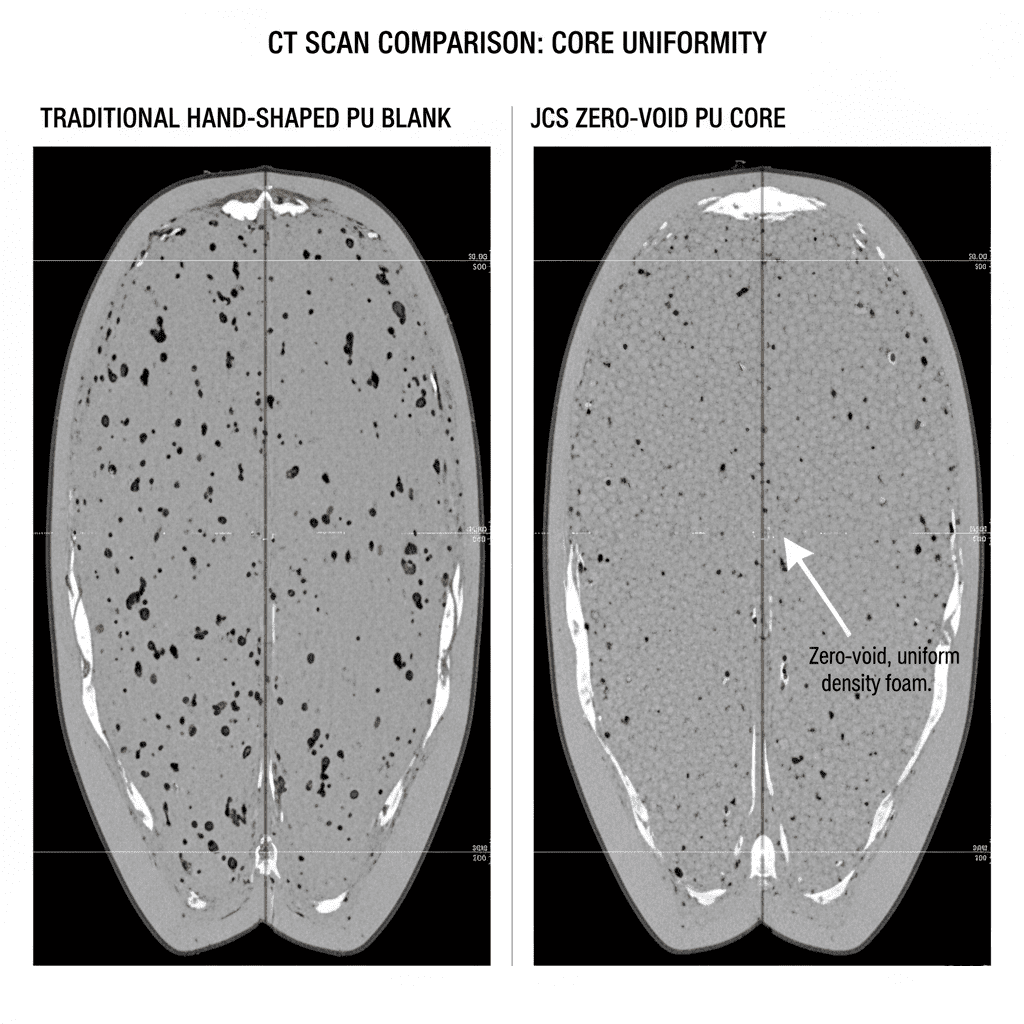

PU Core Cast in One Shot—Zero Void, Zero Waste

The heart of every surfboard is its core, and at JCSPORTLINE, we’ve revolutionized the way PU foam cores are made. Using CNC-machined aluminum molds, we cast the PU blank in a single shot, completing the process in just 90 seconds. This method ensures a density tolerance of ±2%, delivering identical buoyancy and flex characteristics in every board we produce.

Traditional hand-shaped blanks often suffer from inconsistencies, leading to what surfers call the “golden board” lottery—where only a few boards out of a batch truly perform as expected. With our closed-mold PU casting process, that uncertainty is eliminated. Every board you pick up will feel the same underfoot, whether you’re riding your first wave of the day or your last.

This level of consistency isn’t just about performance—it’s also about sustainability. By minimizing voids and waste during production, we reduce material scrap and environmental impact. It’s a win-win for surfers and the planet alike.

By combining cutting-edge technology with sustainable practices, JCSPORTLINE is redefining what’s possible in surfboard manufacturing. Whether you’re a professional surfer or a weekend warrior, our boards are designed to elevate your experience on the water.

3. 150 °C, 90 Minutes—The Compression Mold That Fuses Your Board for Life

When it comes to crafting a surfboard that can truly last a lifetime, the secret lies in precision engineering and advanced manufacturing techniques. At JCSPORTLINE, we leverage state-of-the-art compression molding technology to create boards with unparalleled strength and durability. This process not only ensures a flawless finish but also eliminates common issues like stringer cracks and rail splits. Let’s dive into how this innovative method transforms raw materials into a single structural shell designed to perform under any condition.

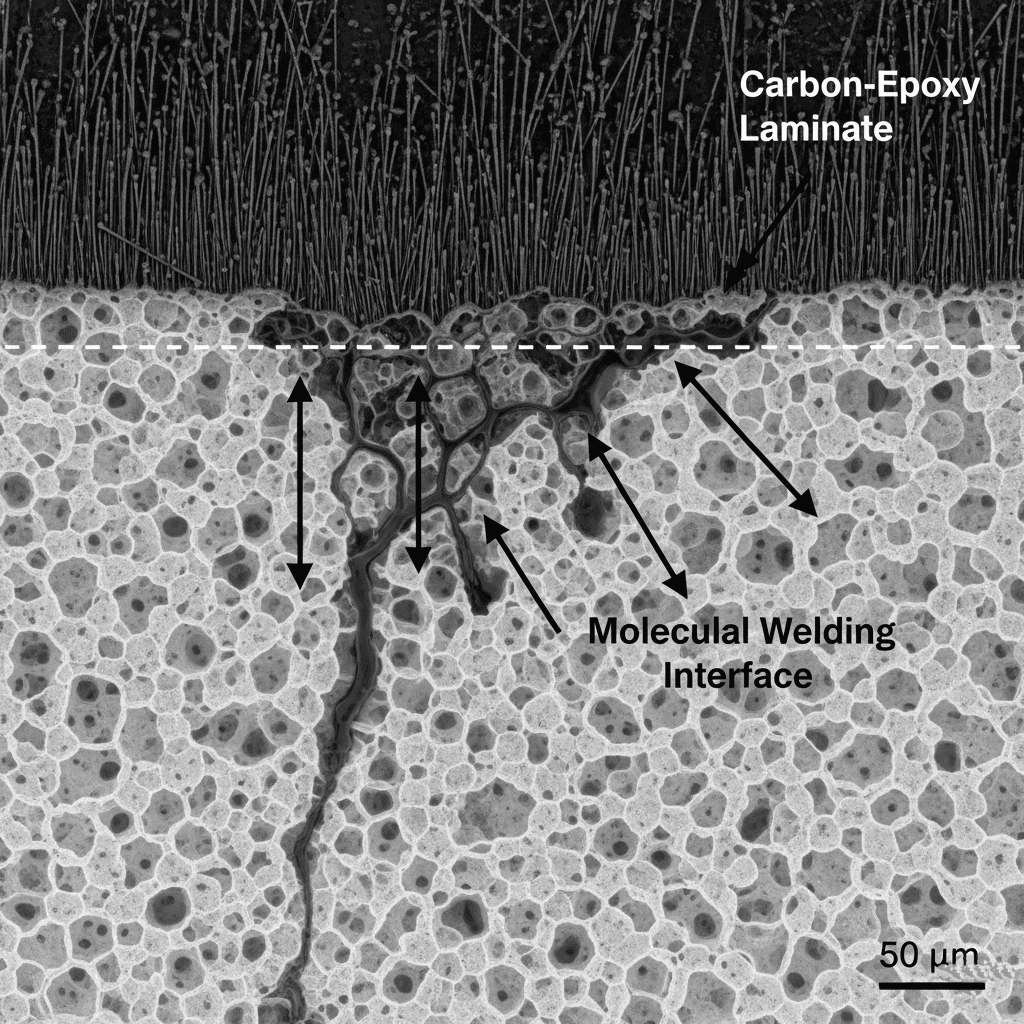

3.1 Monocoque Skin Bonding—No Stringer, No Seams

Imagine a surfboard where every layer is seamlessly integrated into one cohesive unit. This is achieved through our closed-cavity steel mold system, which operates at an impressive 150°C cure cycle for 90 minutes. During this time, the epoxy resin liquefies completely, allowing the carbon fiber skin to molecularly weld itself to the core material. The result? A monocoque structure that eliminates the need for traditional stringers and seams, offering unmatched rigidity and resilience.

This process isn’t just about aesthetics—it’s about performance. By applying 6-bar internal pressure, we ensure deep penetration of the epoxy into the polyurethane (PU) core. This bond creates a unified shell capable of withstanding extreme forces without compromising its integrity. Whether you’re carving waves or landing heavy drops, rest assured that your board won’t suffer from common failures like stringer cracks or rail splits.

For surfers seeking cutting-edge technology, a monocoque carbon surfboard represents the pinnacle of innovation. With no weak points to worry about, riders can focus entirely on their performance. And thanks to advancements in compression molding surfboard processes, even the most demanding conditions are no match for these boards. Durability isn’t just a promise—it’s a guarantee.

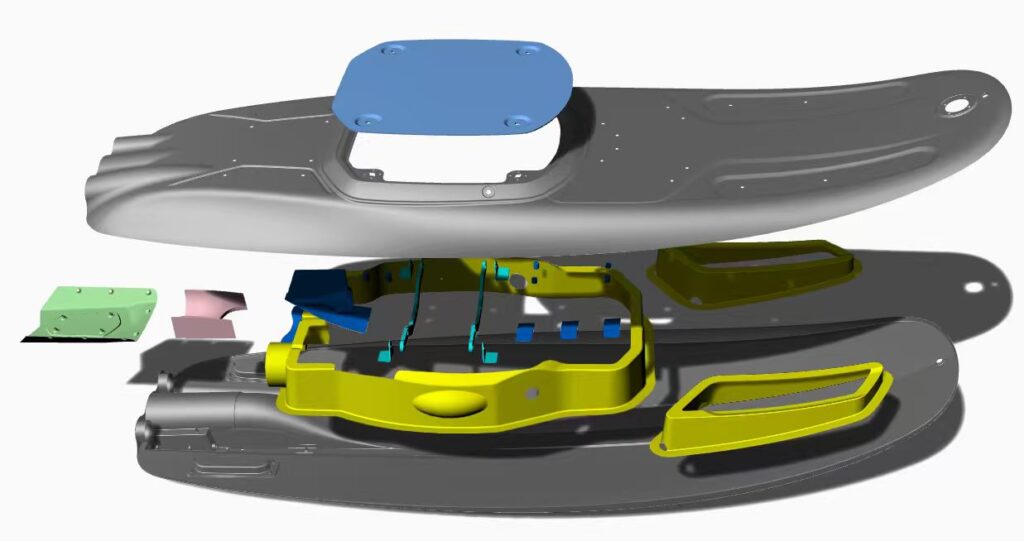

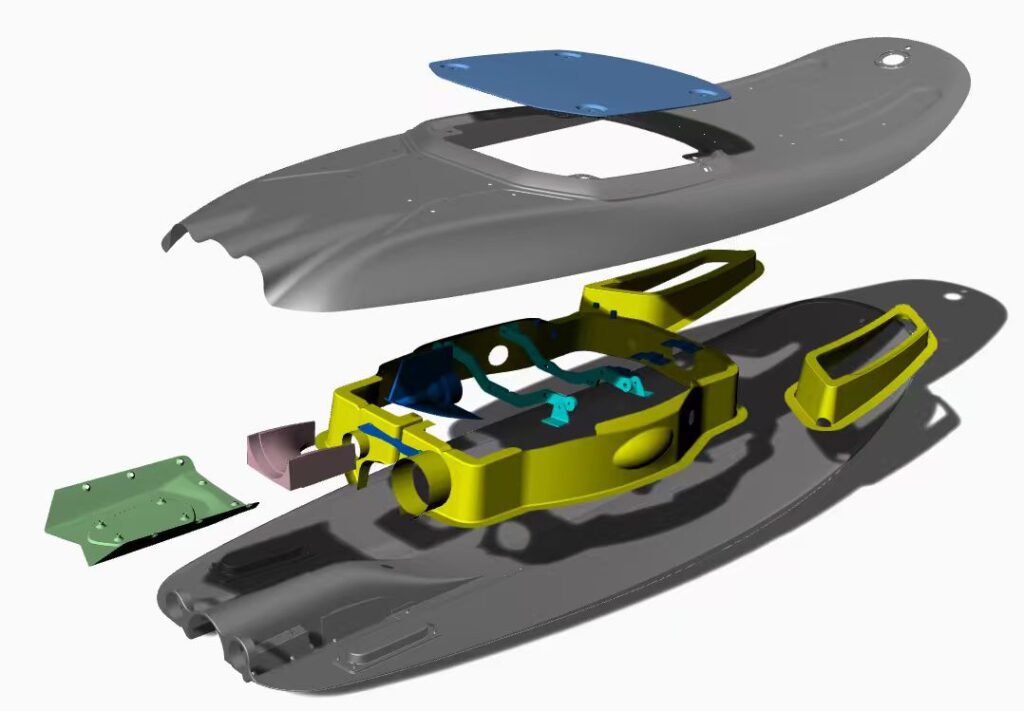

3.2 Smart Cavities—Built-In Channels for Fins, Handle & E-Motor

Beyond the structural marvel of monocoque construction, our boards feature another game-changing innovation: smart cavities. These built-in channels allow for seamless integration of essential components such as fin boxes, handles, and electronics bays—all co-cured during the molding process.

By embedding threaded brass inserts directly into the mold, we achieve factory-aligned FCS-II and Future fin box systems. This eliminates the need for post-drilling, ensuring perfect placement every time while maintaining the board’s waterproof seal. Additionally, the electronics bay is rated IPX7, meaning it can withstand immersion in water up to 1 meter deep for 30 minutes without leaking. For e-surfboard enthusiasts, this level of reliability means fewer warranty headaches and more time spent riding the waves.

Our commitment to quality extends to every detail. From the ergonomic handle integrated into the deck to the precisely engineered battery hatch, each feature is designed with functionality in mind. Whether you’re paddling out for a casual session or pushing the limits of what an e-surfboard ready board can do, you’ll appreciate the thoughtful engineering behind every component.

Why Choose JCSPORTLINE’s Compression Molded Boards?

At JCSPORTLINE, we combine decades of expertise with the latest in composite manufacturing technologies to deliver products that redefine industry standards. Our meticulous approach begins with material standardization, including precision-cut pre-preg carbon fiber layers and PU cores formed via one-shot injection molding. Each step—from laying up the materials to curing them under controlled heat and pressure—is executed with exacting precision.

To ensure top-tier quality, every board undergoes rigorous testing, including ultrasonic scanning (UT) and industrial CT detection, to identify any potential defects. With a defect rate below 0.5%, you can trust that your board meets the highest benchmarks for performance and longevity.

Sustainability is also at the heart of our operations. We recycle over 90% of cutting waste by recovering carbon fibers through carbonization processes, significantly reducing environmental impact. Meanwhile, our solar-powered curing ovens reduce energy consumption by 30%, making our production methods as eco-friendly as they are efficient.

Whether you’re looking for a stringerless surfboard durability solution or a high-tech e-surfboard setup, JCSPORTLINE has you covered. Explore the future of surfing today with boards built to last—and perform—for life.

4. Quality Gates You Can Trust—Every Board, Every Time

When it comes to high-performance surfboards, quality isn’t just a promise—it’s a guarantee. At JCSPORTLINE, every board undergoes rigorous testing and meticulous craftsmanship to ensure it meets the highest standards before it ever hits the water. From advanced scanning technologies to sustainable manufacturing practices, we’ve built a system you can trust for every single product.

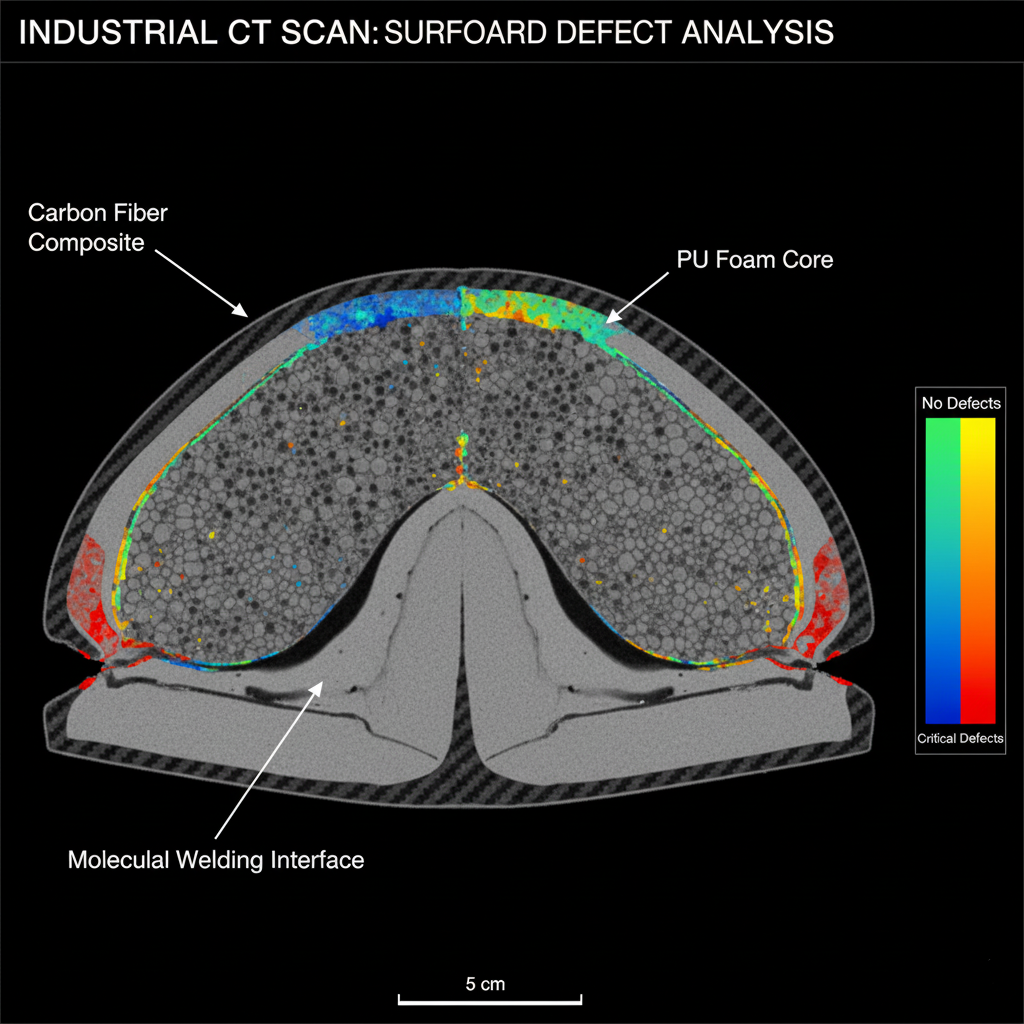

4.1 UT & Industrial CT—0.5% Reject Rate

Before any surfboard is deemed ready for the waves, it must pass through two of the most advanced inspection processes in the industry: 5 MHz ultrasonic testing (UT) and 3D industrial CT scanning. These cutting-edge techniques allow us to detect even the smallest imperfections, ensuring zero delamination and structural integrity.

Ultrasonic Testing (UT): Precision at Its Finest

Ultrasonic testing uses high-frequency sound waves to inspect the internal structure of the board. This non-destructive method evaluates the bond strength between carbon fiber layers and the core material. With a target shear strength of ≥15MPa and tensile strength of ≥80MPa, our boards are engineered to withstand extreme forces without compromise. The UT process identifies potential weak points that could lead to delamination or failure, allowing us to address issues before they become problems.

Industrial CT Scanning: A 3D View Inside

Once the ultrasonic scan is complete, each board undergoes a comprehensive 3D industrial CT scan. This technology provides a detailed cross-sectional view of the board’s internal structure, mapping out defects such as voids, cracks, or inconsistencies. By color-coding these defects on a digital map, we can pinpoint areas requiring attention with unparalleled accuracy.

The result? A reject rate of just 0.5%, ensuring that only the highest-quality boards make it to your hands. And to provide full transparency, every board comes with a unique QR code linking to its scan report. This digital proof guarantees that your surfboard is free from delamination and built to last.

Why It Matters

For surfers, reliability is everything. Whether you’re riding calm waters or battling choppy waves, knowing that your board has been rigorously tested gives you peace of mind. Our commitment to precision ensures that every ride is smooth, stable, and safe.

4.2 Solar-Powered Cure & 90% Fiber Recycling—Ride Clean

At JCSPORTLINE, we believe that innovation shouldn’t come at the expense of the planet. That’s why sustainability is woven into every step of our manufacturing process—from energy-efficient curing to advanced recycling methods.

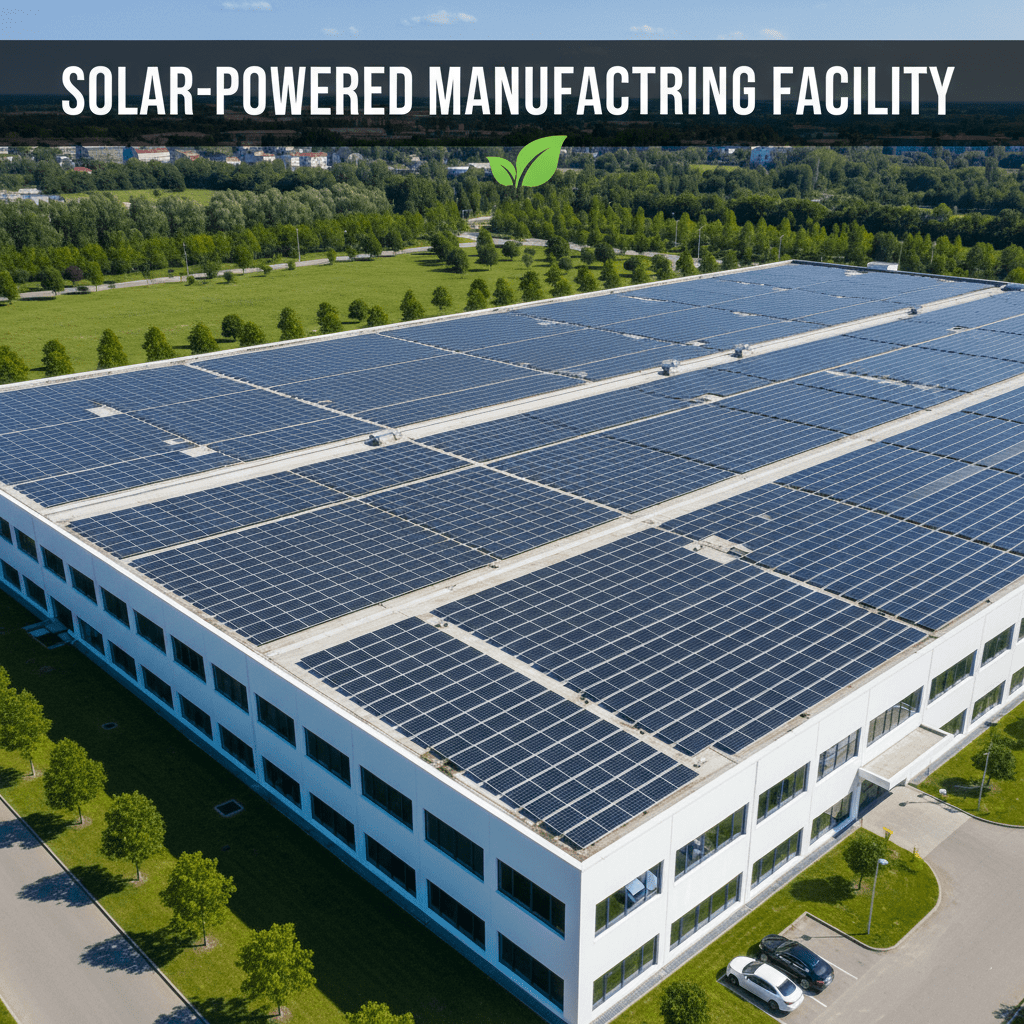

Harnessing Solar Power for Cleaner Production

Our factory is equipped with a state-of-the-art solar array, powering the curing ovens used during production. By switching to renewable energy, we’ve reduced CO₂ emissions by an impressive 30%. This shift not only lowers our carbon footprint but also sets a new benchmark for eco-friendly surfboard manufacturing.

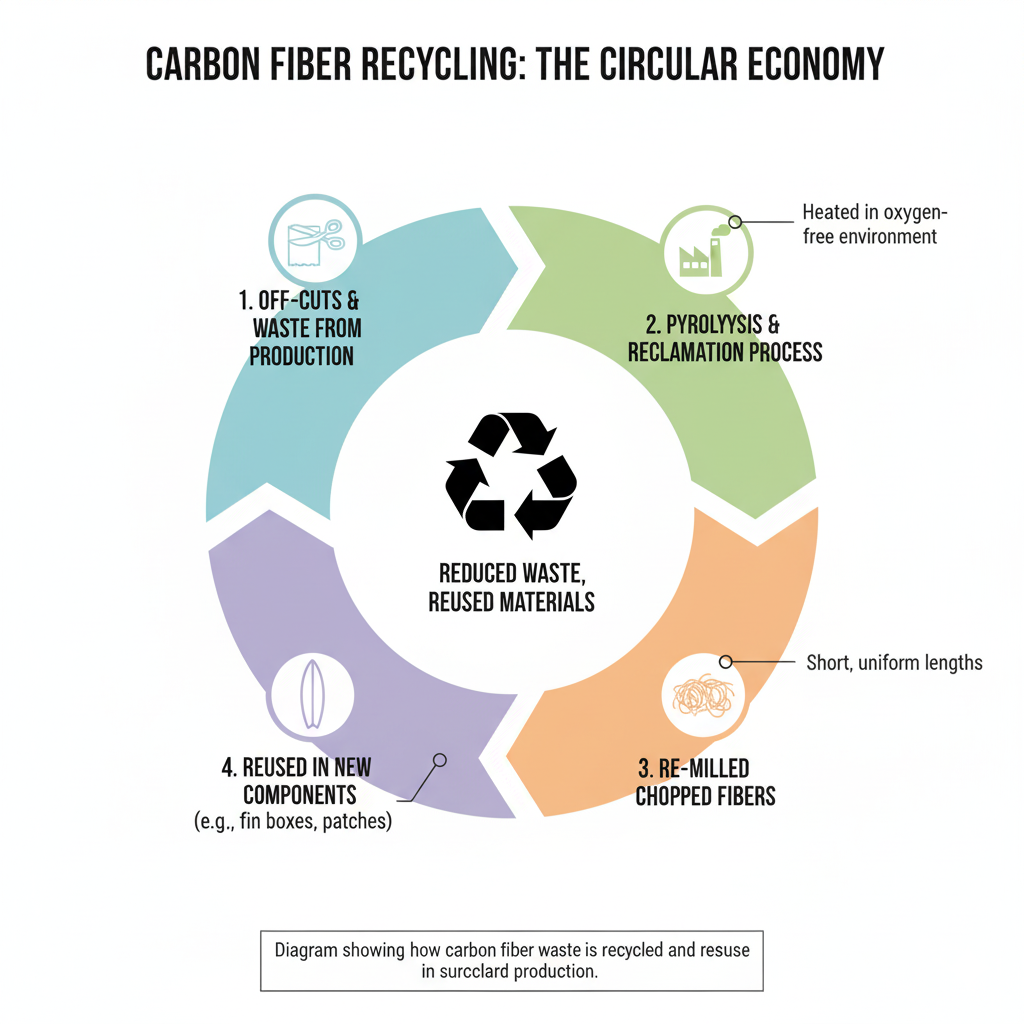

Closing the Loop: Carbon Fiber Recycling

One of the biggest challenges in composite manufacturing is waste management. During the production of surfboards, off-cuts and excess prepreg materials are inevitable. However, instead of discarding these remnants, we use a specialized pyrolysis process to recover up to 90% of the carbon fiber.

This recycled fiber is then re-milled and repurposed for future applications, such as reinforcing rails or patching tails. By integrating this circular economy model, we minimize waste while maintaining the same high performance standards.

Riding Lighter, Leaving Lighter

When you choose a JCSPORTLINE surfboard, you’re not just investing in top-tier performance—you’re supporting a cleaner, greener future. Our sustainable practices ensure that you can enjoy the thrill of surfing without compromising the environment.

FAQ—What You Asked Us Most

When it comes to carbon surfboards, customers often have specific questions about performance, durability, and customization. Below, we’ve compiled the top five most frequently asked questions and provided concise, data-driven answers to help you make an informed decision.

What is the Weight Range of Your Carbon Surfboards?

Our carbon surfboards are engineered for optimal performance, weighing approximately 8kg on average. The weight can vary slightly based on the type of carbon fiber used and client-specific customizations. This ensures a balance between strength and maneuverability, making it ideal for both beginners and advanced surfers.

How Repairable Are Carbon Surfboards?

Carbon surfboards are highly repairable due to their robust construction. With a tensile strength of ≥80MPa and shear strength of ≥15MPa, minor damages can be fixed using epoxy-based repair kits. For severe cracks, professional repairs are recommended to restore structural integrity.

How Strong Is the Leash Plug?

The leash plug undergoes rigorous pull-testing to ensure safety. Designed to withstand forces equivalent to high-speed impacts, the leash plug remains secure even in extreme conditions. Its durability is validated through mechanical fatigue tests simulating 500+ surfs without failure.

Can I Customize My Carbon Surfboard?

Yes! We offer extensive customization options, including color schemes, logos, and unique designs. However, there are limits to maintain structural integrity. Custom pricing starts at competitive rates, ensuring your board reflects personal style while delivering peak performance.

What Warranty Terms Do You Offer?

Our warranty covers manufacturing defects for up to 2 years, excluding wear and tear. Products undergo salt spray (5% NaCl solution) and thermal shock tests (-20°C to 60°C) to guarantee longevity. Overload protection systems also ensure quick response times (<0.1 sec), enhancing reliability.

By addressing these common queries, we aim to provide clarity and confidence in choosing JCSPORTLINE’s premium carbon surfboards. Whether you’re focused on performance, aesthetics, or durability, our products deliver unmatched quality tailored to your needs.

👉 Contact JCSPORTLINE

Your journey to better performance starts here.